Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-72-300-007 LPC Bleed Valve Ring - Replace The Guide, Repair-007 (VRS1785)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Drilling machine | LOCAL | Drilling machine | ||

| Horizontal Boring Mill | LOCAL | Horizontal Boring Mill | ||

| IAE 3J12819 Riveting fixture | 0AM53 | IAE 3J12819 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-275 CHROMATE CONVERSION COATING FOR ALUMINIUM | 00BB6 | CoMat 01-275 | ||

| CoMat 05-016 GARNET PAPER, 80-GRIT | LOCAL | CoMat 05-016 | ||

| CoMat 05-017 GARNET PAPER, 60 GRIT | LOCAL | CoMat 05-017 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 | ||

| CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) | X222X | CoMat 06-063 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | X222X | CoMat 06-064 | ||

| CoMat 08-015 RESIN | LOCAL | CoMat 08-015 | ||

| CoMat 08-016 HARDENER | LOCAL | CoMat 08-016 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Guide | 5A0789 | A/R | ||

| Rivet | 5A1506 | A/R | ||

| Rivet | 5A1873 | A/R |

Safety Requirements

CAUTION

Procedure

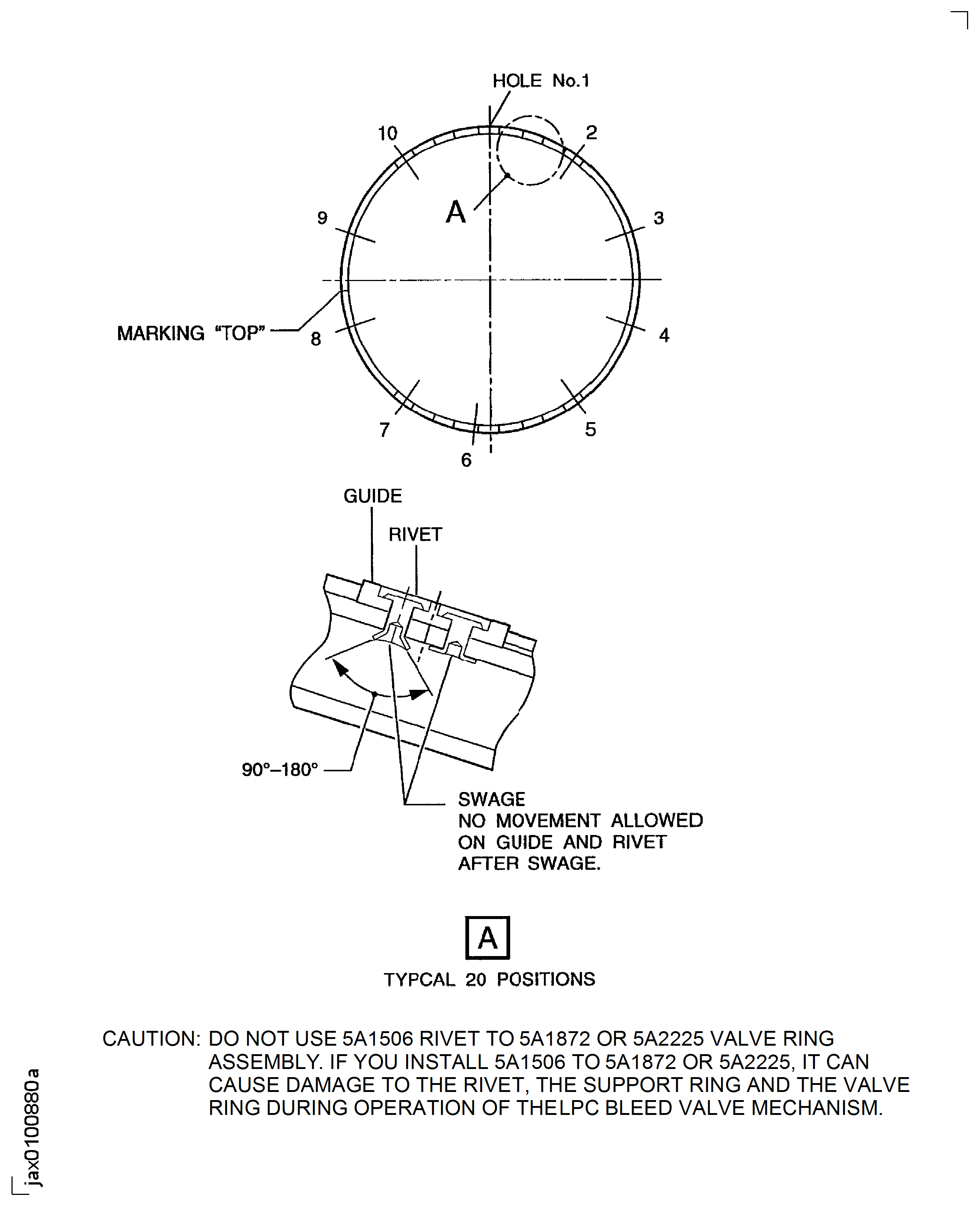

Refer to Figure.

Drill through the rivet.

Use drill 0.10 in. (2.50 mm).

Drive out the rivet bodies with a small hammer and punch.

Care must be taken to make sure the flange bore or face do not become damaged.

Use Drilling machine and Horizontal Boring Mill.

Remove the damaged guide.

Use the scraper or CoMat 05-020 WATERPROOF SILICON CARBIDE and CoMat 05-021 WATERPROOF SILICON CARBIDE.

NOTE

It is not necessary to do Step if there is no remaining compound.Remove the remaining compound and the sharp edge around the rivet hole.

SUBTASK 72-32-72-350-057 Remove the Damaged Guide from the Valve Ring Assembly

Refer to the SPM TASK 70-23-05-230-501.

Do a crack test for the rivet holes.

SUBTASK 72-32-72-230-057 Examine the Rivet Holes of the Valve Ring Assembly

Refer to the SPM TASK 70-38-02-300-503.

Apply chromate conversion coating to the repair surface, if necessary.

SUBTASK 72-32-72-380-055 Apply the Surface Protection to the Valve Ring Assembly

Use CoMat 08-015 RESIN and CoMat 08-016 HARDENER.

Refer to the SPM TASK 70-36-02-360-501.

NOTE

The pot life of resin/hardener mixture is about two hours at room temperature.Mix resin and hardener.

SUBTASK 72-32-72-360-054 For 5A1506: Make-up of the Two Part Low Temperature Curing Sealant/Adhesive

Refer to Figure.

Refer to the SPM TASK 70-11-26-300-503.

Cold liquid degrease the mating surfaces of the valve ring assembly and the guide.

Refer to the SPM TASK 70-36-02-360-501.

Hand clean the mating surface of the guide only.

Do Step.

Refer to the SPM TASK 70-36-02-360-501.

Do a break-test.

SUBTASK 72-32-72-360-055 For 5A1506: Prepare the Mating Surfaces for the Two Part Low Temperature Curing Sealant/Adhesive

CAUTION

YOU MUST NOT EAT OR SMOKE AT LOCATIONS WHERE THESE MATERIALS ARE USED.

CAUTION

AFTER PREPARATION THE MATING SURFACES MUST BE FULLY CLEANED AND MUST NOT BE TOUCHED BY HAND, TO PREVENT CONTAMINATION.

CAUTION

BONDING MUST BE DONE IMMEDIATELY AFTER THE SURFACE PREPARATION.Refer to Figure.

Refer to the SPM TASK 70-36-02-360-501.

Apply mixture to the mating surfaces of the valve ring assembly and the guide.

Make sure that the adhesive can be seen around the sealed surfaces.

Refer to the SPM TASK 70-36-02-360-501.

Install the guide to the valve ring assembly.

Refer to the SPM TASK 70-36-02-360-501.

Cure the adhesive.

SUBTASK 72-32-72-330-052 For 5A1506: Apply and Cure the Two Part Low Temperature Curing Sealant/Adhesive

Refer to Figure.

SUBTASK 72-32-72-350-058 For 5A1506: Install the Rivets to the Valve Ring Assembly

Refer to Figure.

SUBTASK 72-32-72-350-065 For 5A1873: Install the Guide to the Valve Ring Assembly

Refer to Figure.

SUBTASK 72-32-72-220-072 Examine the Repaired Area of the Valve Ring Assembly

Refer to the SPM TASK 70-38-02-300-503.

Apply chromate conversion coating to the repaired area, if necessary.

SUBTASK 72-32-72-380-056 Apply the Surface Protection to the Valve Ring Assembly

Figure: For 5A1506: Repair Details and Dimensions

For 5A1506: Repair Details and Dimensions

Figure: For 5A1873: Repair Details And Dimensions

For 5A1873: Repair Details And Dimensions