Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-83-300-015 LPC Stage 2 Stator - Replace The Stator Vane, Repair-015 (VRS1401)

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

LPC stage 2 vane assembly | Vane: Titanium alloy Inner ring: Aluminum alloy |

General

Price and availability - none

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Plastic chisel type tool | LOCAL | Plastic chisel type tool | ||

| Injector | LOCAL | Injector | (Air pressure type) | |

| IAE 3J12136 Molding fixture | 0AM53 | IAE 3J12136 | 1 | (Alternative to IAE 3J12758) |

| IAE 3J12758 Molding fixture | 0AM53 | IAE 3J12758 | 1 | (Alternative to IAE 3J12136) |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-005 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-005 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 05-121 SILICON CARBIDE GRIT | IAE72 | CoMat 05-121 | ||

| CoMat 05-122 SILICON CARBIDE GRIT | IAE72 | CoMat 05-122 | ||

| CoMat 05-123 SILICON CARBIDE GRIT | IAE72 | CoMat 05-123 | ||

| CoMat 05-124 SILICON CARBIDE GRIT | IAE72 | CoMat 05-124 | ||

| CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT | 0AM53 | CoMat 08-014 | ||

| CoMat 08-036 SILICONE RUBBER COMPOUND | LOCAL | CoMat 08-036 | ||

| CoMat 08-042 SILICONE RUBBER COMPOUND | IAE55 | CoMat 08-042 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Vane, stage 2 LPC A | 5A7379 | 49 | (Assembly A) | |

| Vane, stage 2 LPC A | 5A0072 | 49 | (Assembly B) | |

| Vane, stage 2 LPC B | 5A7380 | 49 | (Assembly A) | |

| Vane, stage 2 LPC B | 5A0073 | 49 | (Assembly B) |

Safety Requirements

NONEProcedure

Repair, VRS1400 TASK 72-32-83-300-014 (REPAIR-014).

Remove all abradable seal on inner ring.

SUBTASK 72-32-83-360-057 Remove the Abradable Seal

Refer to the SPM TASK 70-36-04-360-501.

Apply dry abrasive blast to mold areas.

Use CoMat 01-124 ISOPROPYL ALCOHOL with 02-099 lint free cloth.

Refer to the SPM TASK 70-36-04-360-501.

Wipe and clean the surfaces of vane and inner ring.

Refer to the SPM TASK 70-36-04-360-501.

NOTE

After cleaning the component must not be touched by hand and must be covered by craft paper to prevent contamination.Air dry for 15 minutes minimum.

SUBTASK 72-32-83-120-052 Clean the Surfaces which are to be Applied the Silicone Rubber Compound

Refer to the SPM TASK 70-36-04-360-501.

Mix silicone rubber compound.

Refer to the SPM TASK 70-36-04-360-501.

Degas from the mixture.

Use IAE 3J12136 Molding fixture 1 off or IAE 3J12758 Molding fixture 1 off.

NOTE

Make sure that the clearance between each vane is in the limits given in the figure.Set up the mold with the molding fixture.

Refer to the SPM TASK 70-36-04-360-501.

Cure the silicone rubber compound.

SUBTASK 72-32-83-360-060-A00 Mold the Silicone Rubber Compound

Use CoMat 08-042 SILICONE RUBBER COMPOUND and a clean spatula or equivalent.

NOTE

When mixed, the life of the silicone rubber compound is a maximum of 1.5 hours at room temperature.Mix 9.5 to 10.5 parts by weight of the base material with 0.8 to 1.2 parts by weight of the curing agent in 8 to 10 minutes at 70 to 80 deg F (21 to 27 deg C) until the material is a constant color.

Use IAE 3J12136 Molding fixture 1 off or IAE 3J12758 Molding fixture 1 off.

NOTE

Make sure that the clearance between each vane is in the limit in the figure.Set up the mold with the molding fixture.

SUBTASK 72-32-83-360-060-B00 Mold the Silicone Rubber Compound

Repair, VRS1400 TASK 72-32-83-300-014 (REPAIR-014).

Put the abradable seal back on the inner ring after repairing.

SUBTASK 72-32-83-360-061 Put Back the Abradable Seal

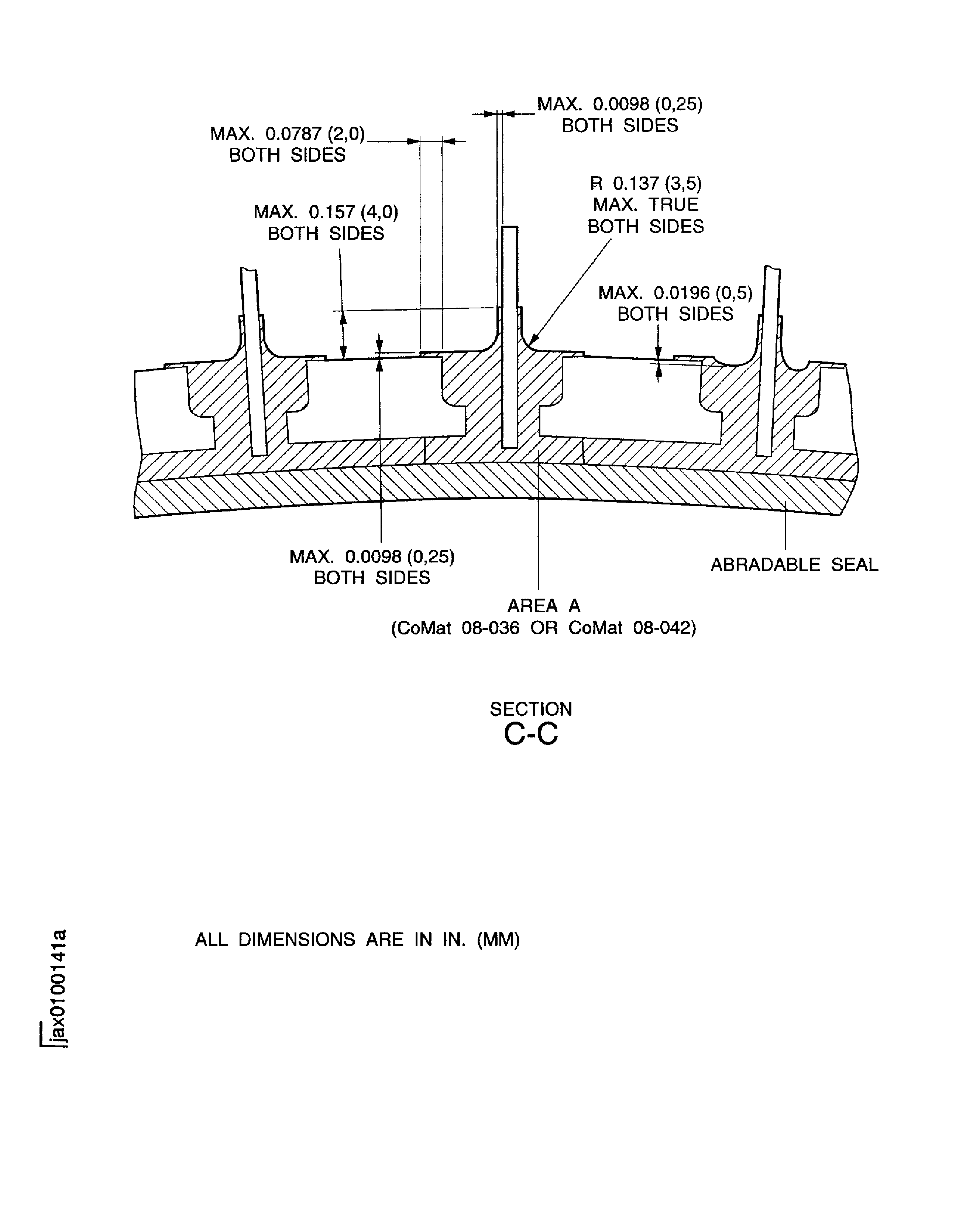

Figure: Repair Details and Dimensions

Sheet 1

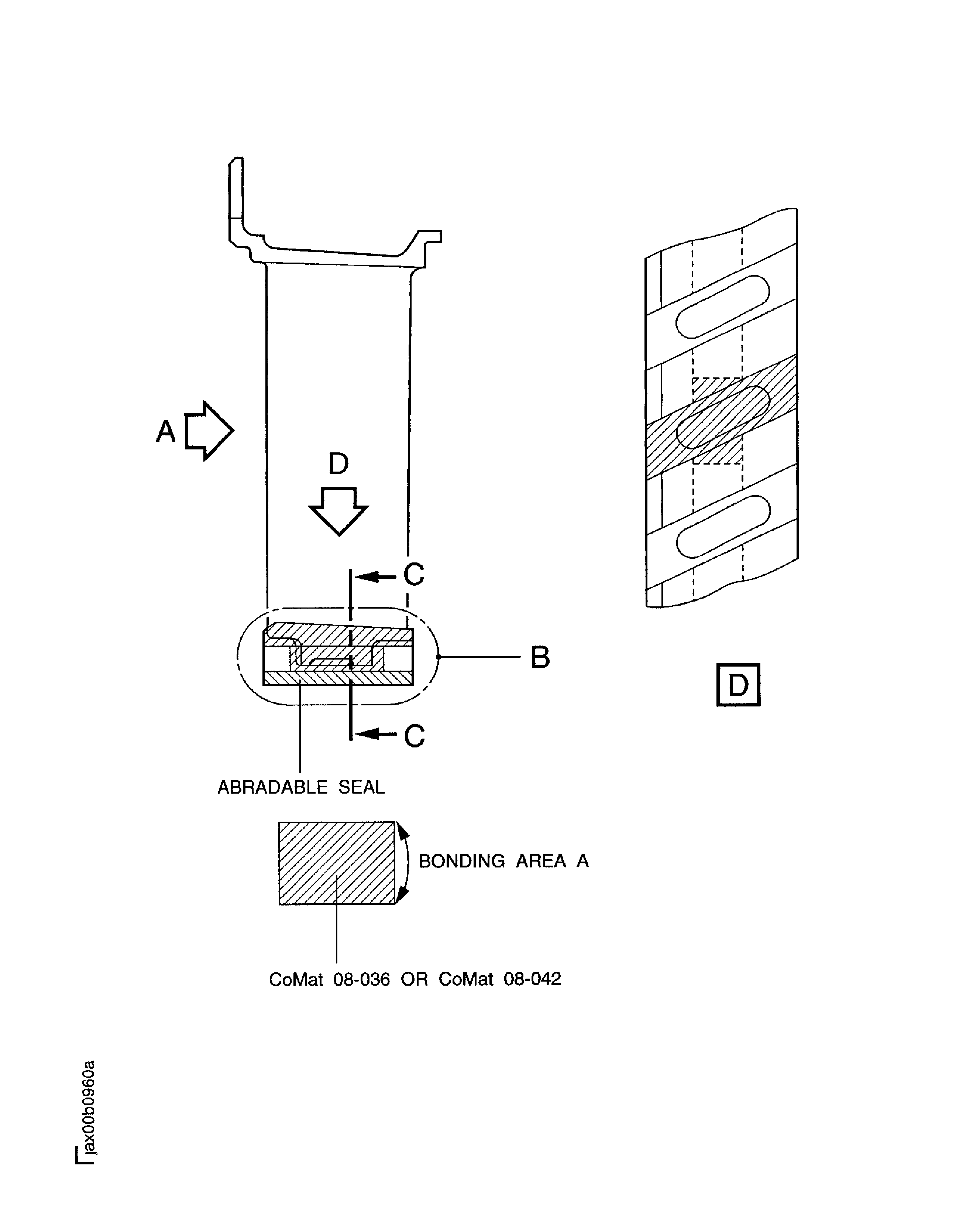

Figure: Repair Details and Dimensions

Sheet 2

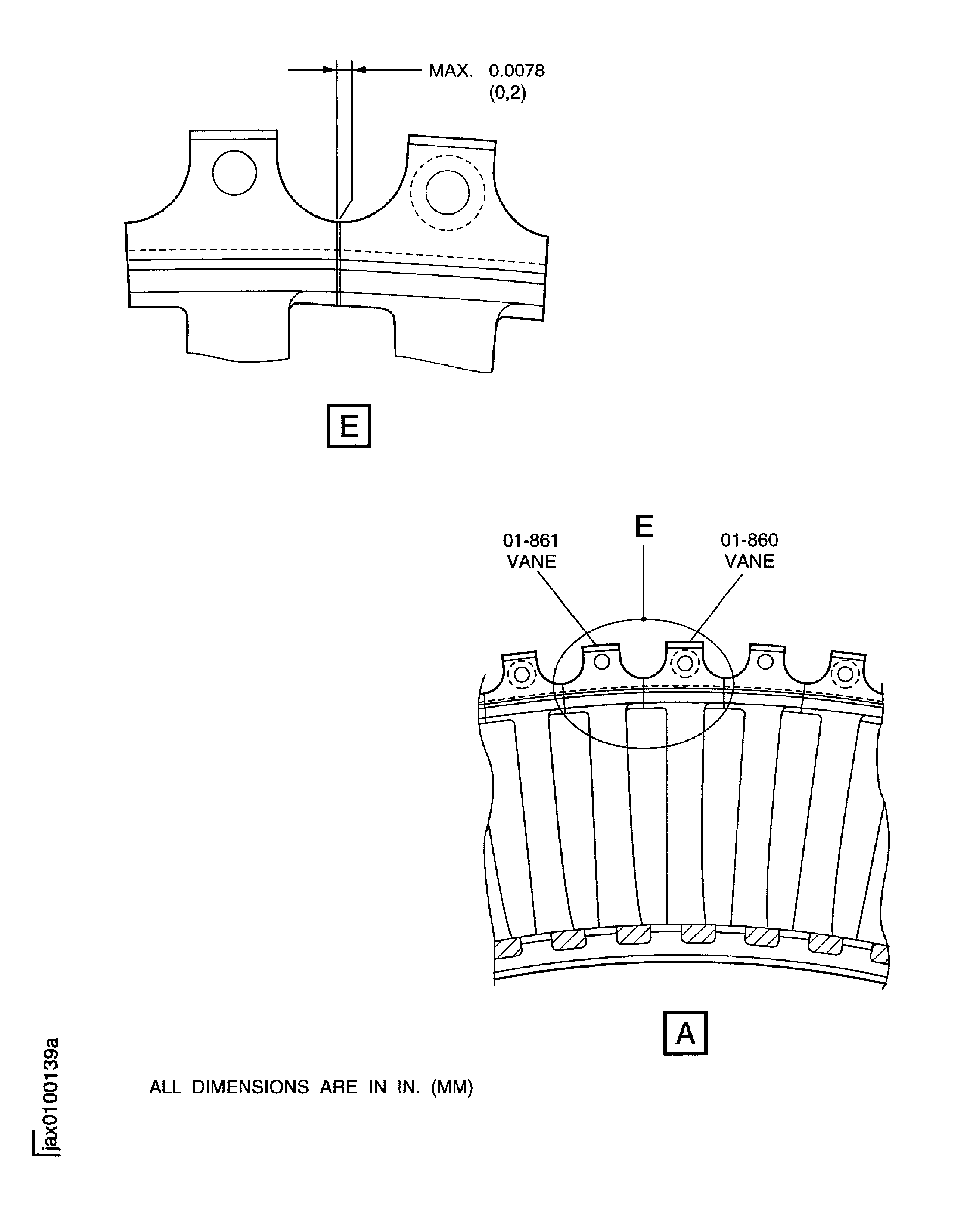

Figure: Repair Details and Dimensions

Sheet 3

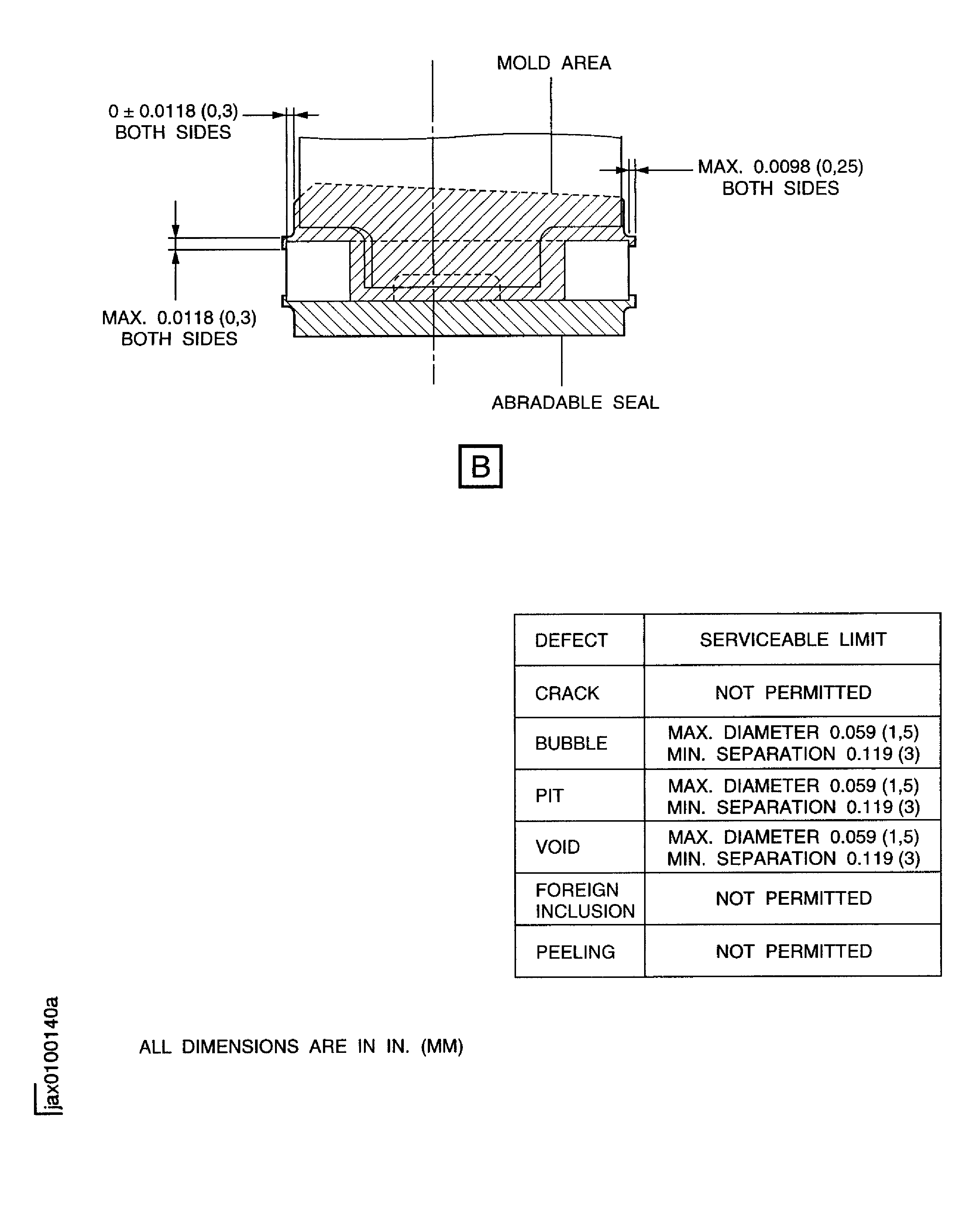

Figure: Repair Details and Dimensions

Sheet 4