Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-38-11-300-010 Inlet Cone Assembly - Replace The Spiral Marking Paint, Repair-010 (VRS1458)

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

Inlet cone | Fiber-reinforced plastic with polyurethane coating |

General

Price and availability - none

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Spray gun | LOCAL | Spray gun | ||

| Spray booth | LOCAL | Spray booth | ||

| Oven | LOCAL | Oven | ||

| Abrasive Blast Equipment | LOCAL | Abrasive Blast Equipment | ||

| IAE 3J12783 Masking fixture | 0AM53 | IAE 3J12783 | 1 | |

| IAE 3J12786 Scribe fixture | 0AM53 | IAE 3J12786 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-040 COLD PAINT STRIPPER | K6835 | CoMat 01-040 | ||

| CoMat 01-076 METHYL ETHYL KETONE | LOCAL | CoMat 01-076 | ||

| CoMat 01-082 SODIUM SULPHATE Na2SO4ANHYDROUS | LOCAL | CoMat 01-082 | ||

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 02-005 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-005 | ||

| CoMat 02-099 LINT-FREE CLOTH | X222X | CoMat 02-099 | ||

| CoMat 05-019 WATERPROOF SILICON CARBIDE | 1E1X8 | CoMat 05-019 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-025 ALUMINUM OXIDE ABRASIVEGRIT (50 MICRON) | 0KZS2 | CoMat 05-025 | ||

| CoMat 07-080 TWO-PACK EPOXY PRIMER AND CATALYST | 5HCF1 | CoMat 07-080 | ||

| CoMat 07-082 THINNER | 5HCF1 | CoMat 07-082 | ||

| CoMat 07-117 EPOXY MATT FINISH-BLACK | K2096 | CoMat 07-117 | ||

| CoMat 07-118 CATALYST (FOR GLOSS FINISH) | K2096 | CoMat 07-118 | ||

| CoMat 07-119 EPOXY GLOSS FINISH-WHITE | K2096 | CoMat 07-119 | ||

| CoMat 07-120 CATALYST (FOR MATT FINISH) | K2096 | CoMat 07-120 | ||

| CoMat 08-077 CURING AGENT | LOCAL | CoMat 08-077 | ||

| CoMat 08-069 RESIN | LOCAL | CoMat 08-069 | ||

| CoMat 07-081 EPOXY PRIMER CATALYST | 0AM53 | CoMat 07-081 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Repair, VRS1462, TASK 72-38-11-300-002 (REPAIR-002).

Remove the inlet cone tip.

SUBTASK 72-38-11-330-056 Remove the Inlet Cone Tip from the Inlet Cone Assembly

SUBTASK 72-38-11-120-051 Remove the Epoxy Paint, Assembly A and Assembly B

CAUTION

DO NOT ABRASIVE BLAST ON THE SAME AREA FOR MORE THAN TWO SECONDS.

CAUTION

WHEN REMOVING THE COATING MAKE SURE THAT THE PARENT FIBER CLOTH MATERIAL IS NOT EXPOSED. THIS REPAIR CANNOT BE DONE IF THE PARENT FIBER CLOTH MATERIAL IS EXPOSED.NOTE

This SUBTASK is an alternative to Step.Mask the area which does not require painting.

Use CoMat 05-025 ALUMINUM OXIDE ABRASIVEGRIT (50 MICRON). Use abrasive blast equipment.

Abrasive blast the epoxy paint between point AA and point AC at an air pressure of 28.5 to 35.5 psi (196 to 245 kPa) and a distance of 7.9 in. (200 mm) minimum between the part and the blast nozzle.

SUBTASK 72-38-11-120-052-A00 Remove the Epoxy Paint, Assembly A

CAUTION

DO NOT ABRASIVE BLAST ON THE SAME AREA FOR MORE THAN TWO SECONDS.

CAUTION

WHEN REMOVING THE COATING MAKE SURE THAT THE PARENT FIBER CLOTH MATERIAL IS NOT EXPOSED. THIS REPAIR CANNOT BE DONE IF THE PARENT FIBER CLOTH MATERIAL IS EXPOSED.NOTE

This SUBTASK is an alternative to Step.Mask the area which does not require painting.

