Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-93-300-003 Intermediate Structure Front Fairing - Repair The Unbond, Repair-003 (VRS1447)

General

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

All adhesive application and bonding operations shall be done in controlled environment rooms that are designated for non-silicon materials

This repair gives two alternative procedures for adhesive process.

Price and availability - none

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Abrasive blast equipment | LOCAL | Abrasive blast equipment | ||

| Oven | LOCAL | Oven | ||

| Tensile tester | LOCAL | Tensile tester | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| IAE 3J12765 Bonding fixture | 0AM53 | IAE 3J12765 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 01-060 ACETONE (CH3)2CO | LOCAL | CoMat 01-060 | ||

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 01-201 DISTILLED, DEIONIZED, DEMINERALIZED, OR REVERSE OSMOSIS (RO) WATER | LOCAL | CoMat 01-201 | ||

| CoMat 01-275 CHROMATE CONVERSION COATING FOR ALUMINIUM | LOCAL | CoMat 01-275 | ||

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE | LOCAL | CoMat 05-003 | ||

| CoMat 05-016 GARNET PAPER, 80-GRIT | LOCAL | CoMat 05-016 | ||

| CoMat 05-017 GARNET PAPER, 60 GRIT | LOCAL | CoMat 05-017 | ||

| CoMat 06-021 SURFACE INSPECTION FLUID | LOCAL | CoMat 06-021 | ||

| CoMat 08-013 COLD CURING SILICONE COMPOUND | LOCAL | CoMat 08-013 | ||

| CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT | 0AM53 | CoMat 08-014 | ||

| CoMat 08-015 RESIN | LOCAL | CoMat 08-015 | ||

| CoMat 08-016 HARDENER | LOCAL | CoMat 08-016 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

SUBTASK 72-32-93-360-054 Remove the Damaged Stiffeners or Edge Plate for Bond Repair

Refer to Figure.

SUBTASK 72-32-93-360-055 Remove Adhesive Residue

Refer to the SPM TASK 70-11-26-300-503.

Remove the grease from the bonding surfaces.

Refer to the SPM TASK 70-12-02-120-501.

Use an air pressure of 43 to 57 psi (297 to 393 Kpa) for the minimum time necessary to clean the parts.

Dry abrasive blast the bonding surfaces.

Do Step again.

Refer to the SPM TASK 70-36-02-360-501 and SUBTASK 70-36-02-360-010.

Do a water break test to make sure that the bonding surfaces are clean.

SUBTASK 72-32-93-360-057 Prepare the Surfaces of the Front or Rear Stiffeners and the Edge Plate for Bonding

CAUTION

AFTER PREPARATION, THE MATING SURFACES MUST BE FULLY CLEANED AND MUST NOT BE TOUCHED BY HAND, TO PREVENT CONTAMINATION.Refer to Figure.

Refer to the SPM TASK 70-12-02-120-501.

Use an air pressure of 43 to 57 psi (297 to 393 Kpa) for the minimum time necessary to clean the part.

Dry abrasive blast the bonding surfaces.

Do Step again.

Refer to the SPM TASK 70-36-02-360-501 and SUBTASK 70-36-02-360-011.

Do a water break test to make sure that the bonding surfaces are clean.

SUBTASK 72-32-93-360-058 Prepare the Surface of the CFRP Fairing for Bonding

Use CoMat 08-015 RESIN and CoMat 08-016 HARDENER.

Refer to the SPM TASK 70-36-02-360-501 and SUBTASK 70-36-02-360-021.

CAUTION

YOU MUST USE PLASTIC GLOVES, DURING THE PREPARATION AND USE OF THE ADHESIVE TO PREVENT CONTAMINATION OF THE SKIN.

CAUTION

YOU MUST NOT EAT ANYTHING OR SMOKE AT THE LOCATIONS WHERE THESE MATERIALS ARE USED.NOTE

This SUBTASK is an alternative to Step.Make up the adhesive from the two parts.

Use IAE 3J12765 Bonding fixture 1 off.

Assemble the CFRP fairing front or rear stiffener and the edge plate on the bonding fixture and apply pressure.

SUBTASK 72-32-93-360-059 Apply and Cure the Two Part Low Temperature Curing Sealant/Adhesive

Refer to the SPM TASK 70-36-02-360-501 and SPM SUBTASK 70-36-02-360-020.

CAUTION

YOU MUST USE PLASTIC GLOVES, DURING THE PREPARATION AND USE OF THE ADHESIVE TO PREVENT CONTAMINATION OF THE SKIN.

CAUTION

YOU MUST NOT EAT ANYTHING OR SMOKE AT THE LOCATIONS WHERE THESE MATERIALS ARE USED.NOTE

This SUBTASK is an alternative to Step.NOTE

The primer must be applied immediately after the mating surfaces are prepared. It is cured at room temperature by touching to moisten in air.If the parts are not used immediately, after the primer is applied, they must be kept in polythene bags; but for no longer than 24 hours.Apply a thin layer of primer only to the mating surface of the stiffener, edge plate and CFRP fairing. Dry in air for 30 minutes.

Refer to the SPM TASK 70-36-02-360-501 and SPM SUBTASK 70-36-02-360-020.

Use a spatula and CoMat 08-013 COLD CURING SILICONE COMPOUND.

Apply cold curing silicone rubber compound to each of the mating surface of the stiffener, edge plate and CFRP fairing.

Use IAE 3J12765 Bonding fixture 1 off.

Assemble the CFRP fairing front or rear stiffener and the edge plate on the bonding fixture and apply pressure.

SUBTASK 72-32-93-360-063 Apply and Cure the Cold Curing Silicone Rubber Compound

Refer to the SPM TASK 70-38-02-300-503.

Apply the chromate conversion coating to the marked repair number.

SUBTASK 72-32-93-350-053 Make a Mark on the Front Fairing Assembly

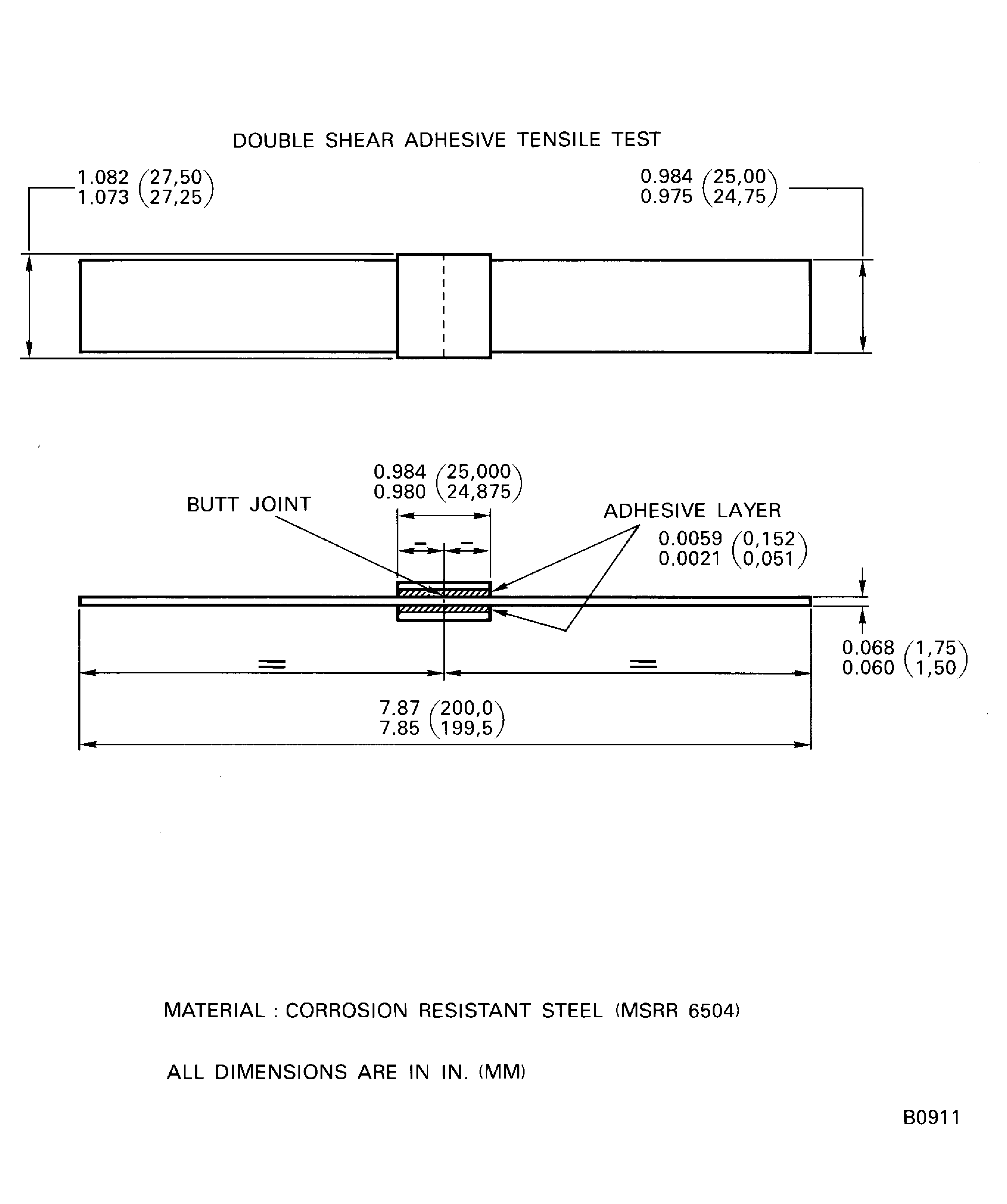

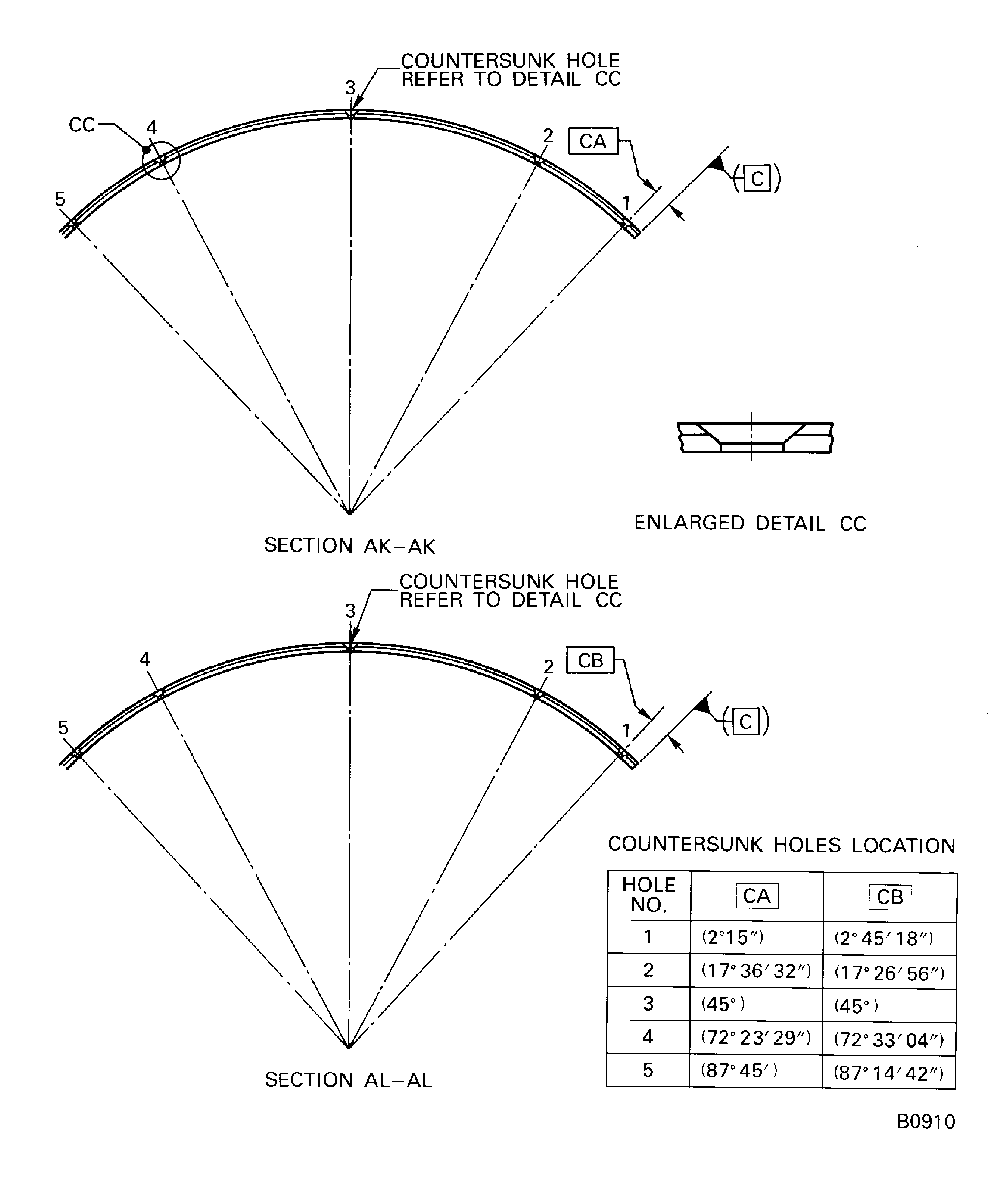

