Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-38-11-300-002 Inlet Cone Assembly - Replace The Inlet Cone Tip, Repair-002 (VRS1462)

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

Inlet cone | - | Fibre-reinforced plastic with polyurethane coating |

General

Price and availability - none

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Lathe | LOCAL | Lathe | ||

| Milling machine | LOCAL | Milling machine | ||

| Drilling machine | LOCAL | Drilling machine | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-016 GARNET PAPER, 80-GRIT | LOCAL | CoMat 05-016 | ||

| CoMat 05-019 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-019 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 08-012 COLD CURING SILICONE COMPOUND | 0AM53 | CoMat 08-012 | ||

| CoMat 08-013 COLD CURING SILICONE COMPOUND | LOCAL | CoMat 08-013 | ||

| CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT | 0AM53 | CoMat 08-014 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Tip holder | 5A0005 | 1 | ||

| Inlet cone tip | 5A0016 | 1 |

Safety Requirements

NONEProcedure

Use a cutter knife or a scraper, CoMat 05-019 WATERPROOF SILICON CARBIDE and CoMat 05-020 WATERPROOF SILICON CARBIDE.

Remove damaged inlet cone tip without any damage to the parent material, and remove the remaining compound.

SUBTASK 72-38-11-330-053 Remove the Damaged Inlet Cone Tip from the Inlet Cone Assembly

Refer to the SPM TASK 70-11-26-300-503.

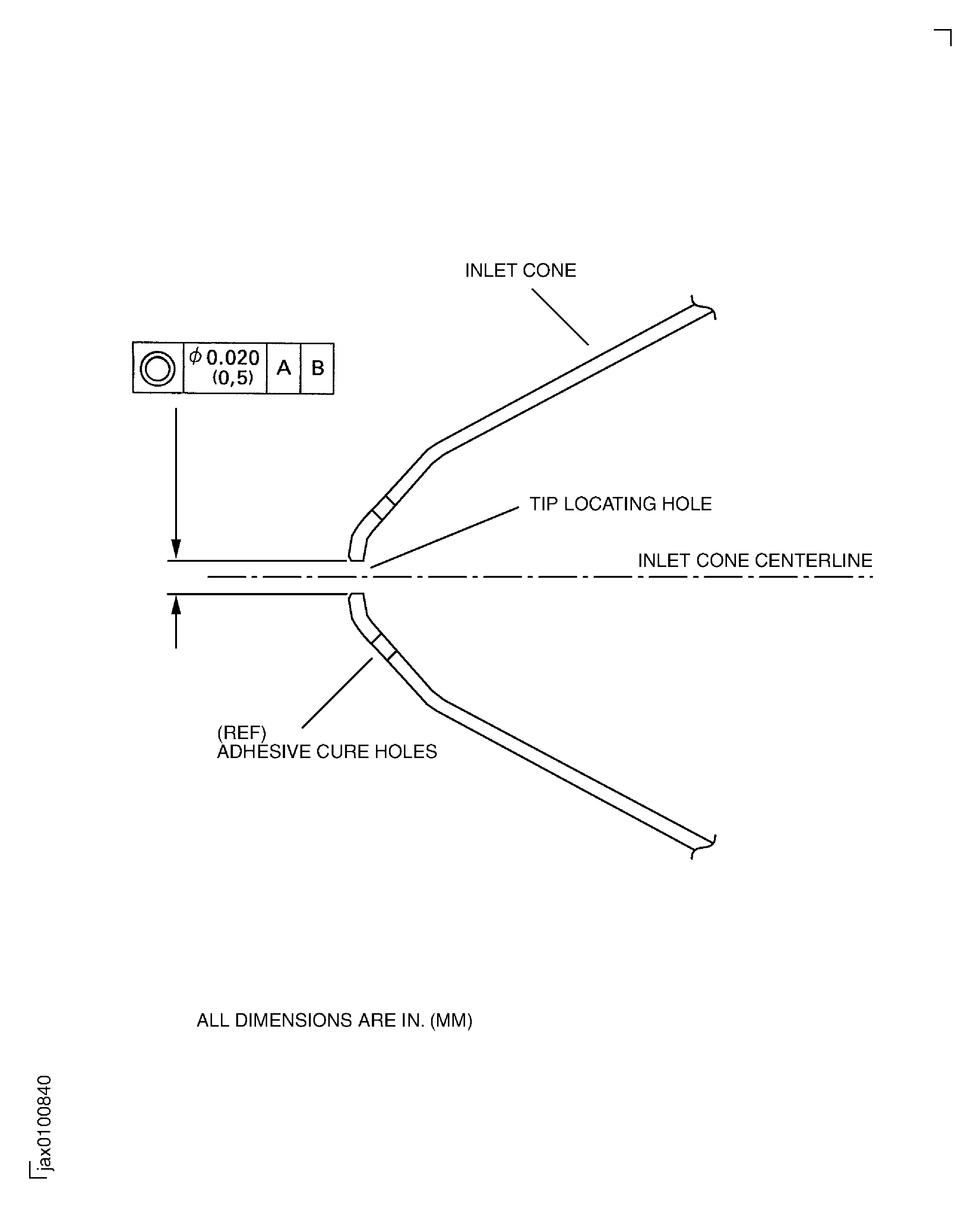

Wipe and clean the tip locating hole area of the inlet cone.

SUBTASK 72-38-11-110-056 Clean the Inlet Cone Tip Locating Hole

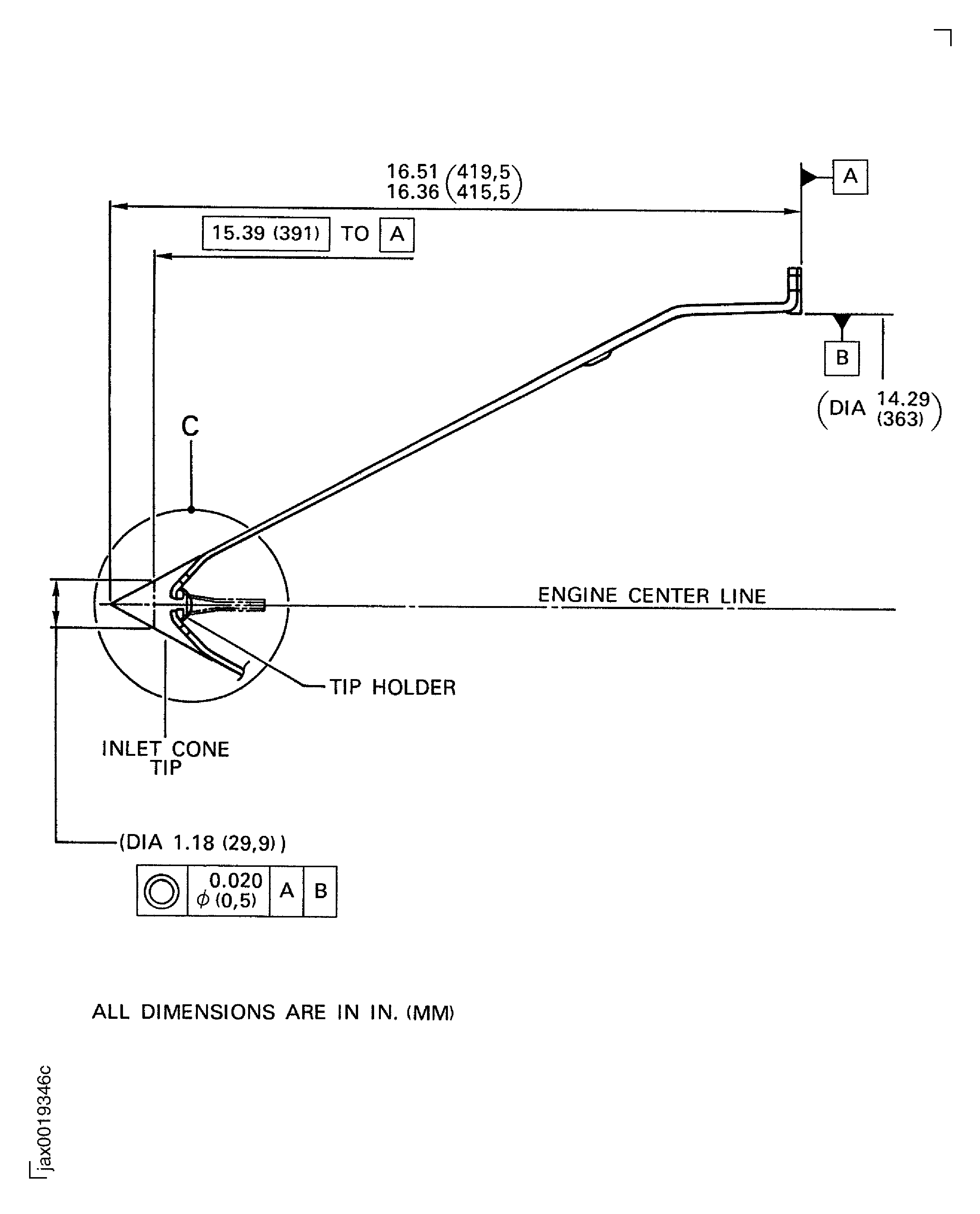

Hold the Inlet cone aft flange ID (Datum B) concentric within 0.002 in. (0.05 mm).

NOTE

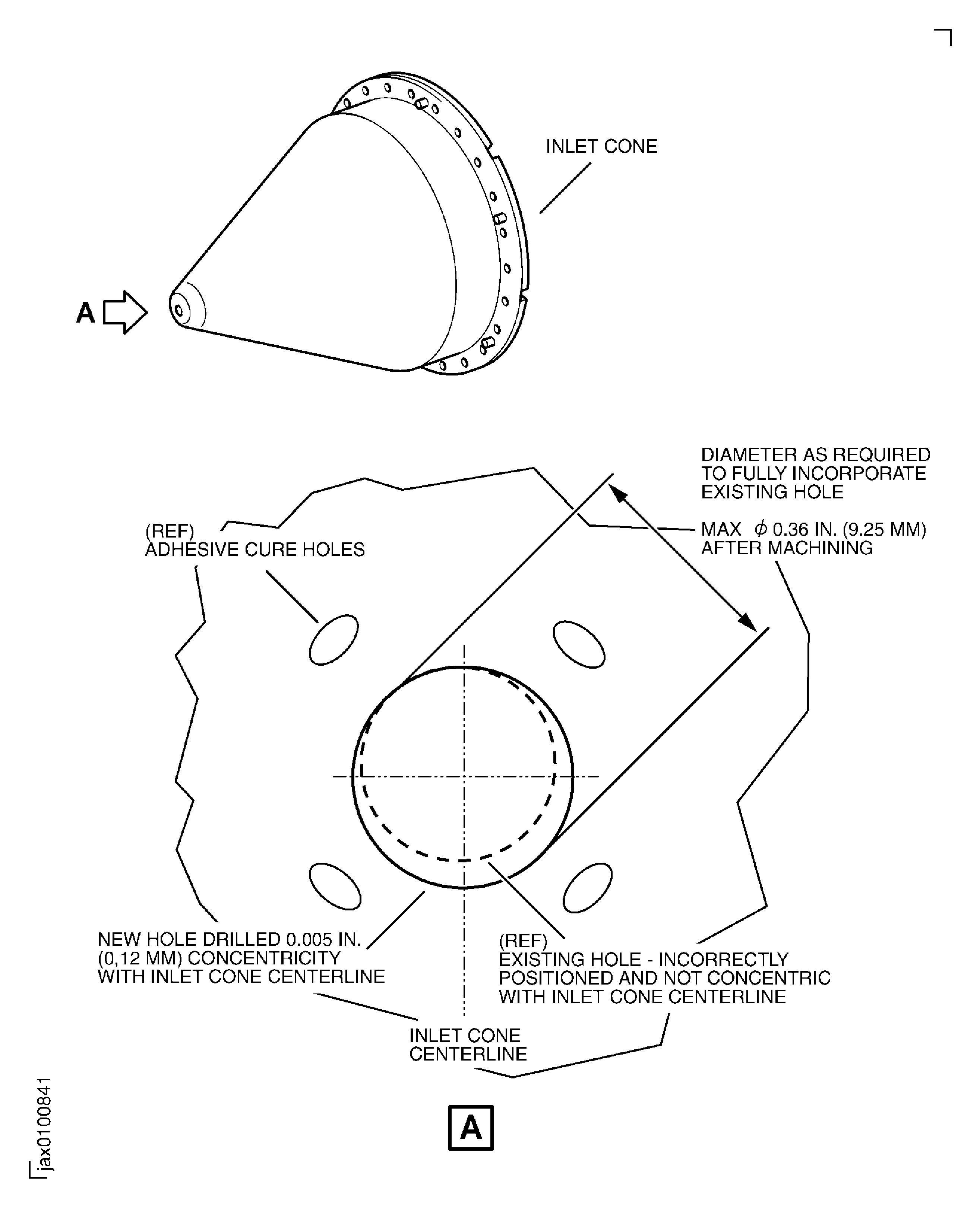

Do this SUBTASK only if the concentricity of the locating hole is out of limit in Step.Install the inlet cone on the lathe or milling machine.

SUBTASK 72-38-11-320-054 Machine the Inlet Cone Tip Locating Hole

Refer to the TASK 70-11-26-300-503.

Wipe the mating surface.

SUBTASK 72-38-11-360-052 Prepare the Mating Surfaces for the Cold Curing Silicone Rubber Compound

CAUTION

DO NOT EAT ANYTHING OR SMOKE AT LOCATIONS WHERE THESE MATERIAL ARE USED.

CAUTION

AFTER PREPARATION THE MATING SURFACES MUST BE FULLY CLEANED AND MUST NOT BE TOUCHED BY HAND, TO PREVENT CONTAMINATION.NOTE

The primer must be applied immediately after the mating surfaces are prepared.If the parts are not used immediately after the primer is applied, the parts can be kept in polyethylene bags for use within 24 hours.Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-020.

Apply a thin layer of primer only to the prepared mating surface of the inlet cone, other than elastomeric surfaces. Dry in air for 30 minutes.

Refer to the SPM TASK 70-11-26-300-503.

Swab degrease the mating surface of the inlet cone tip.

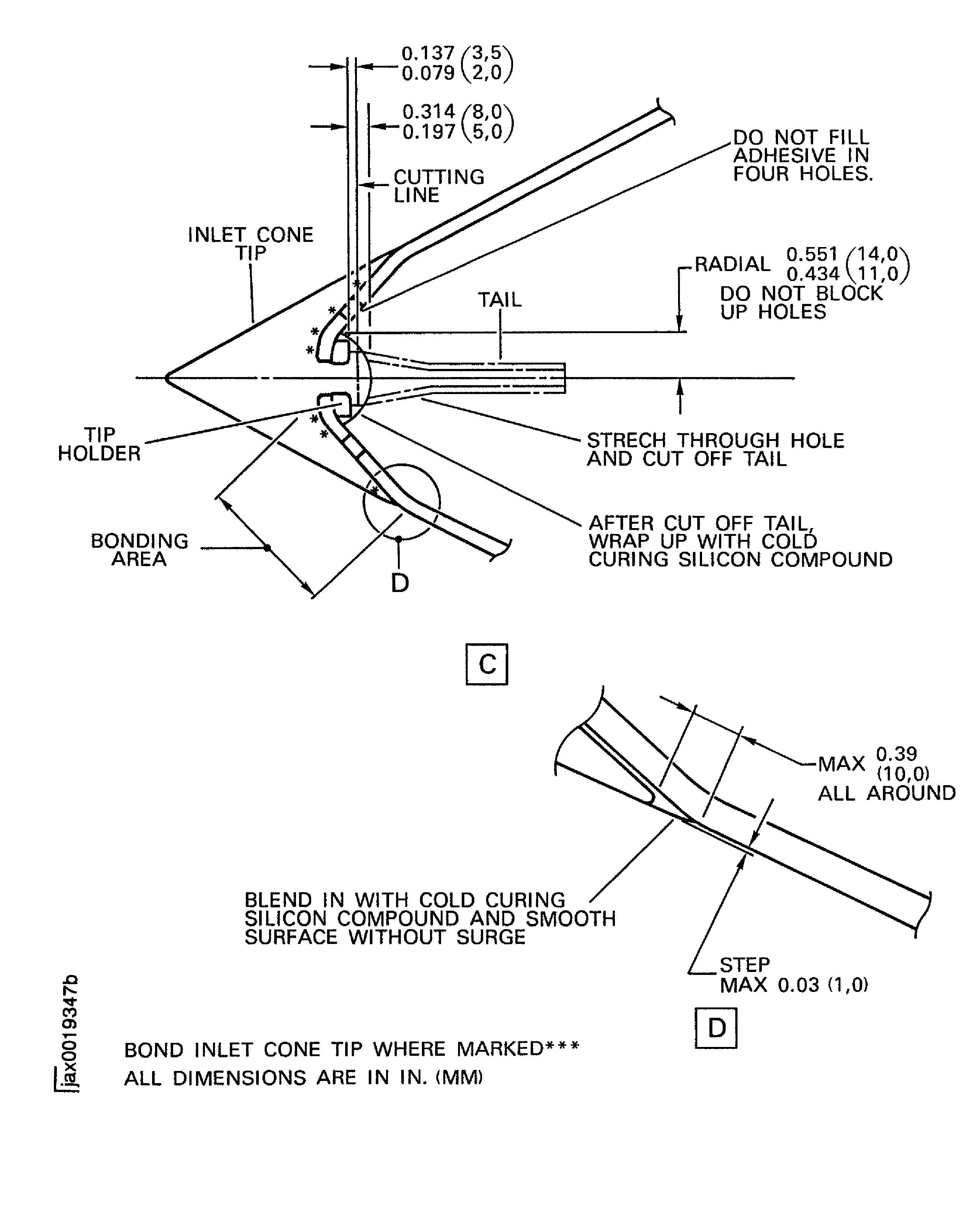

Use a spatula and CoMat 08-013 COLD CURING SILICONE COMPOUND.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-020.

Apply the cold curing silicon rubber compound to each of the mating surfaces of the inlet cone tip and inlet cone. Thickness to be 0.010 to 0.015 in. (0.25 to 0.38 mm).

Use CoMat 08-012 COLD CURING SILICONE COMPOUND and make smooth without waves.

Blend in the joint portion of inlet cone and the tip with the compound.

Do not apply a load during this time. Refer to the SPM TASK 70-36-02-360-501.

Cure the compound at 68 deg F (20 deg C) for 48 hours.

SUBTASK 72-38-11-360-053 Apply and Cure the Cold Curing Silicone Rubber Compound

Refer to Figure.

SUBTASK 72-38-11-220-075 Examine the Repaired Areas of the Inlet Cone

Refer to the SPM TASK 70-09-00-400-501.

Mark VRS1462 adjacent to the part number.

SUBTASK 72-37-11-350-001 Identify the Repair

Figure: Repair Details and Dimensions

Sheet 1

Figure: Repair Details and Dimensions

Sheet 2

Figure: Repair Details and Dimensions

Sheet 3

Figure: Repair Details and Dimensions

Sheet 4