Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-00-31-300-002 LPC Fan Blade - Repair The Airfoil By Scalloping, Repair-002 (VRS1111)

General

This repair must only be done when the instruction to do so is given in 72-00-31 Inspection/Check.

Deterioration of SFC, performance and balance of the LP compressor rotor will occur when the fan blades are dressed to this repair.

The maximum quantity of material which can be removed from a given rotor assembly is the equivalent of three blades dressed to the maximum limits. The remaining serviceable blades are not dressed.

This repair can only be used on an LP compressor (fan) module, with the fan blades still assembled in position.

Fan blades repaired to this scheme, must be glass bead peened when the blades are removed from the LP fan disk by 72-00-31 Inspection/Check. Glass bead peening instructions are specified in VRS1724.

Price and availability - none

A log book entry is necessary when you complete this repair.

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Portablegrinding equipment | LOCAL | Portable grinding equipment | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent Penetrant Inspection Equipment | ||

| Chemical Cleaning Equipment | LOCAL | Chemical Cleaning Equipment | ||

| IAE 3R19016 LE profile gage | 0AM53 | IAE 3R19016 | 1 | |

| IAE 3R19017 LE profile gage | 0AM53 | IAE 3R19017 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-075 WATERPROOF SILICON CARBIDE | IE241 | CoMat 05-075 | ||

| CoMat 05-076 WATERPROOF SILICON CARBIDE | K3895 | CoMat 05-076 | ||

| CoMat 05-077 WATERPROOF SILICON CARBIDE | K6835 | CoMat 05-077 | ||

| CoMat 05-078 WATERPROOF SILICON CARBIDE | K3895 | CoMat 05-078 | ||

| CoMat 05-079 WATERPROOF SILICON CARBIDE | K3895 | CoMat 05-079 | ||

| CoMat 05-080 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-080 | ||

| CoMat 05-081 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-081 | ||

| CoMat 05-082 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-082 | ||

| CoMat 05-083 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-083 | ||

| CoMat 05-084 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-084 | ||

| CoMat 05-085 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-085 |

Spares

NONESafety Requirements

CAUTION

Procedure

Use IAE 3R19016 LE profile gage 1 off and IAE 3R19017 LE profile gage 1 off.

Remove the minimum material to give correct radius.

Put back the leading edge radius.

SUBTASK 72-00-31-350-053 Put Back the Leading Edge Shape

Refer to Figure.

Refer to TASK 72-38-11-020-001.

Remove the inlet cone.

Refer to TASK 72-38-11-420-001.

NOTE

Fan blades repaired to this scheme must be glass bead peened when the blades are removed from the LP compressor fan disk. Refer to paragraph '2. General'.Install the inlet cone.