Figure: Repair details and dimensions

Repair details and dimensions

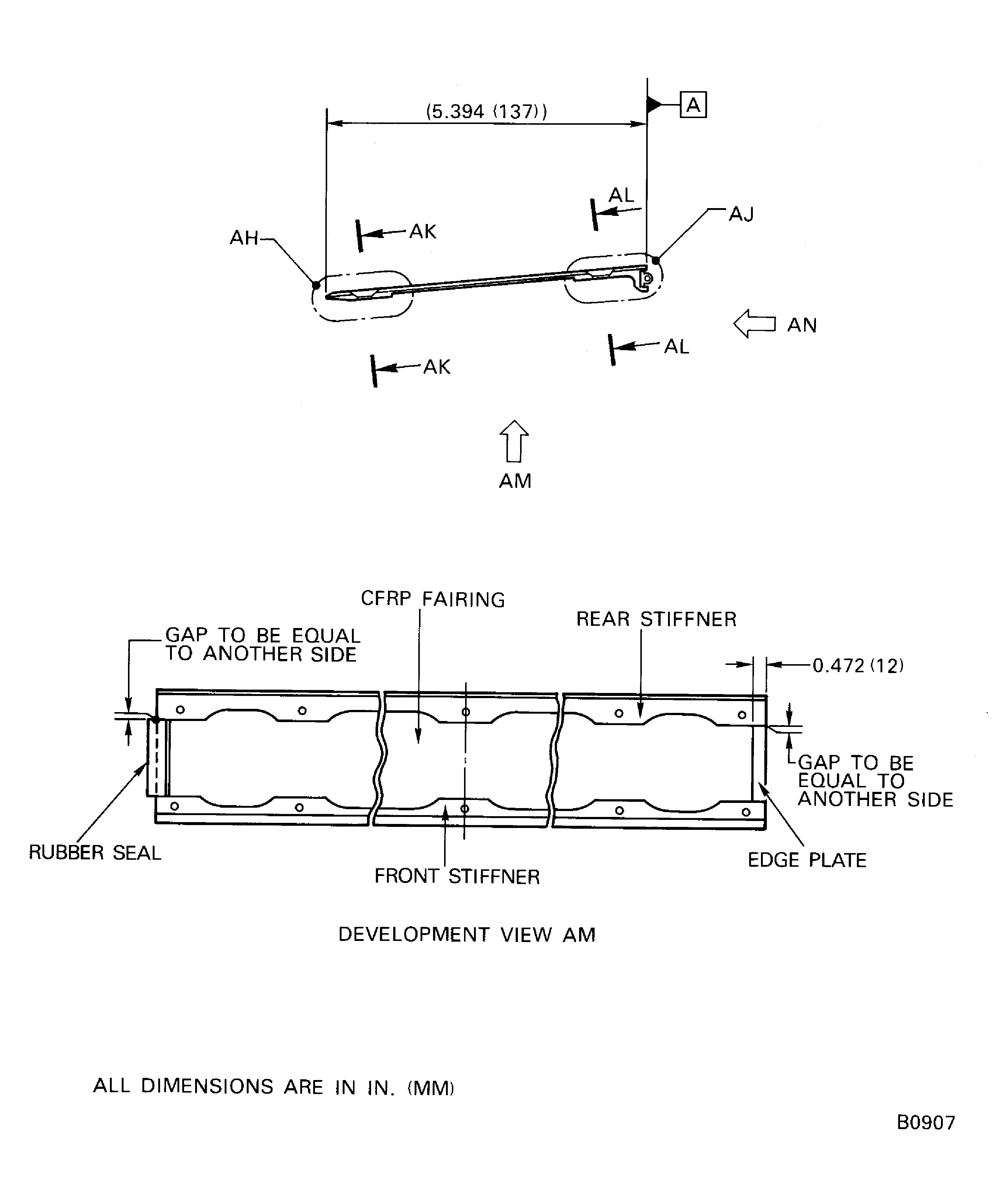

