Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-50-560-002 LPT Module - Turn The LPT Module From Vertical (Front End Down) To Horizontal, Installation-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to TASK 70-41-01-400-501 and TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to TASK 70-44-01-400-501.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of the air drying enamel. Refer to TASK 70-38-21-380-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Transportation covers/blanks must be removed immediately before installation of the components.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1F10049 Vertical stand | 0AM53 | IAE 1F10049 | 1 | |

| IAE 1F10052 Two cables sling | 0AM53 | IAE 1F10052 | 1 | |

| IAE 1F10058 Handling fixture | 0AM53 | IAE 1F10058 | 1 | |

| IAE 1F10063 Expanding retainer | 0AM53 | IAE 1F10063 | 1 | |

| IAE 1F10084 Support fixture | 0AM53 | IAE 1F10084 | 1 | |

| IAE 1F10101 Counter weights kit | 0AM53 | IAE 1F10101 | 1 | |

| IAE 1M14127 Support plate | 0AM53 | IAE 1M14127 | 2 | |

| IAE 1R18907 Expanding retainer | 0AM53 | IAE 1R18907 | 1 | |

| IAE 1M14146 Support plate | 0AM53 | IAE 1M14146 | 2 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 07-038 AIR DRYING ENAMEL | K3504 | CoMat 07-038 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

NOTE

Make sure that the IAE 1F10101 Counter weights kit 1 off is installed to the

IAE 1F10049 Vertical stand 1 off.

Safety the vertical stand with the four arms.

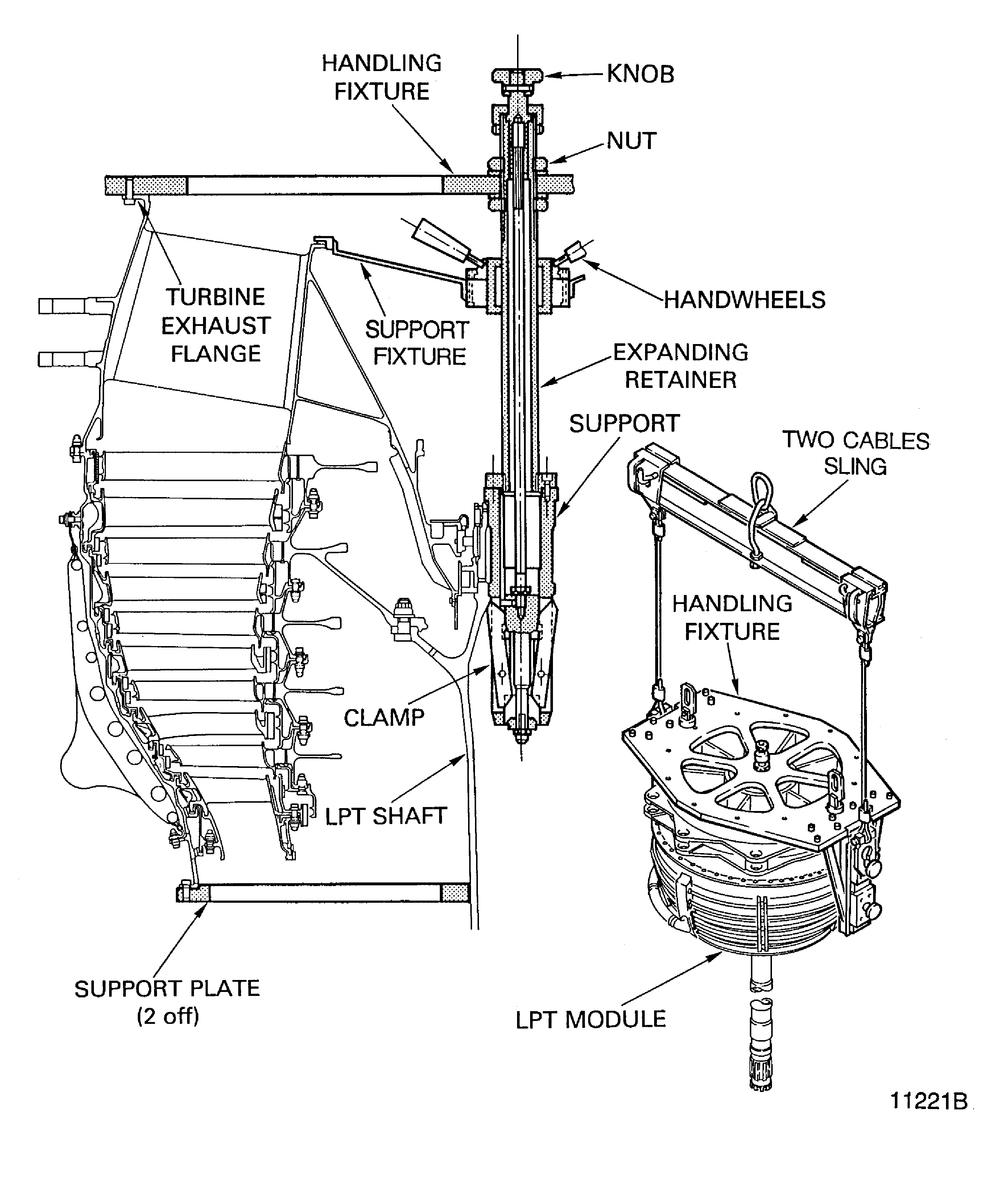

Refer to Figure.

Install the IAE 1F10084 Support fixture 1 off to the IAE 1F10063 Expanding retainer 1 off.

Attach the IAE 1F10052 Two cables sling 1 off to the rear spools of the IAE 1F10058 Handling fixture 1 off.

Attach the handling fixture to the rear flange of the turbine exhaust case with the 13 bolts and washers. Tighten the bolts, refer to Figure.

SUBTASK 72-00-50-560-054-A00 V2500-A1: Attach the Handling Fixture to the LP Turbine Module

NOTE

Make sure that the IAE 1F10101 Counter weights kit

1 off is installed to the IAE 1F10049 Vertical stand 1 off.

Safety the vertical stand with the four arms.

Refer to Figure.

Install the IAE 1F10084 Support fixture 1 off to the IAE 1R18907 Expanding retainer 1 off.

Attach the IAE 1F10052 Two cables sling 1 off to the rear spools of the IAE 1F10058 Handling fixture 1 off.

Attach the handling fixture to the rear flange of the turbine exhaust case with the 13 bolts and washers. Tighten the bolts, refer to Figure.

SUBTASK 72-00-50-560-054-B00 V2500-A5: Attach the Handling Fixture to the LP Turbine Module

Examine the HP system module at interface D-45. Refer to TASK 72-00-45-220-001 (INSPECTION/CHECK-001).

Examine the front face of the LP turbine module at interface D-50/10. Refer to TASK 72-00-50-220-001 (INSPECTION/CHECK-001).

Examine the LP compressor/intermediate case module at interface F-32. Refer to TASK 72-00-32-220-004 (INSPECTION/CHECK-004).

Examine the LP turbine module at interface F50. Refer to TASK 72-00-50-220-005 (INSPECTION/CHECK-005).

SUBTASK 72-00-50-210-055 Examine the Module Interfaces

Refer to Figure.

Attach the IAE 1F10052 Two cables sling 1 off to the front spools of the handling fixture. Make sure that the spools of the handling fixture are in the correct position at the center of gravity.

SUBTASK 72-00-50-560-055 Remove the LP Turbine Module from the Vertical Stand

SUBTASK 72-00-50-560-057-A00 V2500-A1: Turn the LP Turbine Module in to Horizontal Position

NOTE

If IAE 1M14127 Support plate 2 off are removed, install support plates to the LP turbine case front flange and the LP turbine shaft before LP turbine module is turned into the horizontal position.SUBTASK 72-00-50-560-057-B00 V2500-A5: Turn the LP Turbine Module into Horizontal Position

NOTE

If IAE 1M14146 Support plate 2 off are removed, install support plates to the LP turbine case front flange and the LP turbine shaft before LP turbine module is turned into the horizontal position.

Figure: Attachment of the handling fixture and the expanding retainer

Attachment of the handling fixture and the expanding retainer

Figure: Removal of the LP turbine module from the vertical stand

Removal of the LP turbine module from the vertical stand