Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-85-300-057 Repair By Installing The Bush At Countersunk Bolthole Of Flange FA, Repair 057 (VRS1565)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-100 | 5W0069 |

01-100 | 5W0072 |

01-100 | 5W0081 |

01-100 | 5W0093 |

01-100 | 5W0094 |

01-100 | 5W0100 |

01-100 | 5W0124 |

01-100 | 5W0144 |

01-100 | 5W0149 |

01-100 | 5W0154 |

01-100 | 5W0168 |

01-100 | 5W0169 |

01-100 | 5W0171 |

01-100 | 5W0172 |

01-100 | 5W0184 |

01-100 | 5W0186 |

01-100 | 5W0187 |

01-100 | 5W0188 |

01-100 | 5W0189 |

01-100 | 5W0190 |

01-100 | 5W0191 |

01-100 | 5W0192 |

01-100 | 5W0193 |

01-100 | 5W0194 |

01-100 | 5W0195 |

01-100 | 5W0196 |

01-100 | 5W0197 |

01-100 | 5W0198 |

01-100 | 5W0199 |

01-100 | 5W0200 |

01-100 | 5W0201 |

01-100 | 5W0202 |

01-100 | 5W0203 |

01-100 | 5W0204 |

01-100 | 5W0205 |

01-100 | 5W0206 |

01-100 | 5W0207 |

01-100 | 5W0208 |

01-100 | 5W0209 |

01-100 | 5W0210 |

01-100 | 5W0211 |

01-100 | 5W0212 |

01-100 | 5W0213 |

01-100 | 5W0214 |

01-100 | 5W0215 |

01-100 | 5W0216 |

01-100 | 5W0217 |

01-100 | 5W0218 |

01-100 | 5W0219 |

01-100 | 5W0220 |

01-100 | 5W0221 |

01-100 | 5W0222 |

01-100 | 5W0223 |

01-100 | 5W0224 |

01-100 | 5W0225 |

01-100 | 5W0226 |

01-100 | 5W0306 |

01-100 | 5W0307 |

01-100 | 5W0313 |

General

This repair scheme gives the procedure for re-shape the bolt hole by the installation of steel bush repair for worn or damaged bolt hole in the Fan Case Assembly.

The practices and processes referred to in the procedure by the TASK numbers are in SPM.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Boring machine | LOCAL | Boring machine | ||

| Heat Protective Gloves | LOCAL | Protective Gloves, Heat | ||

| Non-metallic drift | LOCAL | Non-metallic drift | ||

| Penetrant crack test equipment | LOCAL | Penetrant Crack Test Equipment | ||

| Portable blending equipment | LOCAL | Portable blending equipment | ||

| Portable heating equipment | LOCAL | Portable heating equipment | ||

| Standard Workshop Equipment | LOCAL | Standard Workshop Equipment | ||

| Vibro-engraving equipment | LOCAL | Vibro-engraving equipment | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Chemical cleaning equipment | LOCAL | Chemical Cleaning Equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 02-097 LINT-FREE GLOVES | LOCAL | CoMat 02-097 | ||

| CoMat 02-100 GLOVES, LINT-FREE | LOCAL | CoMat 02-100 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 | ||

| CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) | LOCAL | CoMat 06-063 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 | ||

| CoMat 08-163 RETAINING COMPOUND PRESSFIT | LOCAL | CoMat 08-163 |

Spares

NONESafety Requirements

NONEProcedure

Refer to SPM TASK 70-11-26-300-503.

Clean the fan case.

Confirm the dimensions of the increased bolthole and fretted surface at front of FWD flange.

Examine the damaged area dimensionally, if necessary.

Refer to SPM TASK 70-23-05-230-501.

Do the crack test.

Reject.

Cracked in the 0.539 in. (13.7 mm) at the counter bore area or the 0.362 in. (9.2 mm) at the bore area on the flange surface.

Crack test on the damaged area.

SUBTASK 72-32-85-220-200 Examine the Fan Case Assembly (01-100) for Damaged Area

WARNING

ALWAYS MAKE SURE THERE IS SUFFICIENT VENTILATION IN THE WORK AREA.

WARNING

EYE PROTECTION MUST ALWAYS BE USED.

WARNING

DO NOT LET THE CLEANER OR ITS VAPOR TOUCH THE EYES OR SKIN.

WARNING

PROTECTIVE CLOTHING AND FACE MASKS MUST ALWAYS BE USED.

WARNING

ALWAYS KEEP OPEN FLAMES AWAY FROM THE WORK AREA.

WARNING

IT IS THE RESPONSIBILITY OF THE OPERATOR TO OBTAIN AND OBSERVE THE MANUFACTURERS MATERIAL SAFETY DATA SHEETS FOR CONSUMABLE MATERIALS FORMATION SUCH AS, HAZARDOUS INGREDIENTS, PHYSICAL/CHEMICAL CHARACTERISTICS, FIRE EXPLOSION, REACTIVITY, HEALTH HAZARD DATA, PRECAUTIONS FOR SAFE HANDLING, USE AND CONTROL MEASURES AND ALSO TO TAKE LOCAL REGULATIONS INTO CONSIDERATION.

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT. IF MECHANICAL CUTTERS ARE USED, ONLY LIGHT CUTS MUST BE MADE TO AVOID OVERHEATING THE MATERIAL.

CAUTION

TITANIUM COMPONENT - AVOID BUILD UP OF HEAT BY APPLYING ONLY GENTLE PRESSURE AND KEEPING THE TOOL SPEED AS LOW AS POSSIBLE. USE TECHNIQUES WHICH ALLOW FOR PROGRESSIVE WEAR OF THE DRESSING MEDIA TO PRESENT A CONTINUALLY FRESH CUTTING SURFACE TO THE WORK PIECE. DO NOT DWELL ON ONE AREA OF THE COMPONENT. DRESS, WHERE POSSIBLE, IN A CIRCULAR MOTION; TAKING LIGHT CUTS TO AVOID OVERHEATING.

CAUTION

TITANIUM COMPONENT - YOU MUST MAKE SURE THAT WHEN YOU REMOVE MATERIAL, BLEND AND POLISH, TO MAKE SMOOTH, THAT NO SPARKS ARE PRODUCED AND THE ADJACENT AREA IS MASKED OFF.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR DURING DRESSING, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.

CAUTION

POWER BLENDING TOOLS MAY BE USED IF DAMAGED TITANIUM PART IS PERIODICALLY CHECKED FOR HEAT BUILD-UP BY TOUCHING OCCASIONALLY WITH UNGLOVED HAND. IF TITANIUM PART BECOMES TOO HOT TO TOUCH, ALLOW MATERIAL TO COOL BEFORE CONTINUING REPAIR.

CAUTION

THE FAN CASE IS MADE FROM TITANIUM ALLOY AND IS THIN IN SOME AREAS. IF YOU BLEND TOO MUCH, THE PART CANNOT BE SERVICEABLE AND WILL HAVE TO BE REPLACED.

CAUTION

DO NOT OPERATE WITHOUT SAFETY GOGGLES AND OTHER GUARDS EQUIPMENT. FLYING PARTICLES CAN CAUSE INJURY.NOTE

Dull tools and worn or loaded abrasive equipments generate heat rapidly and should be checked frequently and replaced when necessary.NOTE

Remove the minimum quantity of material necessary to remove the damage. All blends must be smooth and continuous.NOTE

The surface finish of all the repaired surfaces must have the same or better quality to that of the adjacent, not damaged, areas.NOTE

Keep the material removal to the minimum necessary to remove damage.Use suitable Boring machine, with Standard Workshop Equipment.

Machine the worn or damaged bolt hole.

Remove the sharp edges.

SUBTASK 72-32-85-320-056 Machine the Worn or Damaged Fan Case Assembly (01-100)

Refer to SPM TASK 70-11-08-300-503, SUBTASK 70-11-08-300-001.

Chemically clean.

Refer to SPM TASK 70-11-08-300-503, SUBTASK 70-11-08-300-002.

Swab etch the machined area.

SUBTASK 72-32-85-110-093 Do a Swab Etch

Refer to SPM TASK 70-23-05-230-501.

No cracks are permitted.

Do the test for cracks.

SUBTASK 72-32-85-230-071 Examine the Machined Area of the Fan Case Assembly (01-100)

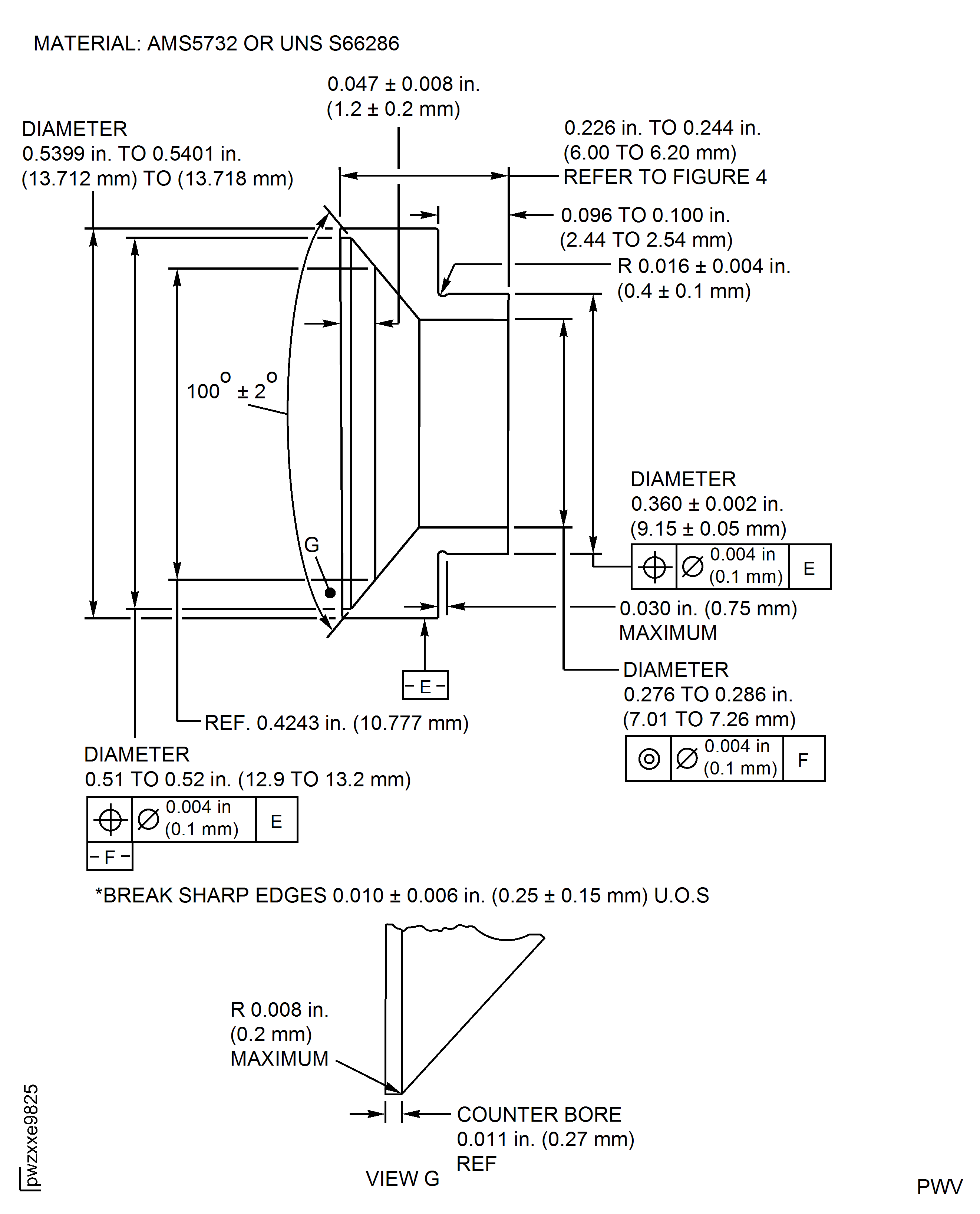

Use material AMS5732 or UNS S66286.

Manufacture the repair part.

Refer to SPM TASK 70-11-26-300-503. Use CoMat 01-031 ACETONE (CH3)2CO.

Clean the repair part.

Refer to SPM TASK 70-23-01-230-501, TASK 70-23-02-230-501 or TASK 70-23-05-230-501.

No cracks are permitted.

Crack test on the repair part.

SUBTASK 72-32-85-320-054 Manufacture the Repair part

Refer to Figure.

Refer to SPM TASK 70-11-26-300-503. Use CoMat 01-031 ACETONE (CH3)2CO.

Clean the bush.

Apply retaining compound to the outer diameter and flange surface of the bush.

SUBTASK 72-32-85-350-161 Prepare the Repair Part for Installation

WARNING

ALWAYS MAKE SURE THERE IS SUFFICIENT VENTILATION IN THE WORK AREA.

WARNING

EYE PROTECTION MUST ALWAYS BE USED.

WARNING

DO NOT LET THE CLEANER OR ITS VAPOR TOUCH THE EYES OR SKIN.

WARNING

PROTECTIVE CLOTHING AND FACE MASKS MUST ALWAYS BE USED.

WARNING

ALWAYS KEEP OPEN FLAMES AWAY FROM THE WORK AREA.

WARNING

IT IS THE RESPONSIBILITY OF THE OPERATOR TO OBTAIN AND OBSERVE THE MANUFACTURERS MATERIAL SAFETY DATA SHEETS FOR CONSUMABLE MATERIALS FORMATION SUCH AS, HAZARDOUS INGREDIENTS, PHYSICAL/CHEMICAL CHARACTERISTICS, FIRE EXPLOSION, REACTIVITY, HEALTH HAZARD DATA, PRECAUTIONS FOR SAFE HANDLING, USE AND CONTROL MEASURES AND ALSO TO TAKE LOCAL REGULATIONS INTO CONSIDERATION.Use a Portable heating equipment.

Heat the flange FA to 120 deg F (94.5 deg C).

Heat the flange FA.

Use a Non-metallic drift and Heat Protective Gloves.

Install the bush in to the machined hole, immediately after removal of the heating equipment from the fan case assembly.

SUBTASK 72-32-85-350-162 Install Repair Bush

Refer to Figure.

Make sure the bush is in position.

If necessary, do this procedure again.

Visually examine the bush for location.

SUBTASK 72-32-85-220-155 Examine the Bush for Location

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Make a mark repair symbol, VRS1565 and hole numbers adjacent the part number, refer to Figure.

SUBTASK 72-32-85-350-163 Identify the Repair

Figure: Fan Case Assembly

Fan Case Assembly

Figure: Fan Case Assembly

Fan Case Assembly

Figure: Fan Case Assembly

Fan Case Assembly

Figure: Fan Case Assembly

Fan Case Assembly

Figure: Fan Case Assembly

Fan Case Assembly