Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-31-12-300-008 LPC Fan Disk - Replace The Plate Washer, Repair-008 (VRS1159)

General

The practices and processes referred to in the procedure by the TASK number are in SPM.

Price and availability - not applicable.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 3J12732 clamping fixture | 0AM53 | IAE 3J12732 | 1 | |

| Fluorescent penetrant inspection equipment | LOCAL | Fluorescent Penetrant Inspection Equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 01-201 DISTILLED, DEIONIZED, DEMINERALIZED, OR REVERSE OSMOSIS (RO) WATER | LOCAL | CoMat 01-201 | ||

| CoMat 02-019 TAPE, ADHESIVE PAPER HEAT RESISTING MASKING | 94960 | CoMat 02-019 | ||

| CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE | LOCAL | CoMat 05-003 | ||

| CoMat 05-019 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-019 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 | ||

| CoMat 08-015 RESIN | LOCAL | CoMat 08-015 | ||

| CoMat 08-016 HARDENER | LOCAL | CoMat 08-016 |

Safety Requirements

NONEProcedure

Refer to Figure.

SUBTASK 72-31-12-350-060 Remove the Damaged Plate Washer from the Stage 1 Fan Disk Assembly

Refer to SPM TASK 70-11-26-300-503.

Clean the plate washer.

SUBTASK 72-31-12-350-001 Remove the Remaining Adhesive from the Removed Plate Washer (01-220)

Refer to SPM TASK 70-23-02-230-501.

Fluorescent penetrant examine the removed plate washer

SUBTASK 72-31-12-230-062 Examine the Removed Plate Washer (01-220) for Cracks

Refer to SPM TASK 70-23-05-230-501.

Use fluorescent penetrant inspection equipment and CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY).

Make sure there are no cracks in the repaired surface.

Fluorescent penetrant examine the repaired surface.

SUBTASK 72-31-12-230-058 Examine the Stage 1 Fan Disk Assembly for Cracks

Refer to SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-010.

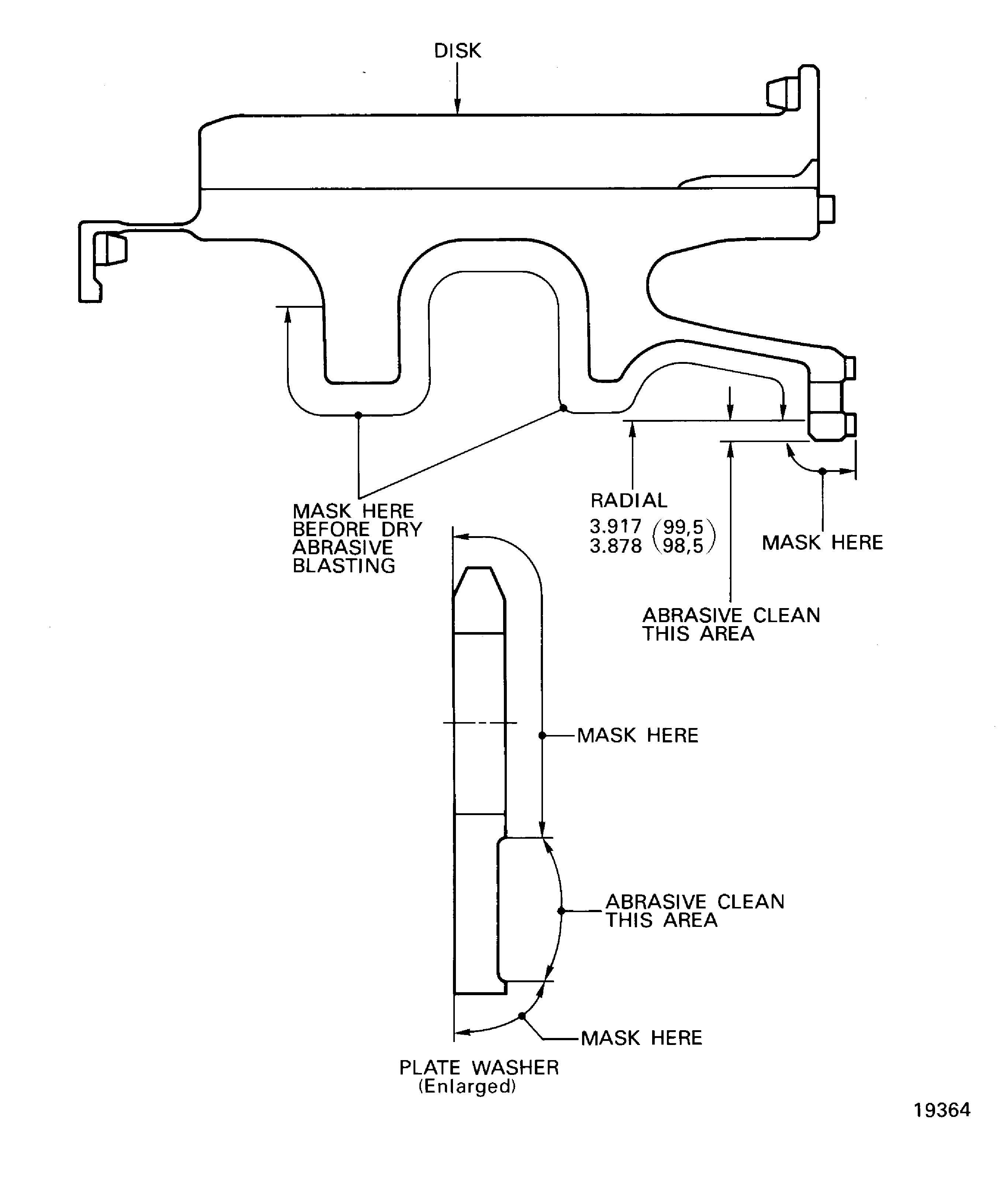

Refer to Figure.

Cold liquid degrease the mating surfaces.

Refer to SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-010.

Refer to Figure.

Dry abrasive blast the mating surface of the plate washers and disk.

Refer to SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-010.

Use a clean soft brush with clean CoMat 01-201 DISTILLED, DEIONIZED, DEMINERALIZED, OR REVERSE OSMOSIS (RO) WATER and clean CoMat 01-031 ACETONE (CH3)2CO.

Do a break-test to make sure that the mating surfaces are clean.

SUBTASK 72-31-12-350-061 Prepare the Mating Surfaces for the Two Part Low Temperature Curing Sealant/Adhesive

Refer to SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-004.

Use CoMat 08-015 RESIN and CoMat 08-016 HARDENER.

Make-up the adhesive from two parts.

SUBTASK 72-31-12-360-052 Make-up of the Two Part Low Temperature Curing Sealant/Adhesive

Refer to SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-021.

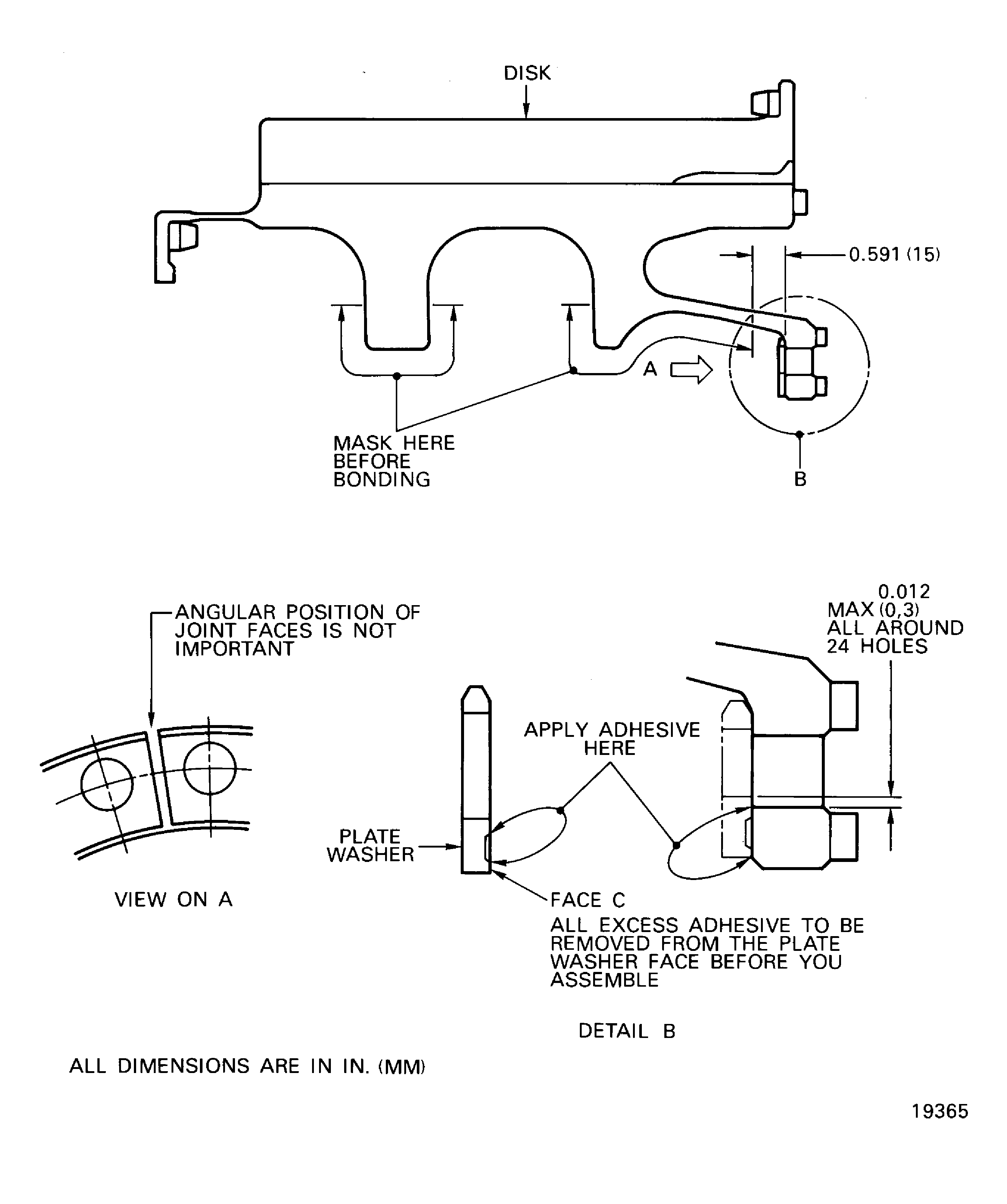

Apply adhesive to the mating surfaces of the disk and plate washer with a spatula or small trowel removing any excess.

Apply the two part adhesive to each of the mating surfaces.

The plate washers are kept and adjusted in the center by the tool bolts and nuts during curing.

Torque tighten the nuts to 300 lbfin (33.90 Nm).

Use IAE 3J12732 clamping fixture 1 off to apply sufficient pressure.

Assemble the plate washers to the disk and apply a pressure.

Refer to SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-021 or cure the adhesive at room temperature for 48 hours.

Cure the adhesive.

SUBTASK 72-31-12-360-053 Apply and Cure the Two Part Low Temperature Curing Sealant/Adhesive

Refer to Figure.

SUBTASK 72-31-12-220-073 Examine the Repaired Areas of the Stage 1 Fan Disk Assembly

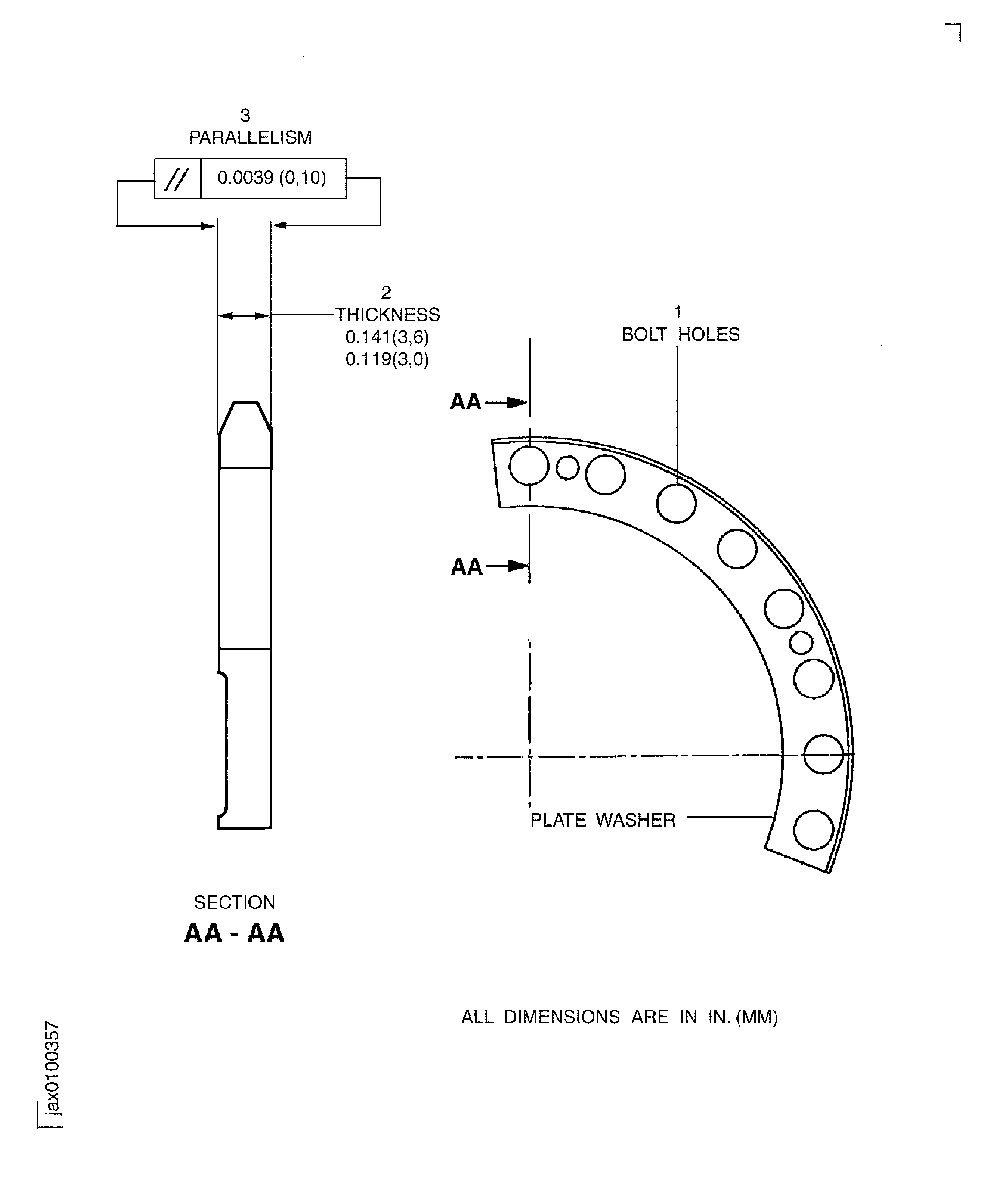

Figure: Replace the plate washer

Replace the plate washer

Figure: Replace the plate washer

Replace the plate washer

Figure: Location on the plate washer (01-220)

Location on the plate washer (01-220)