Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-91-300-014 LPC Inlet Guide Vane (Stator) - Replace The Vane, Repair-014 (VRS1433)

General

This Repair TASK gives the procedure for replacement of the LPC inlet guide vane.

Material of component

PART IDENT | IAE SYMBOL | MATERIAL |

|---|---|---|

LPC inlet guide vane assembly | Vane: Titanium alloy Inner ring: Aluminum alloy |

Price and availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Plastic chisel type tool | LOCAL | Plastic chisel type tool | ||

| Vacuum cleaner | LOCAL | Vacuum cleaner | ||

| Spatula | LOCAL | Spatula | ||

| Mass weighing scale | LOCAL | Mass weighing scale | ||

| Vacuum pump | LOCAL | Vacuum pump | ||

| Injector | LOCAL | Injector | (Air pressure type) | |

| IAE 3J12818 Molding fixture | 0AM53 | IAE 3J12818 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-005 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-005 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 05-121 SILICON CARBIDE GRIT | IAE72 | CoMat 05-121 | ||

| CoMat 05-122 SILICON CARBIDE GRIT | IAE72 | CoMat 05-122 | ||

| CoMat 05-123 SILICON CARBIDE GRIT | IAE72 | CoMat 05-123 | ||

| CoMat 05-124 SILICON CARBIDE GRIT | IAE72 | CoMat 05-124 | ||

| CoMat 08-032 PRIMER | LOCAL | CoMat 08-032 | ||

| CoMat 08-036 SILICONE RUBBER COMPOUND | LOCAL | CoMat 08-036 | ||

| CoMat 08-042 SILICONE RUBBER COMPOUND | IAE55 | CoMat 08-042 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Vane, STG. 1.0 LPC Type A | 5A0180 | 46 A/R | ||

| Vane, STG. 1.0 LPC Type B | 5A0181 | 46 A/R |

Safety Requirements

NONEProcedure

Refer to Figure.

NOTE

If it is necessary to replace the abradable seal rubber on the inner ring, remove the rubber after the vanes have been removed. The new rubber should be put back and cured after the new vanes have been attached and bonded.Refer to VRS1437 (TASK 72-32-91-300-008) (REPAIR-008).NOTE

If it is not necessary to repair the rubber, put on a shield to prevent damage to the rubber during this repair.Remove the remaining molding rubber from the removed vane if the vane is serviceable.

SUBTASK 72-32-91-350-063 Remove the Damaged Vane

Refer to Figure.

SUBTASK 72-32-91-120-055 Abrasive Blast for the Bonding Area

Refer to Figure.

SUBTASK 72-32-91-110-060 Clean the Blasted Area

Refer to Figure.

The primer must be applied to the metal surface only.

Refer to the SPM TASK 70-36-04-360-501.

Use CoMat 08-032 PRIMER.

CAUTION

THE PRIMER MUST NOT BE APPLIED TO THE SILICONE RUBBER.NOTE

Let the primer dry at a room temperature of 77 deg F (25 deg C) for 2 hours minimum, 24 hours maximum at a moisture level equivalent to 50 percent minimum relative humidity.NOTE

Parts must have the silicone rubber compound applied within 24 hours of completion of primer application.Apply the primer to the bonding area.

SUBTASK 72-32-91-360-073 Apply the Primer to the Bonding Area

Use CoMat 08-042 SILICONE RUBBER COMPOUND, a clean spatula and a mass weighing scale.

Mix 9.5 to 10.5 parts by weight of the base material with 0.8 to 1.2 parts by weight of the curing agent in 8 to 10 minutes at 70 to 80 deg F (21 to 27 deg C) until the material is a constant colour.

SUBTASK 72-32-91-360-074 Make-Up of CoMat 08-042 Silicone Rubber Compound

Refer to Figure.

Use IAE 3J12818 Molding fixture 1 off.

Set up the mold with the molding fixture and install the new or serviceable vane in position.

SUBTASK 72-32-91-360-075 Mold CoMat 08-042 Silicone Rubber Compound

Refer to the SPM TASK 70-36-04-360-501.

Mix the base material and the curing agent.

Refer to the SPM TASK 70-36-04-360-501.

Remove all the air from the mixture.

SUBTASK 72-32-91-360-076 Make-Up of CoMat 08-036 Silicone Rubber Compound

Refer to Figure.

Refer to the SPM TASK 70-36-04-360-501.

Cure the silicone rubber compound.

SUBTASK 72-32-91-360-077 Mold CoMat 08-036 Silicone Rubber Compound

Refer to Figure.

SUBTASK 72-32-91-220-086 Examine the Repaired Areas

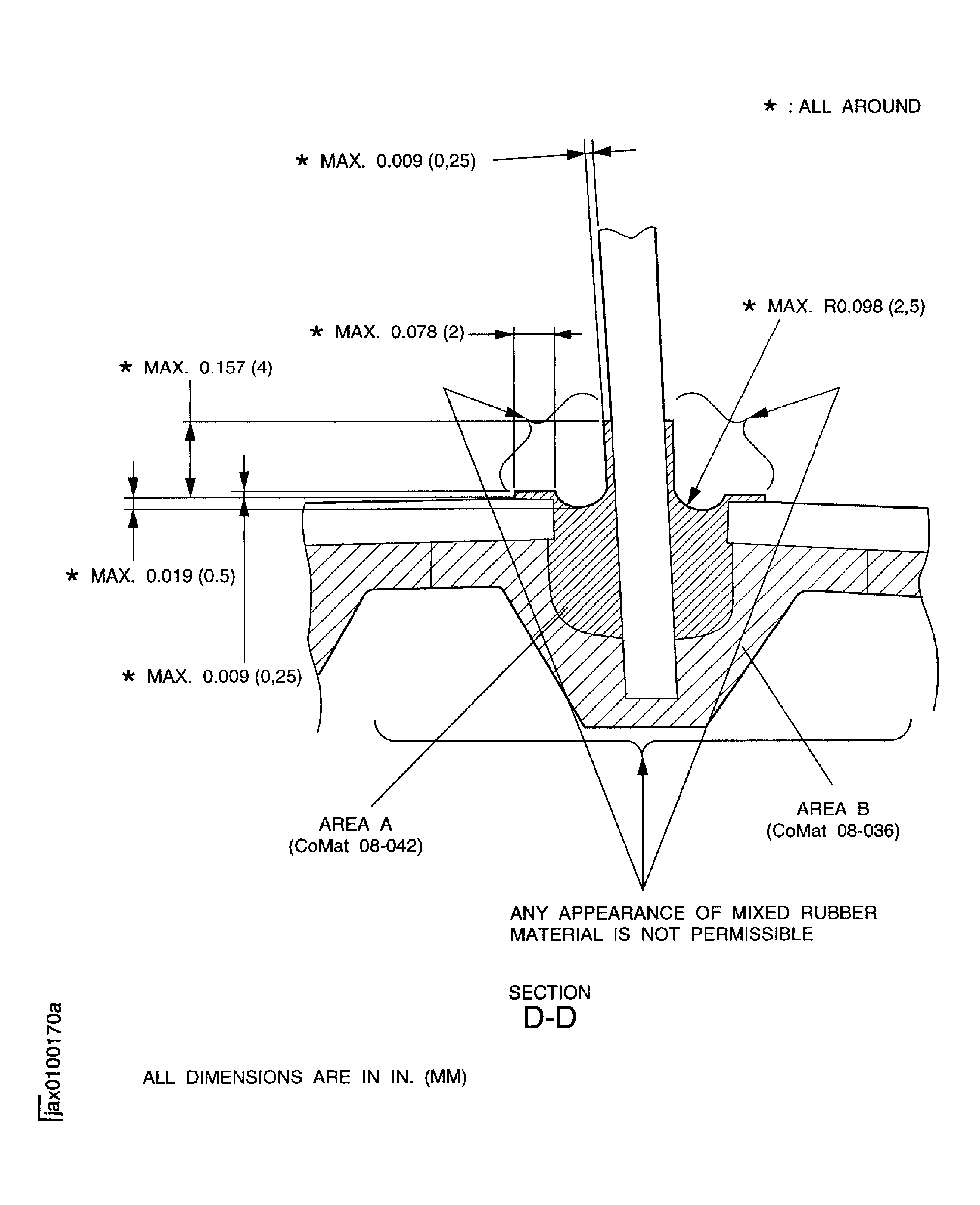

Figure: Replace the stator vane of LPC inlet guide vane assenbly

Sheet 1

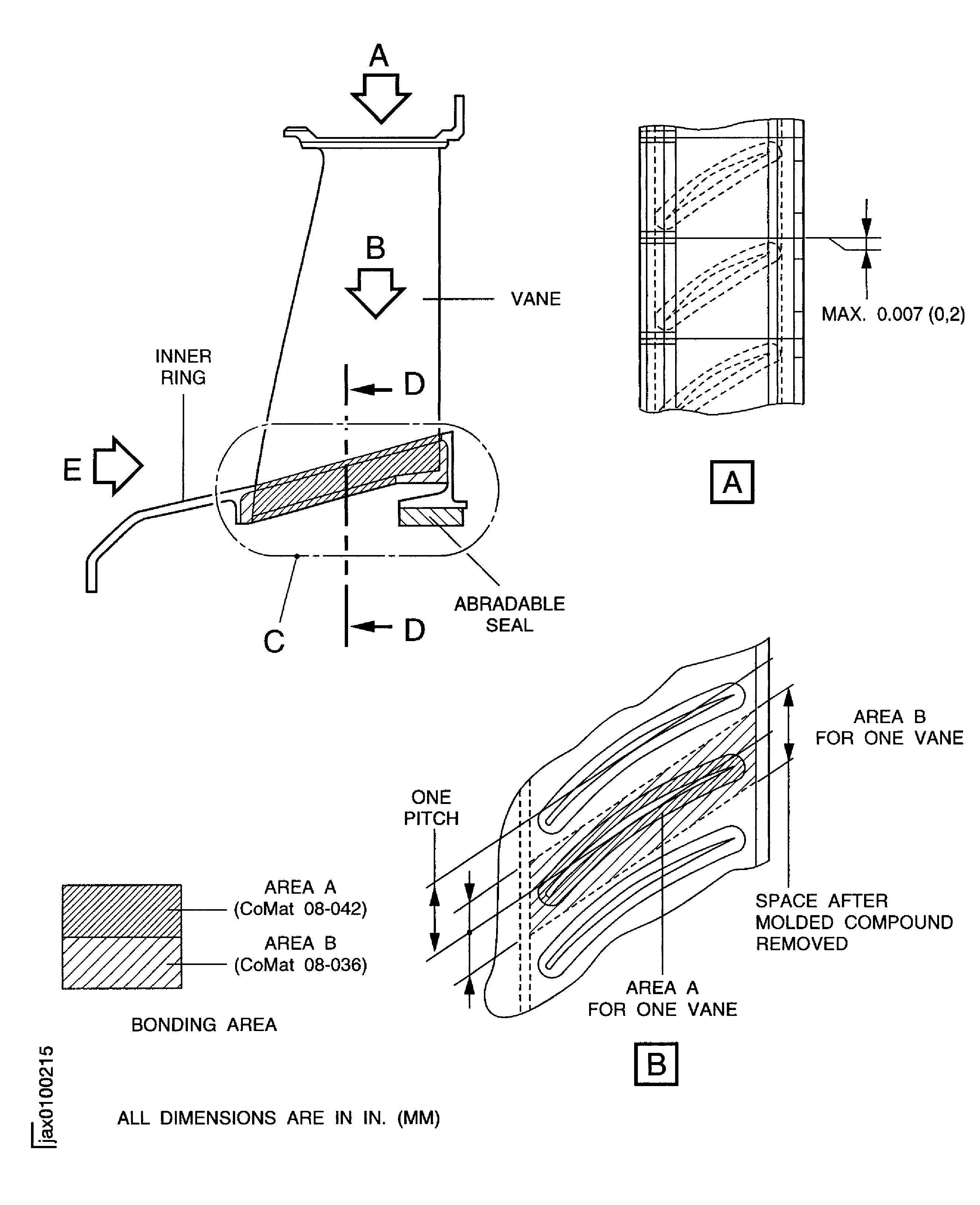

Figure: Replace the stator vane of LPC inlet guide vane assembly

Sheet 2

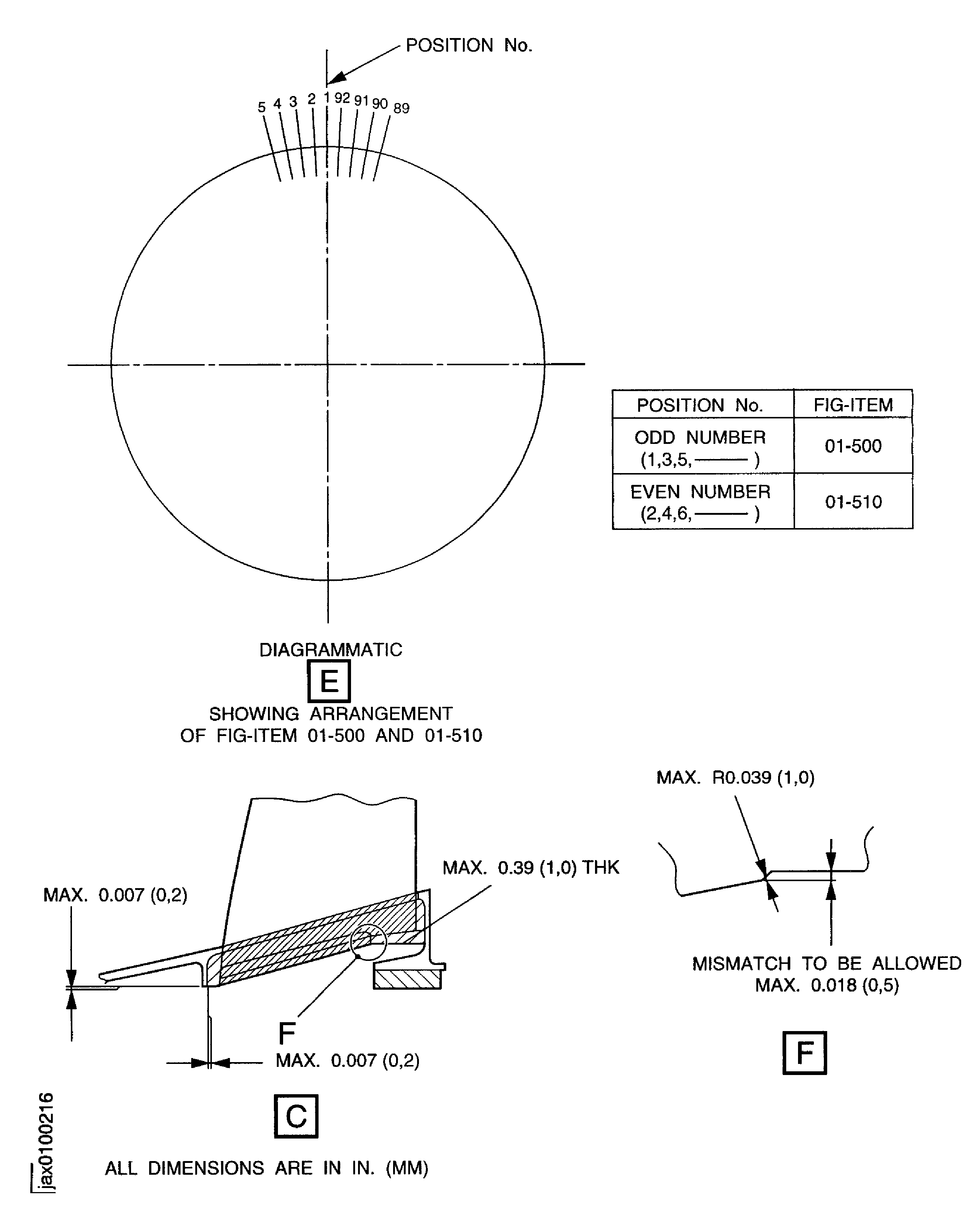

Figure: Replace the stator vane of LPC inlet guide vane assembly

Sheet 3