Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-22-300-007 No. 3 Bearing Seal Support - Repair The Plasma Coat On The Rear Diameter, Repair-007 (VRS3284)

General

This repair must only be done when the instructions to do so are given in TASK 72-32-22-200-000 Inspection-000.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

A ** following SPM TASK referenced in this repair indicates that the process is not yet published in the current revision of the manual. Contact IAE for additional information concerning the process.

Price and availability - refer to IAE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-134 MASKING TAPE, PLASTIC | 99742 | CoMat 02-134 | or equivalent | |

| CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5) | 00741 | CoMat 03-089 | ||

| CoMat 05-051 SILICON CARBIDE GRIT DELETED | 0AM53 | CoMat 05-051 |

Spares

NONESafety Requirements

NONEProcedure

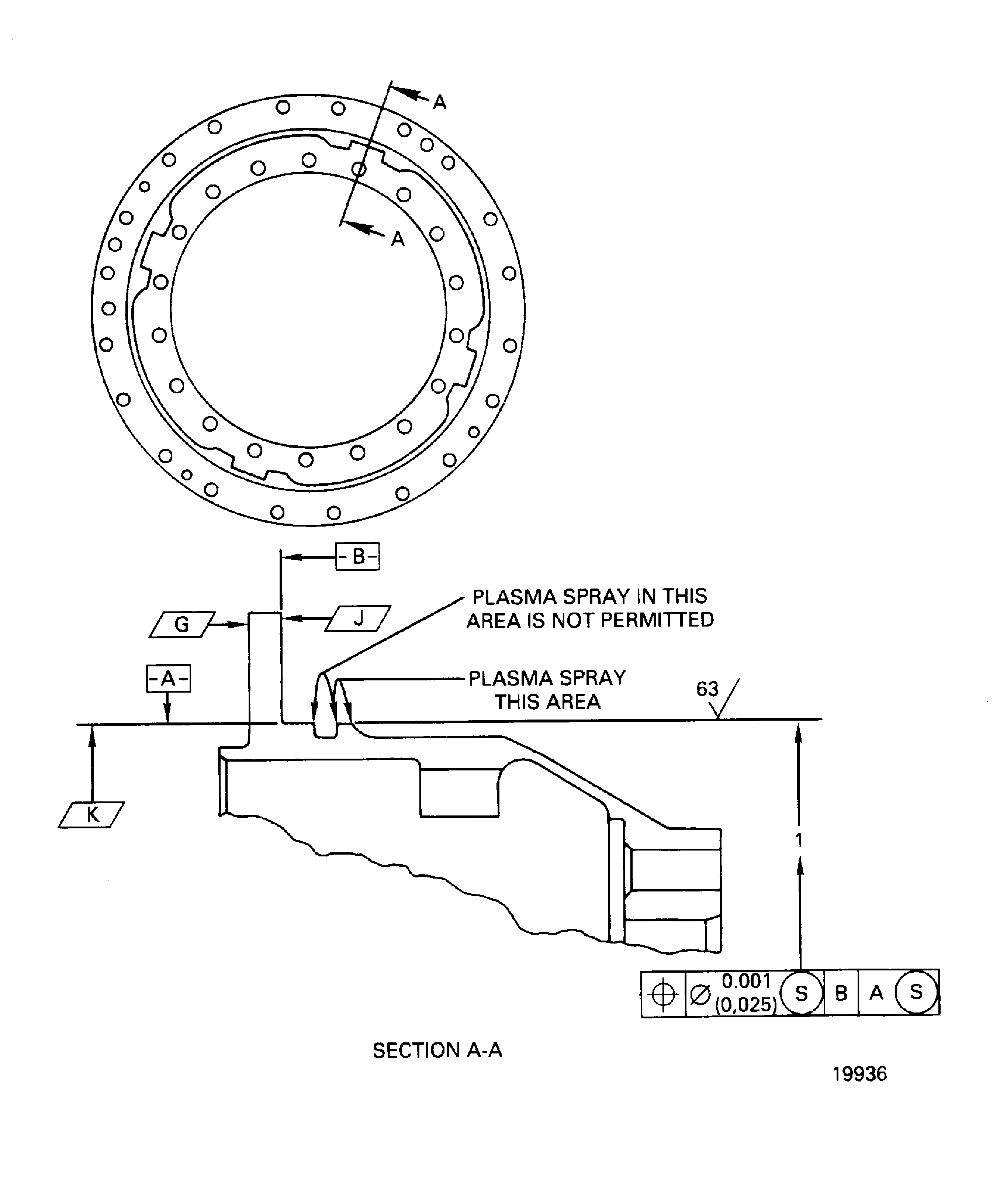

Refer to Figure.

Refer to VRS3003, TASK 72-32-22-300-003.

Remove the inserts from the seal support before you apply plasma coating.

Use CoMat 02-134 MASKING TAPE, PLASTIC or equivalent.

Apply masking to areas that are not to be plasma sprayed.

SUBTASK 72-32-22-350-055 Prepare the No. 3 Bearing Seal Support for Plasma Coating

Use CoMat 05-051 SILICON CARBIDE GRIT DELETED at a pressure of 60 psig (413.7 kPa).

Refer to the SPM TASK 70-12-09-120-501.

NOTE

Use clean gloves to handle the No. 3 bearing seal support after you clean it.

Abrasive blast to clean the seal support.

SUBTASK 72-32-22-120-053 Clean the No. 3 Bearing Seal Support

CAUTION

DO NOT USE ANY SOLUTIONS THAT CONTAIN CHLORIDE TO CLEAN THE NO. 3 BEARING SEAL SUPPORT. CHLORIDE CAN CAUSE CORROSION TO THE SEAL SUPPORT.Refer to Figure.

SUBTASK 72-32-22-320-055 Machine the Rear Diameter of the No. 3 Bearing Seal Support

Refer to Figure.

Refer to the SPM TASK 70-34-03-340-501**.

Apply the coating so that the rear diameter is a minimum of 11.346 in. (288.188 mm).

Apply plasma coating to the rear diameter.

SUBTASK 72-32-22-340-053 Apply Plasma Coating to the Rear Diameter of the No. 3 Bearing Seal Support

Refer to Figure.

SUBTASK 72-32-22-320-056 Machine the Rear Diameter of the No. 3 Bearing Seal Support After Plasma Spray

Refer to Figure.

The diameter must be 11.332 to 11.336 in. (287.833 to 287.934 mm).

NOTE

If the measured diameter in a free condition is not satisfactory, a held condition is permitted. The dimension applies when Surface J is flat by 0.001 in. (0.025 mm) and Diameter K maintains a clearance envelope of 11.345 in. (288.163 mm) in a free or held condition. Hold the support only on Surfaces J and G and Diameter K.

Examine the rear diameter at location 1 after plasma spray repair.

SUBTASK 72-32-22-220-063 Examine the Rear Diameter of the No. 3 Bearing Seal Support after Plasma Spray Repair

Figure: Rear diameter plasma coat repair

Rear diameter plasma coat repair