Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-91-300-005 LPC Inlet Guide Vane (Stator) - Replace The Vane, Repair-005 (VRS1444)

Material of component

DESCRIPTION | SYMBOL | MATERIAL |

|---|---|---|

Inlet guide vane assembly | Vane: Titanium alloy | |

Inner ring: Aluminium alloy |

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Plastic chisel type tool | LOCAL | Plastic chisel type tool | ||

| Injector | LOCAL | Injector | (air pressure type) | |

| Vacuum cleaner | LOCAL | Vacuum cleaner | ||

| IAE 3J12132 Molding fixture | 0AM53 | IAE 3J12132 | 1 | |

| IAE 3J12759 Molding fixture | 0AM53 | IAE 3J12759 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-005 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-005 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 05-121 SILICON CARBIDE GRIT | IAE72 | CoMat 05-121 | ||

| CoMat 05-122 SILICON CARBIDE GRIT | IAE72 | CoMat 05-122 | ||

| CoMat 05-123 SILICON CARBIDE GRIT | IAE72 | CoMat 05-123 | ||

| CoMat 05-124 SILICON CARBIDE GRIT | IAE72 | CoMat 05-124 | ||

| CoMat 08-032 PRIMER | LOCAL | CoMat 08-032 | ||

| CoMat 08-036 SILICONE RUBBER COMPOUND | LOCAL | CoMat 08-036 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Vane, STG 1 LPC A | 5A0061 | 46 | ||

| Vane, STG 1 LPC A | 5A0180 | 46 | ||

| Vane, STG 1 LPC A | 5A7382 | 46 | ||

| Vane, STG 1 LPC B | 5A0064 | 46 | ||

| Vane, STG 1 LPC B | 5A0181 | 46 | ||

| Vane, STG 1 LPC B | 5A7385 | 46 |

Safety Requirements

NONEProcedure

Refer to Figure.

NOTE

If it is necessary to replace the abradable airseal silicone rubber on the inner ring, remove the rubber after the vanes have been removed. The new rubber should be installed and cured after the new vanes have been installed and bonded. Refer to VRS 1437 (TASK 72-32-91-300-008) (REPAIR-008).NOTE

If it is not necessary to repair the rubber, install a shield to prevent damage to the rubber during this repair.Remove the molding compound to break the connection between the vane and the inner ring. Remove the identified vane from the inner ring.

SUBTASK 72-32-91-360-056 Remove the Identified Vane

Use CoMat 05-121 SILICON CARBIDE GRIT Refer to the SPM TASK 70-36-04-360-501.

Dry abrasive blast the molding areas.

SUBTASK 72-32-91-120-052 Abrasive Blast the Surface for Repair

Refer to the SPM TASK 70-36-04-360-501.

Clean the blasted surface of the vane and the inner ring.

Refer to the SPM TASK 70-36-04-360-501.

NOTE

When it has been cleaned the component must not be touched by hand and must be covered with kraft paper to prevent contamination.Air dry for a minimum of 15 minutes.

SUBTASK 72-32-91-110-056 Clean the Blasted Surface

Refer to the SPM TASK 70-36-04-360-501.

Use CoMat 08-032 PRIMER.

Apply the primer to the surfaces that have been cleaned.

SUBTASK 72-32-91-360-057 Apply Primer to the Mold Area

Use CoMat 08-036 SILICONE RUBBER COMPOUND. Refer to the SPM TASK 70-36-04-360-501.

Mix the silicone rubber compound.

Refer to the SPM TASK 70-36-04-360-501.

Remove the gas from the mixture.

SUBTASK 72-32-91-360-058 Make up the Silicone Rubber Compound

Use IAE 3J12132 Molding fixture 1 off or IAE 3J12759 Molding fixture 1 off.

Install the molding fixture to the mold area.

Refer to the SPM TASK 70-36-04-360-501.

Use an air pressure type injector.

Put the mixture into the mold area.

Refer to the SPM TASK 70-36-04-360-501.

Cure the silicone rubber compound.

SUBTASK 72-32-91-360-059 Put the Silicone Rubber Compound into the Mold Area

Refer to the SPM TASK 70-36-04-360-501.

Visually examine the repaired area.

SUBTASK 72-32-91-220-081 Examine the Repaired Area

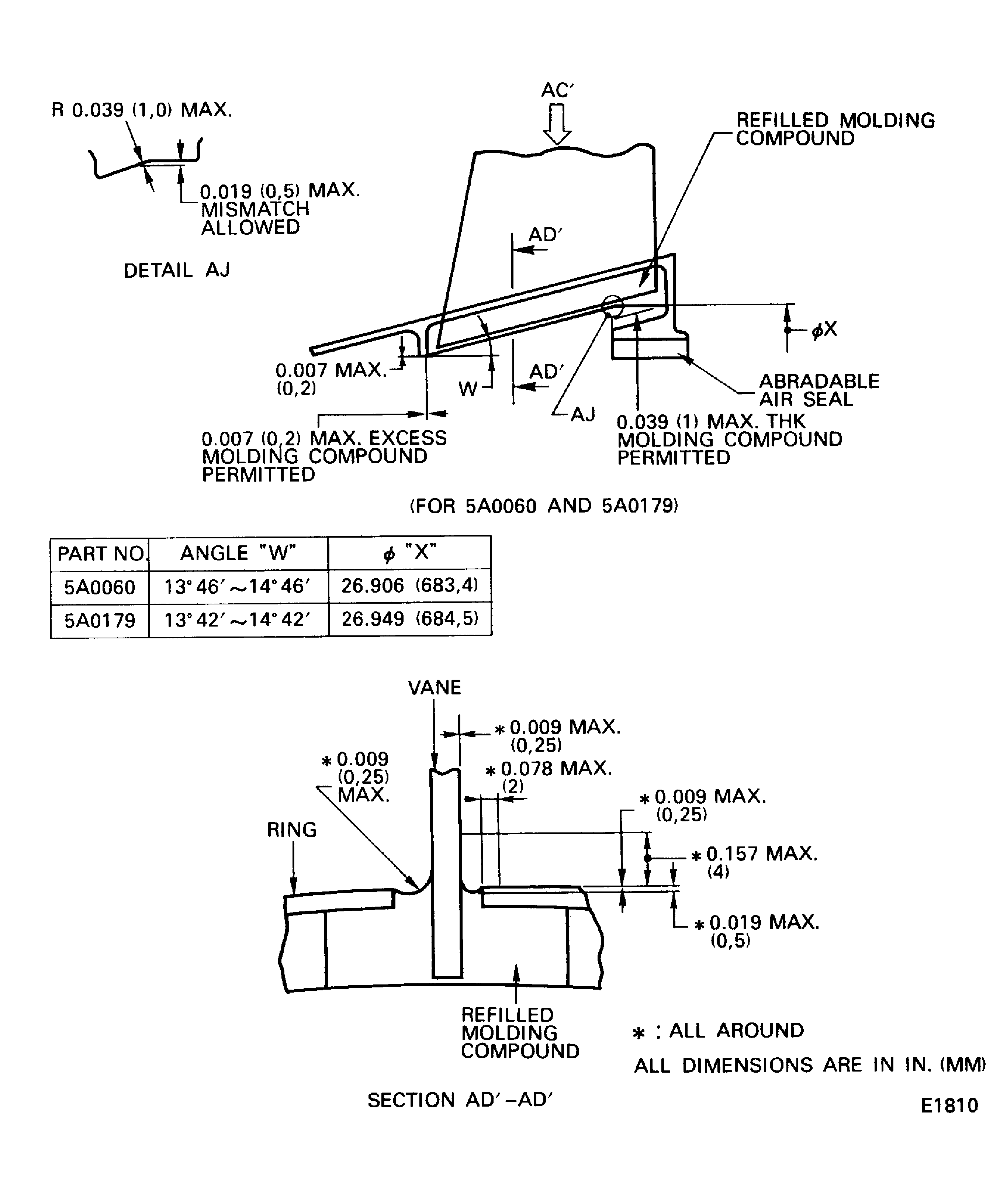

Figure: Repair Details and Dimensions

Sheet 1

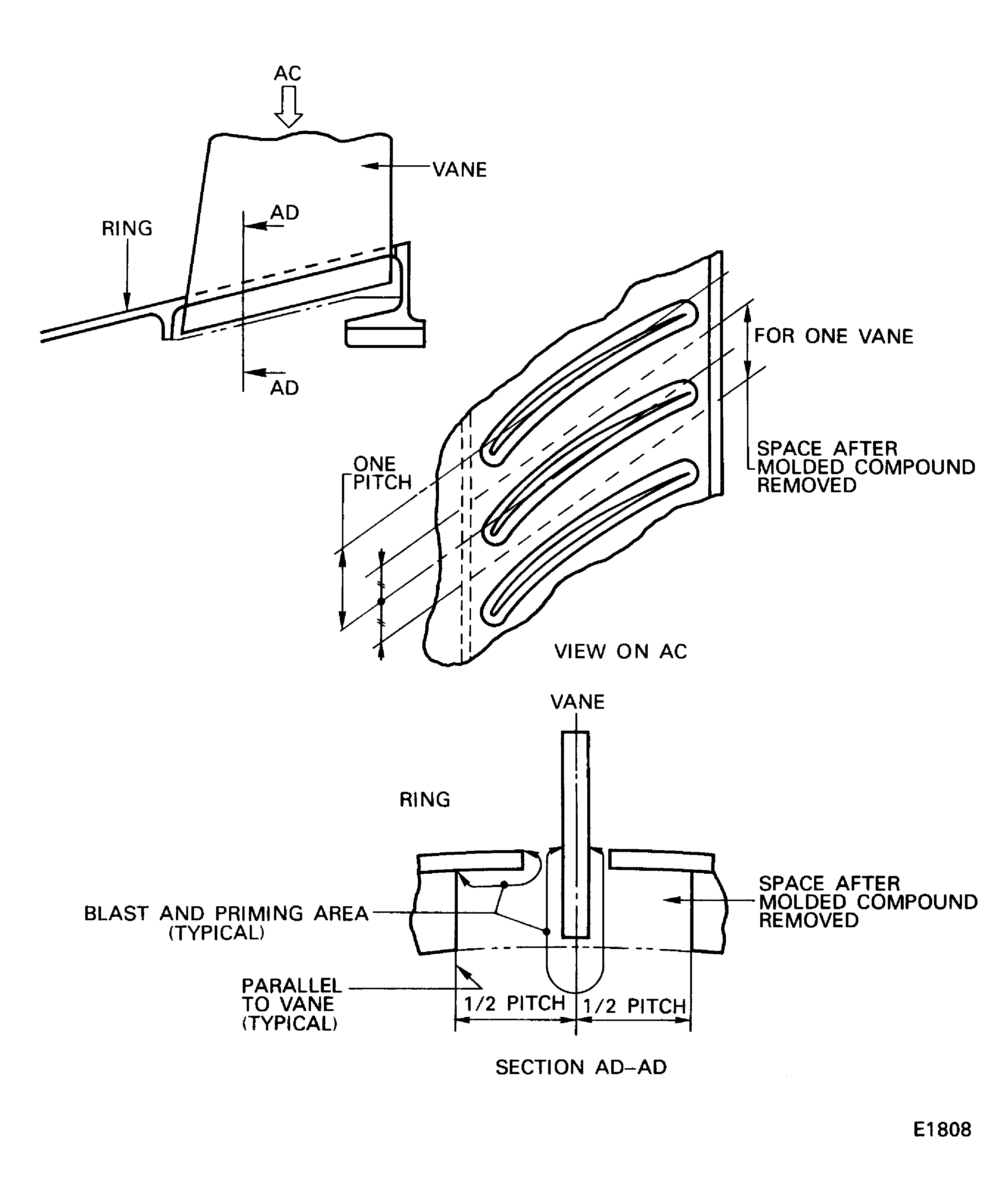

Figure: Repair Details and Dimensions

Sheet 2

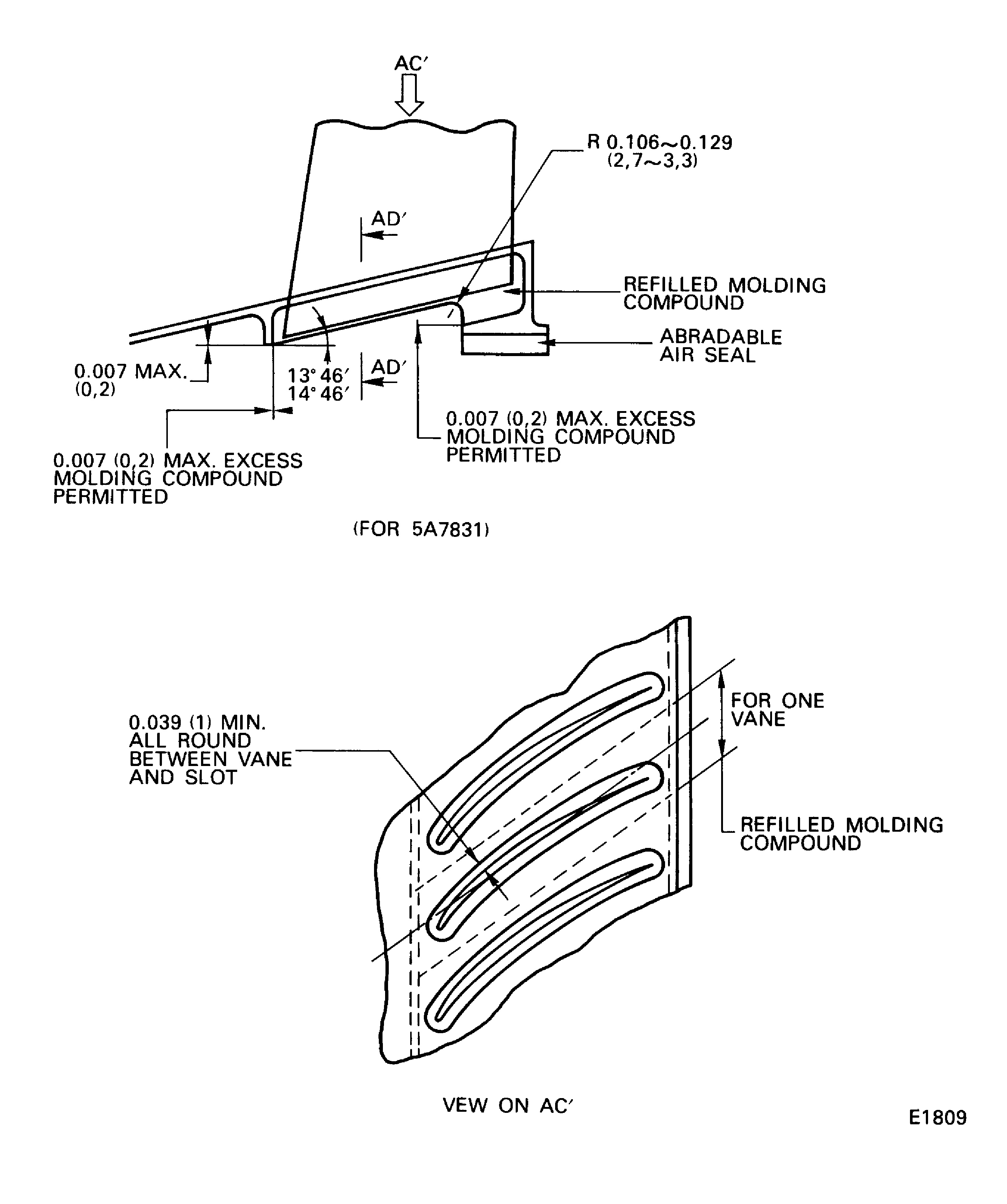

Figure: Repair Details and Dimensions

Sheet 3