Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

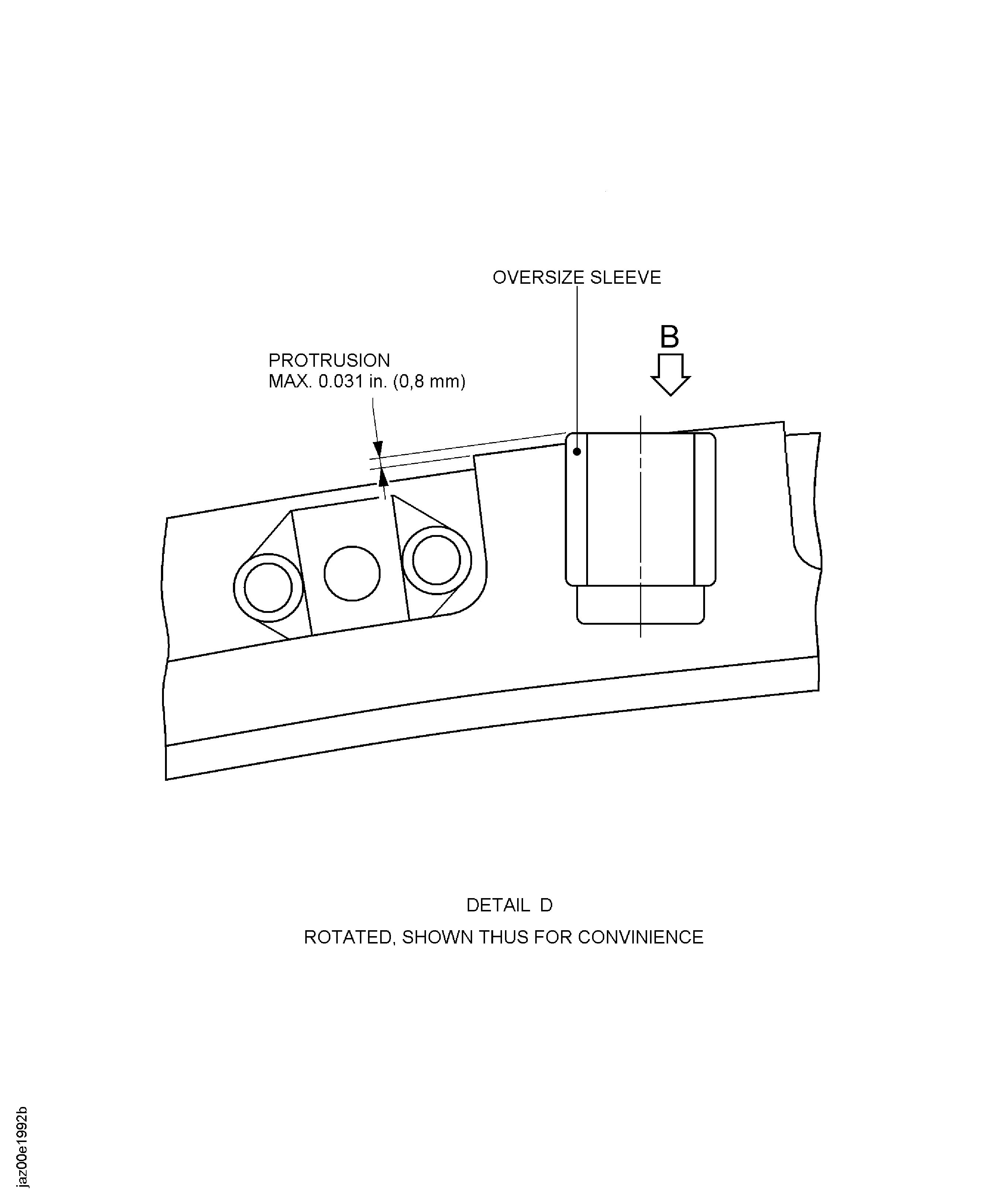

TASK 72-32-83-300-059 LPC Rear Case - Replace The Oversize Sleeve, Repair-059 (VRS1609)

General

Price and availibility - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

For the method to clean the parts, refer to TASK 72-32-83-100-000 (CLEANING-000).

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Magnifying glass, 10x | LOCAL | Magnifying glass, 10x | ||

| Boring machine | LOCAL | Boring machine | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) | LOCAL | CoMat 06-063 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 | ||

| CoMat 07-028 CHROMATE CONVERSION COATING FOR ALUMINUM | LOCAL | CoMat 07-028 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Oversize Sleeve | M81934-1-05C14U |

Safety Requirements

NONEProcedure

Refer to the SPM TASK 70-11-26-300-503.

Clean the LPC rear case assembly.

SUBTASK 72-32-83-110-077 Clean the LPC Rear Case Assembly

Refer to the SPM TASK 70-11-26-300-503.

Clean the LPC rear case assembly.

SUBTASK 72-32-83-110-078 Clean the LPC Rear Case Assembly

Refer to the SPM TASK 70-23-05-230-501.

Examine the machined area for cracks.

SUBTASK 72-32-83-220-248 Examine the Machined Area

Refer to the SPM TASK 70-11-26-300-503.

Clean the repaired area.

SUBTASK 72-32-83-110-079 Clean the Repaired Area

Refer to the SPM TASK 70-38-02-300-503.

Do a chemical touch-up to the repaired area with a brush.

SUBTASK 72-32-83-380-072 Surface Treat the Repaired Area

Refer to the SPM TASK 70-09-00-400-501, SPM SUBTASK 70-09-00-400-001.

Mark VRS1609 next to the part number.

SUBTASK 72-32-83-350-147 Identify the Repair

Refer to the SPM TASK 70-11-26-300-503.

Clean the marking area.

SUBTASK 72-32-83-110-080 Clean the Marking Area

Refer to the SPM TASK 70-38-02-300-503.

Do a chemical touch-up to the marking area with a brush.

SUBTASK 72-32-83-350-148 Surface Treat the Marking Area

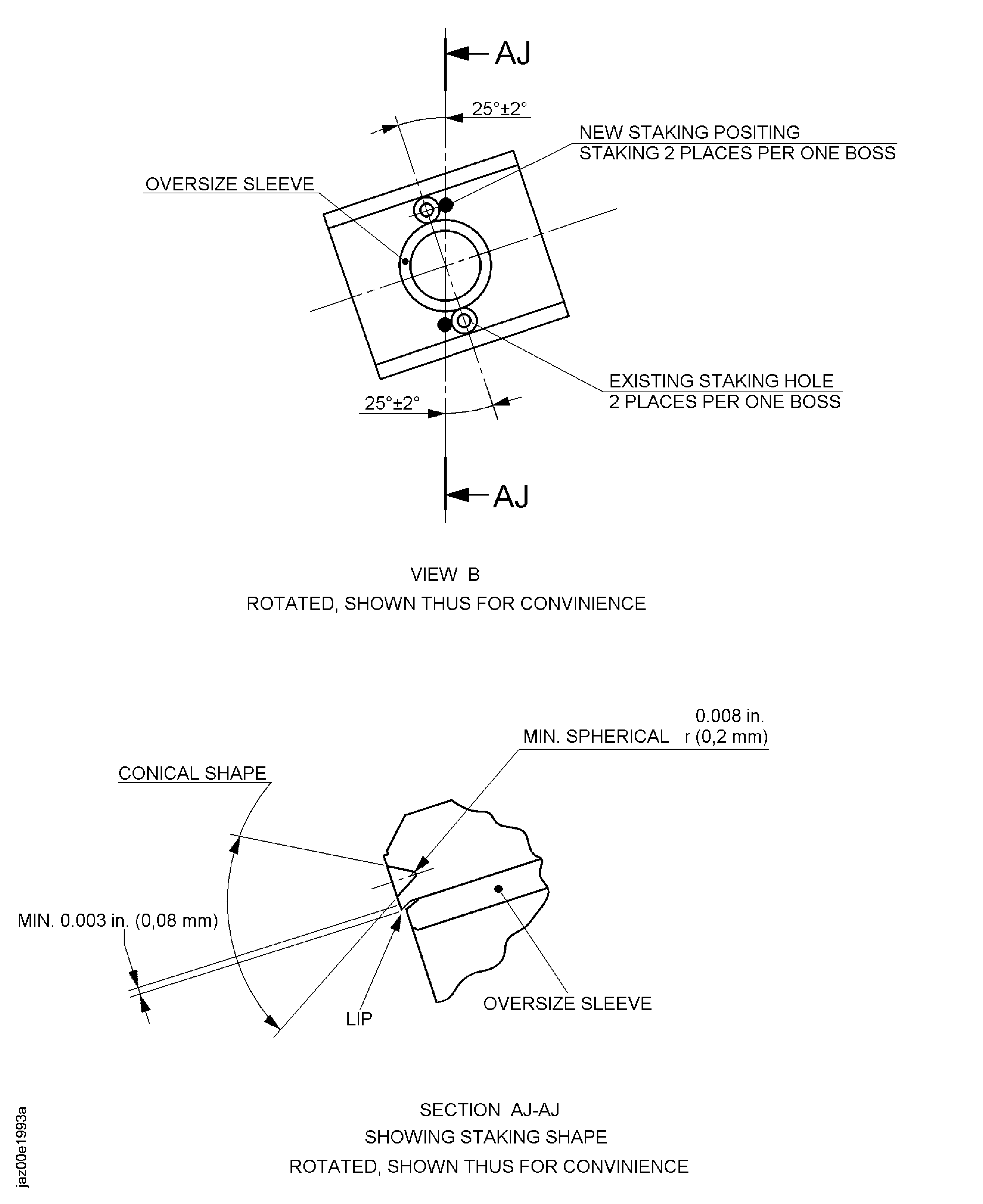

Figure: Repair Details and Dimensions

Sheet 1

Figure: Repair Details and Dimensions

Sheet 2

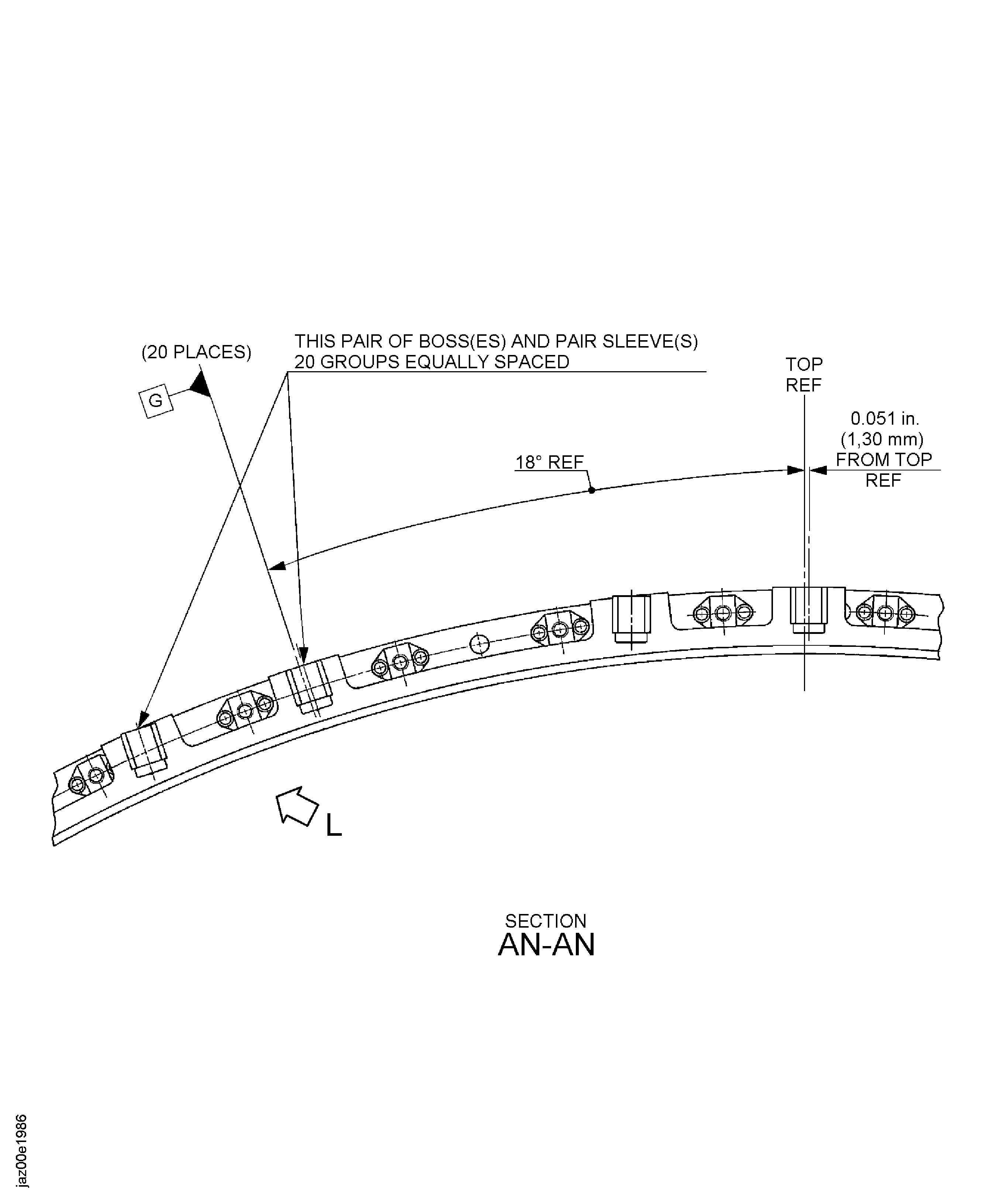

Figure: Repair Details and Dimensions

Sheet 3

Figure: Repair Details and Dimensions

Sheet 4

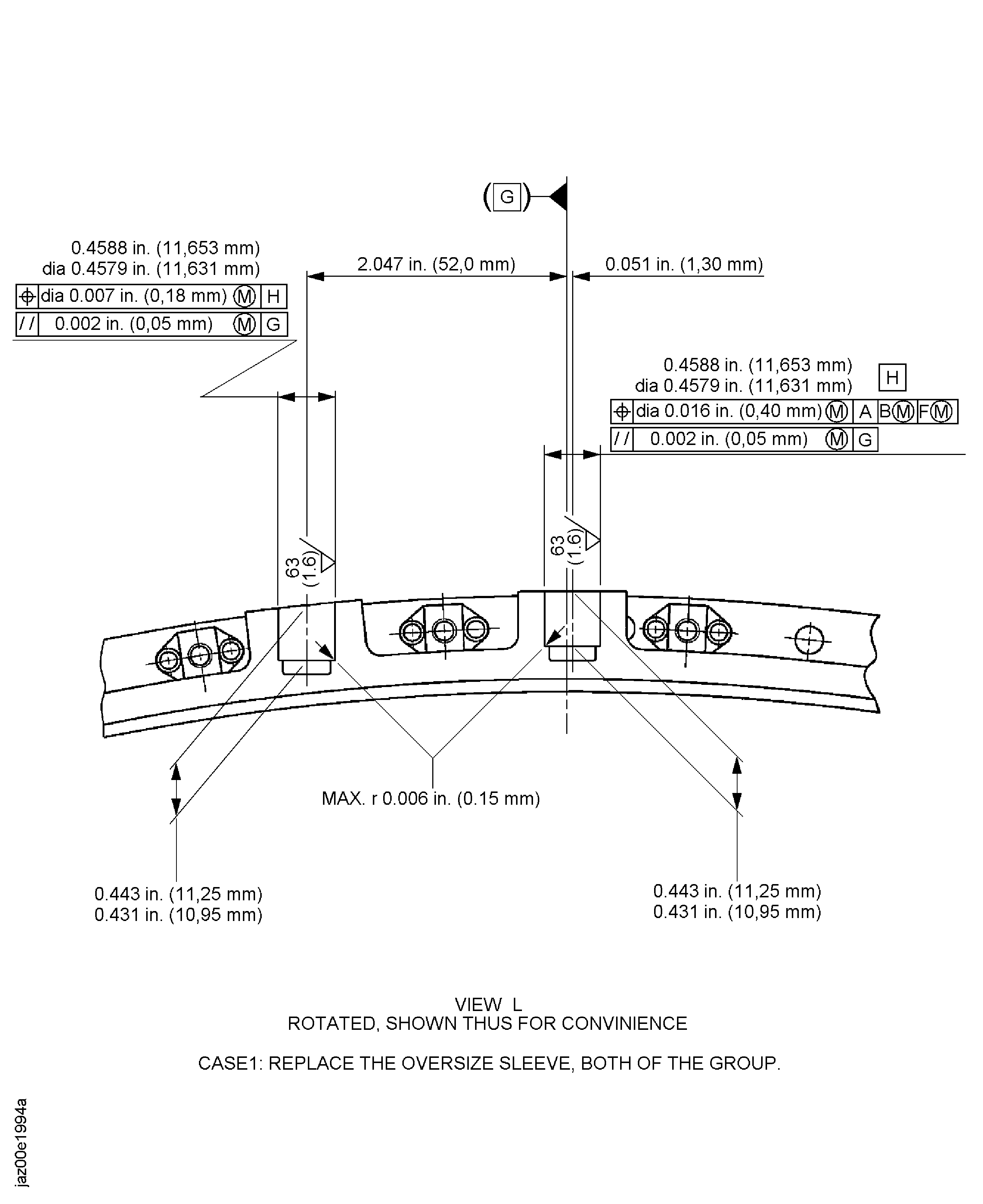

Figure: Repair Details and Dimensions

Sheet 5

Figure: Repair Details and Dimensions

Sheet 6

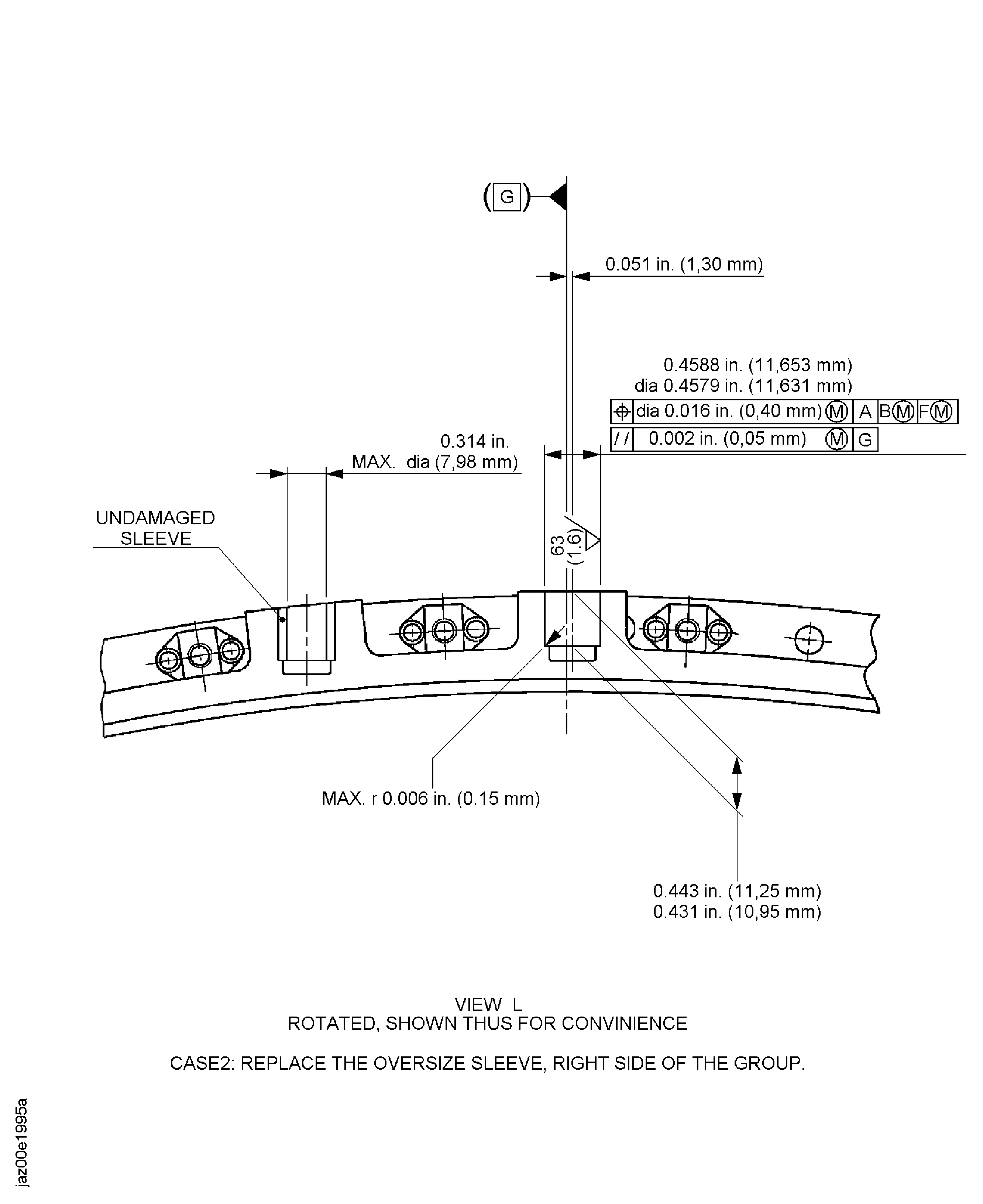

Figure: Repair Details and Dimensions

Sheet 7

Figure: Repair Details and Dimensions

Sheet 8

Figure: Repair Details and Dimensions

Sheet 9

Figure: Repair Details and Dimensions

Sheet 10