Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-11-230-001 HPC Stage 3 - 8 Drum Disk - Do A Fluorescent Penetrant Inspection (FPI) Of The 7-8 Inner Cavity (Focused Inspection Location 10), Inspection-001

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-200 | 6A3508 |

01-200 | 6A3648 |

01-200 | 6A3934 |

01-200 | 6A3936 |

01-200 | 6A4189 |

01-200 | 6A4900 |

01-200 | 6A5467 |

01-200 | 6A5592 |

01-200 | 6A5594 |

01-200 | 6A5659 |

01-200 | 6A6473 |

01-200 | 6A7379 |

01-200 | 6A7380 |

01-200 | 6A7382 |

01-200 | 6A7383 |

01-200 | 6A7384 |

01-200 | 6A7385 |

01-200 | 6A7401 |

01-200 | 6A7705 |

01-200 | 6A8236 |

01-200 | 6A8316 |

01-200 | 6A8318 |

01-200 | 6A8350 |

01-200 | 6B1379 |

01-200 | 6B1380 |

01-200 | 6B1381 |

01-200 | 6B1382 |

01-200 | 6B1383 |

01-200 | 6B1384 |

01-200 | 6B1385 |

01-200 | 6B1386 |

01-200 | 6B1387 |

01-200 | 6B1391 |

01-200 | 6B1392 |

01-200 | 6B1393 |

01-200 | 6B1401 |

01-200 | 6B1402 |

01-200 | 6B1403 |

01-200 | 6B1404 |

01-200 | 6B1405 |

01-200 | 6B1406 |

General

This focus inspection must only be done when specified by 72-41-11 Inspection (Inspection).

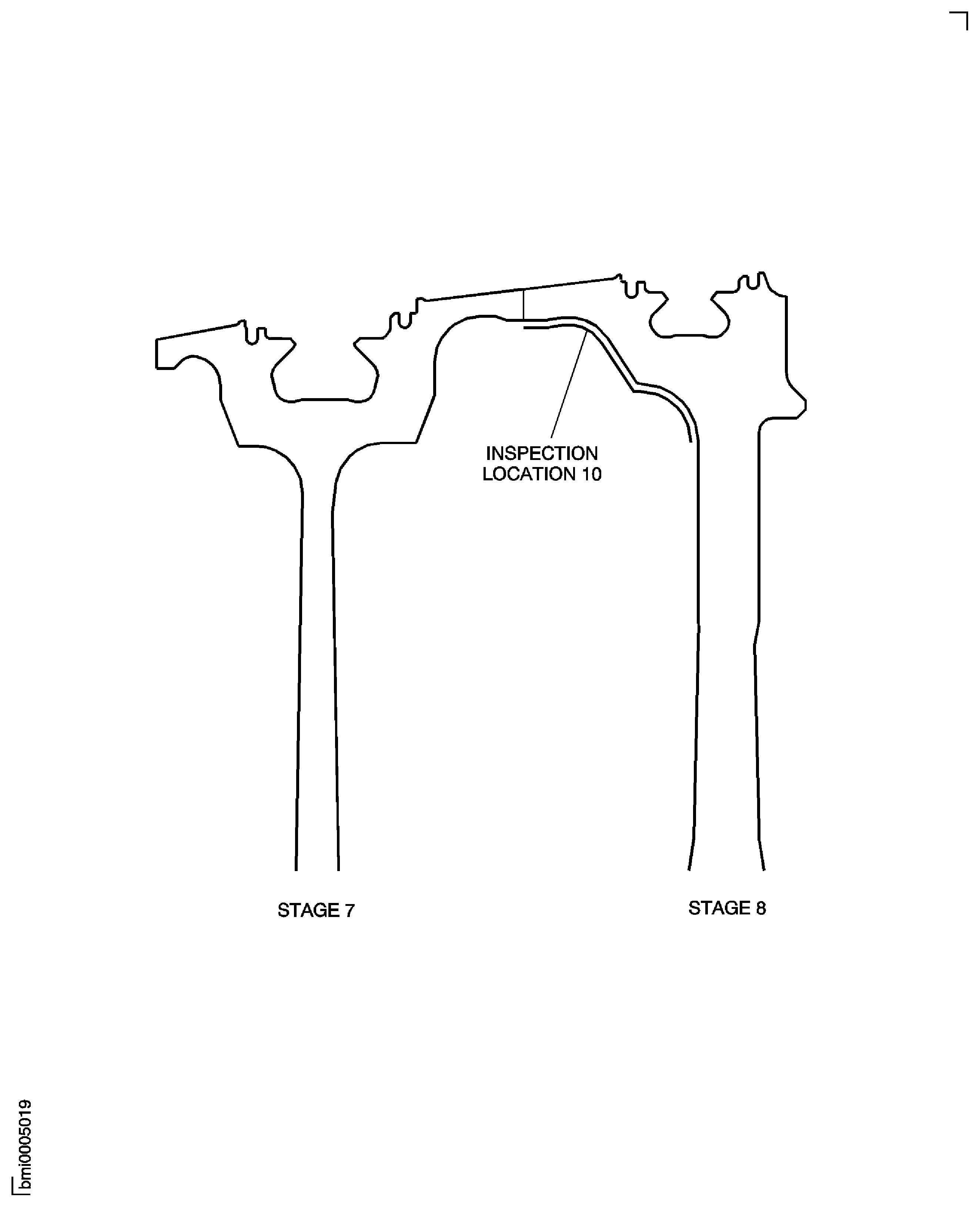

This procedure gives the instruction only to find the cracks in HP compressor stage 7/8 disk inner cavity at the inspection location 10. Refer to Figure. Refer to TASK 72-41-11-200-001-A00 (Inspection-001) for all other areas of the HP compressor stage 3 to 8 drum.

Ultra high sensitivity penetrant must be used for this focused FPI procedure.

The workshop procedure for this focus FPI TASK must be specified by a qualified level three trained Non-Destructive Test (NDT) specialist based on the requirements and procedures given in this TASK and the AMS 2647 - FPI for Aircraft and Engine Components Maintenance.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Penetrant process line | LOCAL | |||

| UV Light | LOCAL | Hand held or fixture mounted | ||

| White light | LOCAL | Hand held or fixture mounted | ||

| Inspection mirror | LOCAL | |||

| Suction device | LOCAL | |||

| IAE 2R19883 Rotary table inspection device | 0AM53 | IAE 2R19883 | 1 | |

| IAE 2R19884 Adapter | 0AM53 | IAE 2R19884 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-025 NITRIC ACID HNO3, TECHNICAL GRADE | LOCAL | CoMat 01-025 | ||

| DELETED | LOCAL | DELETED | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | X222X | CoMat 06-022 | ||

| CoMat 06-030 NON AQUEOUS DEVELOPER | LOCAL | CoMat 06-030 | ||

| CoMat 06-032 DRY DEVELOPER | 37676 | CoMat 06-032 | ||

| CoMat 06-045 EMULSIFIER - FLUORESCENT PENETRANT, HYDROPHILIC | X222X | CoMat 06-045 |

Spares

NONESafety Requirements

NONEProcedure

Refer to the SPM TASK 70-23-00-230-501.

SUBTASK 72-41-11-180-006 Control of Equipment and Materials

Refer to Figure.

Clean the HP compressor stage 3 to 8 drum before you start the inspection. Refer to TASK 72-41-11-110-001 (Special Procedure). Use CoMat 01-025 NITRIC ACID HNO3, TECHNICAL GRADE.

Make sure that the stage 7/8 inner cavity surfaces are fully covered with the penetrant, with the use of a mirror and UV light source, specially on the area outboard from the bolt holes. The penetrant contact time must not be less than 20 minutes and not more than 60 minutes.

NOTE

Penetrant processing must be done in accordance with the SPM TASK 70-23-00-230-501 and SPM TASK 70-23-04-230-501. Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY), CoMat 06-045 EMULSIFIER - FLUORESCENT PENETRANT, HYDROPHILIC and CoMat 06-030 NON AQUEOUS DEVELOPER to find the crack). This TASK gives additional instructions necessary because of part's geometry.Penetrant must be first applied to the stage 7/8 disk inner cavity before you apply it to the external surfaces of the drum.The part must be dry and cool 120 deg F (49 deg C maximum) before you apply the penetrant to prevent damage to the penetrant liquid.Apply CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) to location 10 (refer to Figure).

The maximum total CoMat 06-045 EMULSIFIER - FLUORESCENT PENETRANT, HYDROPHILIC contact time is 90 seconds.

Emulsification.

Oven dry. Refer to SPM TASK 70-23-04-230-501.

Apply CoMat 06-032 DRY DEVELOPER to the HP compressor 7/8 inner cavity surfaces. Use a standard spray gun nozzle to apply the developer to the inner surfaces.

Apply developer.

Penetrant application and processing.

Engage the part onto the inspection devices IAE 2R19883 Rotary table inspection device and IAE 2R19884 Adapter or IAE approved alternative, such that the stage 7/8 inner bores get easy access to the illumination equipment. Make sure that the part can be rotated easily related to the viewing and illumination equipment.

Inspection area location 10 must be directly illuminated with UV light held in the fixture IAE 2R19883 Rotary table inspection device or IAE approved alternative, as reflecting UV off the inspection mirror decreases its intensity. The UV light guide must also be used in its operational range to make sure sufficient UV intensity.

If there is a repeat crack indication, reject the drum.

NOTE

Make sure that a rejected drum is disposed in line with the individual overhaul shop procedure.If crack indications are found, reject the drum.

NOTE

Make sure that a rejected drum is disposed in line with the individual overhaul shop procedure.

If there is no repeat crack indication, examine the part for crack indications again after 10 minutes of application of the CoMat 06-030 NON AQUEOUS DEVELOPER.

If a crack indication is found, apply penetrant wipe off procedure. Refer to the SPM TASK 70-23-04-230-501, SUBTASK 70-23-04-230-004

If there is a repeat crack indication, reject the drum.

NOTE

Make sure that a rejected drum is disposed in line with the individual overhaul shop procedure.If crack indications are found, reject the drum.

NOTE

Make sure that a rejected drum is disposed in line with the individual overhaul shop procedure.

If there is no crack indication, examine the part for cracks again after 10 minutes of application of the CoMat 06-030 NON AQUEOUS DEVELOPER.

If there is no crack indication, apply CoMat 06-030 NON AQUEOUS DEVELOPER with aerosol to the HP compressor stage 7/8 inner cavity inspection location 10 and examine immediately.

Clean location 10 in accordance with SPM TASK 70-11-26-300-503.

Final cleaning.

Examine the HP compressor 7/8 inner cavity at inspection location 10 for cracks.

SUBTASK 72-41-11-230-127 Do a Focus FPI of the HP Compressor Stage 8 Disk Inner Cavity Front Face

Figure: HP Compressor Stage 7/8 Inner Cavity Profile - Focus Inspection Location

HP Compressor Stage 7/8 Inner Cavity Profile - Focus Inspection Location

Figure: HP Compressor Stage 3 to 8 Drum Installation on Inspection Tooling

HP Compressor Stage 3 to 8 Drum Installation on Inspection Tooling