Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-11-840-002-002 HPC Stage 3 - 8 Drum Disk - Machine The Grooves For The Wire Seals, Rework-002 (Method 1) - SBE 72-0160

General

The practices and processes referred to in the procedure by TASK number are in the SPM.

Refer to the indicated Service Bulletin for specific application requirements.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Lathe | LOCAL | Lathe | ||

| Milling machine | LOCAL | Milling machine | ||

| Dial test indicators | LOCAL | Dial test indicators | ||

| Standard turning tool | LOCAL | Standard turning tool | ||

| Ball-nosed milling cutter | LOCAL | Ball-nosed milling cutter | ||

| Standard workshop tools | LOCAL | Standard workshop tools | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| IAE 3R19100 Front groove tool | 0AM53 | IAE 3R19100 | ||

| IAE 3R19079 Front groove tool | 0AM53 | IAE 3R19079 | ||

| IAE 3R19080 Rear groove tool | 0AM53 | IAE 3R19080 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 02-005 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-005 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 | ||

| CoMat 06-032 DRY DEVELOPER | 37676 | CoMat 06-032 | ||

| CoMat 06-045 EMULSIFIER - FLUORESCENT PENETRANT, HYDROPHILIC | LOCAL | CoMat 06-045 |

Spares

NONESafety Requirements

CAUTION

Procedure

Refer to the SPM TASK 70-11-26-300-503.

Clean the disk assembly locating faces.

SUBTASK 72-41-11-110-069 Clean the Surfaces

Make sure that cutting and cleaning fluids cannot penetrate the masking.

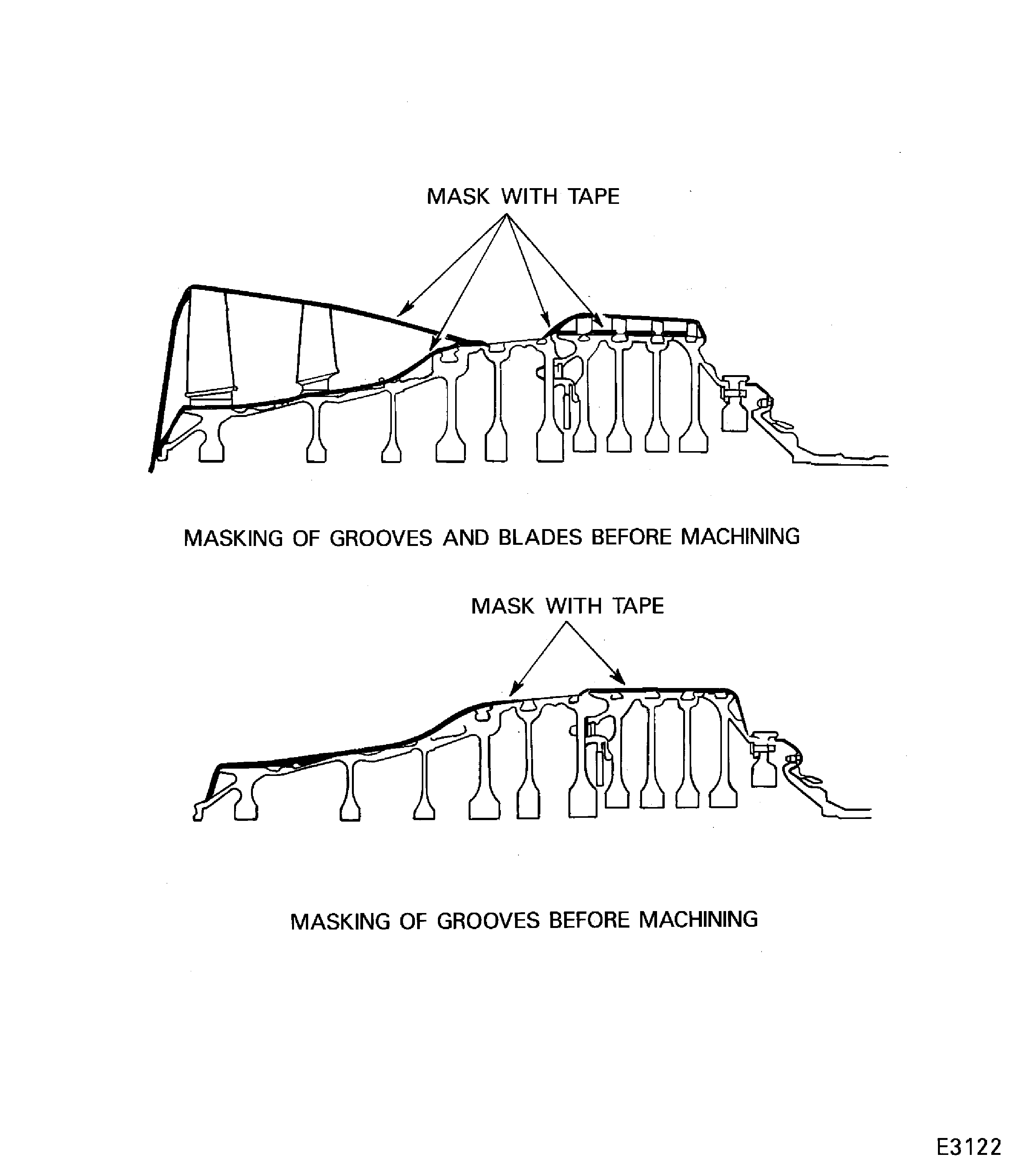

Refer to Figure.

Apply the masking tape to the interface between stage 8 and 9 disks and all other areas, surfaces that do not have to be machined.

SUBTASK 72-41-11-350-073 Apply the Masking Tape

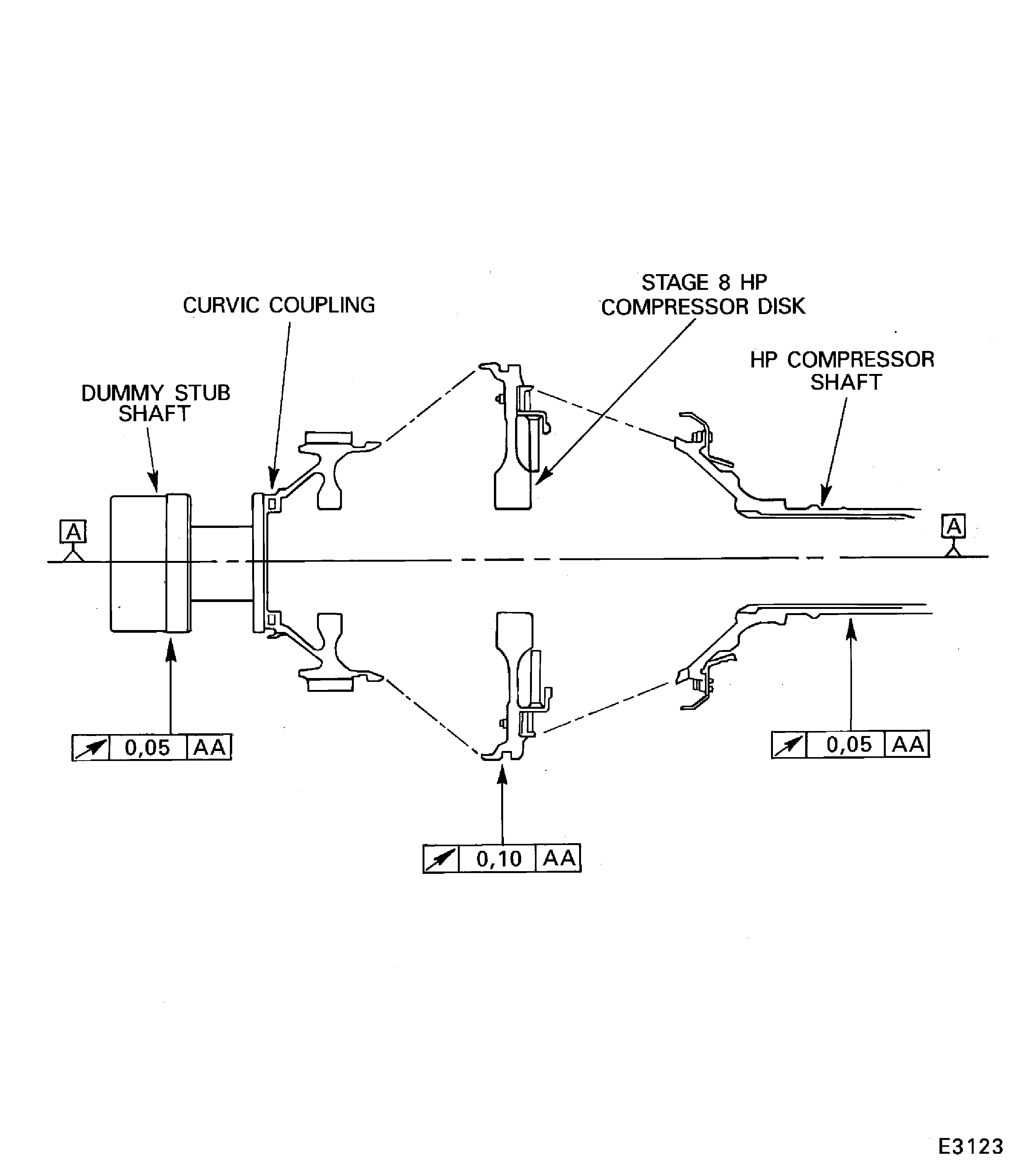

Use dial test indicator to make sure HP compressor runs true.

Refer to Figure.

Set up the HP compressor arrangement for machining.

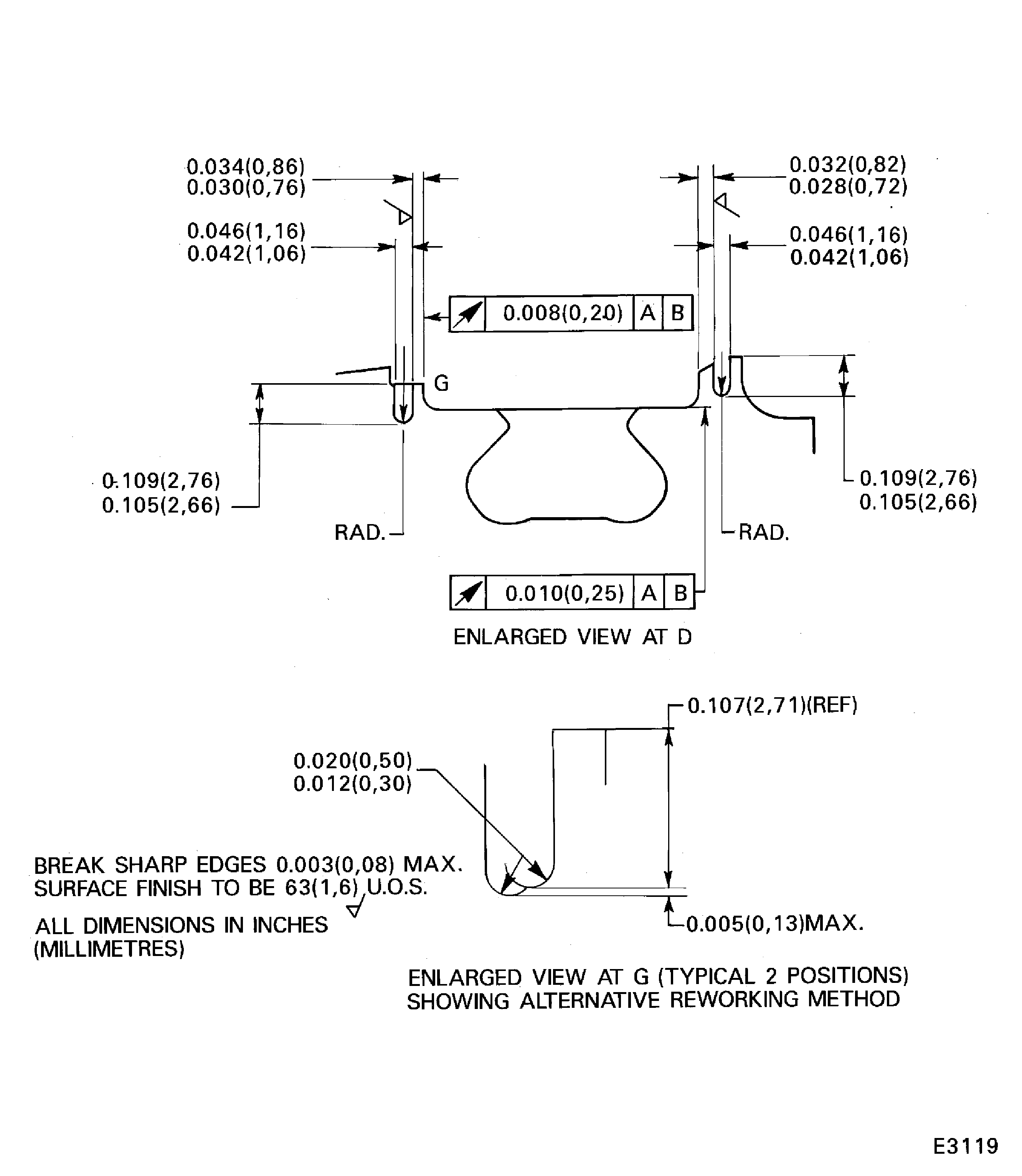

Flat surface required to avoid deflection/breakage of fine groove tool during machining.