Figure: Repair details and dimensions

Repair details and dimensions

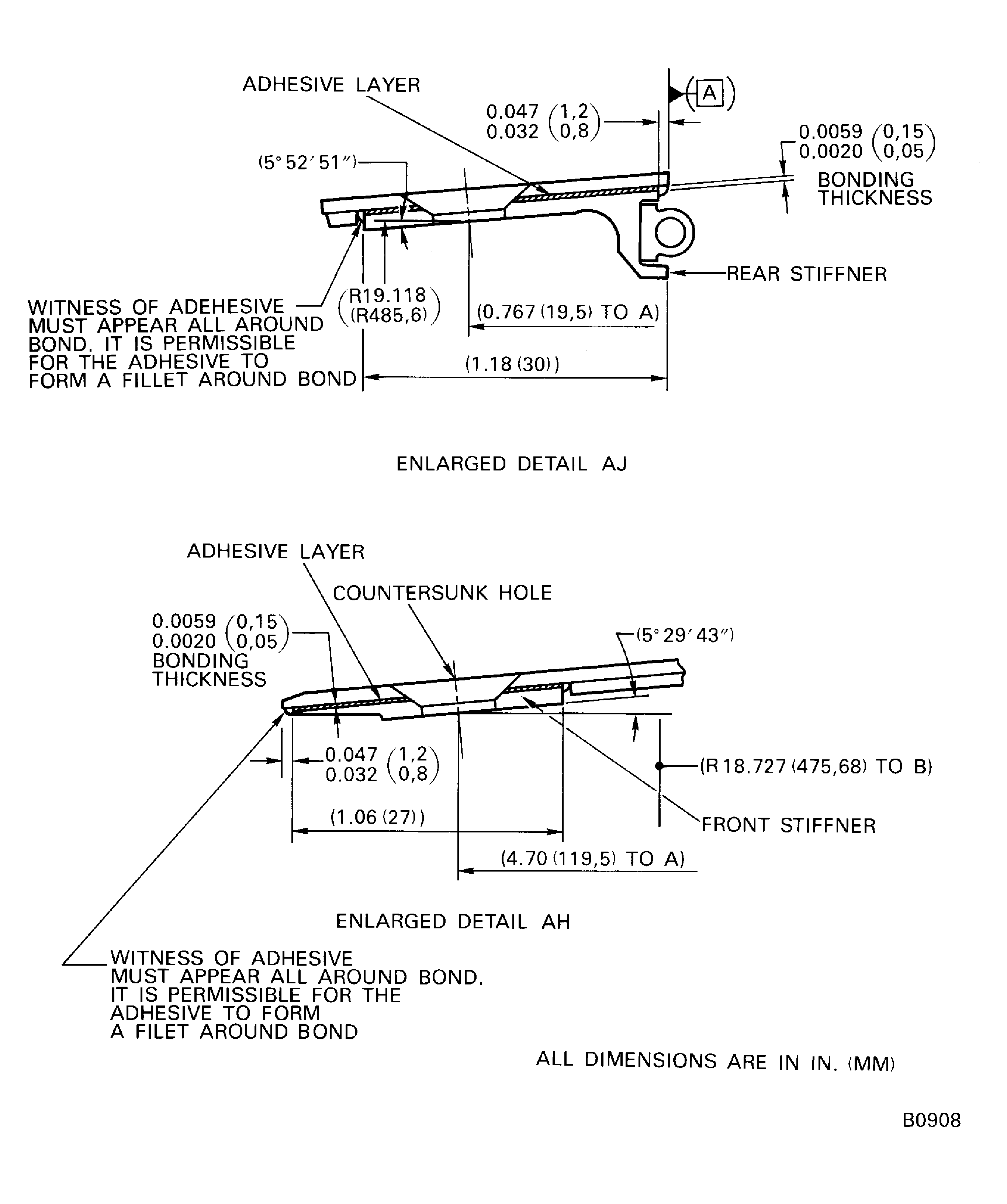

Figure: Repair details and dimensions

