Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-20-040-001 No. 3 Bearing, Seal, HPC Shaft, And Gearshaft Assembly - Disassemble, Disassembly-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

Apply the approved penetrating oil before the removal of threaded parts. Let the parts soak before removal. For the approved oils and procedures, refer to the SPM TASK 70-64-00-640-501.

Discard all packing and cupwasher removed in this procedure.

Refer to TASK 72-32-20-440-001 for a sectional view of a No. 3 bearing, rotor center and support assembly.

Do not disassemble the HP compressor front shaft and seal assembly in this TASK. For the procedure to disassemble the HP compressor front shaft and seal assembly, refer to TASK 72-32-23-040-001 (DISASSEMBLY, CONFIG-001, CONFIG-002)

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Torque multiplier | LOCAL | SWEENEY 8200 | or equivalent | |

| IAE 1F10026 Hydraulic hand pump | 0AM53 | IAE 1F10026 | 1 | |

| IAE 1J12188 Puller bolt | 0AM53 | IAE 1J12188 | 1 | |

| IAE 1J12339 Spanner wrench | 0AM53 | IAE 1J12339 | 1 | |

| IAE 1J12367 Tab bender | 0AM53 | IAE 1J12367 | 1 | |

| IAE 1J12374 Oil flow test stand | 0AM53 | IAE 1J12374 | 1 | |

| IAE 1J12375 Oil flow check box | 0AM53 | IAE 1J12375 | 1 | |

| IAE 1J12376 Oil feed adapter | 0AM53 | IAE 1J12376 | 1 | |

| IAE 1J12378 Ratchet wrench | 0AM53 | IAE 1J12378 | 1 | |

| IAE 1J12387 Work stand | 0AM53 | IAE 1J12387 | 1 | |

| IAE 1J12420 Hydraulic puller | 0AM53 | IAE 1J12420 | 1 | |

| IAE 1J12421 Base holder | 0AM53 | IAE 1J12421 | 1 | |

| IAE 1J12478 Hydraulic pusher/puller | 0AM53 | IAE 1J12478 | 1 | |

| IAE 1J12495 Base plate | 0AM53 | IAE 1J12495 | 1 | |

| IAE 1J12503 Hydraulic pusher | 0AM53 | IAE 1J12503 | 1 | |

| IAE 1J12534 Hydraulic pusher | 0AM53 | IAE 1J12534 | 1 | |

| IAE 1P16023 Build fixture | 0AM53 | IAE 1P16023 | 1 | |

| IAE 1P17043 Knocker puller | 0AM53 | IAE 1P17043 | 1 | |

| IAE 1P17006 Removal fixture | 0AM53 | IAE 1P17006 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 |

Spares

NONESafety Requirements

NONEProcedure

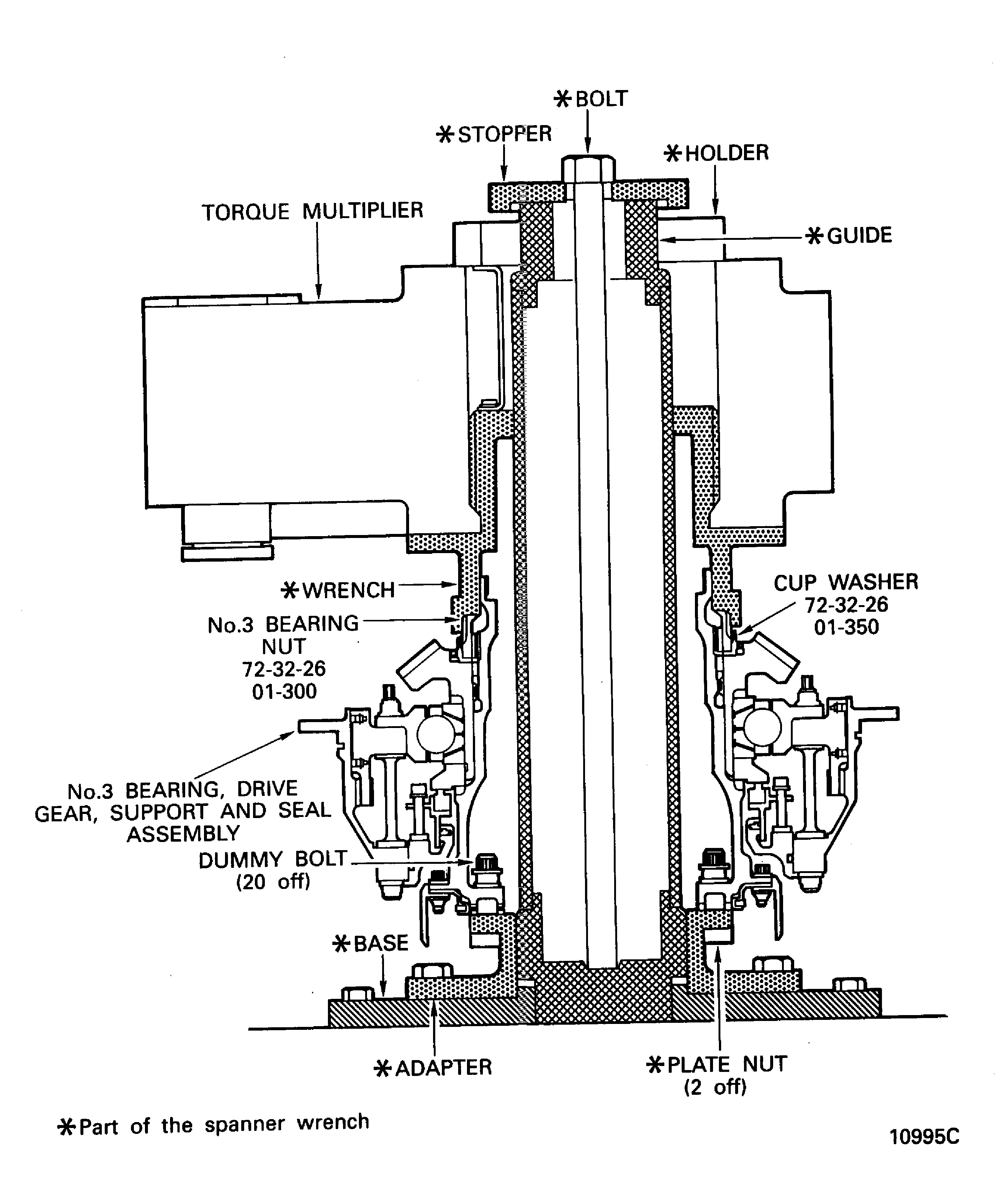

Move IAE 1J12339 Spanner wrench 1 off and IAE 1J12387 Work stand 1 off to the work area.

Clean both sets of curvic teeth on the No. 3 bearing, rotor center and support assembly and the adapter (part of the spanner wrench) with CoMat 01-124 ISOPROPYL ALCOHOL.

Lift and transfer the Torque multiplier with a hoist.

Loosen the No. 3 bearing nut with the wrench in the subsequent steps.

Move IAE 1J12420 Hydraulic puller 1 off to the work area.

Connect the hose (part of IAE 1F10026 Hydraulic hand pump 1 off) to the hydraulic cylinder and pressurize it.

Remove the No. 3 bearing, drive gear, support and seal assembly from the HP compressor front shaft and seal assembly.

SUBTASK 72-32-20-040-051 Remove the No. 3 Bearing, Drive Gear and Support Assembly from the No. 3 Bearing Rotor Center

Remove the No. 3 bearing seal assembly from the No. 3 bearing seal support with the three puller bolts (part of IAE 1J12188 Puller bolt 1 off).

Remove the nine bolts and the No. 3 bearing seal assembly from the No. 3 bearing seal support.

SUBTASK 72-32-20-040-052-A00 V2500-A1: Remove the No. 3 Bearing Seal Assembly and the No. 3 Bearing Seal Seat (Pre SBE 72-0132)

Install IAE 1P17043 Knocker puller 1 off on the No. 3 bearing seal assembly.

Remove the No. 3 bearing seal assembly from the No. 3 bearing seal support.

SUBTASK 72-32-20-040-052-B00 V2500-A1: Remove the No. 3 Bearing Seal Assembly and the No. 3 Bearing Seal Seat (SBE 72-1032)

SBE 72-0132: Removal of the stage 6 buffer air system.

Install IAE 1P17043 Knocker puller 1 off on the No. 3 bearing seal assembly.

Remove the No. 3 bearing seal assembly from the No. 3 bearing seal support.

SUBTASK 72-32-20-040-052-C00 V2500-A5: Remove the No. 3 Bearing Seal Assembly and the No. 3 Bearing Seal Seat

Refer to Figure.

Move IAE 1J12503 Hydraulic pusher 1 off to the work area. Install the 18 push pins into the 18 holes in the holder (part of the hydraulic pusher).

Connect the hose (part of IAE 1F10026 Hydraulic hand pump 1 off) to the cylinder (part of the hydraulic pusher).

SUBTASK 72-32-20-040-053-A00 V2500-A1: Remove the No. 3 Bearing Inner Race and Adjusting Washer - PTO from the Bevel Gearshaft Wheel

Refer to Figure.

Move IAE 1J12534 Hydraulic pusher 1 off to the work area. Install the 18 push pins (part of the hydraulic pusher) in the 18 holes in the holder (part of the hydraulic pusher).

Connect the hose (part of IAE 1F10026 Hydraulic hand pump 1 off) to the cylinder (part of the hydraulic pusher).

SUBTASK 72-32-20-040-053-B00 V2500-A5: Remove the No. 3 Bearing Inner Race and Adjusting Washer - PTO from the Bevel Gearshaft Wheel

Refer to Figure.

Move IAE 1J12374 Oil flow test stand 1 off and IAE 1J12375 Oil flow check box 1 off to the work area.

Install the seal ring to IAE 1J12376 Oil feed adapter 1 off. The seal ring is part of the oil feed adapter (IAE 1J12376 Oil feed adapter).

SUBTASK 72-32-20-710-053 Examine the Oil Flow in the No. 3 Bearing Outer Race and Seal Support Assembly

Refer to Figure.

Move the IAE 1J12478 Hydraulic pusher/puller 1 off and IAE 1J12495 Base plate 1 off to the work area.

Remove the 18 nuts which attach the No. 3 bearing outer race to the bearing No. 3 housing with IAE 1J12378 Ratchet wrench 1 off.

Connect the hose (part of IAE 1F10026 Hydraulic hand pump 1 off) to the hydraulic pusher/puller and pressurize to push the No. 3 bearing outer race from the bearing housing.

SUBTASK 72-32-20-040-054 Remove the No. 3 Bearing Outer Race from the No. 3 Bearing Housing and Seal Support Assembly

Refer to Figure.

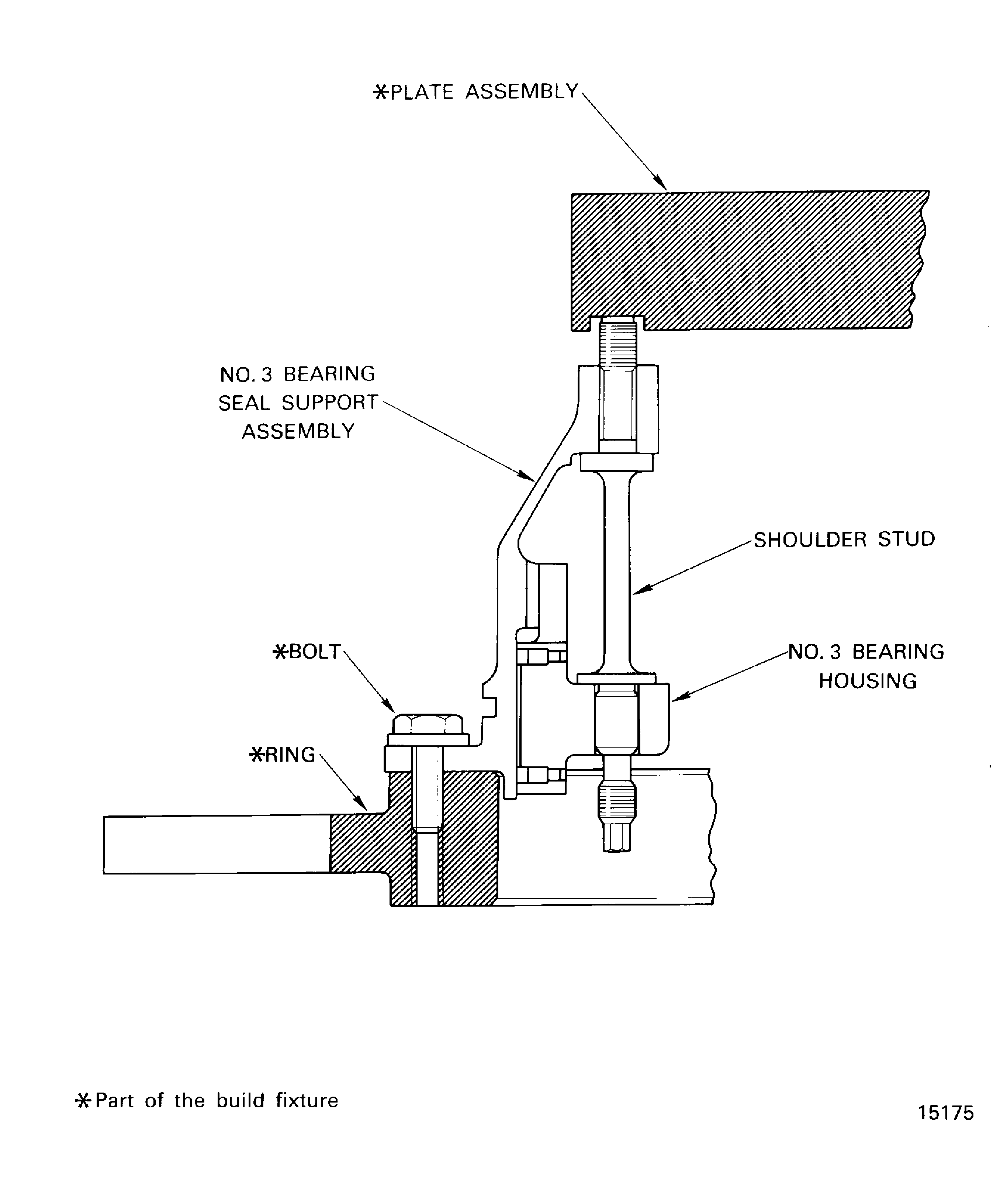

Install the No. 3 bearing damper assembly group to the IAE 1P16023 Build fixture 1 off.

Remove the nuts ENGINE-NO.3 BEARING SEAL SUPPORT (72-32-22, 01-100) from the shoulder studs.

SUBTASK 72-32-20-040-055-A00 V2500-A1: Remove the No. 3 Bearing Housing (72-32-21,01-020) from the No. 3 Bearing Seal Support

Refer to Figure.

Remove the nuts ENGINE-NO.3 BEARING SEAL SUPPORT (72-32-22, 01-060) from the shoulder studs.

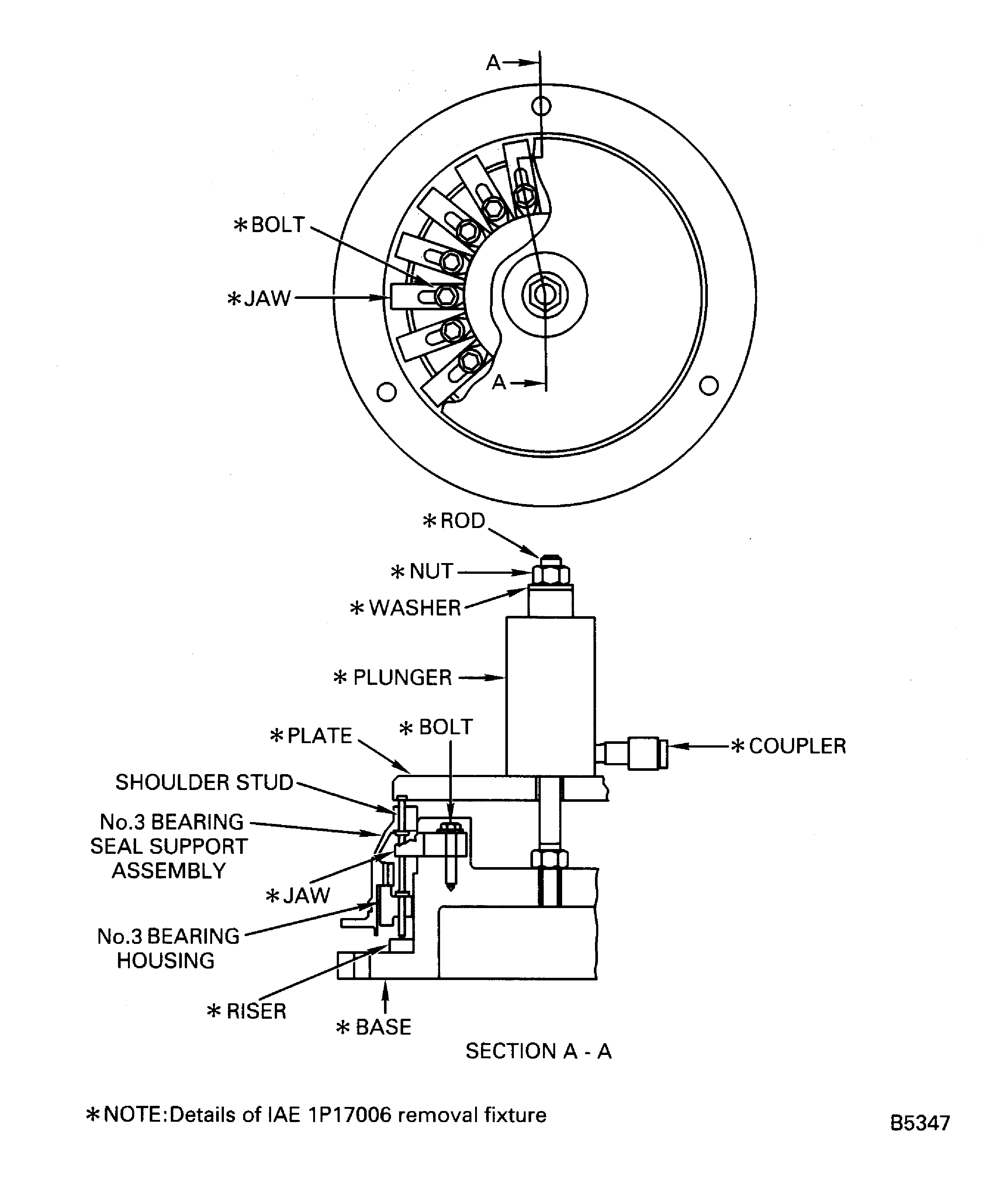

Install the No. 3 bearing damper assembly in the IAE 1P17006 Removal fixture 1 off so that the shoulder studs are between the fixture jaws.

SUBTASK 72-32-20-040-055-B00 V2500-A5: Remove the No. 3 Bearing Housing (72-32-21,01-020) from the No. 3 Bearing Seal Support

Refer to Figure.

Install the No. 3 bearing housing and the shoulder studs in the IAE 1P17006 Removal fixture 1 off.

SUBTASK 72-32-20-040-056-B00 V2500-A5: Remove the Seal Rings and the Shoulder Studs from the No. 3 Bearing Housing

CAUTION

THE STUDS ARE PRESSED INTO THE NO. 3 BEARING HOUSING. DO NOT TRY TO UNSCREW THE STUDS TO REMOVE THEM.

Figure: Remove the No. 3 bearing nut

Remove the No. 3 bearing nut

Figure: Remove the No. 3 bearing, wheel gear and support assembly from the No. 3 bearing rotor center

Remove the No. 3 bearing, wheel gear and support assembly from the No. 3 bearing rotor center

Figure: Remove the No. 3 bearing and the PTO adjusting washer from the bevel gearshaft wheel

Remove the No. 3 bearing and the PTO adjusting washer from the bevel gearshaft wheel

Figure: Examine the oil flow in the No. 3 bearing outer race and seal support assembly

Examine the oil flow in the No. 3 bearing outer race and seal support assembly

Figure: Remove the No. 3 bearing outer race

Remove the No. 3 bearing outer race

Figure: Remove the No. 3 bearing seal support from the No. 3 bearing housing

Remove the No. 3 bearing seal support from the No. 3 bearing housing

Figure: Remove the bearing housing and shoulder studs from the No. 3 bearing seal support assembly

Remove the bearing housing and shoulder studs from the No. 3 bearing seal support assembly

Figure: Remove the shoulder studs from the No. 3 bearing housing

Remove the shoulder studs from the No. 3 bearing housing