Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

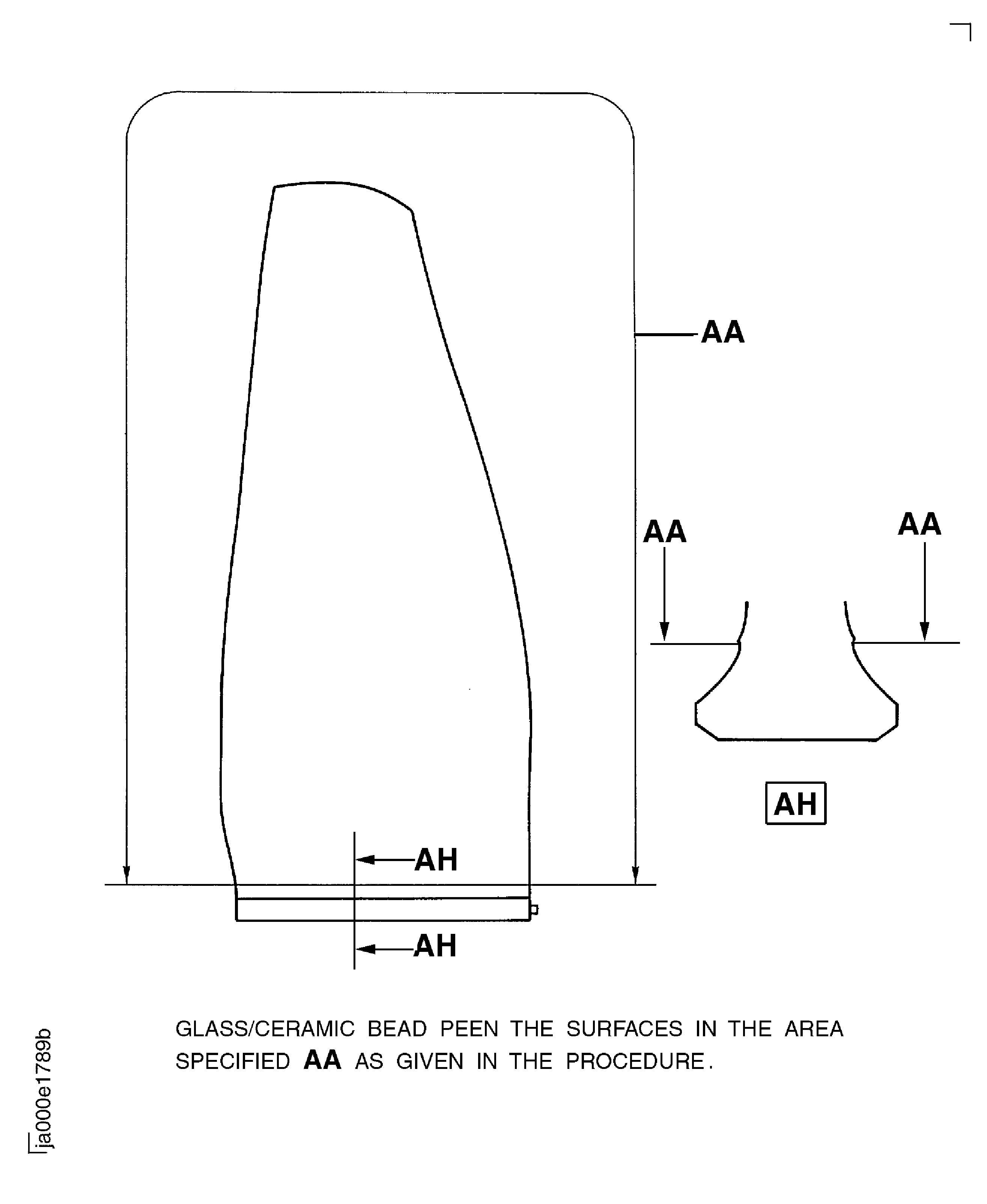

TASK 72-31-11-300-026 LPC Fan Blade - Repair The Airfoil Surface Finish By Glass/Ceramic Bead Peening, Repair 026 (VRS1724)

Effectivity

FIG/ITEM PART NO. | |

|---|---|

01-300 | 6A3494 |

01-300 | 6A3971 |

01-300 | 6A4700 |

01-300 | 6A5485 |

01-300 | 6A6519 |

01-300 | 6A6521 |

01-300 | 6A7403 |

01-300 | 6A7613 |

01-300 | 6A7614 |

01-300 | 6A7649 |

01-300 | 6A7650 |

01-300 | 6A7651 |

01-300 | 6A7652 |

01-300 | 6A7653 |

01-300 | 6A7654 |

01-300 | 6A7655 |

01-300 | 6A7656 |

01-300 | 6A7658 |

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

LP compressor rotor blades | TFH | Titanium |

6 percent Aluminium | ||

4 percent Vanadium | ||

alloy |

General

The blade(s) must have had all other repairs completed and be servicable. Refer to TASK 72-31-11-200-000 (INSPECTION/CHECK-000).

This Repair gives the procedure to glass/ceramic bead peen the LP compressor rotor blade(s) to restore the airfoil surface finish.

This Repair can only be carried out on a blade for a maximum of five times.

When a blade airfoil is repaired by glass/ceramic bead peening for the first time/1 is engraved adjacent to the scheme number, /2 for the second time, /3 for the third time, /4 for the fourth time and /5 for the final time.

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Price and availability - Refer to IAE.

Related repairs

LP Compressor Rotor Blade - Restore the Surface Finish by Vibro-Polishing (VRS1025). Refer to TASK 72-31-11-300-010 (REPAIR-010).

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard equipment | LOCAL | Standard equipment | ||

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Glass/Ceramic bead peening equipment | LOCAL | Glass/Ceramic bead peening equipment | ||

| Vibro-engraving equipment | LOCAL | Vibro-engraving equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-293 GLASS BEADS | LOCAL | CoMat 01-293 | ||

| CoMat 02-003 ADHESIVE TAPE BLACK WATERPROOF | LOCAL | CoMat 02-003 | ||

| CoMat 05-184 CERAMIC BEADS | IE460 | CoMat 05-184 |

Spares

NONESafety Requirements

NONEProcedure

Refer to the SPM TASK 70-11-03-300-503. Use chemical cleaning equipment.

Chemically clean the blade(s).

SUBTASK 72-31-11-110-070 Clean the LP Compressor Rotor Blade(s)

Refer to: Figure

Use CoMat 02-003 ADHESIVE TAPE BLACK WATERPROOF or a locally made mask.

Apply adhesive tape to the LP compressor rotor blade root and areas that are not to be glass/ceramic bead peened.

Refer to the SPM TASK 70-38-04-300-503, SUBTASK 70-38-04-300-002.

Use CoMat 01-293 GLASS BEADS or CoMat 05-184 CERAMIC BEADS to get an Almen instensity of 0.015 to 0.020 in. (0.38 to 0.50 mm) on 'N' type test strip.

A coverage of 200 per cent must be applied.

Use controlled glass/ceramic bead peening equipment.

Make sure the glass/ceramic bead peening equipment can give the parameters.

SUBTASK 72-31-11-380-066 Restore the LP Compressor Rotor Blade(s) Airfoil Surface Finish

CAUTION

DO NOT ABRASIVE BLAST THE AIRFOIL SURFACE BEFORE YOU GLASS/CERAMIC BEAD PEEN.Refer to VRS1025, TASK 72-31-11-300-010 (REPAIR-010).

Vibro-polish the LP compressor rotor blade airfoil.

SUBTASK 72-31-11-380-067 Vibro-Polish the LP Compressor Rotor Blade Airfoil

NOTE

This procedure is not necessary if surface finish within the limit is achieved. Refer to TASK 72-31-11-200-000 (INSPECTION/CHECK-000).Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Use vibro-engraving equipment.

If this is the first repair to this scheme, then vibro-engrave /1 adjacent to the scheme number.

If this is the second repair to this scheme, then vibro-engrave /2 adjacent to the scheme number.

If this is the third repair to the scheme, then vibro-engrave /3 adjacent to the scheme number.

If this is the fourth repair to this scheme, then vibro-engrave /4 adjacent to the scheme number.

If this is the fifth repair to this scheme, then vibro-engrave /5 adjacent to the scheme number.

NOTE

The LP compressor rotor blade can only be glass/ceramic bead peened five times.

Write the repair number, VRS1724, adjacent to the assembly number.

SUBTASK 72-31-11-350-081 Identify the Repair

CAUTION

DO NOT VIBRO-ENGRAVE ON THE BLADE AIRFOIL OR LOCATION FACES.

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions