Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-38-25-300-003 Bifurcation Panel Assembly - Repair of Side Seals and Clips, Repair-003 (VRS9536)

General

Make sure that all the cleaning and inspection procedures are done before this repair per the applicable IAE Engine Manual ATA 72-38-25.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard Workshop Equipment | LOCAL | Standard Workshop Equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-031 ACETONE (CH3)2CO | K6835 | CoMat 01-031 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 05-016 GARNET PAPER, 80-GRIT | K3895 | CoMat 05-016 | Grit Size 80 | |

| CoMat 08-013 COLD CURING SILICONE COMPOUND | LOCAL | CoMat 08-013 | Silcoset 152 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

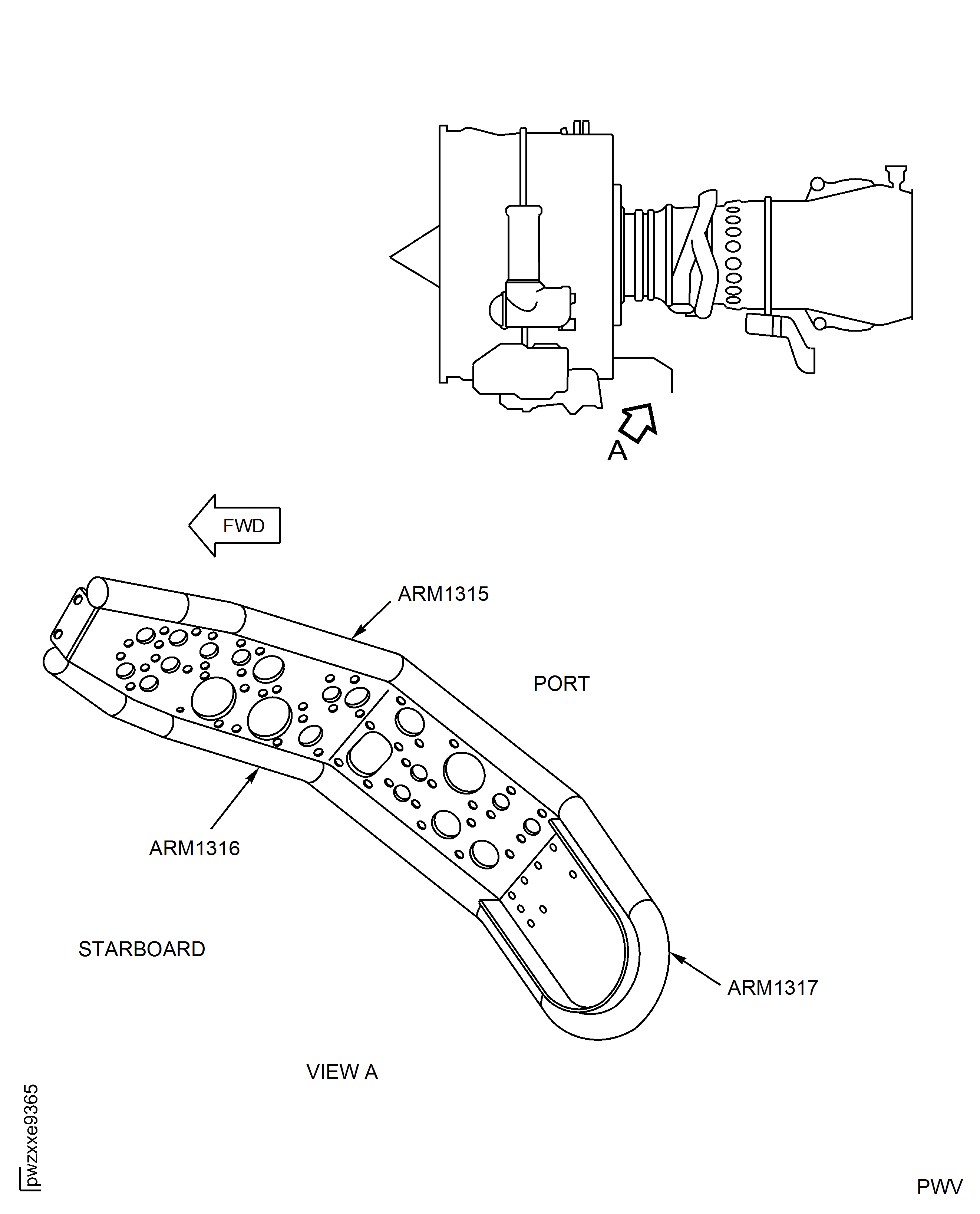

| Seal (LH) | LOCAL | ARM1315 | 1 | |

| Seal (RH) | LOCAL | ARM1316 | 1 | |

| Seal, Clip (LH) | LOCAL | 6A7931 | 1 | |

| Seal, Clip (RH) | LOCAL | 6A7932 | 1 | |

| Seal, Clip (Straight) | LOCAL | 6A7933 | 2 |

Safety Requirements

NONEProcedure

CAUTION

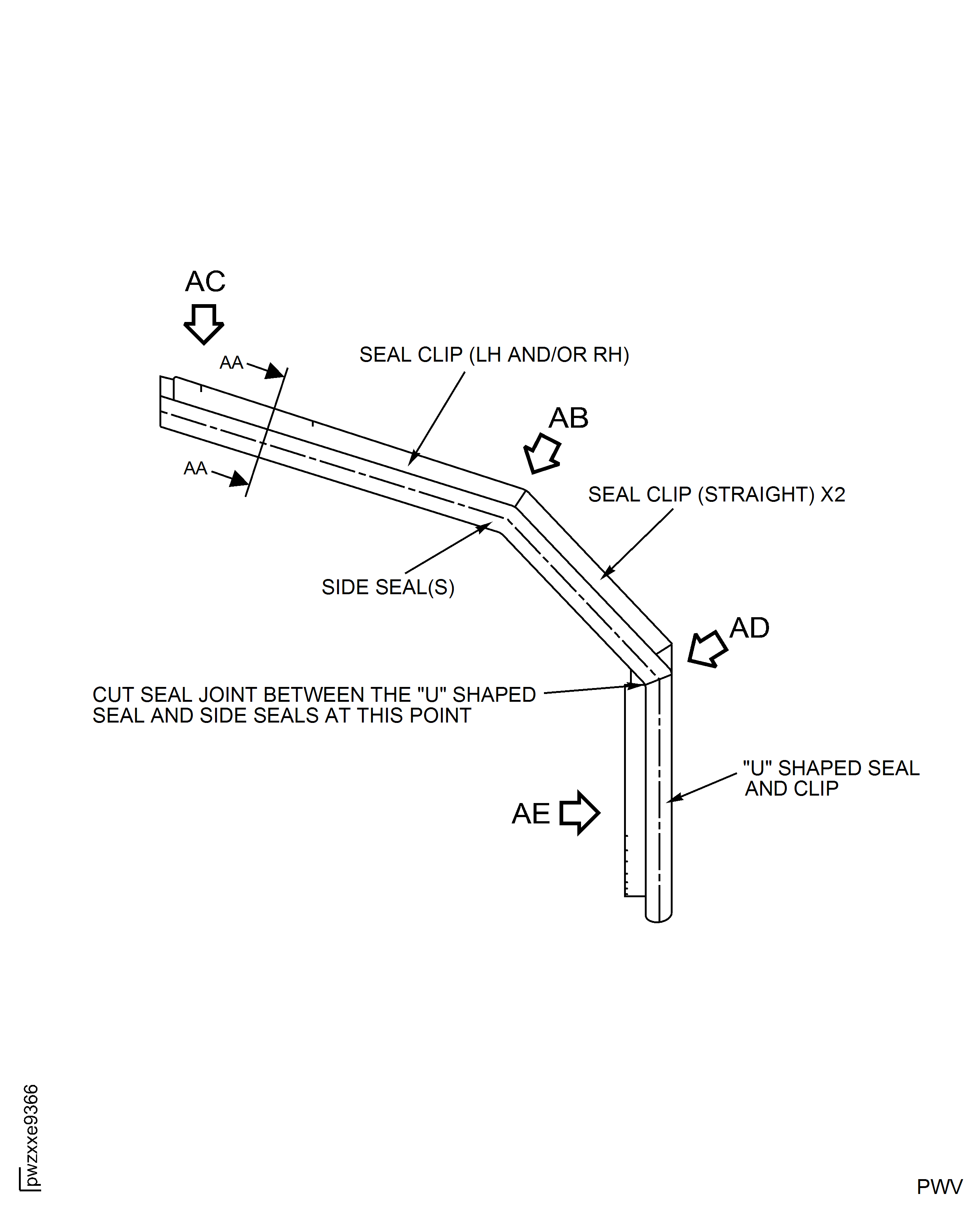

CARE MUST BE TAKEN NOT TO DAMAGE SEAL(S) THAT ARE NOT BEING REPLACED OR THE BUNG(S) AT THE JUNCTION BETWEEN THE SEAL(S).Use a sharp knife to cut through the sealant at the interface between the damaged side seal(s) and the "U" seal.

Carefully removed the side seal(s) from between the bifurcation panel and the seal clips by pulling from one end and working towards the other until the seal is free. Discard the removed item(s).

Remove the seal clip(s) from the side(s) to be repaired. Discard removed item(s).

SUBTASK 72-38-25-350-001 Remove Damaged Side Seal(s)

Refer to Figure.

CAUTION

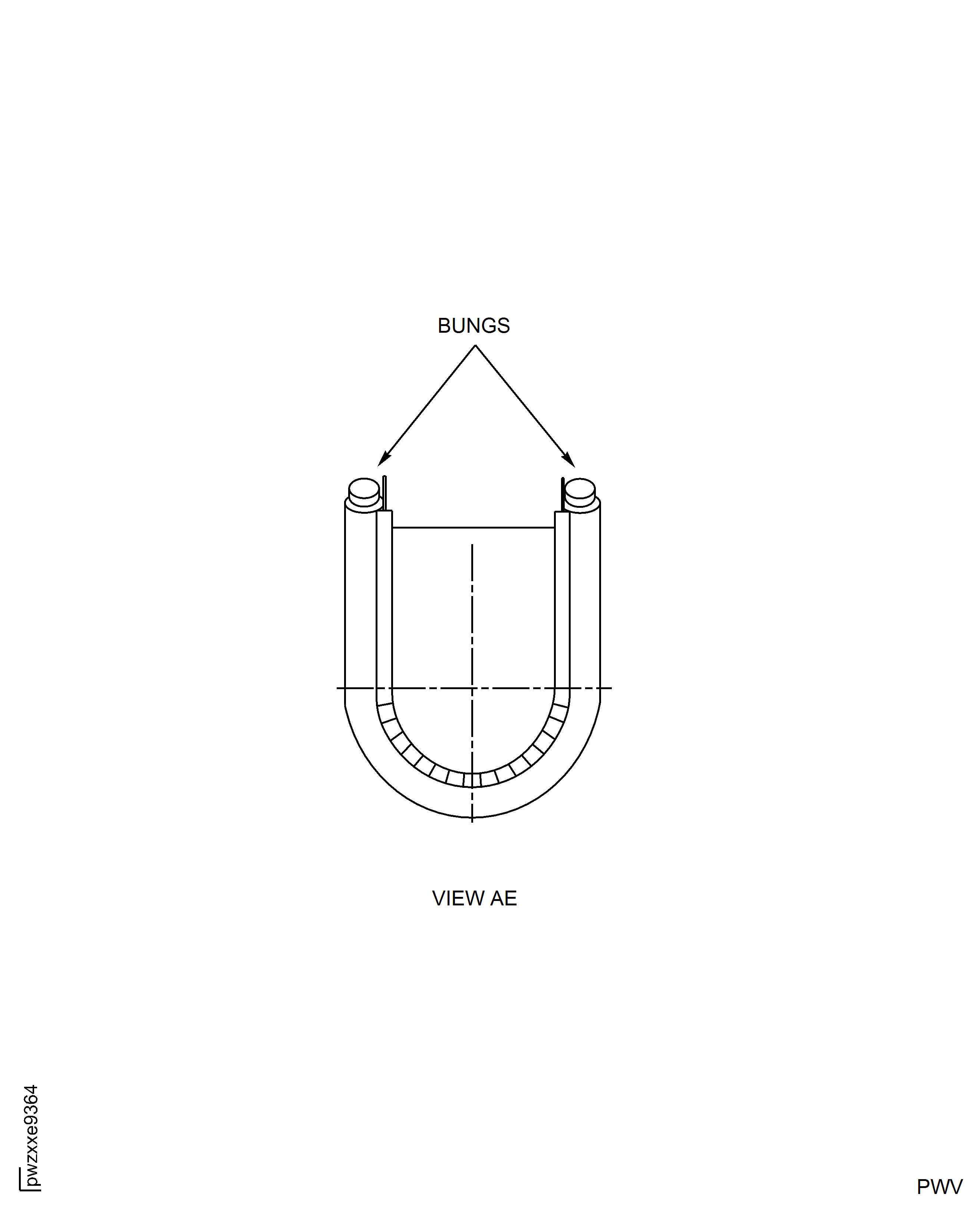

CARE MUST BE TAKEN NOT TO DAMAGE THE MATING SURFACES OR BUNG(S) AT THE JUNCTION BETWEEN SEALS.Carefully remove the sealant from the bung(s) and the end(s) of seal(s) in order to accommodate the replacement seal(s).

Carefully remove all remaining traces of sealant using CoMat 05-016 GARNET PAPER, 80-GRIT.

Clean mating surfaces at the end(s) of the bung(s) and seal(s) using CoMat 02-099 LINT-FREE CLOTH moistened with CoMat 01-031 ACETONE (CH3)2CO.

SUBTASK 72-38-25-350-002 Remove Sealant from "U" Seal and Bung(s)

Refer to Figure.

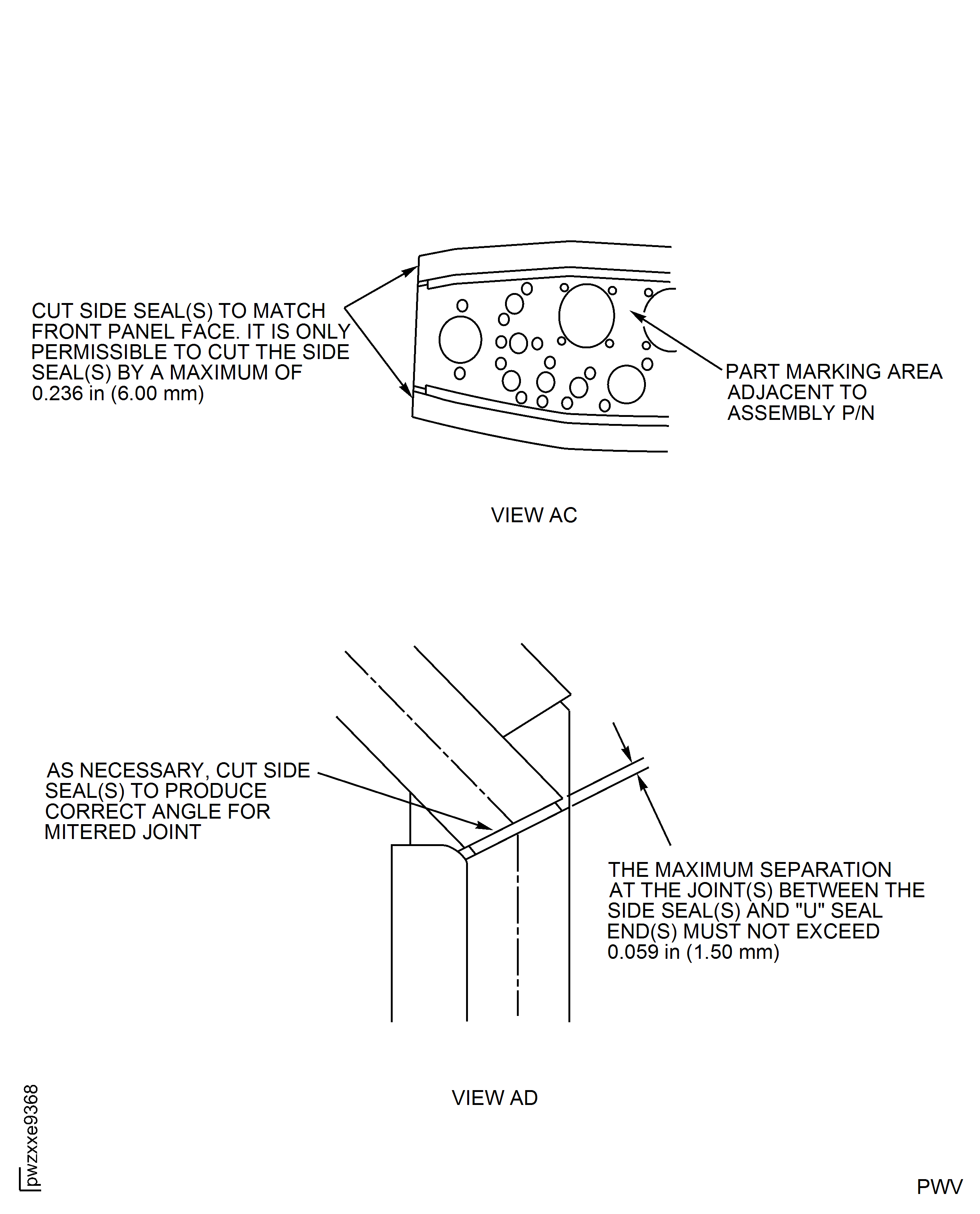

It is only permissible to cut the side seal(s) by a maximum of 0.236 in (6.00 mm).

No seal fibers should be exposed.

Apply sealant to the end(s) of the "U" seal and bung(s) using CoMat 08-013 COLD CURING SILICONE COMPOUND (Silcoset 152) per SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-020.

Apply sealant to the connecting end of the side seal(s) using CoMat 08-013 COLD CURING SILICONE COMPOUND (Silcoset 152) per SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-020.

Attach side seal(s) over the bung(s) on the "U" seal ensuring a neat and flush fit is achieved.

The maximum separation between seal ends must be less than 0.059 in (1.50 mm).

NOTE

Ensure the side seal(s) fit flush with the "U" seal.Position side seal(s) in place along the panel.

NOTE

Care must be taken to ensure side seal(s) fit flush at end of the bifurcation panel.Remove any excess sealant compound from the area of the joint(s) using CoMat 02-099 LINT-FREE CLOTH moistened with CoMat 01-031 ACETONE (CH3)2CO.

SUBTASK 72-38-25-350-003 Fit Replacement Side Seal(s)

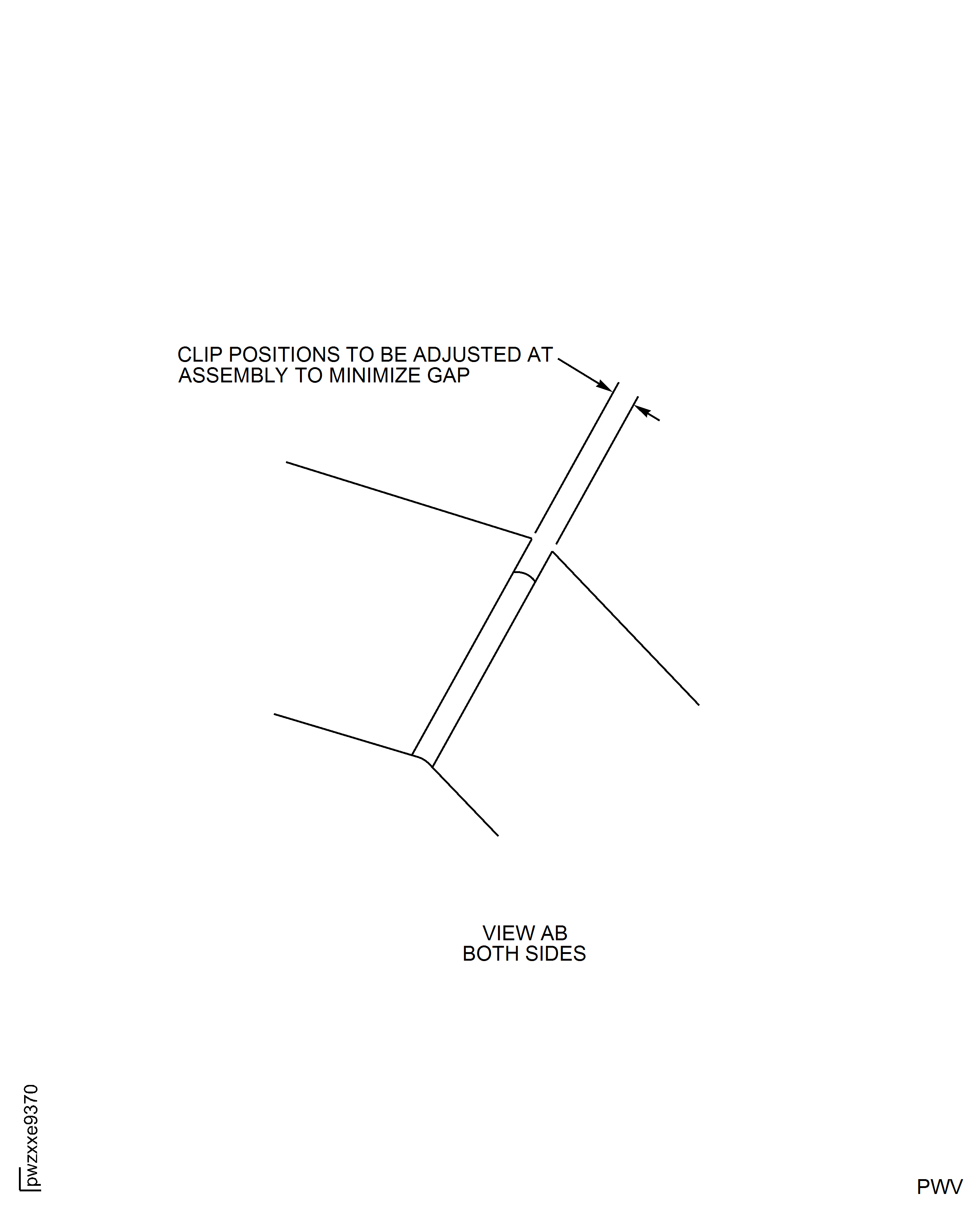

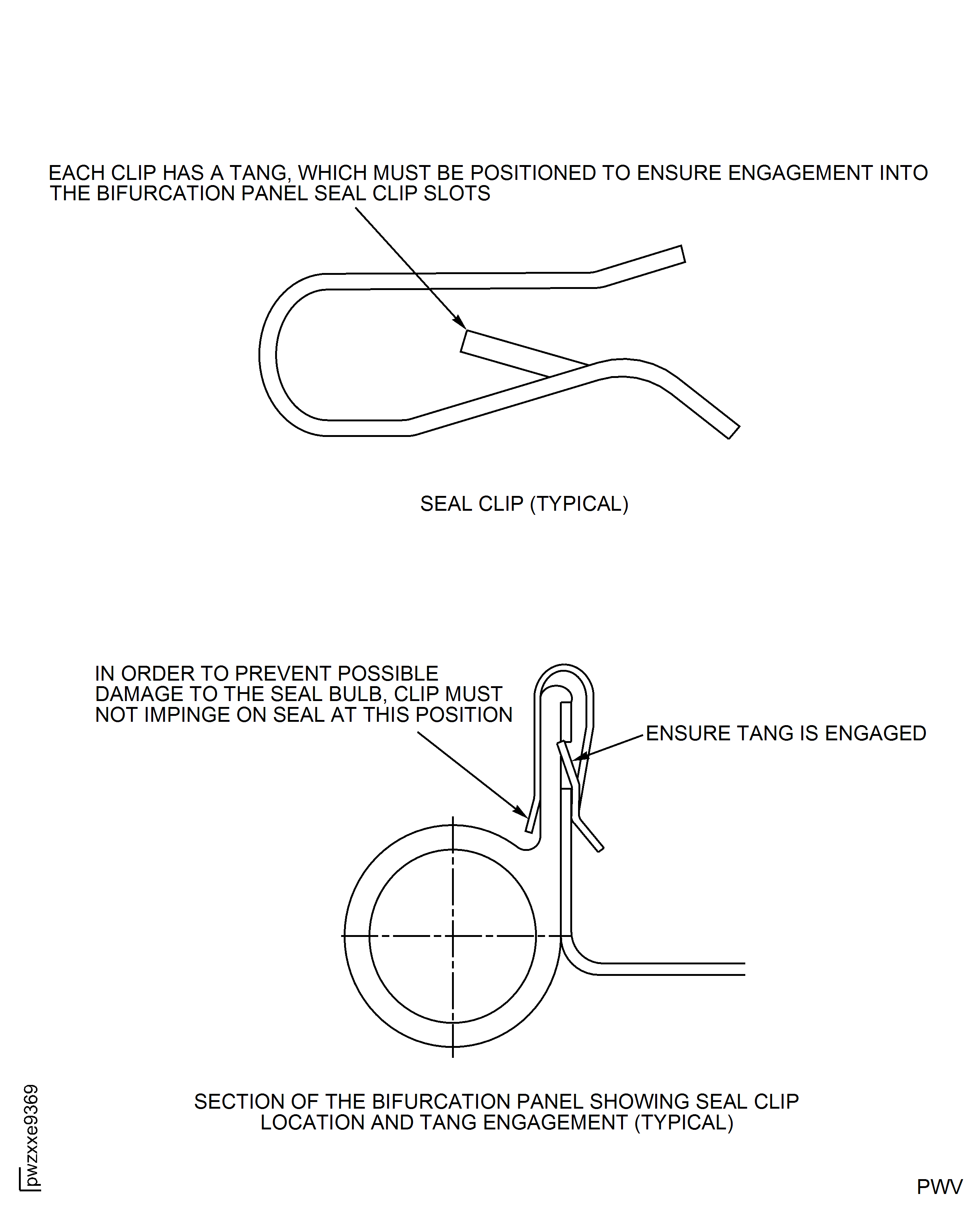

Ensure that the replacement clips are pushed down firmly and clip tang engages into the tang slot.

Tang will audibly click as it engages.

NOTE

Care must be taken to ensure that a minimal gap is maintained between the side seal clips and the straight seal clips.Remove any excess sealant compound from the area of repair using CoMat 02-099 LINT-FREE CLOTH moistened with CoMat 01-031 ACETONE (CH3)2CO.

Silicone must be smooth and flush with the contour of the seal and fill the separation between the "U" and side seals.

Allow the silicone compound to cure for 12 hours at 61°F (16°C).

NOTE

It is ok to handle the part after 2 hours, however the silicone will not be fully cured for 12 hours and no load should be applied during that time.

SUBTASK 72-38-25-350-005 Fit Replacement Seal Clips

Visually examine the silicone compound on the repair area(s). No holes or splits should be seen at the joint(s). Repair area(s) must be smooth and flush with the seal contour.

Ensure there are no open gas paths at joint between side seal(s) and "U" seal. If any crack or separation is seen then the repair should be repeated.

Visually examine the side seal clips and ensure that a minimum gap is achieved between the side seal clips and the straight seal clips.

Dimensionally examine gap at the joint(s) between the side seal(s) and "U" seal ends. Joint gap must not exceed 0.059 in (1.50 mm).

SUBTASK 72-38-25-220-001 Visual and Dimensional Inspection of the Repair Area(s)

Mark the part by vibropeening "VRS9536" in the part marking area per SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Mark Bifurcation Panel. Refer to Figure.

POSTREQUISITES

Figure: Bifurcation Panel General

Bifurcation Panel General

Figure: Bifurcation Panel Port Side View

Bifurcation Panel Port Side View

Figure: Bifurcation Panel Showing Bungs At "U" Seal (Side Seals Removed For Clarity)

Bifurcation Panel Showing Bungs At "U" Seal (Side Seals Removed For Clarity)

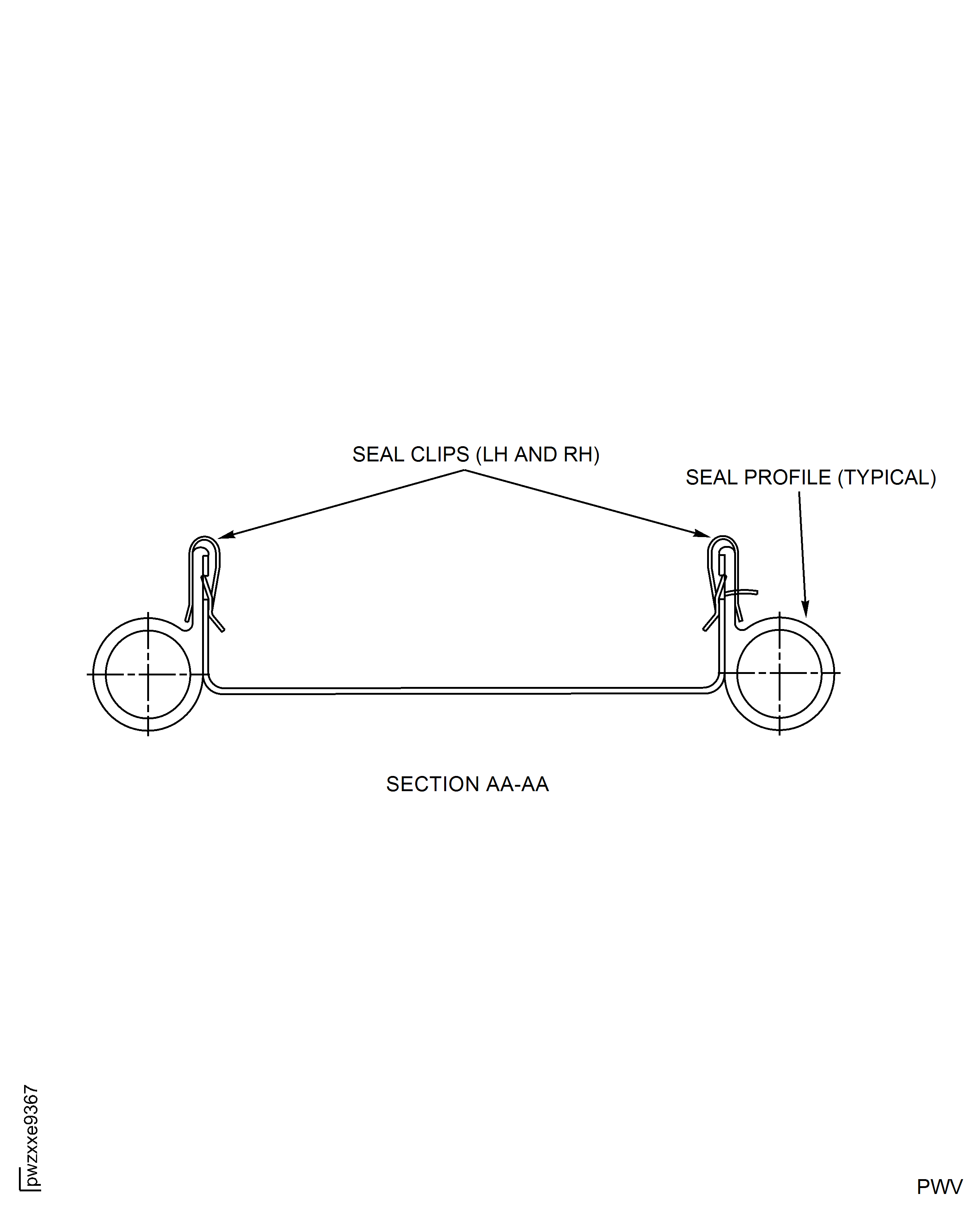

Figure: Bifurcation Panel Section View Seals & Clips

Bifurcation Panel Section View Seals & Clips

Figure: Bifurcation Panel Marking Area & Seal Gap

Bifurcation Panel Marking Area & Seal Gap

Figure: Bifurcation Panel Seal Clips

Bifurcation Panel Seal Clips

Figure: Bifurcation Panel Seal Clip Gap

Bifurcation Panel Seal Clip Gap