SUBTASK 72-38-11-120-052-B00 Remove the Black Epoxy Paint, Assembly B

Use CoMat 07-080 TWO-PACK EPOXY PRIMER AND CATALYST and CoMat 07-081 EPOXY PRIMER CATALYST in equal parts.

Mix the primer base and the catalyst.

NOTE

If necessary, the CoMat 07-082 THINNER can be added. Up to 10 percent by volume.NOTE

The mixture must be allowed to stand for 30 minutes before it is used.NOTE

The pot life of the mixture is eight hours. If you do not use the mixture within eight hours, discard it.

SUBTASK 72-38-11-380-055 Make Up the Epoxy Primer

Refer to Figure.

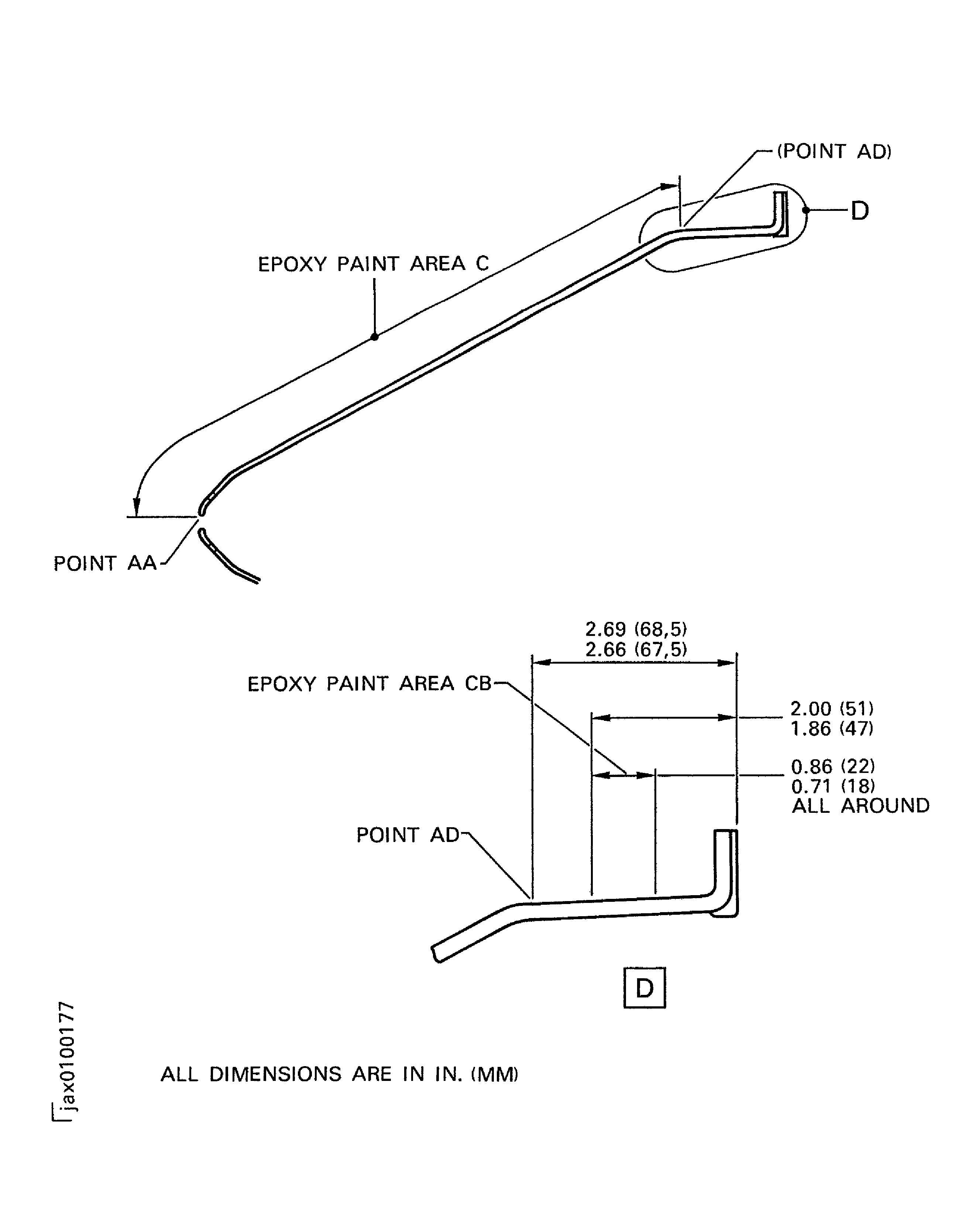

SUBTASK 72-38-11-380-056-A00 Apply the Epoxy Primer, Assembly A

Refer to Figure

SUBTASK 72-38-11-380-056-B00 Apply the Epoxy Primer, Assembly B,

Use CoMat 07-117 EPOXY MATT FINISH-BLACK and CoMat 07-120 CATALYST (FOR MATT FINISH) in equal parts.

NOTE

If necessary, the CoMat 07-082 THINNER can be added. Up to 10 percent by volume.NOTE

The mixture must be allowed to stand for 30 minutes before it is used.NOTE

The pot life of the mixture is eight hours. If you do not use the mixture within eight hours, discard it.Mix the base finish and the catalyst.

SUBTASK 72-38-11-380-057 Make Up the Epoxy Finish (Black)

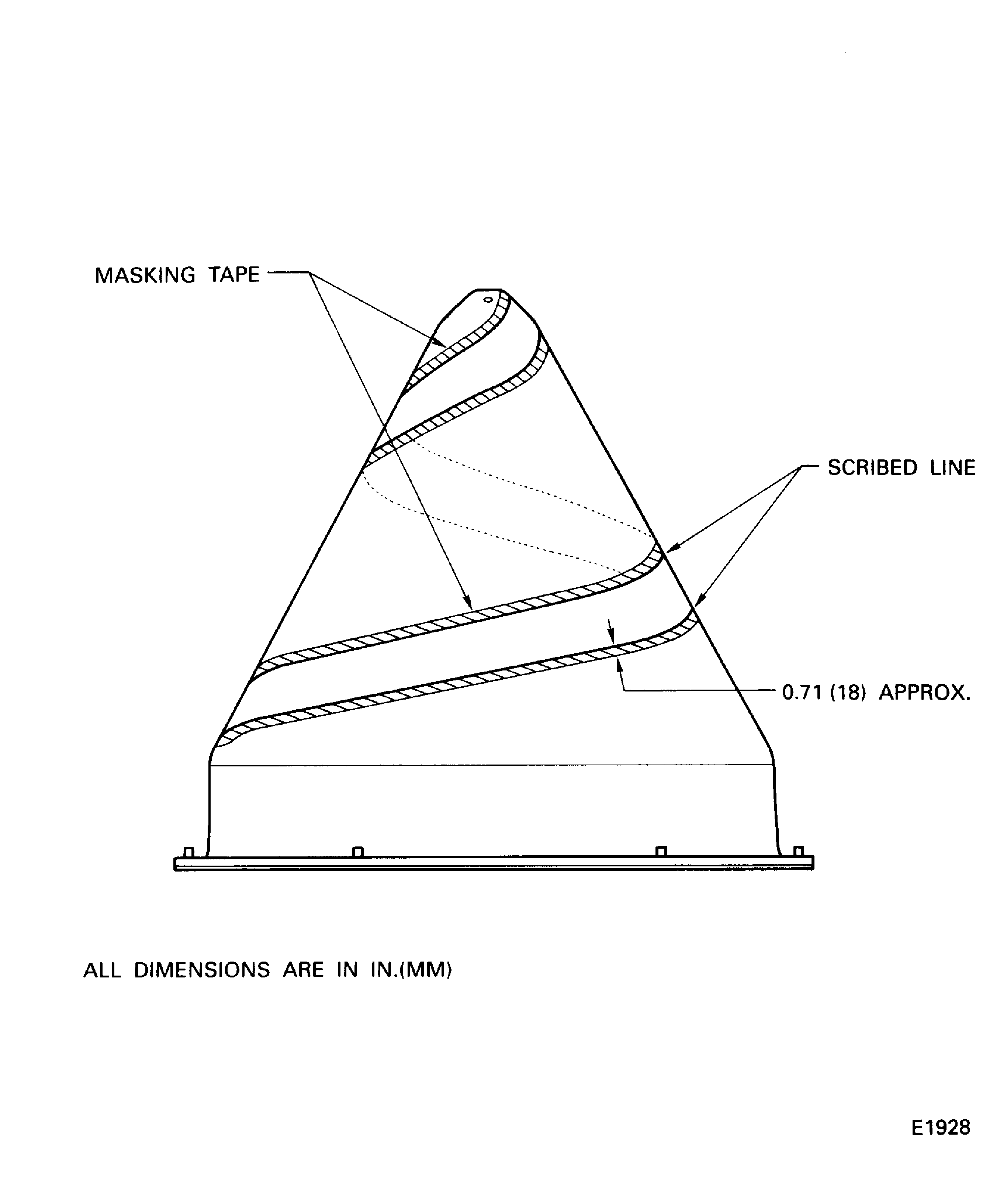

Use IAE 3J12786 Scribe fixture 1 off.

Install the scribing fixture on the inlet cone.

Use IAE 3J12783 Masking fixture 1 off.

Install the masking fixture on the inlet cone.

SUBTASK 72-38-11-490-051 Install the Support Equipment on the Inlet Cone,

Use CoMat 07-119 EPOXY GLOSS FINISH-WHITE and CoMat 07-118 CATALYST (FOR GLOSS FINISH) in equal parts.

NOTE

If necessary, the CoMat 07-082 THINNER can be added. Up to 10 percent by volume.NOTE

The mixture must be allowed to stand for 30 minutes before it is used.NOTE

The pot life of the mixture is eight hours. If you do not use the mixture within eight hours, discard it.Mix the base finish and the catalyst.

SUBTASK 72-38-11-380-059 Make Up the Epoxy Finish (White)

Refer to Figure.

Use CoMat 08-069 RESIN (100 parts by weight), CoMat 08-077 CURING AGENT (13.5 parts by weight) and CoMat 01-076 METHYL ETHYL KETONE (40 to 70 parts by weight).

Mix the elastmers.

NOTE

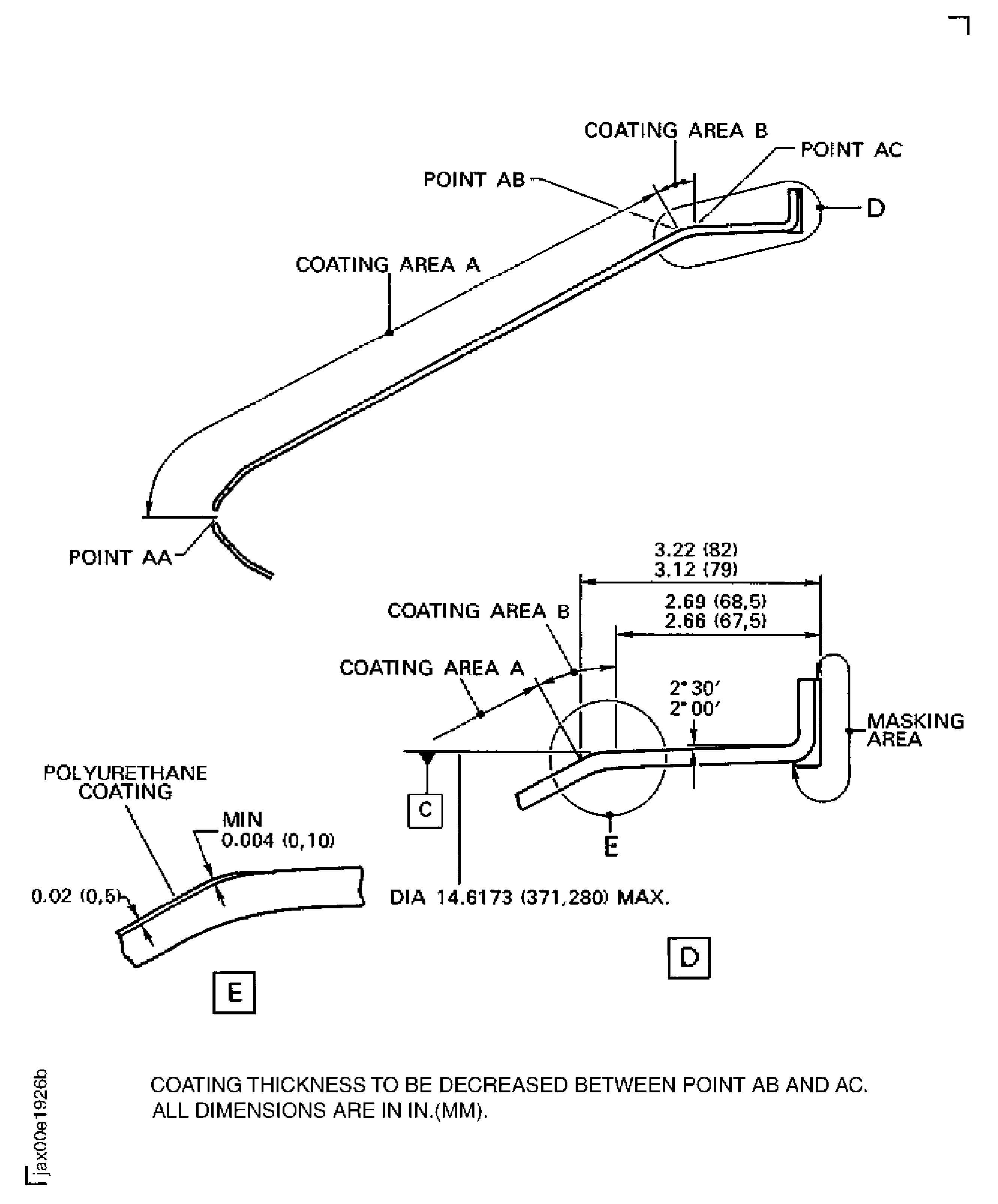

The methyl ethyl ketone must be dried by adding 50 gm CoMat 01-082 SODIUM SULPHATE Na2SO4ANHYDROUS per 2.5 liters, shaking well, and allowing to stand for 24 hours before decanting the supernatant liquid as necessary.Apply the mixed compound with a spray gun and let it air-dry for 10 to 30 minutes between coats. Apply one coat of 0.004 to 0.008 in. (0.1 to 0.2 mm) thickness on the area A, followed by a coat of 0.004 in. (0.1 mm) maximum thickness on the area B.

SUBTASK 72-38-11-380-061-A00 Apply the Polyurethane Coating, Assembly A

Refer to Figure.

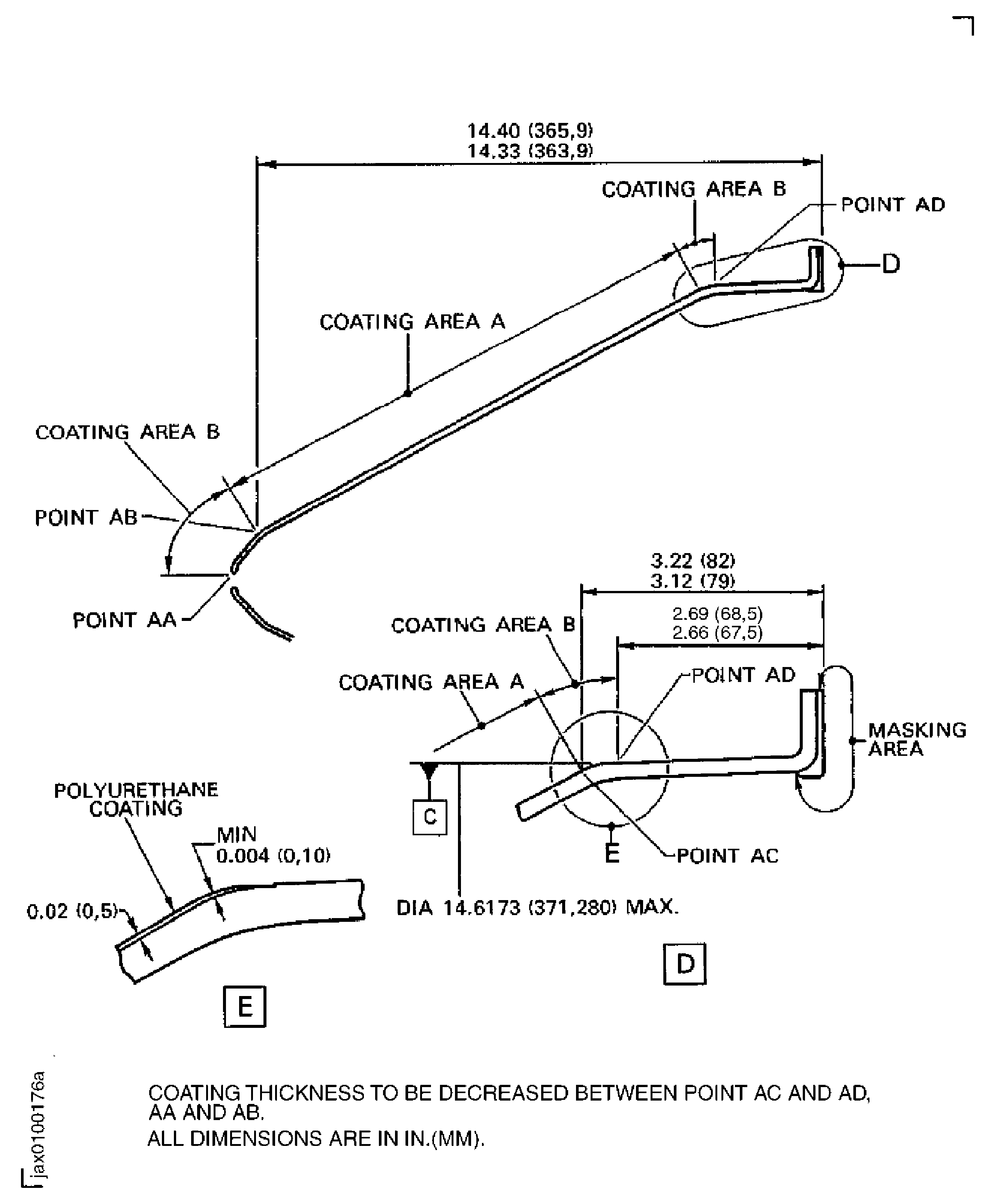

Use CoMat 08-069 RESIN (100 parts by weight), CoMat 08-077 CURING AGENT (13.5 parts by weight) and CoMat 01-076 METHYL ETHYL KETONE (40 to 70 parts by weight).

Mix the elastmers.

NOTE

The methyl ethyl ketone must be dried by adding 50 gm CoMat 01-082 SODIUM SULPHATE Na2SO4ANHYDROUS per 2.5 liters, shaking well, and allowing to stand for 24 hours before decanting the supernatant liquid as necessary.Apply the mixed compound with a spray gun and let it air-dry for 10 to 30 minutes between coats. Apply one coat of 0.004 to 0.008 in. (0.1 to 0.2 mm) thickness on the area A, followed by a coat of 0.004 in. (0.1 mm) maximum thickness on the area B.

SUBTASK 72-38-11-380-061-B00 Apply the Polyurethane Coating, Assembly B

Refer to Repair, VRS1462, TASK 72-38-11-300-002 (REPAIR-002).

Install the inlet cone tip.

SUBTASK 72-38-11-360-068 Install the Inlet Cone Tip

Refer to the SPM TASK 70-09-00-400-501.

Make a mark, VRS1458, adjacent to the part number.

SUBTASK 72-38-11-350-059 Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions