Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-42-420-001 Combustion System - Install The Diffuser Case Assembly, Installation-001

General

The word 'reject' after an interface inspection statement requires that further detailed inspection or repair as applicable, of the affected area be accomplished using data in the applicable ATA section of the part in question. Contact IAE for FAA approved data if the referenced TASK is not in the manual.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to TASK 70-41-00-400-501 and TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in this procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to TASK 70-44-01-400-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Transportation covers/blanks must be removed immediately before the installation of the components.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1P16104 Cover | 0AM53 | IAE 1P16104 | 1 | |

| IAE 1P16108 cover | 0AM53 | IAE 1P16108 | 1 | |

| IAE 1P16122 Installation fixture | 0AM53 | IAE 1P16122 | 1 | |

| IAE 1R18247 Rigging pin | 0AM53 | IAE 1R18247 | 1 | |

| IAE 1R18234 Support rod | 0AM53 | IAE 1R18234 | 3 | |

| IAE 1P16107 cover | 0AM53 | IAE 1P16107 | 1 | |

| IAE 1P16004 Handling bracket | 0AM53 | IAE 1P16004 | 2 | |

| IAE 1P16005 Build stand | 0AM53 | IAE 1P16005 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

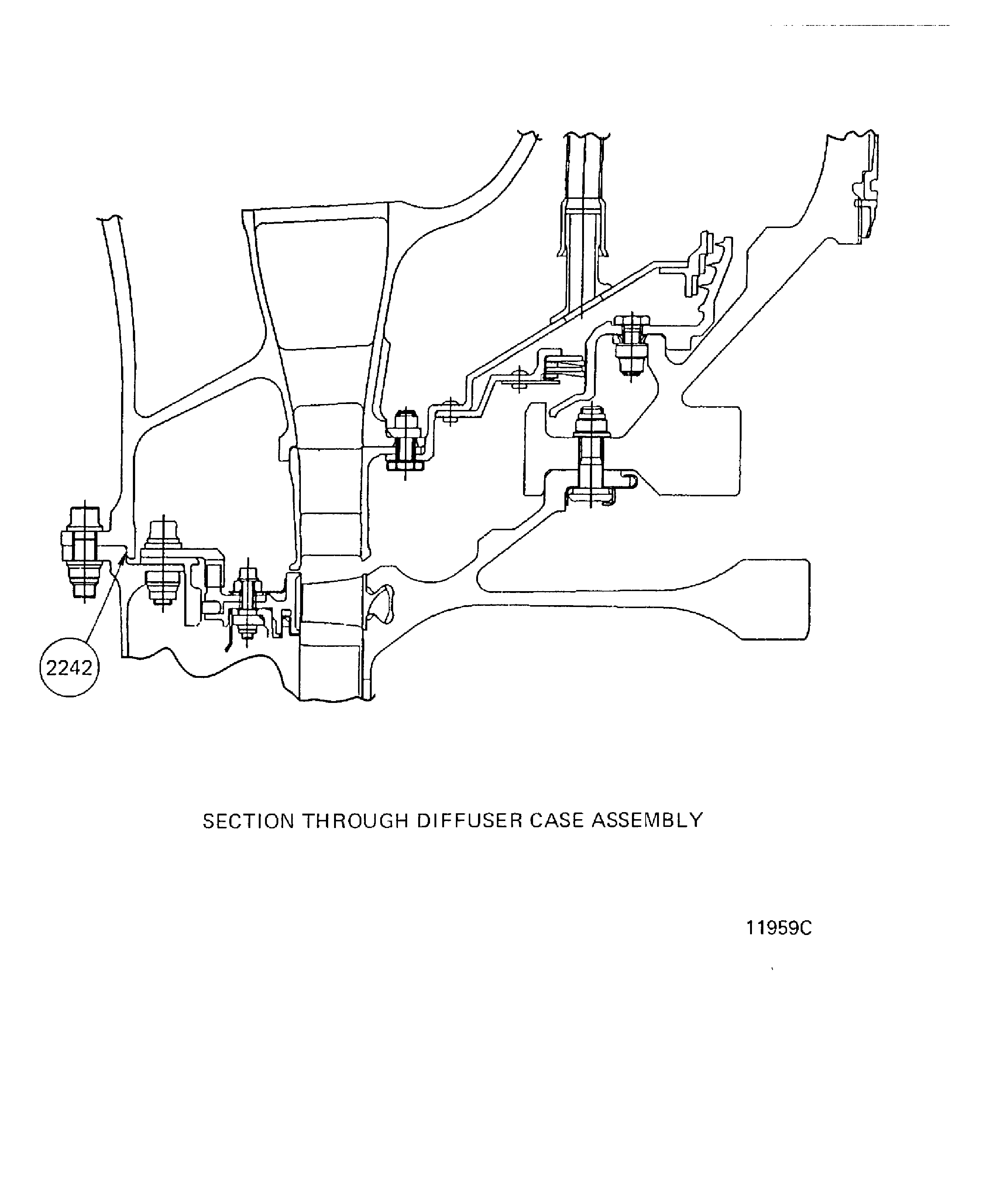

Refer to Figure.

Calculate the interference at location 2242. Use the data made as a note in TASK 72-41-23-200-001-A00 (INSPECTION-001, CONFIG-001) and TASK 72-42-11-200-001-A00 (INSPECTION-001, CONFIG-001).

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF MORE THAN

LOCATION 2242

HP compressor case HPC Rear Outer Case And Related Parts (72-41-23, 02-400), bore and diffuser case assembly Diffuser Case (72-42-11, 01-010), location diameter

Case bore

25.2017

Intf

25.2017

Intf

25.1969

0.0023

25.1969

0.0023

Diffuser case assembly location diameter

25.2090

0.012

25.209

0.012

25.2040

25.199

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF MORE THAN

LOCATION 2242

HP compressor case HPC Rear Outer Case And Related Parts (72-41-23, 02-400), bore and diffuser case assembly Diffuser Case (72-42-11, 01-010), location diameter

Case bore

640.125

Intf

640.125

Intf

640.000

0.057

640.000

0.057

Diffuser case assembly location diameter

640.308

0.308

640.31

0.308

640.182

640.05

SUBTASK 72-00-42-220-051 Make sure that the Fits and Clearances of the Combustion System are in the Limits given at Location 2242

NOTE

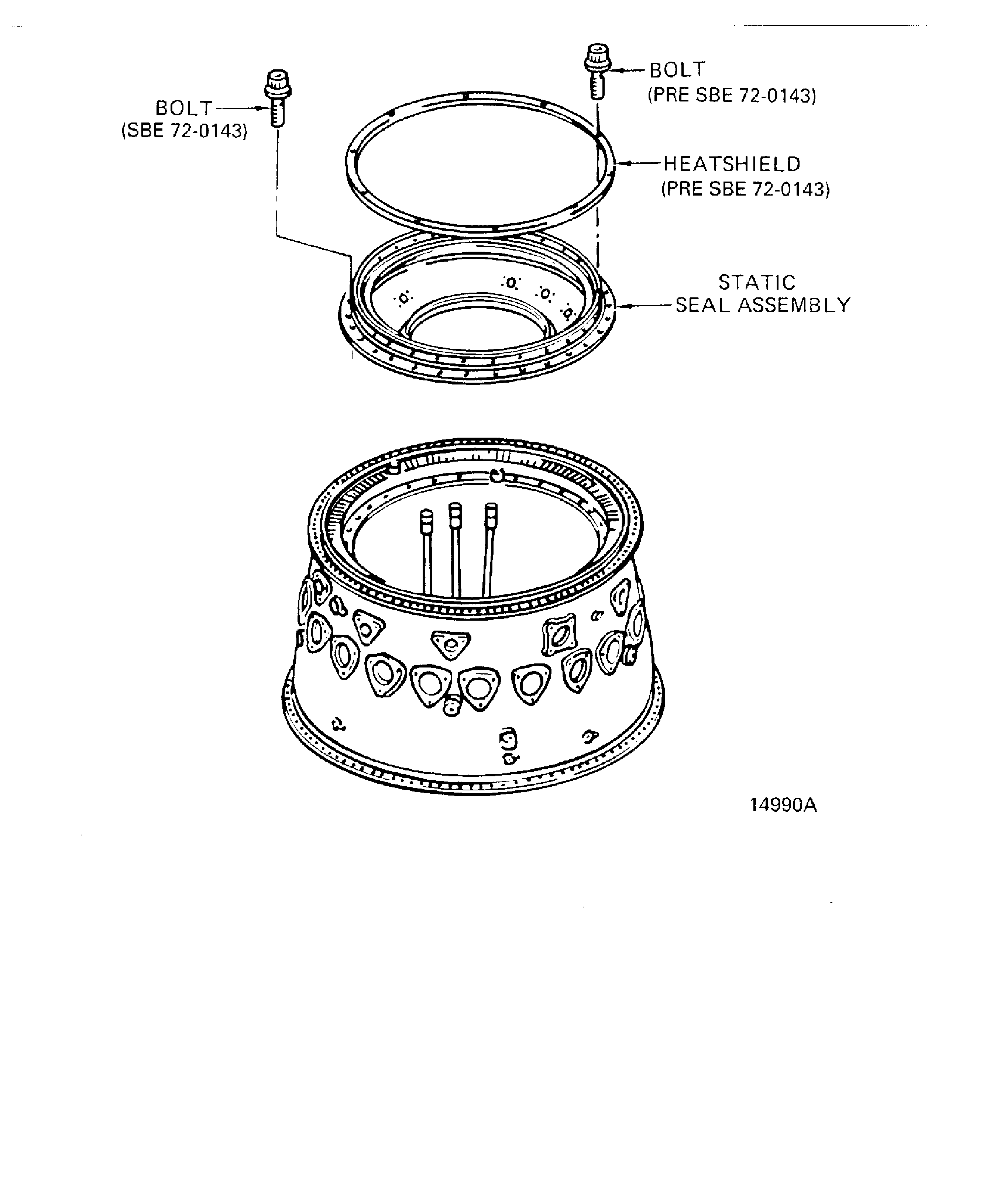

This SUBTASK is only to be completed if the diffuser case has not been overhauled.Refer to Figure.

Remove the IAE 1P16108 cover from the ID of the No. 4 bearing cooling duct.

Install six of the bolts ENGINE-STATIC SEAL (72-42-50, 01-102) at equal distances around the static seal assembly.

Do Step again until the static seal assembly is fully installed.

Install the static seal assembly.

Install 20 of the 30 bolts ENGINE-STATIC SEAL (72-42-50, 01-102) through the seal assembly and OGV case, in to the diffuser case. Install the 20 bolts by hand and start with the offset hole. Do not install every third bolt after the offset hole. Torque the bolts to 85 to 105 lbf.in (10.0 to 12.0 Nm).

Install the heatshield ENGINE-STATIC SEAL (72-42-50, 01-096).

Install the IAE 1P16108 cover 1 off to the ID of the No. 4 bearing cooling duct.

SUBTASK 72-00-42-420-063-A00 V2500-A1: Install the Static Seal Assembly and the Heatshield (Pre SBE 72-0143)

NOTE

This SUBTASK is only to be completed if the diffuser case has not been overhauled.Refer to Figure.

Remove the IAE 1P16108 cover from the ID of the No. 4 bearing cooling duct.

Install six of the bolts ENGINE-STATIC SEAL (72-42-50, 01-102) at equal distances around the static seal assembly.

Do Step again until the static seal assembly is fully installed.

Install the static seal assembly.

Install the 30 bolts ENGINE-STATIC SEAL (72-42-50, 01-102) through the seal assembly and OGV case, in to the diffuser case. Install the bolts by hand and start with the offset hole. Torque the bolts to 85 to 105 lbf.in (10.0 to 12.0 Nm).

Install the IAE 1P16108 cover 1 off to the ID of the No. 4 bearing cooling duct.

SUBTASK 72-00-42-420-063-B00 V2500-A1: Install the Static Seal Assembly (SBE 72-0143)

NOTE

This SUBTASK is only to be completed if the diffuser case has not been overhauled.Refer to Figure.

Remove the IAE 1P16108 cover from the ID of the No. 4 bearing cooling duct.

Install six of the bolts ENGINE-STATIC SEAL (72-42-50, 01-102) at equal distances around the static seal assembly.

Do Step again until the static seal assembly is fully installed.

Install the static seal assembly.

Install the 30 bolts ENGINE-STATIC SEAL (72-42-50, 01-102) through the seal assembly and OGV case, into the diffuser case. Install the bolts by hand and start with the offset hole. Torque the bolts to 85 to 105 lbf.in (10.0 to 12.0 Nm).

Install the IAE 1P16108 cover 1 off to the ID of the No. 4 bearing cooling duct.

SUBTASK 72-00-42-420-063-C00 V2500-A5: Install the Static Seal Assembly

Remove the IAE 1P16108 cover 1 off from the No. 4 bearing cooling duct.

Remove the IAE 1P16107 cover 1 off from the No. 4 bearing support.

SUBTASK 72-00-42-420-056 Remove the Covers from the Combustion System

Refer to Figure.

Make sure the IAE 1P16104 Cover 1 off is installed.

Attach a hoist to the eyebolt of the IAE 1P16122 Installation fixture 1 off. Raise the fixture over the combustion system.

SUBTASK 72-00-42-420-057 Install the Fixture on to the Rear Flange of the Combustion System

Refer to Figure.

Remove the 10 screws that attach the IAE 1P16004 Handling bracket 2 off to the front flange of the diffuser case assembly.

Lift the combustion system away from the IAE 1P16005 Build stand 1 off.

SUBTASK 72-00-42-420-058 Remove the Combustion System from the Build Stand

Refer to Figure.

Install IAE 1R18247 Rigging pin 1 off through the bracket and into the HP compressor case to lock the VSVs.

Remove the six bolts HP COMPRESSOR SPLIT CASE (72-41-31, 01-122), the two brackets HP COMPRESSOR SPLIT CASE (72-41-31, 01-115) and HP COMPRESSOR SPLIT CASE (01-118) and three blanks HP COMPRESSOR SPLIT CASE (72-41-31, 01-120) from the HP compressor front cases.

Install the IAE 1R18234 Support rod 3 off.

SUBTASK 72-00-42-420-070 Install the HP Compressor Support Rods

Lower the combustion system until the IAE 1P16122 Installation fixture 1 off engages the HP compressor rear hub.

Remove the work bolts from the IAE 1P16122 Installation fixture 1 off and lift the fixture away from the combustion system.

SUBTASK 72-00-42-420-059 Install the Combustion System on to the HP Compressor

Figure: Remove the combustion system from the IAE 1P16005 build stand

Remove the combustion system from the IAE 1P16005 build stand

Figure: Install the combustion system on to the HP compressor

Install the combustion system on to the HP compressor

Figure: V25000-A1: Combustion system installation - Fits and Clearances

V25000-A1: Combustion system installation - Fits and Clearances

Figure: V2500-A5: Combustion system installation - Fits and Clearances

V2500-A5: Combustion system installation - Fits and Clearances

Figure: Install the heatshield and the static seal

Install the heatshield and the static seal

Figure: V2500-A5: Install the static seal

V2500-A5: Install the static seal

Figure: Install the support rods into the HP compressor front cases

Install the support rods into the HP compressor front cases

Figure: Install the support rods into the HP compressor front cases

Install the support rods into the HP compressor front cases

Figure: Pre SBE 73-0131 Install the bolts, the nuts and the brackets to diffuser case front flange

Sheet 1

Figure: SBE 73-0131 Install the bolts, the nuts and the brackets to diffuser case front flange

Sheet 2