SUBTASK 72-00-31-350-054 Identify the Location of Repaired Fan Blade

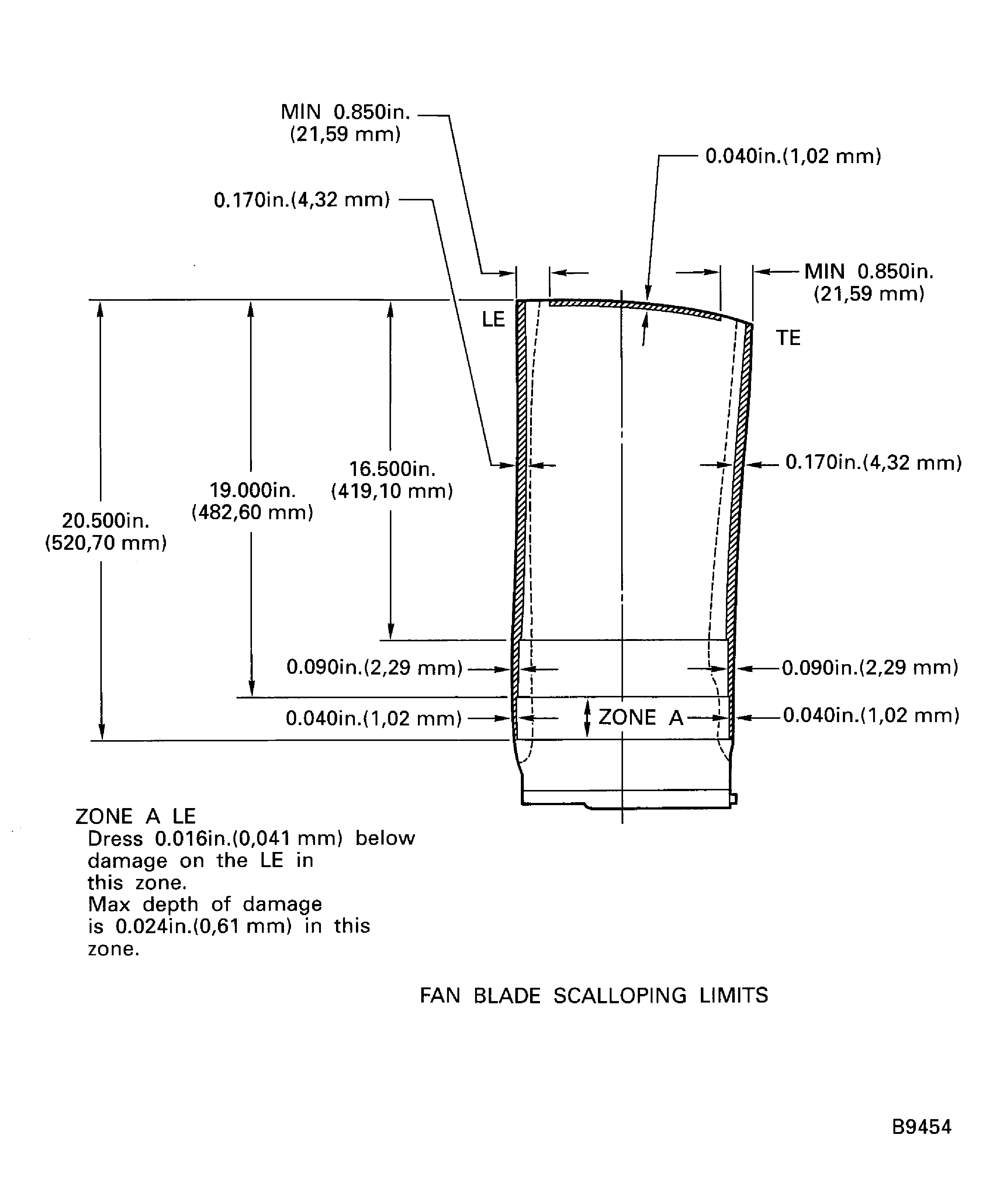

Figure: Fan blade scalloping limit

Fan blade scalloping limit

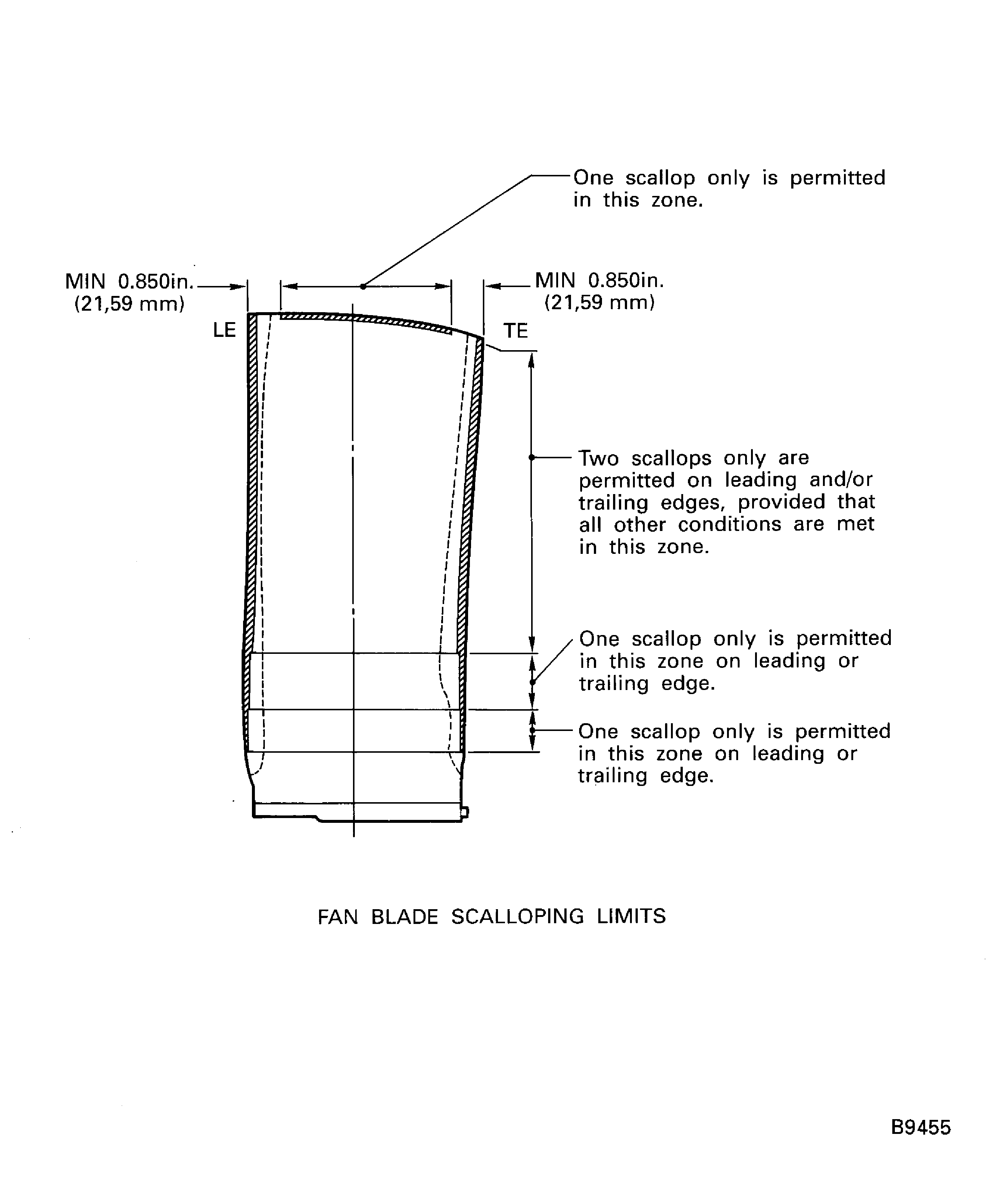

Figure: Fan blade scalloping limits

Fan blade scalloping limits

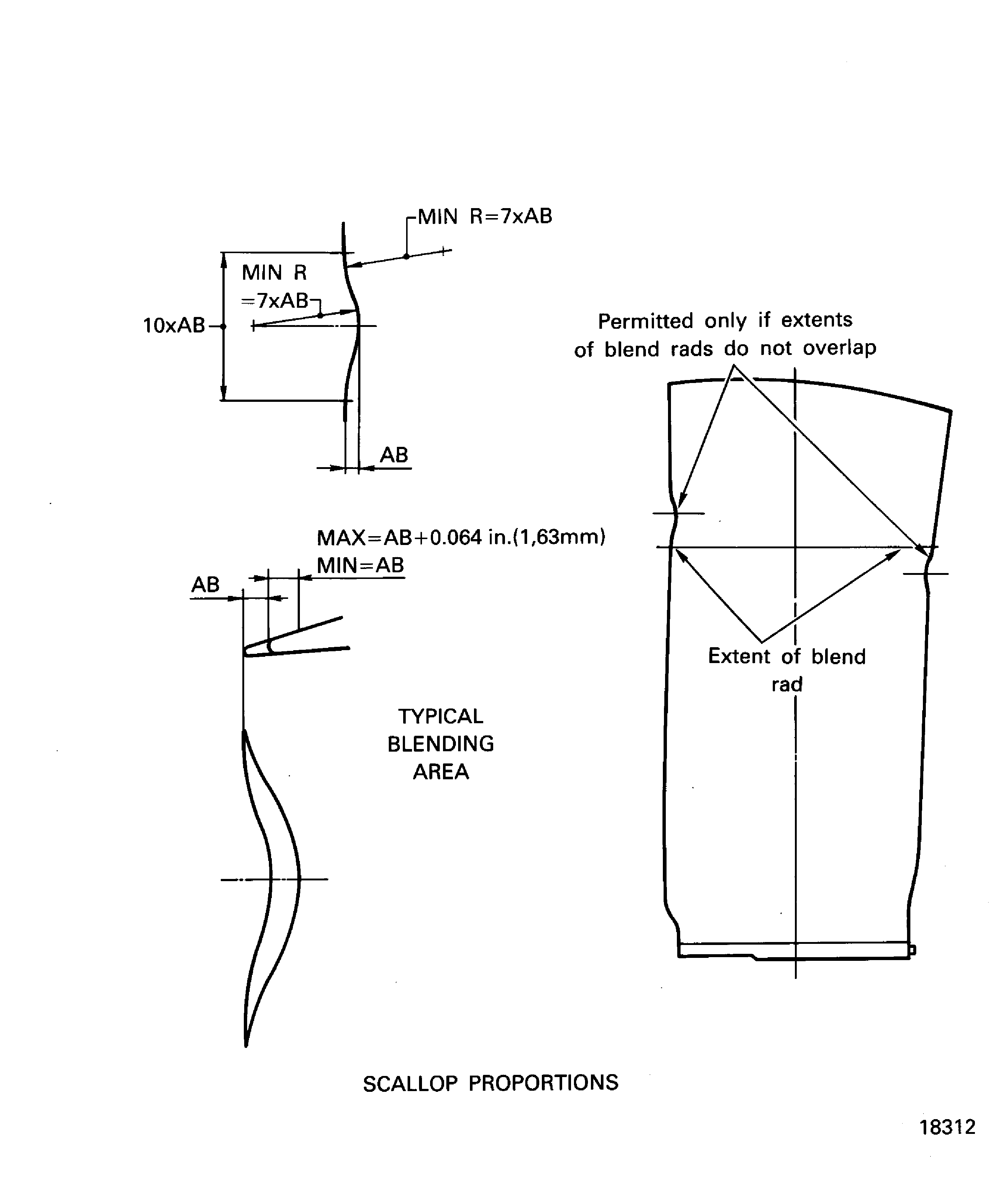

Figure: Scallop proportions

Scallop proportions

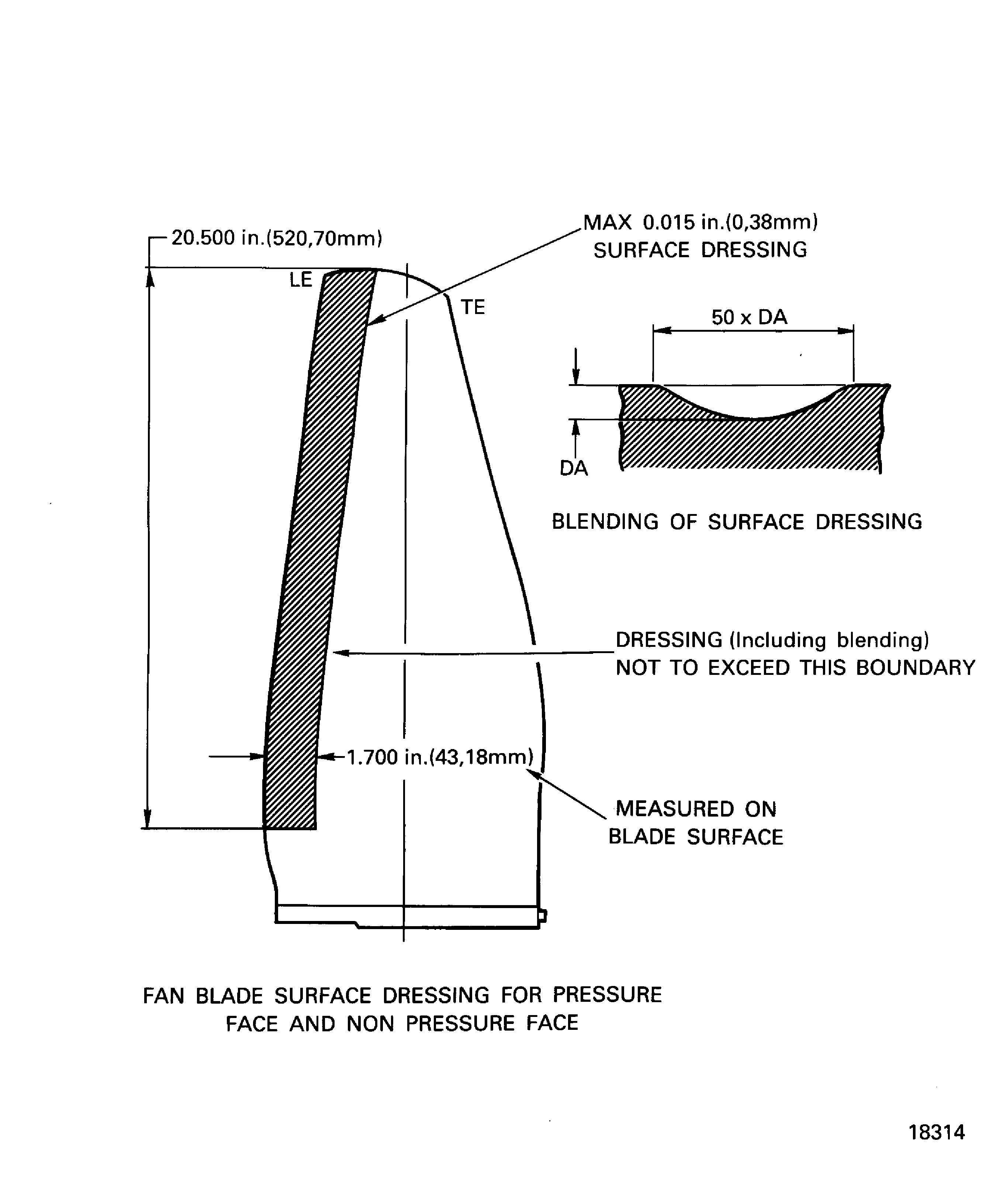

Figure: Fan blade surface dressing for pressure face and non pressure face

Fan blade surface dressing for pressure face and non pressure face

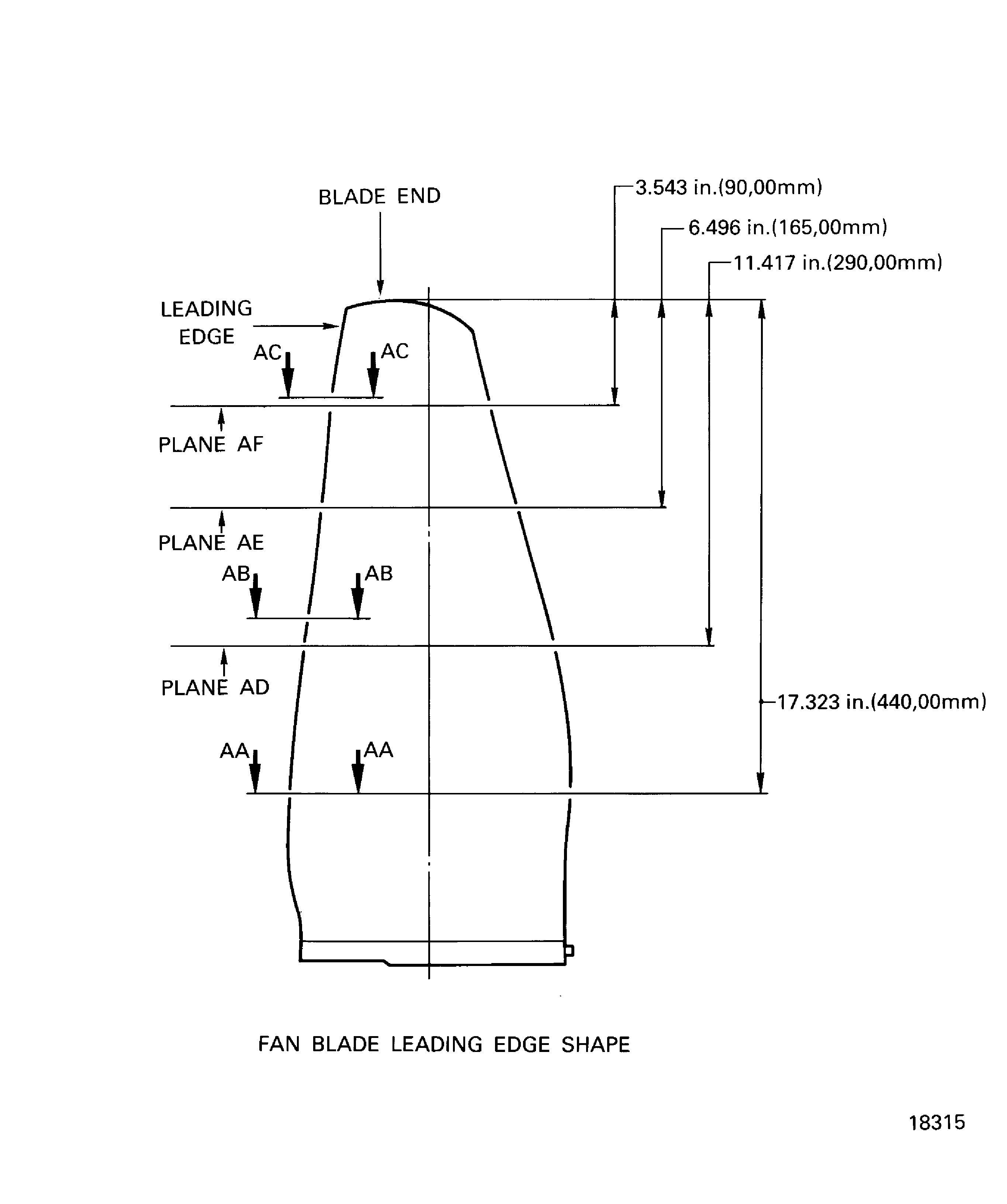

Figure: The fan blade leading edge shape

The fan blade leading edge shape

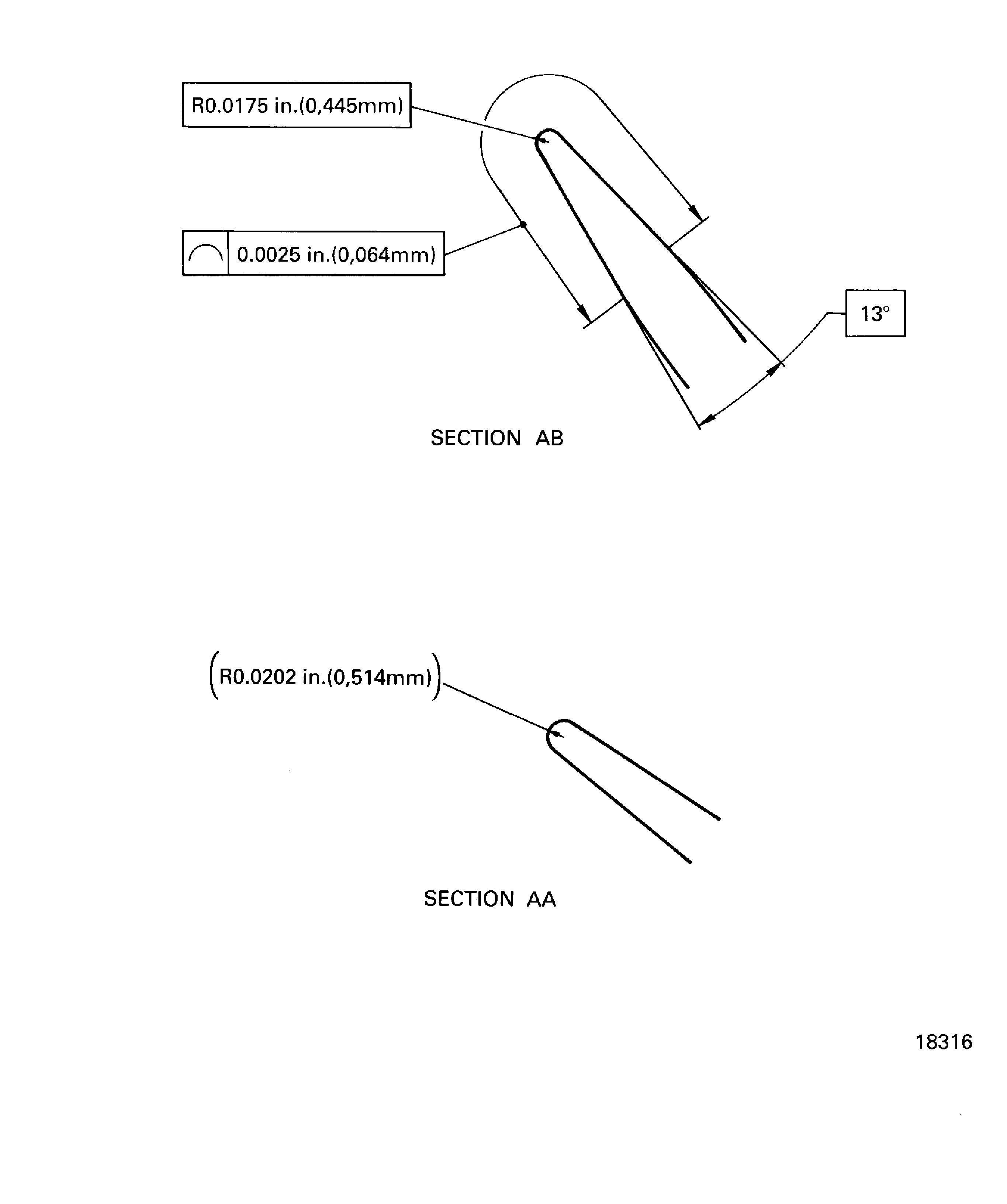

Figure: Section AA-AA and section AB-AB

Section AA-AA and section AB-AB

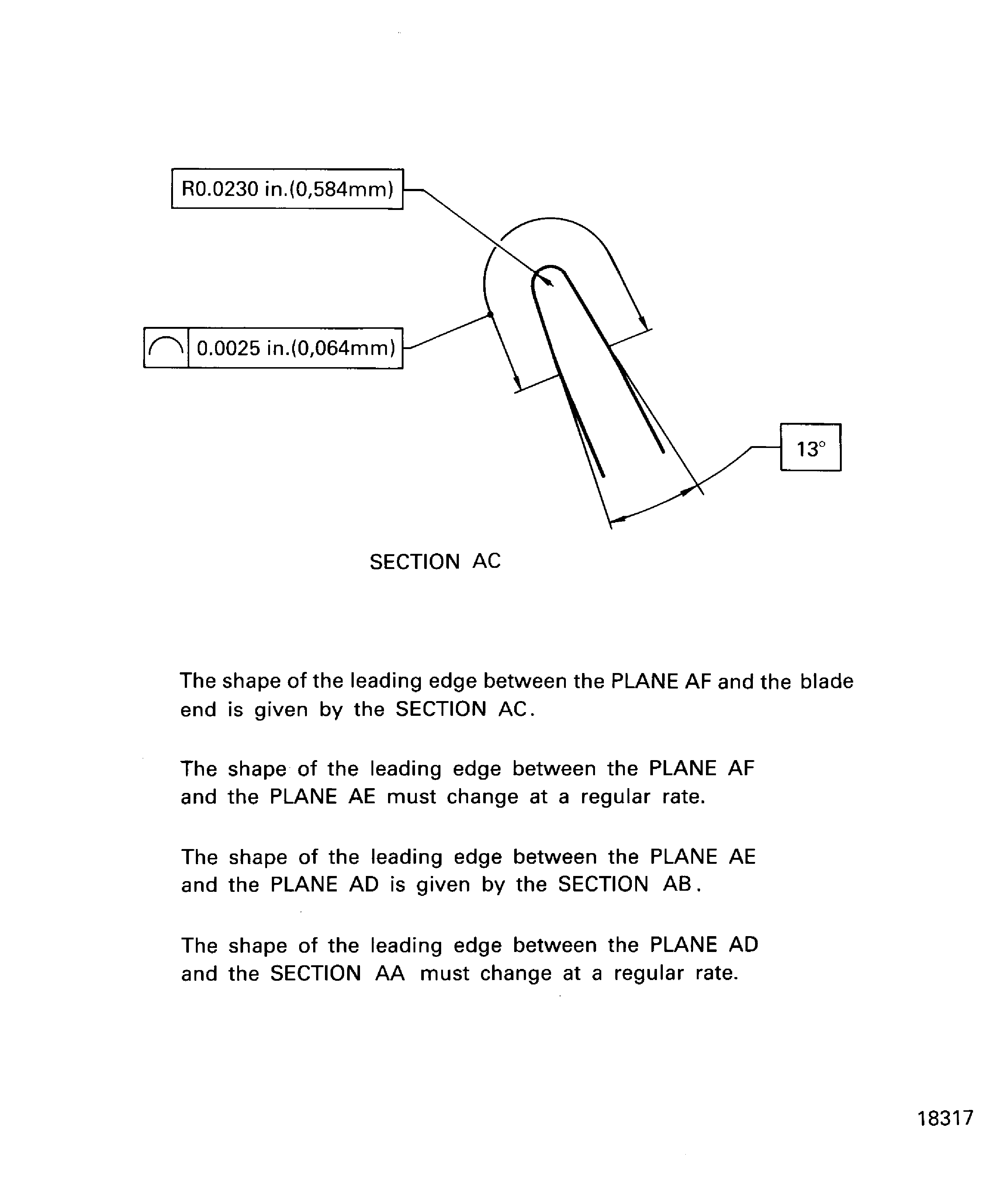

Figure: Section AC-AC

Section AC-AC

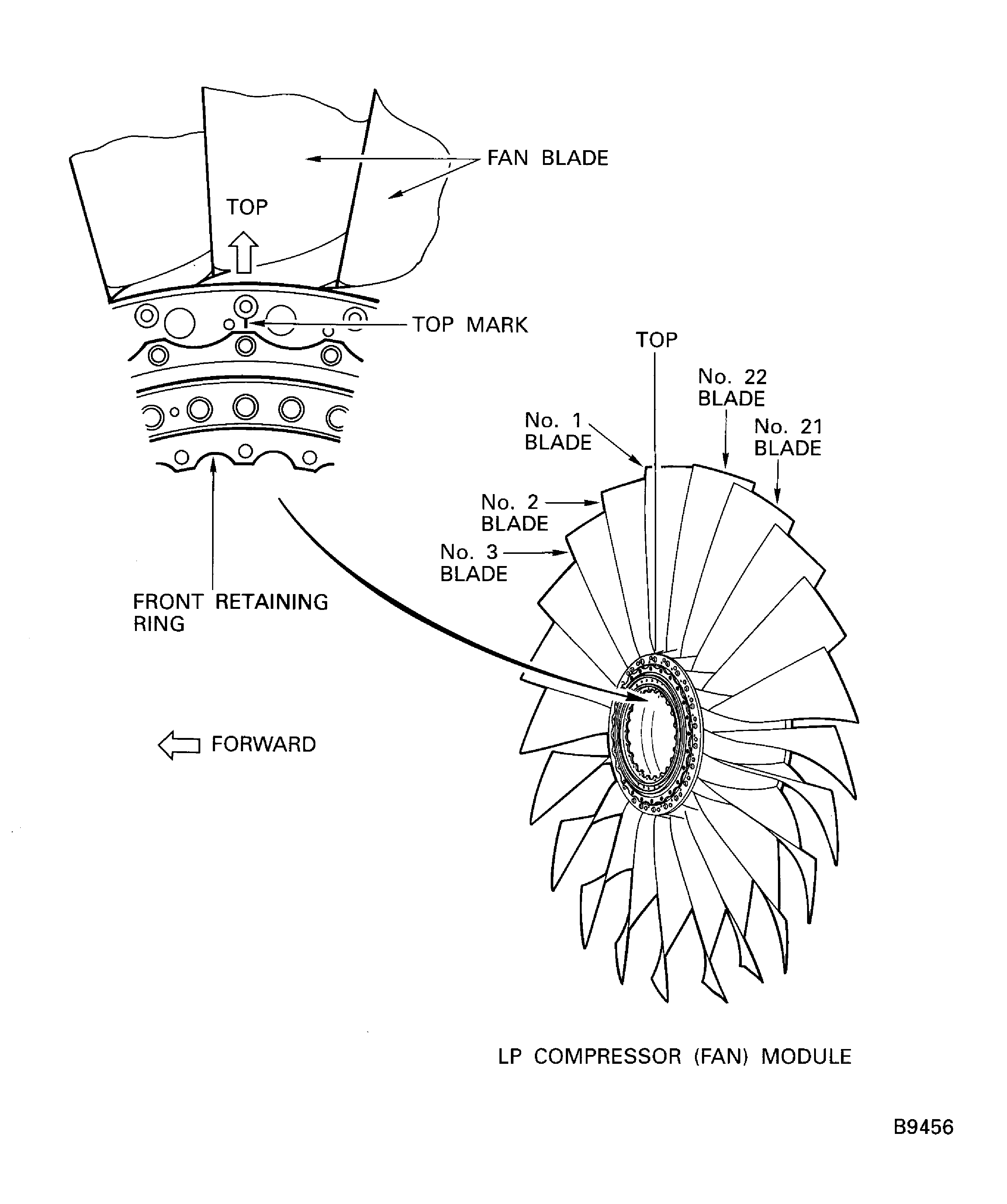

Figure: Location number of the fan blade

Location number of the fan blade