Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-88-300-002 Fan Exit Guide Vane - Replace The Vanes, Outer Platform And/or Repair The Unbonding, Repair-002 (VRS1420)

Effectivity

FIG/ITEM | PART NO | |||||

06-100 | 5A0037 | 5A0283 | Assembly A | |||

06-100 | 5A1363 | Assembly B | ||||

06-100 | 5A0041 | Assembly C | ||||

06-300 | 5A0037 | 5A0283 | Assembly A | |||

06-300 | 5A1363 | Assembly B | ||||

06-300 | 5A0041 | Assembly C | ||||

06-500 | 5A0037 | 5A0283 | Assembly A | |||

06-500 | 5A1363 | Assembly B | ||||

06-500 | 5A0041 | Assembly C | ||||

06-700 | 5A0037 | 5A0283 | Assembly A | |||

06-700 | 5A1363 | Assembly B | ||||

06-700 | 5A0041 | Assembly C | ||||

07-100 | 5A0037 | 5A0283 | Assembly A | |||

07-100 | 5A1363 | Assembly B | ||||

07-100 | 5A0041 | Assembly C | ||||

07-300 | 5A0037 | 5A0283 | Assembly A | |||

07-300 | 5A1363 | Assembly B | ||||

07-300 | 5A0041 | Assembly C | ||||

07-500 | 5A0037 | 5A0283 | Assembly A | |||

07-500 | 5A1363 | Assembly B | ||||

07-500 | 5A0041 | Assembly C | ||||

07-700 | 5A0037 | 5A0283 | Assembly A | |||

07-700 | 5A1363 | Assembly B | ||||

07-700 | 5A0041 | Assembly C | ||||

08-100 | 5A0037 | 5A0283 | Assembly A | |||

08-100 | 5A1363 | Assembly B | ||||

08-100 | 5A0041 | Assembly C | ||||

08-300 | 5A0037 | 5A0283 | Assembly A | |||

08-300 | 5A3613 | Assembly B | ||||

08-300 | 5A0041 | Assembly C | ||||

08-500 | 5A0037 | 5A0283 | Assembly A | |||

08-500 | 5A1363 | Assembly B | ||||

08-500 | 5A0041 | Assembly C | ||||

08-700 | 5A0037 | 5A0283 | Assembly A | |||

08-700 | 5A1363 | Assembly B | ||||

08-700 | 5A0041 | Assembly C | ||||

09-100 | 5A0037 | 5A0283 | Assembly A | |||

09-100 | 5A1363 | Assembly B | ||||

09-100 | 5A0041 | Assembly C | ||||

09-300 | 5A0037 | 5A0283 | Assembly A | |||

09-300 | 5A1363 | Assembly B | ||||

09-300 | 5A0041 | Assembly C | ||||

09-500 | 5A0037 | 5A0283 | Assembly A | |||

09-500 | 5A1363 | Assembly B | ||||

09-500 | 5A0041 | Assembly C | ||||

09-700 | 5A0037 | 5A0283 | Assembly A | |||

09-700 | 5A1363 | Assembly B | ||||

09-700 | 5A0041 | Assembly C | ||||

10-100 | 5A0037 | 5A0283 | Assembly A | |||

10-100 | 5A1316 | Assembly B | ||||

10-100 | 5A0041 | Assembly C | ||||

10-300 | 5A0037 | 5A0283 | Assembly A | |||

10-300 | 5A1363 | Assembly B | ||||

10-300 | 5A0041 | Assembly C | ||||

10-500 | 5A0037 | 5A0283 | Assembly A | |||

10-500 | 5A1363 | Assembly B | ||||

10-500 | 5A0041 | Assembly C | ||||

10-700 | 5A0037 | 5A0283 | Assembly A | |||

10-700 | 5A1363 | Assembly B | ||||

10-700 | 5A0041 | Assembly C | ||||

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

Fan exit guide vane assembly Assembly A, B and C | Aluminum alloy |

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPM.

All priming and bonding operations shall be done in controlled - environment rooms designated for non-silicone materials.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Plastic scraper | LOCAL | Plastic scraper | ||

| Tweezers | LOCAL | Tweezers | ||

| Oven | LOCAL | Oven | Electric | |

| Teflon beaker | LOCAL | Teflon beaker | ||

| Vacuum vessel | LOCAL | Vacuum vessel | ||

| Protective gloves and goggles | LOCAL | Protective gloves and goggles | ||

| Soldering iron | LOCAL | Soldering iron | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Vacuum pump | LOCAL | Vacuum pump | ||

| Stainless spoon | LOCAL | Stainless spoon | ||

| Digital depth gage | LOCAL | Digital depth gage | ||

| Hardness tester (Durometer) | LOCAL | Hardness tester (Durometer) | ||

| Tensile tester | LOCAL | Tensile tester | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| IAE 3J12766 Molding fixture | 0AM53 | IAE 3J12766 | 1 | |

| IAE 3J12767 Inspection fixture | 0AM53 | IAE 3J12767 | 1 | |

| IAE 3J12768 Inspection fixture | 0AM53 | IAE 3J12768 | 1 | |

| IAE 3J12770 Fixture, test piece | 0AM53 | IAE 3J12770 | 1 | |

| IAE 3J12833 Molding fixture | 0AM53 | IAE 3J12833 | 1 | |

| IAE 3J12835 Inspection fixture | 0AM53 | IAE 3J12835 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-120 HOT PAINT STRIPPER | 71410 | CoMat 01-120 | ||

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 03-026 LIQUID NITROGEN | LOCAL | CoMat 03-026 | ||

| CoMat 01-275 CHROMATE CONVERSION COATING FOR ALUMINIUM | LOCAL | CoMat 01-275 | ||

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 05-050 SILICON CARBIDE GRIT | 1E1X8 | CoMat 05-050 | ||

| CoMat 07-068 PRIMER | IE401 | CoMat 07-068 | ||

| CoMat 07-069 POLYURETHANE RESIN | 24664 | CoMat 07-069 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Vane | 5A4113 | A/R | ||

| Vane | 5A4113 | A/R | ||

| Vane | 5A4113 | A/R | ||

| Vane | 5A4113 | A/R | ||

| Vane | 5A4113 | A/R | ||

| Vane | 5A4113 | A/R | ||

| Vane | 5A4113 | A/R | ||

| Vane | 5A4113 | A/R | ||

| Vane | 5A4113 | A/R | ||

| Vane | 5A4113 | A/R | ||

| Vane | 5A4113 | A/R | ||

| Vane | 5A4113 | A/R | ||

| Vane | 5A4113 | A/R | ||

| Vane | 5A4113 | A/R | ||

| Vane | 5A4113 | A/R | ||

| Vane | 5A4113 | A/R | ||

| Vane | 5A4113 | A/R | ||

| Vane | 5A4113 | A/R | ||

| Vane | 5A4113 | A/R | ||

| Platform, Outer Assembly B | 5A1364 | A/R | ||

| Platform, Outer Assembly B | 5A1364 | A/R | ||

| Platform, Outer Assembly B | 5A1364 | A/R | ||

| Platform, Outer Assembly B | 5A1364 | A/R | ||

| Platform, Outer Assembly C | 5A0042 | A/R | ||

| Platform, Outer Assembly C | 5A0042 | A/R | ||

| Platform, Outer Assembly C | 5A0042 | A/R | ||

| Platform, Outer Assembly C | 5A0042 | A/R | ||

| Platform, Outer Assembly B | 5A1364 | A/R | ||

| Platform, Outer Assembly B | 5A1364 | A/R | ||

| Platform, Outer Assembly B | 5A1364 | A/R | ||

| Platform, Outer Assembly B | 5A1364 | A/R | ||

| Platform, Outer Assembly C | 5A0042 | A/R | ||

| Platform, Outer Assembly C | 5A0042 | A/R | ||

| Platform, Outer Assembly C | 5A0042 | A/R | ||

| Platform, Outer Assembly C | 5A0042 | A/R | ||

| Platform, Outer Assembly B | 5A1364 | A/R | ||

| Platform, Outer Assembly B | 5A1364 | A/R | ||

| Platform, Outer Assembly B | 5A1364 | A/R | ||

| Platform, Outer Assembly B | 5A1364 | A/R | ||

| Platform, Outer Assembly C | 5A0042 | A/R | ||

| Platform, Outer Assembly C | 5A0042 | A/R | ||

| Platform, Outer Assembly C | 5A0042 | A/R | ||

| Platform, Outer Assembly C | 5A0042 | A/R | ||

| Platform, Outer Assembly B | 5A1364 | A/R | ||

| Platform, Outer Assembly B | 5A1364 | A/R | ||

| Platform, Outer Assembly B | 5A1364 | A/R | ||

| Platform, Outer Assembly B | 5A1364 | A/R | ||

| Platform, Outer Assembly C | 5A0042 | A/R | ||

| Platform, Outer Assembly C | 5A0042 | A/R | ||

| Platform, Outer Assembly C | 5A0042 | A/R | ||

| Platform, Outer Assembly C | 5A0042 | A/R | ||

| Platform, Outer Assembly B | 5A1364 | A/R | ||

| Platform, Outer Assembly B | 5A1364 | A/R | ||

| Platform, Outer Assembly B | 5A1364 | A/R | ||

| Platform, Outer Assembly B | 5A1364 | A/R | ||

| Platform, Outer Assembly C | 5A0042 | A/R | ||

| Platform, Outer Assembly C | 5A0042 | A/R | ||

| Platform, Outer Assembly C | 5A0042 | A/R | ||

| Platform, Outer Assembly C | 5A0042 | A/R |

Safety Requirements

NONEProcedure

Refer to Repair, VRS1423 TASK 72-32-88-300-003 (REPAIR-003).

Remove the strip seal from the fan exit guide vane.

SUBTASK 72-32-88-350-060 Remove the Strip Seal from the Fan Exit Guide Vane Assembly

Refer to TASK 72-32-88-200-000 (INSPECTION-000).

WARNING

DURING THE OPERATION, WEAR PROTECTIVE GLOVES AND GOGGLES TO PROTECT AGAINST THE EXTREME LOW TEMPERATURE FOR COOLING.

WARNING

MAKE SURE THERE IS SUFFICIENT VENTILATION DURING THE OPERATION.

WARNING

DISPOSE OF REMOVED POLYURETHANE RUBBER INTO A SPECIFIED BOX FOR PLASTIC WASTE.

WARNING

AVOID EXTREMELY STRONG STROKES DURING HAMMERING IN ORDER NOT TO DAMAGE VANE, INNER AND OUTER PLATFORM.Examine and identify damaged vanes, outer platform and unbonds.

If the fan exit guide vane cannot be disassembled completely, do Step again.

SUBTASK 72-32-88-330-052-001 Remove the Polyurethane Rubber from the Fan Exit Gude Vane Assembly - Cooling Method

Refer to TASK 72-32-88-200-000 (INSPECTION-000).

WARNING

WEAR HEAT RESISTANT GLOVES AND GOGGLES DURING HEATING OF THE FAN EXIT GUIDE.

WARNING

MAKE SURE THERE IS SUFFICIENT VENTILATION DURING THE OPERATION.

WARNING

MAXIMUM TEMPERATURE IN THE OVEN SHOULD NOT EXCEED 338 DEG. F (170 DEG. C) IN ORDER TO PREVENT GENERATING POISONOUS GASES AND DAMAGING ALUMINUM OF BASE METAL.NOTE

This Step is an alternative to SUBTASK 72-32-88-052-001.Examine and identify the damaged vanes, outer platform and unbonds.

SUBTASK 72-32-88-330-052-002 Remove the Polyurethane Rubber from the Fan Exit Gude Vane Assembly - Heating Method

A presence of residual polyurethane as a brownish color film is acceptable.

Use Soldering iron.

Use bamboo scraper.

Keep temperature of the iron at 302 to 329 deg. F (150 to 165 deg. C).

WARNING

MAXIMUM TEMPERATURE IN THE SOLDERING IRON SHOULD NOT EXCEED 338 DEG. F (170 DEG. C) IN ORDER TO PREVENT GENERATINF POISONOUS GAS AND DAMAGING ALUMINUM OF BASE METAL.

WARNING

WEAR HEAT RESISTANT GLOVES AND GOGGLES DURING OPERATION.

WARNING

MAKE SURE THERE IS SUFFICIENT VENTILATION DURING THE OPERATION.

WARNING

DISPOSE OF REMOVED POLYURETHANE RUBBER INTO A SPECIFIED BOX FOR PLASTIC WASTE.

CAUTION

USE A SOLDERING IRON WITH A ROUND TIP TO AVOID DAMAGE ON BASE METAL.NOTE

This Step is an alternative to SUBTASK 72-32-88-330-002.Scrape residual polyurethane rubber from vane, inner and outer platform by soldering iron and scraper.

SUBTASK 72-32-88-330-053-001 Remove the Residual Polyurethane Rubber from the Fan Exit Guide Vane Assembly - Soldering Iron Method

Refer to the SPM TASK 70-23-02-230-501.

Refer to TASK 72-32-88-200-000 (INSPECTION-000).

Use penetrant crack test equipment.

Make sure there are no cracks in the outer platform, inner platform and vanes.

Fluorescent penetrant examine the outer platform, inner platform and vanes.

SUBTASK 72-32-88-230-054 Examine the Outer Platform, Inner Platform and Vanes for Cracks

Refer to Figure.

Refer to Step.

Prepare the surfaces of the test pieces.

Use IAE 3J12770 Fixture, test piece 1 off test piece.

Refer to Step, A, B, G, J, K, for the use of the same mixed batch as applied to FEGV in mold.

Apply and cure the CoMat 07-069 POLYURETHANE RESIN.

SUBTASK 72-32-88-290-051 Make the Test Pieces for the Tensile Test

Refer to the SPM TASK 70-11-26-300-503.

Remove the grease from the inner platform, outer platform and vanes.

Use CoMat 01-124 ISOPROPYL ALCOHOL with lint-free cheese cloth.

Clean the blasted surfaces.

SUBTASK 72-32-88-360-053 Prepare the Surfaces of the Inner Platform, Outer Platform and Vanes

Use CoMat 07-068 PRIMER with lint-free cheese cloth and tweezers.

WARNING

YOU MUST USE PLASTIC GLOVES, DURING PREPARATION AND USE OF THE RESIN TO PREVENT CONTAMINATION OF THE SKIN.

CAUTION

AFTER PREPARATION THE MATING SURFACES MUST BE FULLY CLEANED AND MUST NOT BE TOUCHED BY HAND, TO PREVENT CONTAMINATION.Apply a thin layer of the primer to molding surfaces within half an hour after cleaning.

NOTE

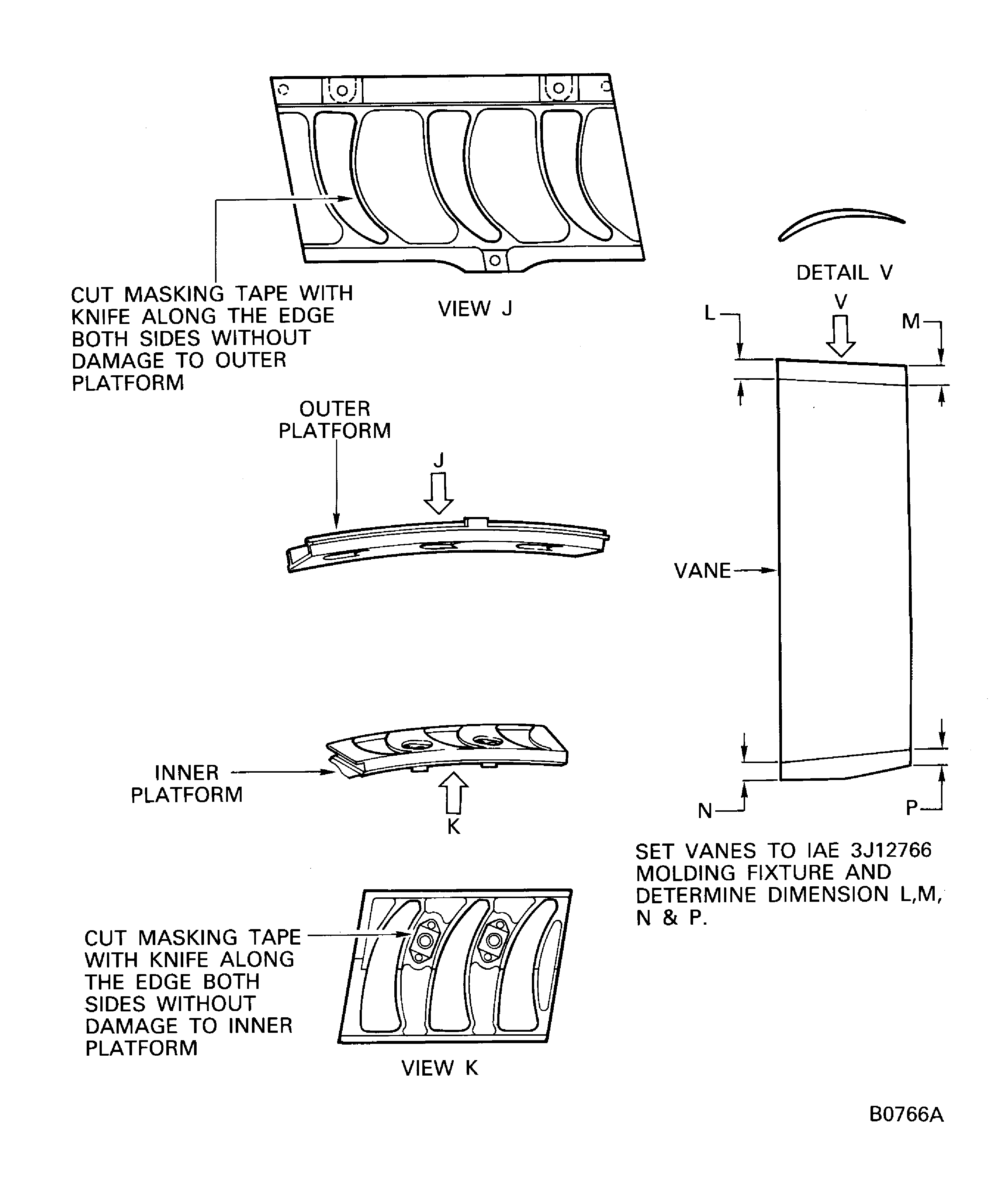

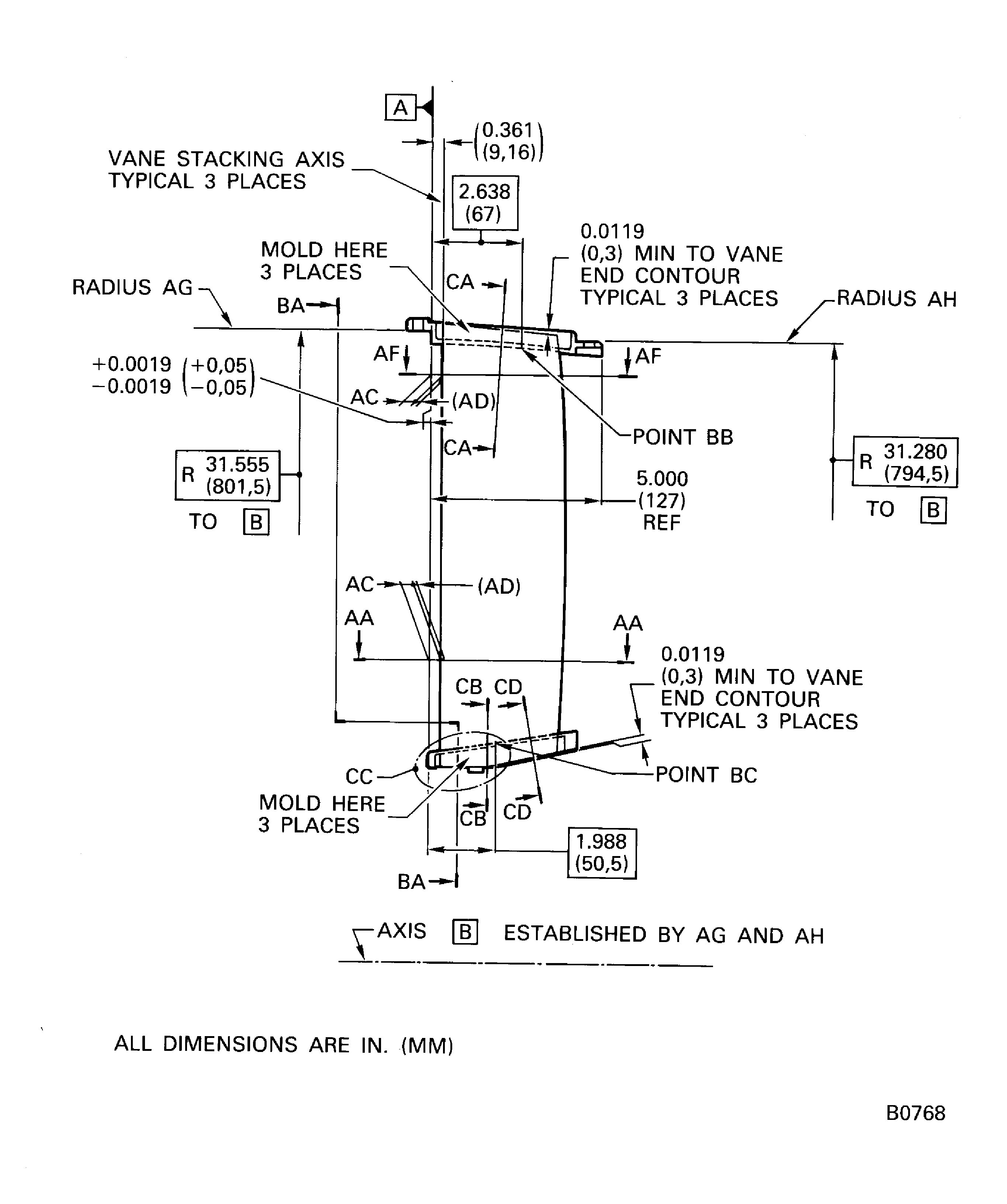

Locally manufactured tool may be used instead of IAE 3J12766 Molding fixture or IAE 3J12833 Molding fixture if all the requirements in Figure. Figure. Figure and Figure are satisfied after the molding.Use IAE 3J12766 Molding fixture 1 off or IAE 3J12833 Molding fixture 1 off.

Assemble the new or serviceable vanes, inner platform and the outer platform onto the molding fixture.

Put 5.29 oz (150 g) of part A into teflon beaker.

Put 0.88 oz (25 g) of the part B into another beaker.

The quantity of the part A and B above can be applied between three vanes and inner or outer platform.

Use CoMat 07-069 POLYURETHANE RESIN part A and B.

Prepare the polyurethane resin.

Use an electric Oven.

Heat the part A at 167 to 185 deg F (75 to 85 deg C) and part B at 275 to 293 deg F (135 to 145 deg C).

Preheat the polyurethane resin to reduce the viscosity sufficient to allow for pour and pump.

Mix CoMat 07-069 POLYURETHANE RESIN for one minute.

Use IAE 3J12770 Fixture, test piece 1 off.

Use IAE 3J12766 Molding fixture 1 off or IAE 3J12833 Molding fixture 1 off.

NOTE

Locally manufactured tool may be used instead of IAE 3J12766 Molding fixture or IAE 3J12833 Molding fixture if all the requirements in Figure. Figure. Figure and Figure are satisfied after the molding.Apply polyurethane resin to FEGV and test specimens.

SUBTASK 72-32-88-360-054 Apply and Cure the Polyurethane Resin

Refer to the SPM TASK 70-38-02-300-503.

Apply chromate conversion coating to the minor damage on the fan exit guide vane assembly.

SUBTASK 72-32-88-350-054 Apply the Surface Protection on the Fan Exit Guide Vane Assembly

Use Tensile tester.

Tensile strength min. 2418 psi (1.7 kg/mm2).

Refer to ASTM D412.

Do a tensile test for three test pieces.

Use the IAE 3J12767 Inspection fixture 1 off IAE 3J12768 Inspection fixture 1 off, IAE 3J12835 Inspection fixture 1 off and depth gage.

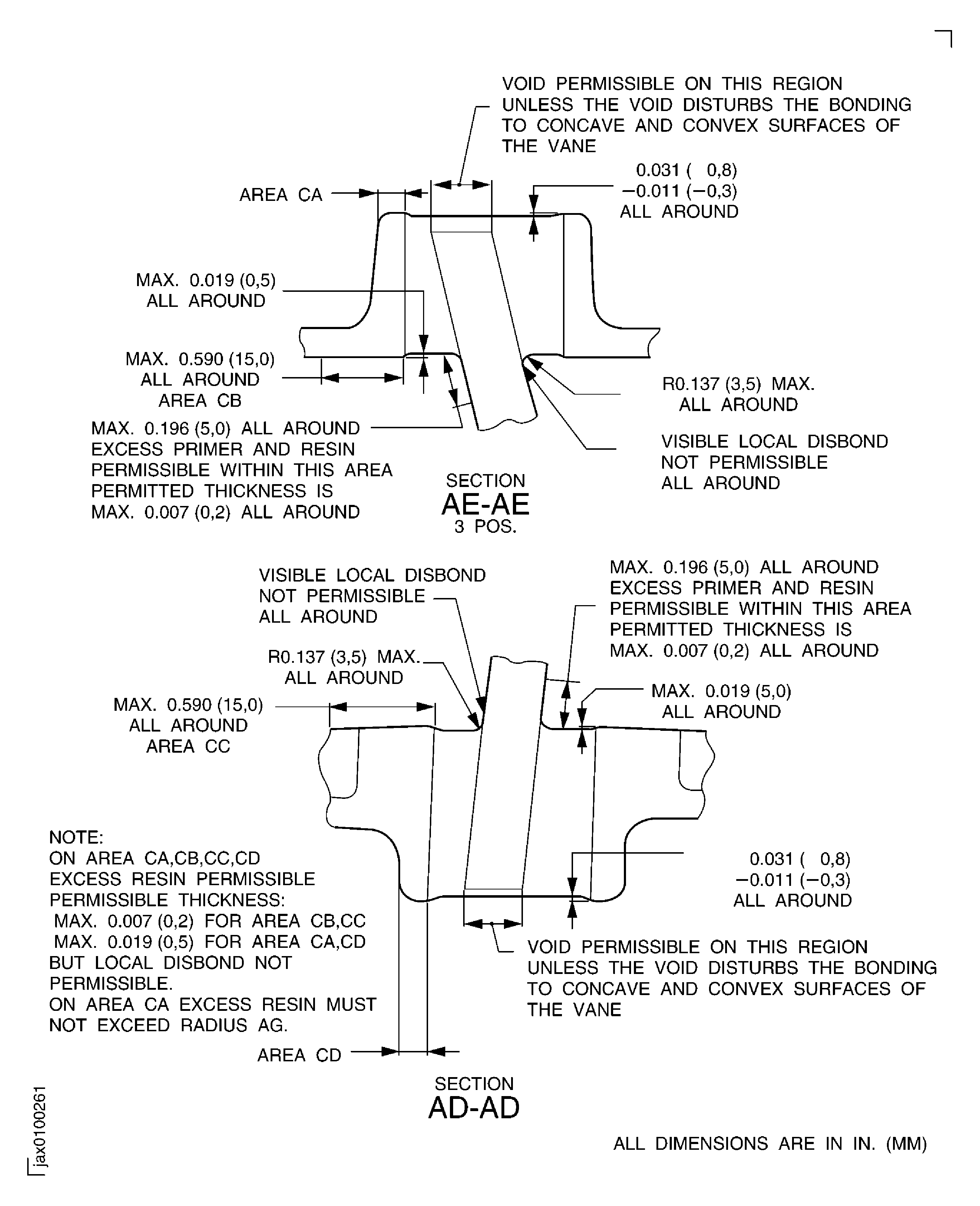

Dimensionally examine the fan exit guide vane assembly including the molding areas.

SUBTASK 72-32-88-220-065 Examine the Repaired Areas of the Fan Exit Guide Vane Assembly

Refer to Repair VRS1423, TASK 72-32-88-300-003 (REPAIR-003).

Install the strip seal to the fan exit guide vane.

SUBTASK 72-32-88-350-061 Install the Strip Seal to the Fan Exit Gude Vane Assembly

Refer to the SPM TASK 70-38-02-300-503.

Apply the chromate conversion coating to the marked repair number.

SUBTASK 72-32-88-350-055 Mark Repair Number on the Fan Exit Guide Vane Assembly

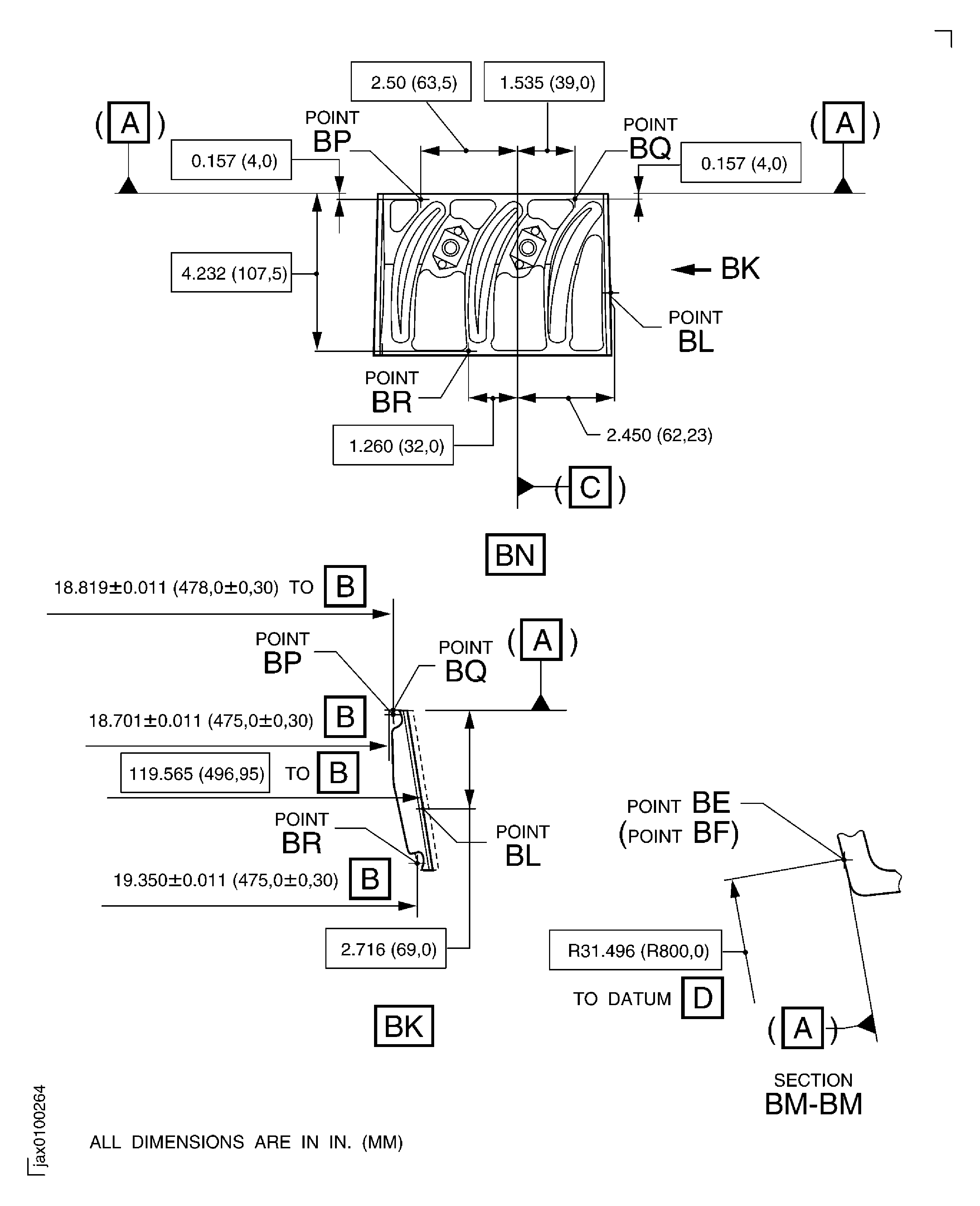

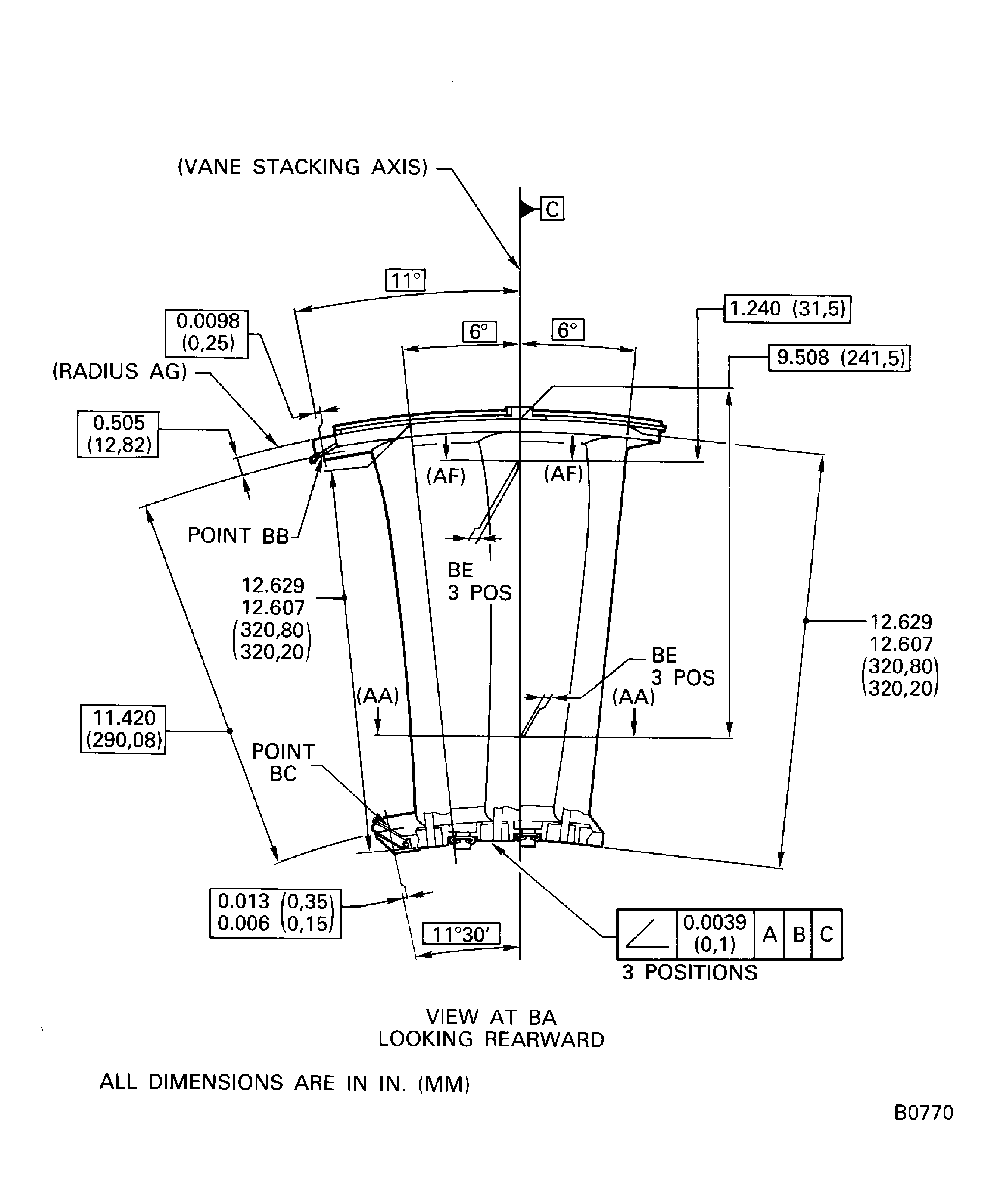

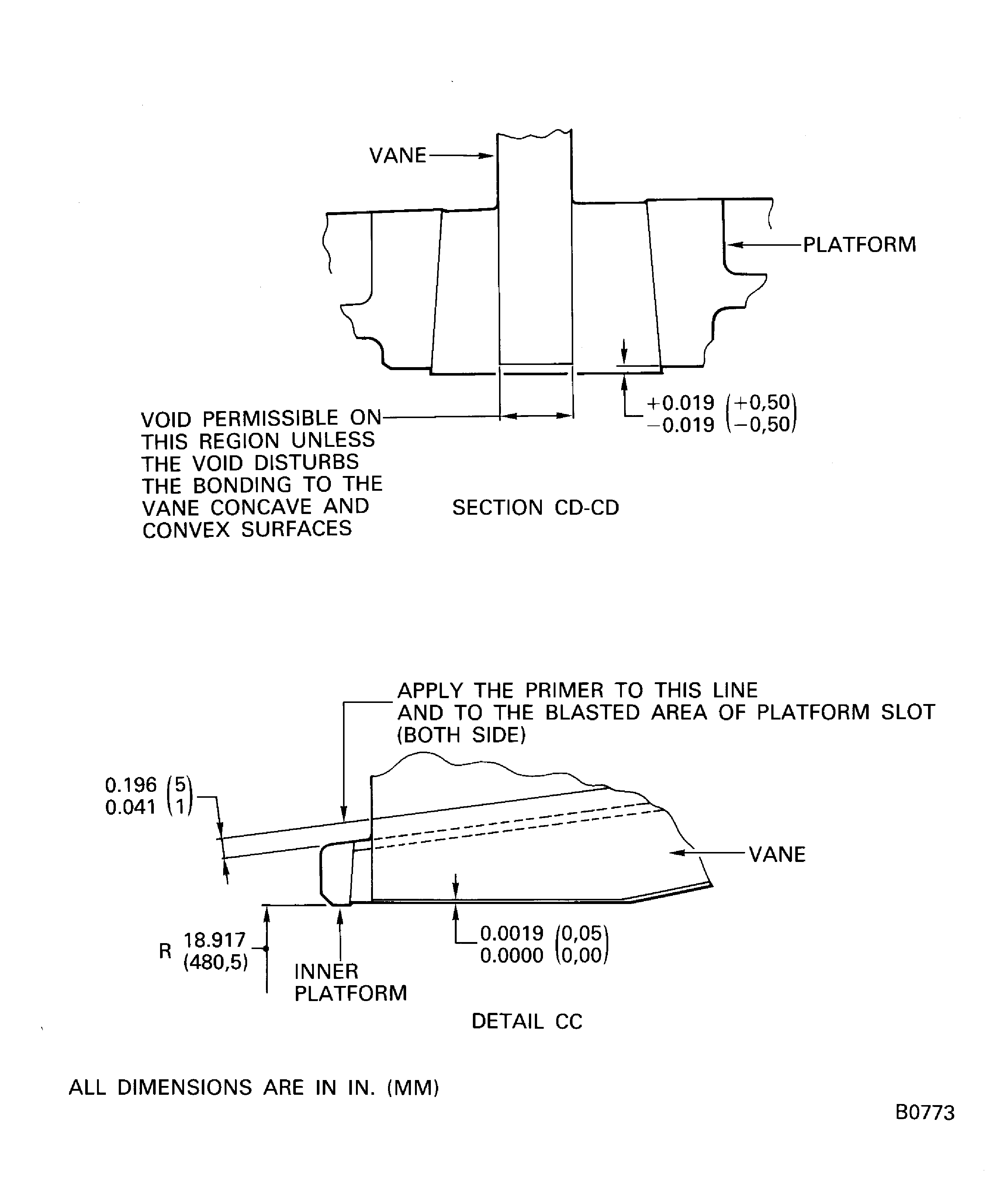

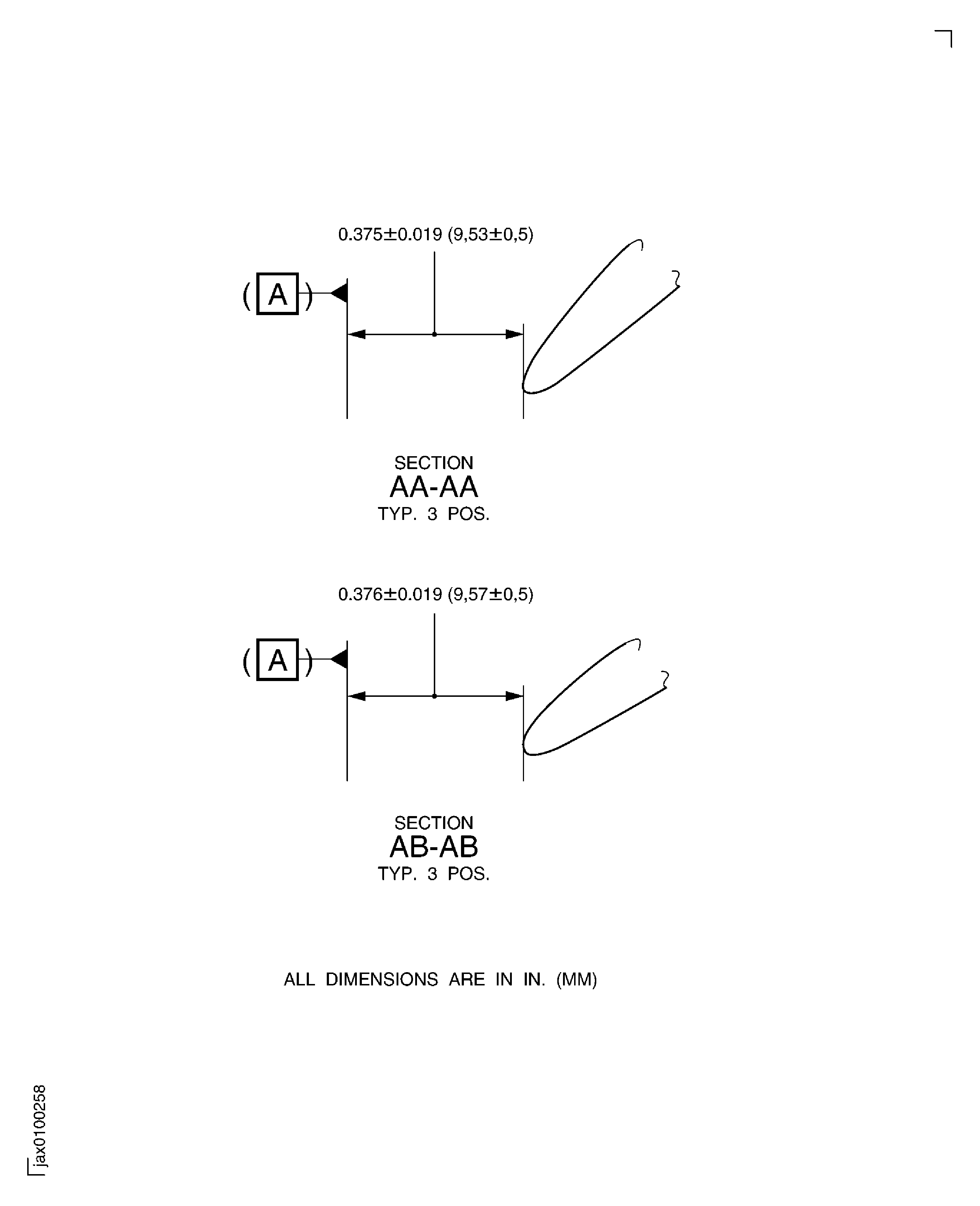

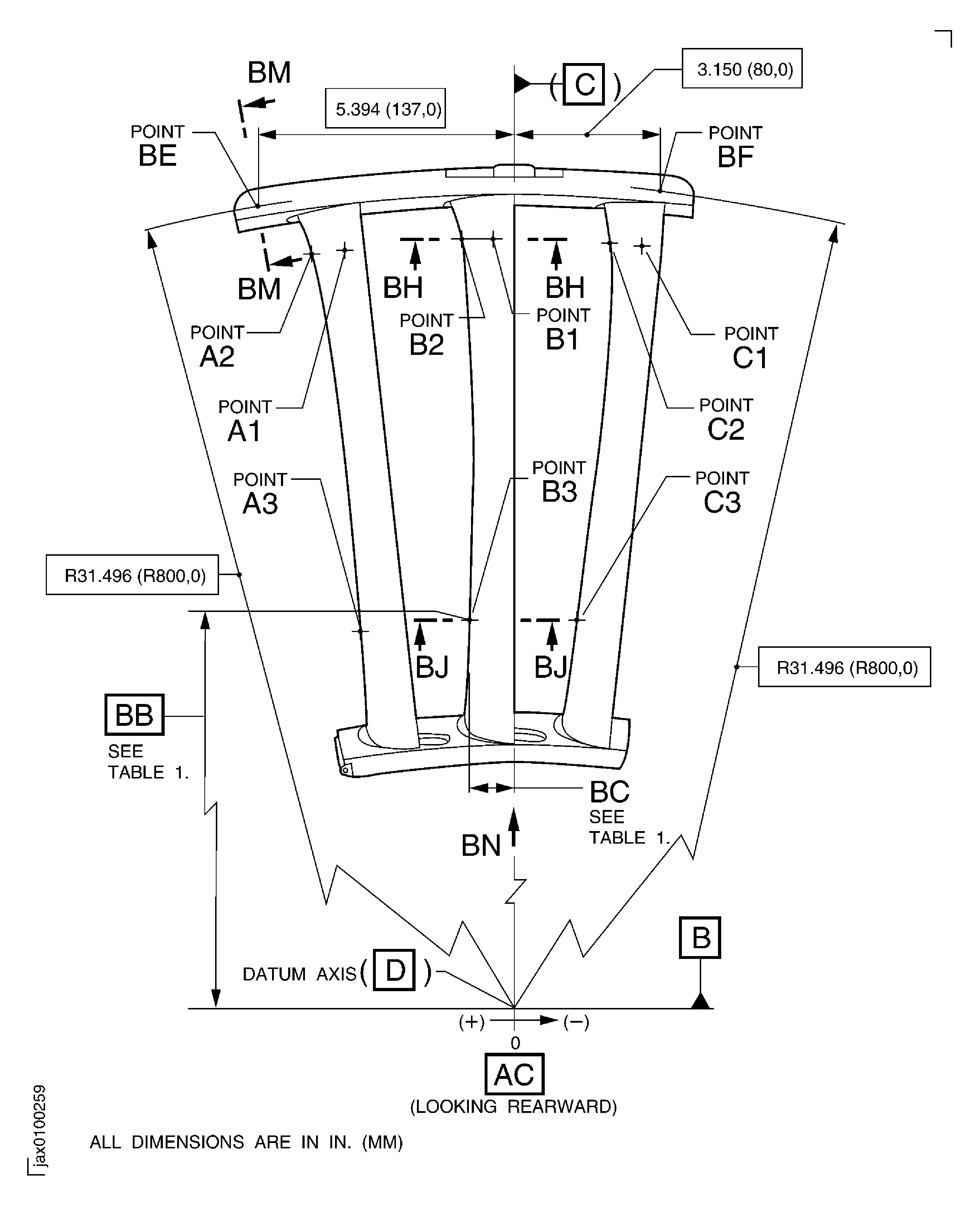

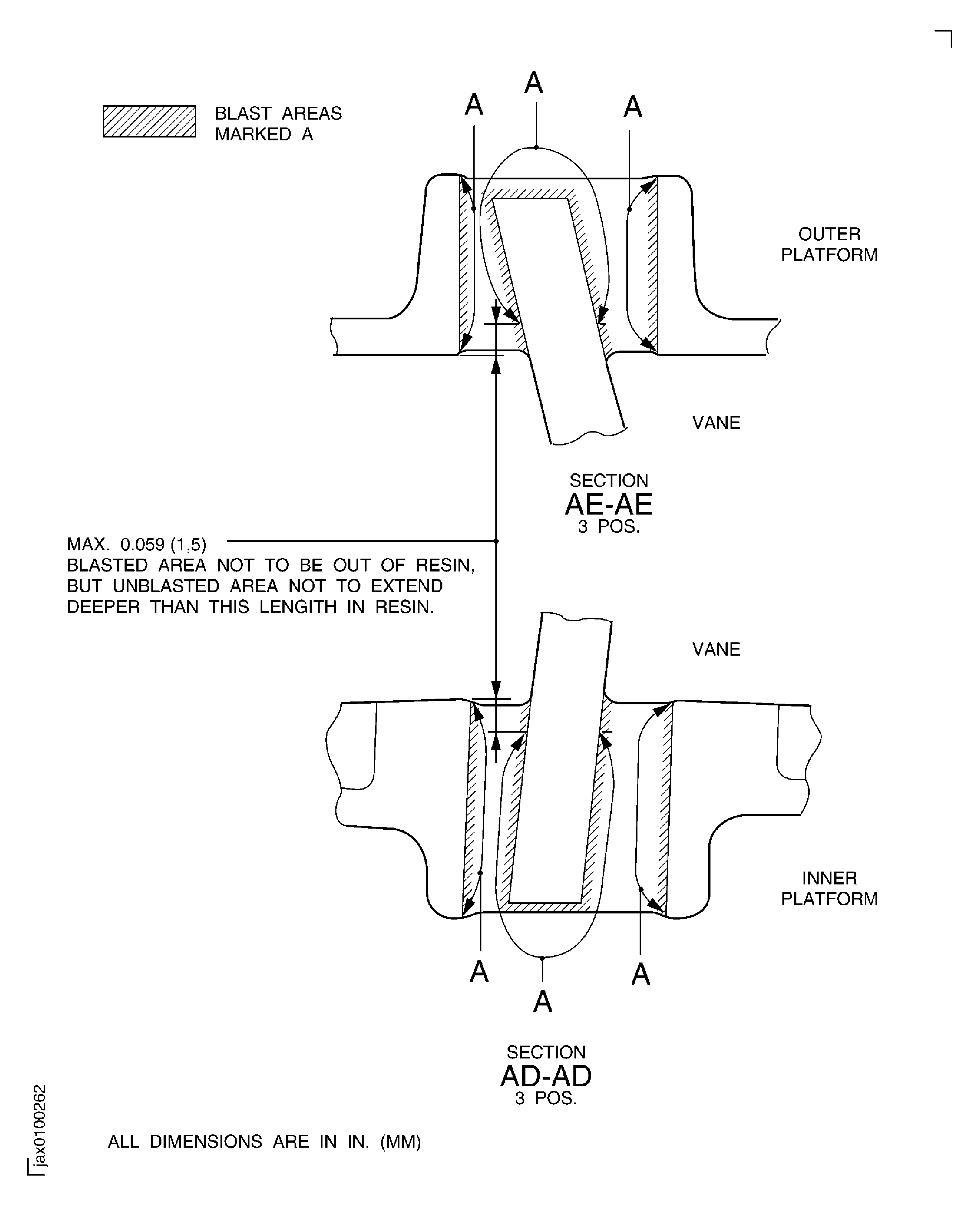

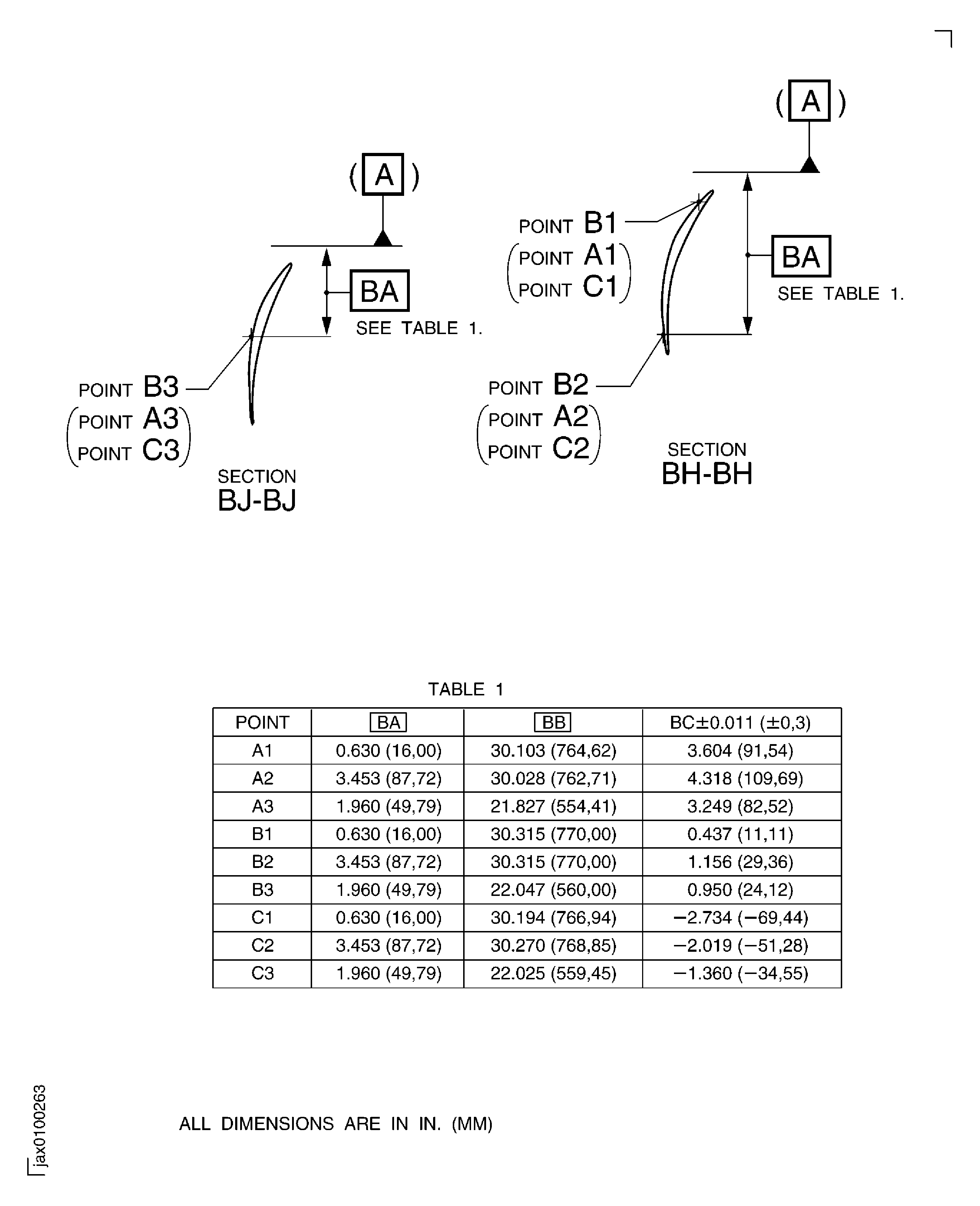

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

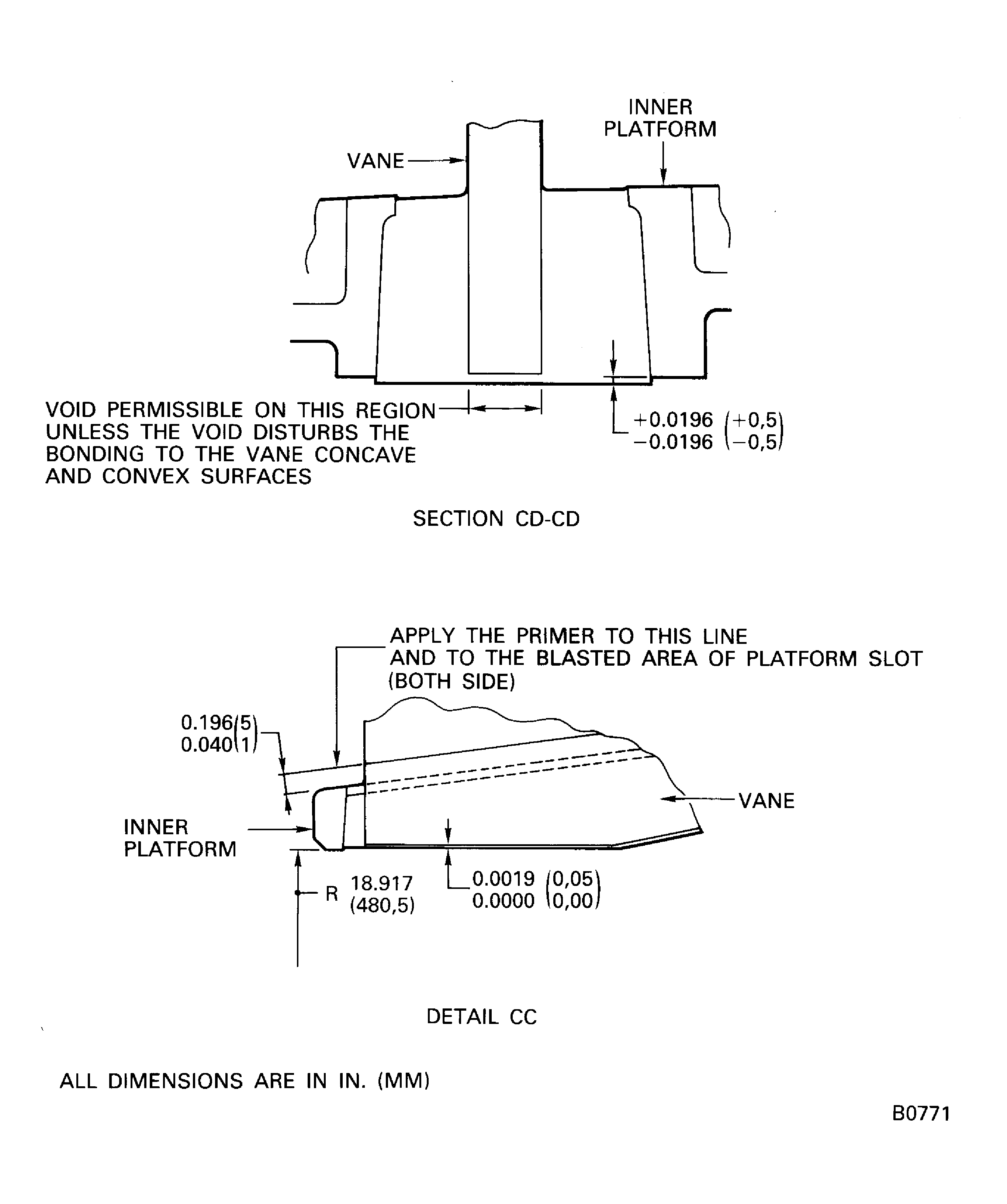

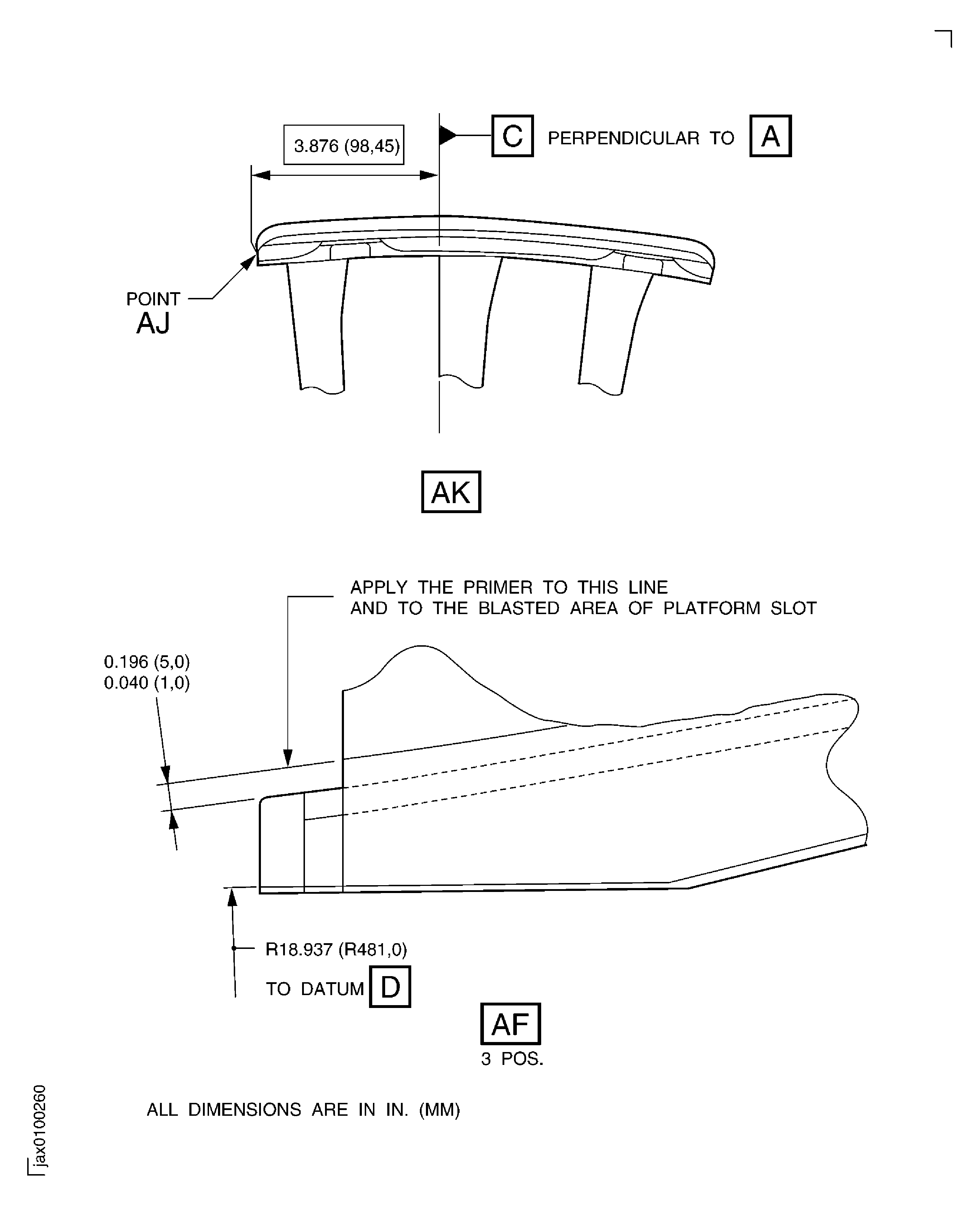

Figure: Repair details and dimensions - Assembly A and C

Repair details and dimensions - Assembly A and C

Figure: Repair details and dimensions - Assembly A and C

Repair details and dimensions - Assembly A and C

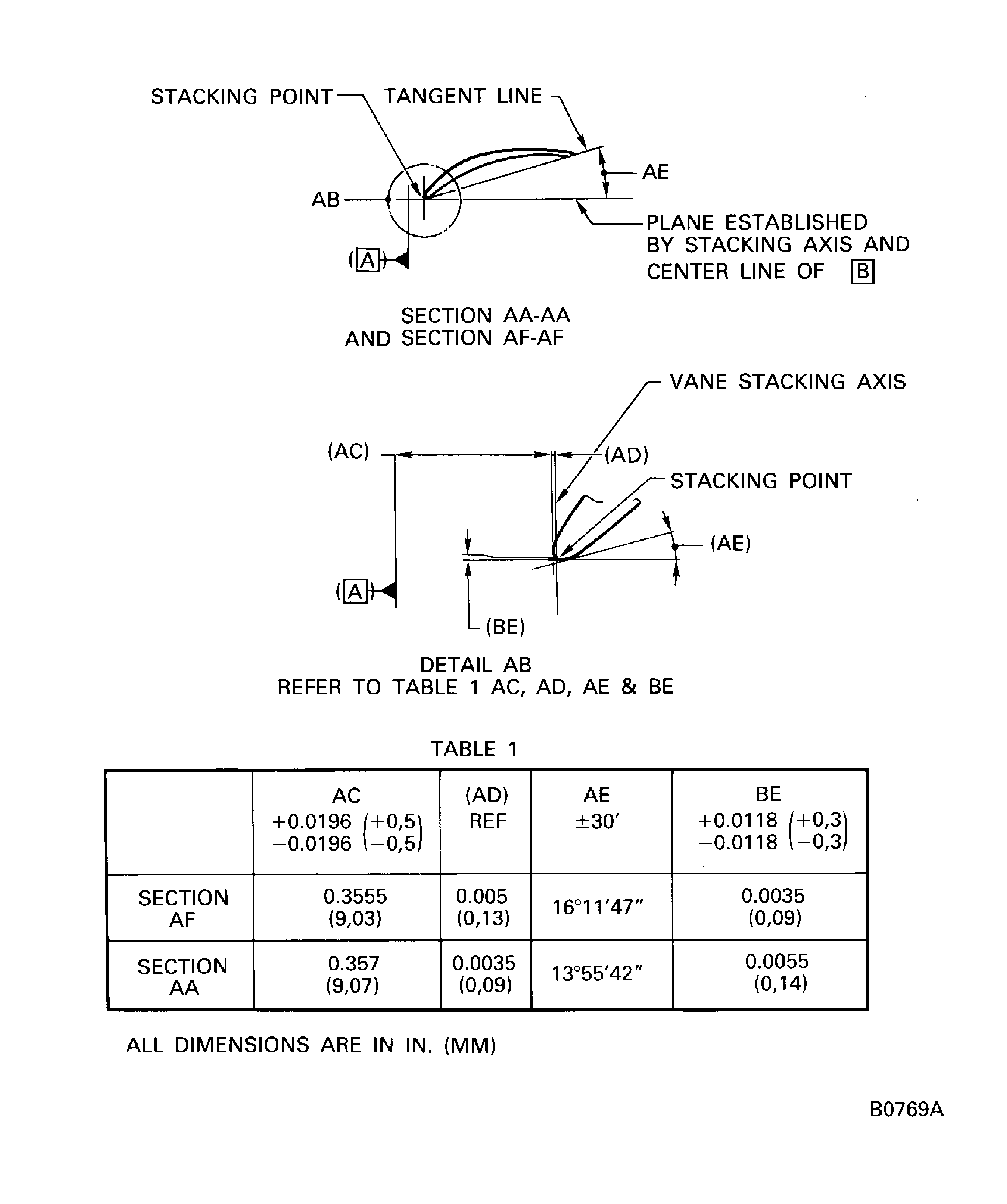

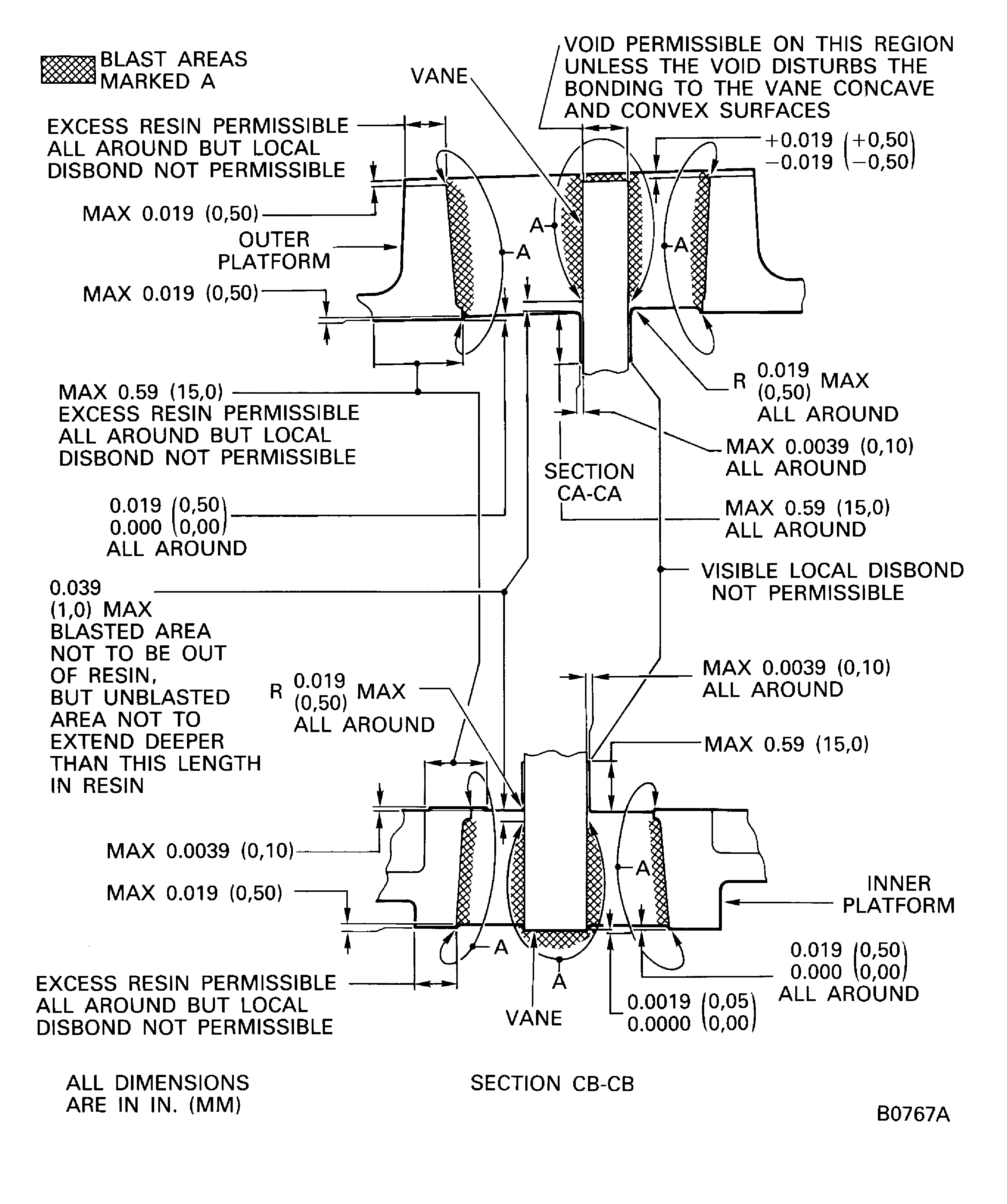

Figure: Repair details and dimensions - Assembly Aand C

Repair details and dimensions - Assembly Aand C

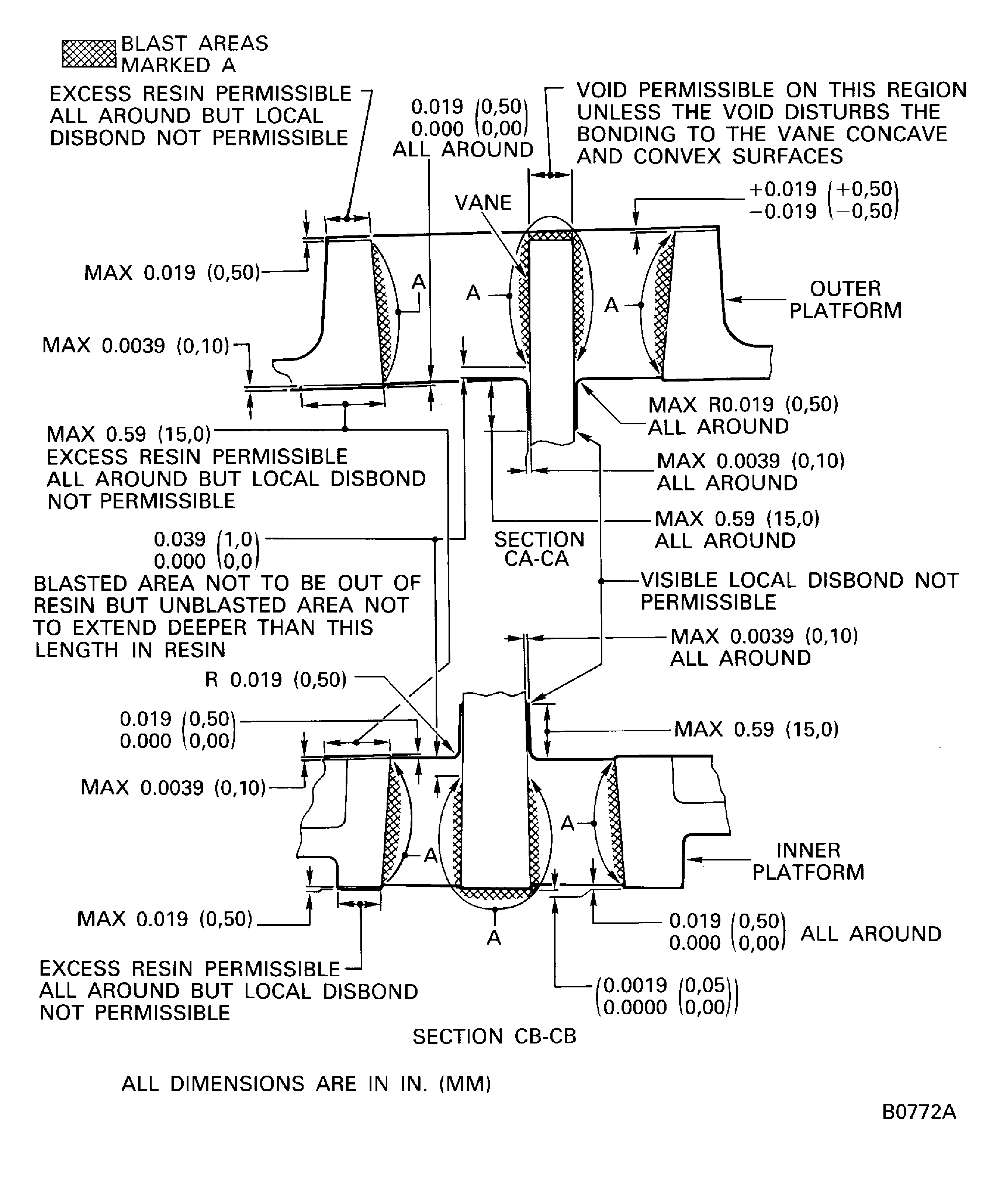

Figure: Repair details and dimensions - Assembly A and C

Repair details and dimensions - Assembly A and C

Figure: Repair details and dimensions - Assmebly A

Repair details and dimensions - Assmebly A

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

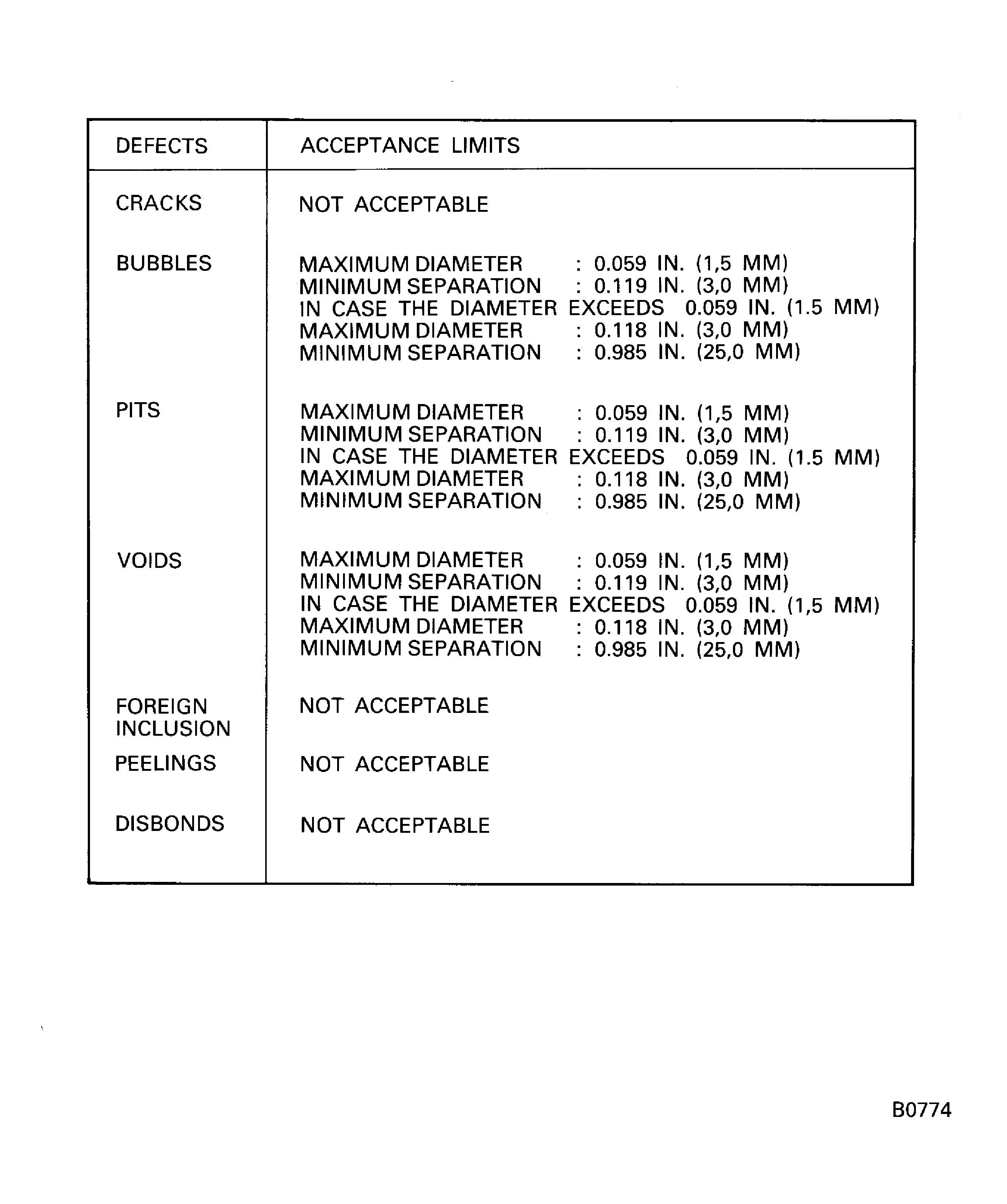

Figure: Acceptance limits for visual inspection

Acceptance limits for visual inspection

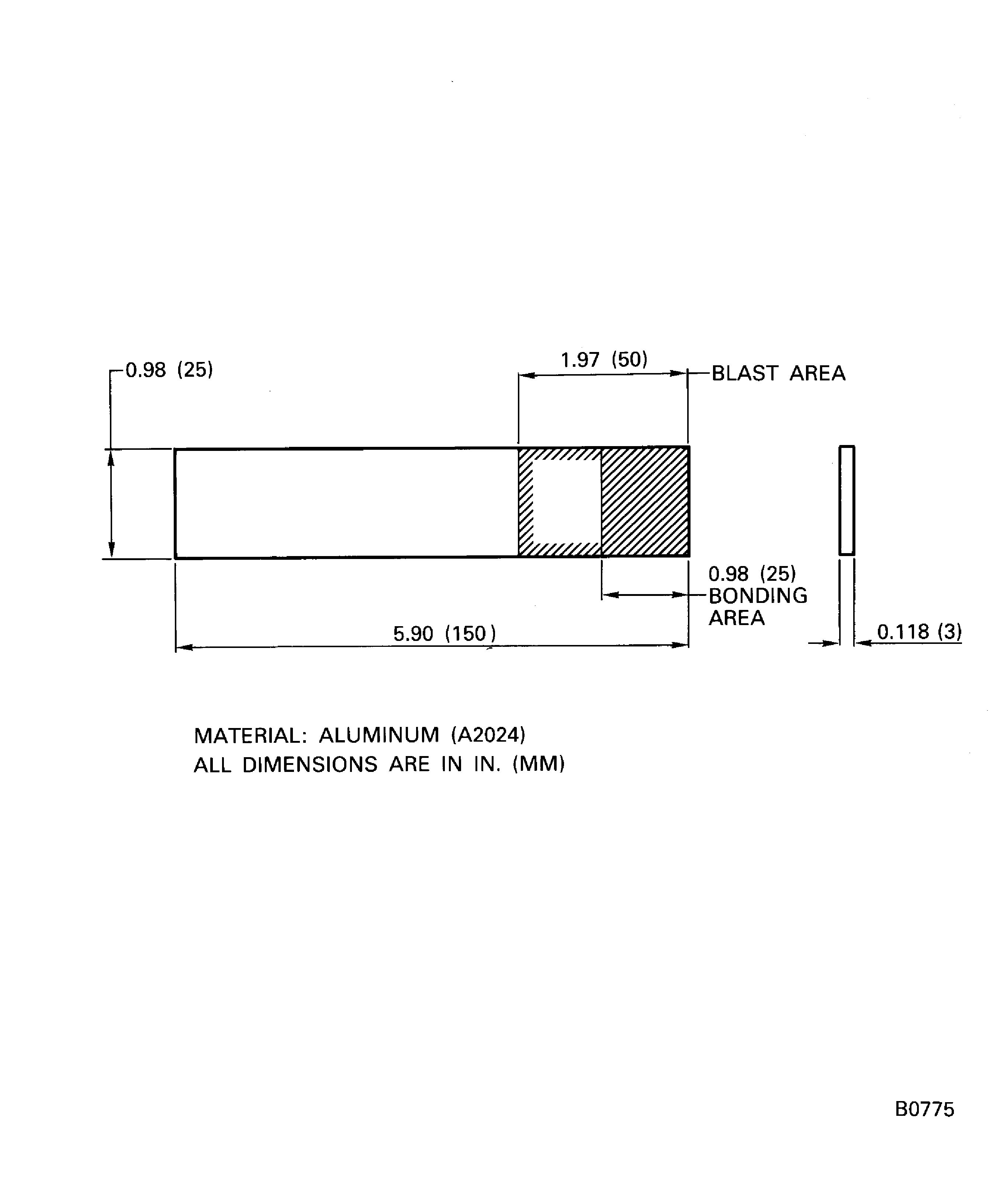

Figure: Test piece details and dimensions

Test piece details and dimensions

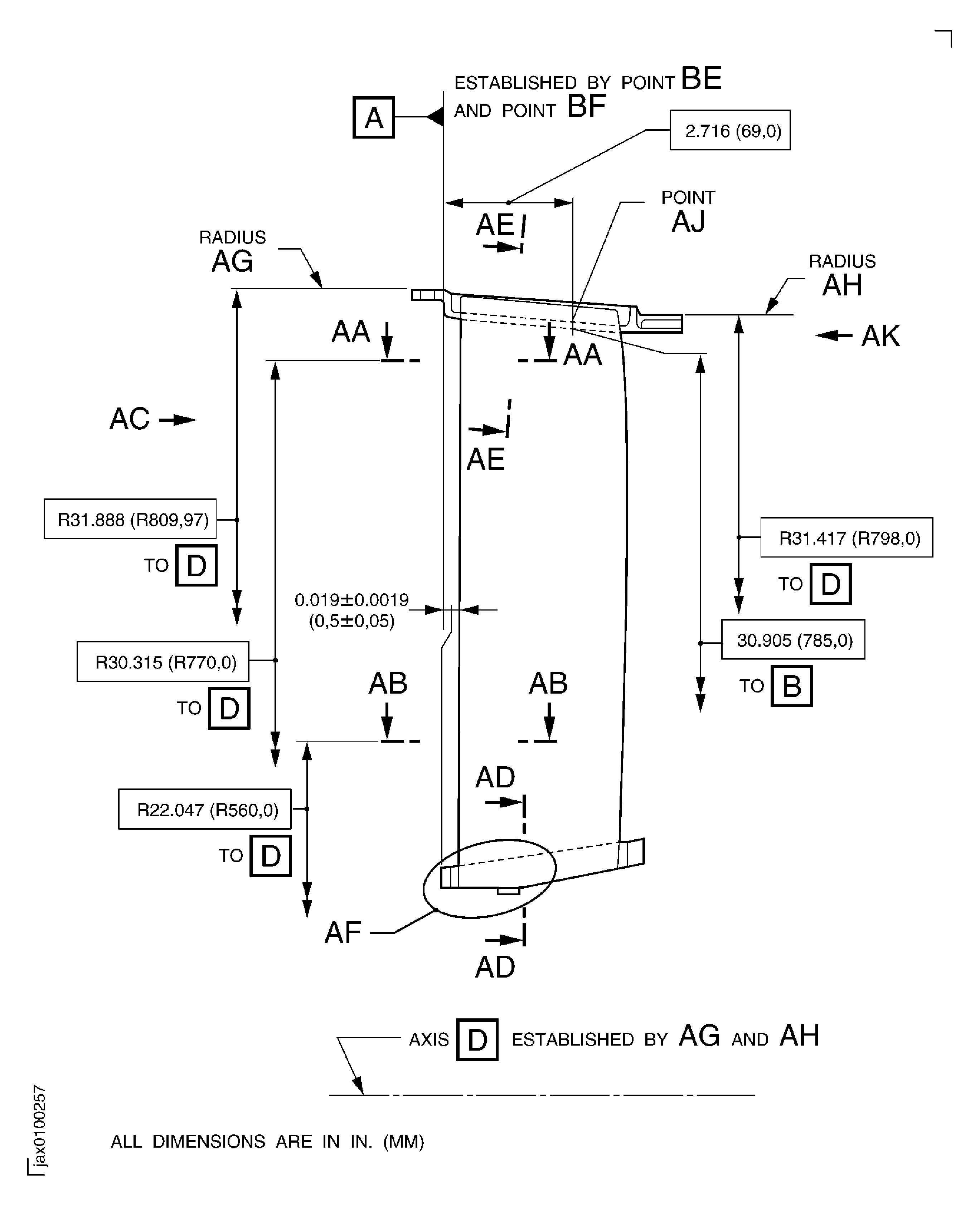

Figure: Repair details and dimensions - Assembly B

Sheet 1

Figure: Repair details and dimensions - Assembly B

Sheet 2

Figure: Repair details and dimensions - Assembly B

Sheet 3

Figure: Repair details and dimensions - Assembly B

Sheet 4

Figure: Repair details and dimensions - Assembly B

Sheet 5

Figure: Repair details and dimensions - Assembly B

Sheet 6

Figure: Repair details and dimensions - Assembly B

Sheet 7

Figure: Repair details and dimensions - Assembly B

Sheet 8