Repair details and dimensions

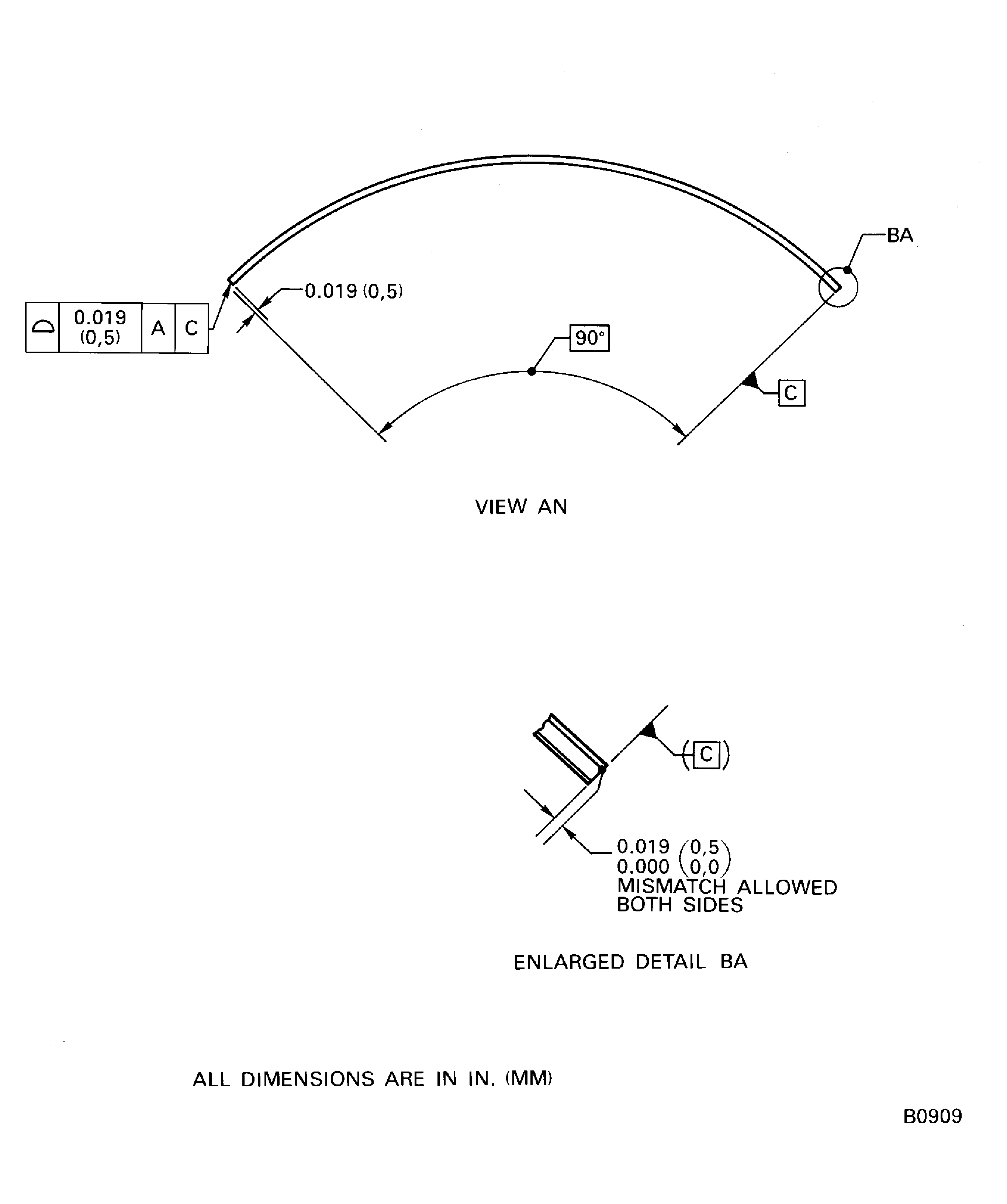

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions