Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-32-050-007 LPC/Intermediate Case Module Components - Remove The Air Modulating Valve, Removal-014

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Remove and discard the lockwire before the component is disconnected.

Apply the approved CoMat 10-058 PENETRATING OIL before the removal of threaded parts. Let the parts soak before removal.

During the removal procedure make sure that the harnesses are held temporarily along their different lengths. This is to prevent too much strain on the harnesses, cables and electrical connectors.

During the removal procedure put the special plastic caps on the electrical connectors and receptacles. This is to give protection from unwanted fluids or materials.

Seal all openings when the tubes or components are disconnected to prevent contamination from unwanted material.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 06-086 TIES | 18992 | CoMat 06-086 | ||

| CoMat 10-058 PENETRATING OIL | 0AM53 | CoMat 10-058 |

Spares

NONESafety Requirements

NONEProcedure

Attach the disconnected harnesses to the primary harness bundles (so the disconnected harnesses do not bend) with CoMat 06-086 TIES.

Disconnect the tube 218 OIL,HYDRAULIC AND WATER DRAIN TUBES-POWER PLANT (71-73-48, 03-100) from the drain union.

Disconnect the electrical connectors and the fuel tubes.

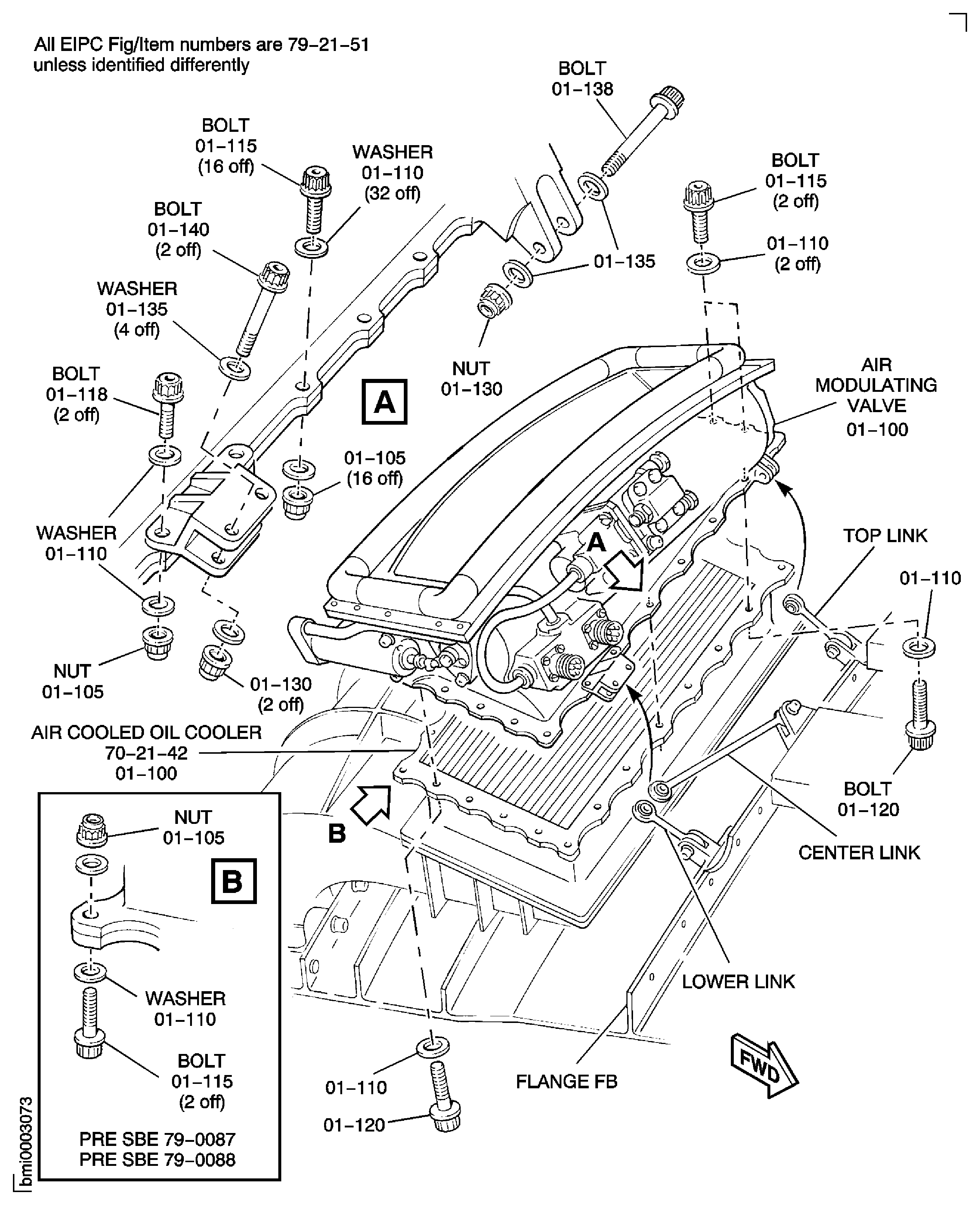

Remove the bolt, the nut and the washer which attaches the bracket Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-070) to the modulating valve and the air cooled oil cooler (ACOC) flanges.

Loosen the nut which attaches the bracket to the bracket Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-230), move the bracket away from the modulating valve flange.

WARNING

BE CAREFUL DURING REMOVAL OF THE AIR MODULATING VALVE BECAUSE IT WEIGHS 18 LB (8 KG).NOTE

The air modulating valve removed in this procedure must have its maintenance completed, as given in the Lucas Component Maintenance Manual (79-21-51).Hold the modulating valve and remove the four bolts and the four washers Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-120 , Air Cooled Oil Cooler (ACOC) Modulating Valve 01-115 and Air Cooled Oil Cooler (ACOC) Modulating Valve 01-110) which attach the modulating valve to the ACOC flange. Remove the modulating valve.

Pre SBE 79-0087 and Pre SBE 79-0088: Remove the modulating valve.

Remove the bolt, the nut and the washer which attach the bracket Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-070) to the modulating valve and the air cooled oil cooler (ACOC) flanges.

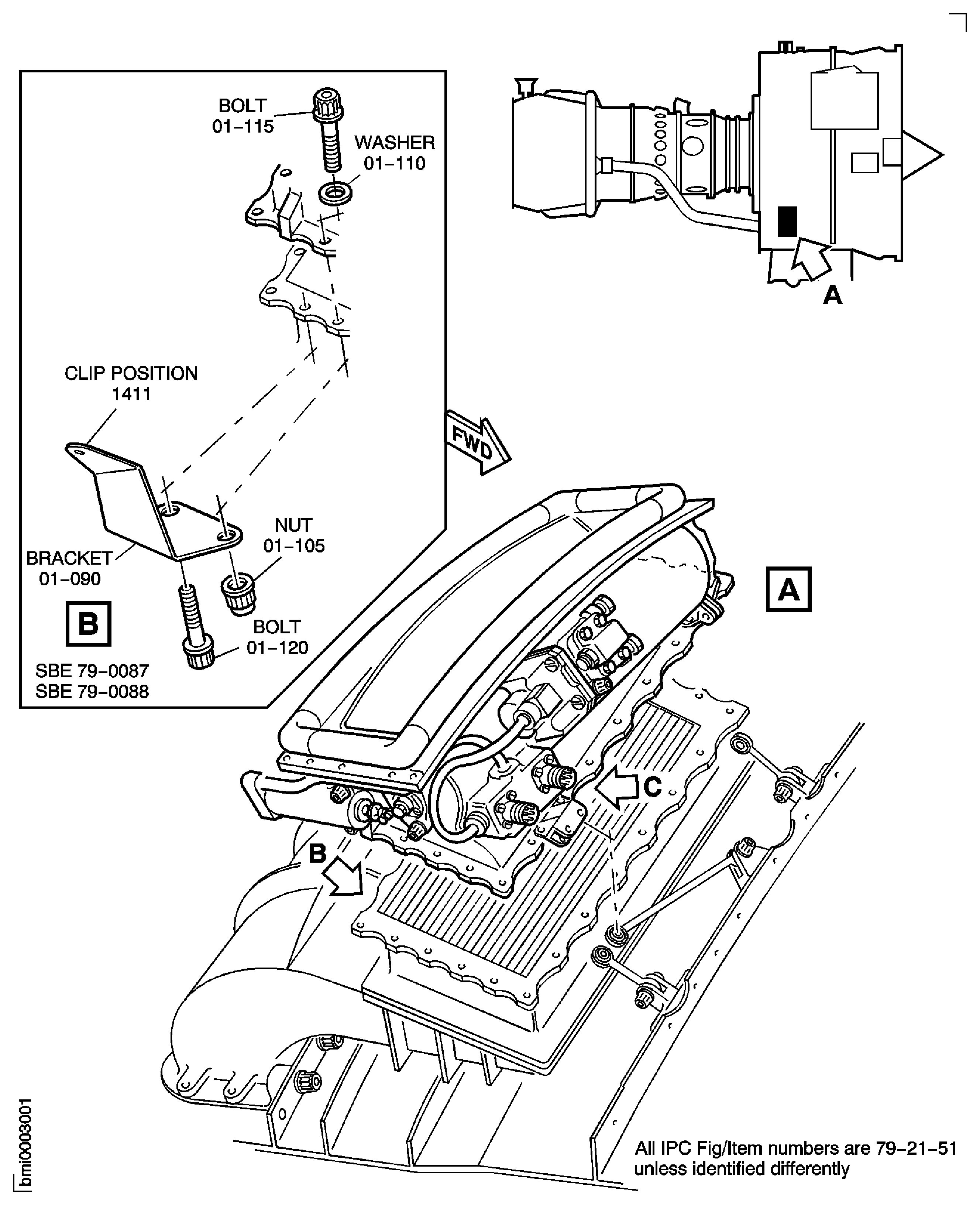

Remove the bolt Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-115), the nut Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-105) and the washer Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-110) which attach the bracket Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-090) to the modulating valve and the air cooled oil cooler (ACOC) flange.

Remove the bolt Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-120) at the blind hole position which attaches the bracket Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-090) to the modulating valve and the air cooled oil cooler (ACOC) flange.

Remove the two bolts Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-115) and the two washers Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-110) at the blind hole positions.

Loosen the nut which attaches the bracket Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-070) to the bracket Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-230). Move the bracket away from the modulating valve flange.

WARNING

BE CAREFUL DURING REMOVAL OF THE AIR MODULATING VALVE BECAUSE IT WEIGHS 18 LB (8 KG).NOTE

The air modulating valve removed in this procedure must have its maintenance completed, as given in the Lucas Component Maintenance Manual (79-21-51).Hold the modulating valve and remove the four bolts and the four washers Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-120) , Air Cooled Oil Cooler (ACOC) Modulating Valve (01-115) and Air Cooled Oil Cooler (ACOC) Modulating Valve 01-110) which attach the modulating valve to the ACOC flange. Remove the modulating valve.

SBE 79-0087 and SBE 79-0088: Remove the modulating valve.

SUBTASK 72-00-32-050-057 Remove the Air Modulating Valve (01-100) (Pre SBE 79-0087, Pre SBE 79-0088, SBE 79-0087 and SBE 79-0088)

Figure: Pre SBE 79-0087 and Pre SBE 79-0088: Remove the Air Modulating Valve

Sheet 1

Figure: SBE 79-0087 and SBE 79-0088: Remove the Air Modulating Valve

Sheet 2

Figure: Remove the Air Modulating Valve

Sheet 3