Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

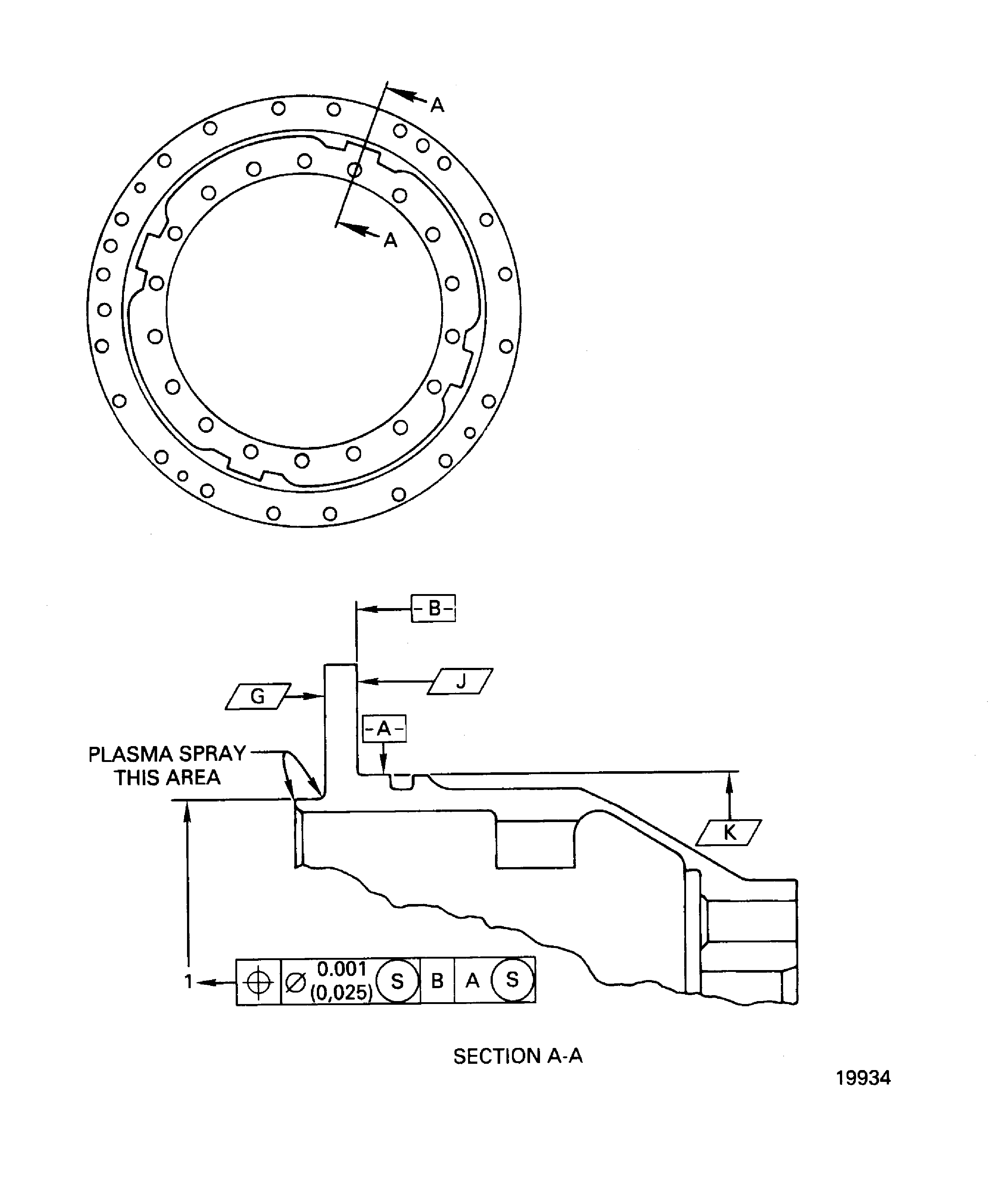

TASK 72-32-22-300-002 No. 3 Bearing Seal Support - Repair The Plasma Coat On The Outer Front Flange Front Diameter, Repair-002 (VRS3002)

General

This repair must only be done when the instructions to do so are given in TASK 72-32-22-200-000 Inspection-000.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

Price and availability - refer to IAE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-134 MASKING TAPE, PLASTIC | 99742 | CoMat 02-134 | or equivalent | |

| CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5) | 00741 | CoMat 03-089 | ||

| CoMat 05-051 SILICON CARBIDE GRIT DELETED | 0AM53 | CoMat 05-051 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Refer to VRS3003, TASK 72-32-22-300-003.

Remove the inserts from the seal support before you apply plasma coating.

Use CoMat 02-134 MASKING TAPE, PLASTIC or equivalent.

Apply masking to areas that are not to be plasma sprayed.

SUBTASK 72-32-22-350-051 Prepare the No. 3 Bearing Seal Support for Plasma Coating

Use CoMat 05-051 SILICON CARBIDE GRIT DELETED at a pressure of 60 psig (413.7kPa).

Refer to the SPM TASK 70-12-09-120-501.

NOTE

Use clean gloves to handle the No. 3 bearing seal support after you clean it.

Abrasive blast to clean the seal support.

SUBTASK 72-32-22-120-051 Clean the No. 3 Bearing Seal Support

CAUTION

DO NOT USE ANY SOLUTIONS THAT CONTAIN CHLORIDE TO CLEAN THE NO. 3 BEARING SEAL SUPPORT. CHLORIDE CAN CAUSE CORROSION TO THE SEAL SUPPORT.Refer to Figure.

SUBTASK 72-32-22-320-051 Machine the Outer Front Flange Diameter of the No. 3 Bearing Seal Support

Refer to Figure.

Refer to the SPM TASK 70-34-03-340-501.

Apply the coating so that the front diameter is a minimum of 10.996 in. (279.298 mm).

Apply plasma coating to the front diameter.

SUBTASK 72-32-22-340-051 Apply Plasma Coating to the Outer Front Flange Front Diameter of the No. 3 Bearing Seal Support

Refer to Figure.

SUBTASK 72-32-22-320-052 Machine the Outer Front Flange Front Diameter of the No. 3 Bearing Seal Support after Plasma Spray

Refer to Figure.

The diameter must be 10.982 to 10.986 in. (278.943 to 279.044 mm).

NOTE

If the measured diameter in a free condition is not satisfactory, a held condition is permitted. The dimension applies when Surface J is flat by 0.001 in. (0.025 mm) and Diameter K maintains a clearance envelope of 11.345 in. (288.163 mm) in a free or held condition. Hold the support only of Surfaces J and G and Diameter K.

Examine the front diameter at location 1 after plasma spray repair.

SUBTASK 72-32-22-220-060 Examine the Outer Front Flange Front Diameter of the No. 3 Bearing Seal Support after Plasma Spray Repair

Figure: Outer front flange front diameter plasma coat repair

Outer front flange front diameter plasma coat repair