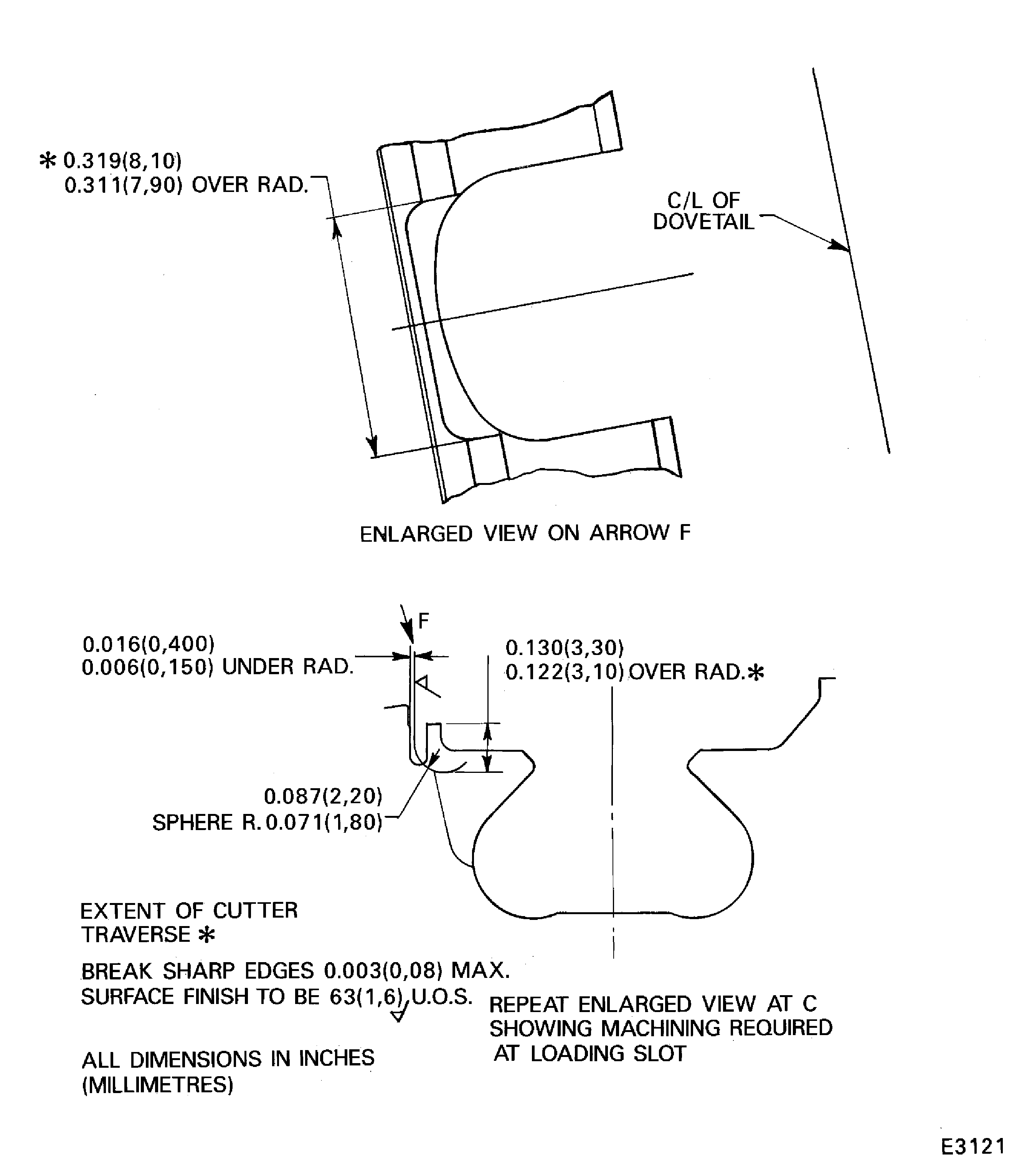

Refer to Figure.

Face-off angled surface at the rear of the stage 8 dovetail slot leaving the 0.028 in. (0.72mm) to 0.032 in. (0.82mm) dimension intact.

Use IAE 3R19100 Front groove tool 1 off.

Machine the damping wire location slots at the front and rear of stages 7 and 8 blade root location slots.

Use IAE 3R19079 Front groove tool 1 off and IAE 3R19080 Rear groove tool 1 off as applicable.

NOTE

Do not machine to full depth of above, allowance for final machining is required.Machine the damping wire location slots at the front and rear of stages 7 and 8 blade root location slots.

SUBTASK 72-41-11-320-053 Machine the Damping Wire Location Slots

Refer to the SPM TASK 70-11-26-300-503.

Chemically clean the machined surfaces in preparation for crack test.

Refer to the SPM TASK 70-11-08-300-503.

Swab etch machined surfaces.

SUBTASK 72-41-11-110-070 Clean the Surfaces

Refer to the SPM TASK 70-11-03-300-503 SUBTASK 70-11-03-300-002.

Clean the machined surfaces.

Refer to the SPM TASK 70-11-03-300-503, SUBTASK 70-11-03-300-002.

Chemically clean to remove masking tape remnants as necessary.

SUBTASK 72-41-11-110-071 Clean the Disk Assembly

Refer to the SPM TASK 70-09-00-400-501.

NUMBER BEFORE 6A4189.

NEW NUMBER 6A5594.

NUMBER BEFORE 6A3934.

NEW NUMBER 6A5592.

NUMBER BEFORE 6A3936.

NEW NUMBER 6A5659.

Use vibro-engraving equipment.

NOTE

Stage 3 rotor blades require to be moved forwards to allow re-identification of stage 3 to 8 HP disk assembly. Disassembly/Assembly of stage 3 to 8 HP disk assembly. Refer to Engine Manual, 72-41-10.Replace the part number with the new part number.

SUBTASK 72-41-11-350-074 Identify the Reworked Part with the New Part Number

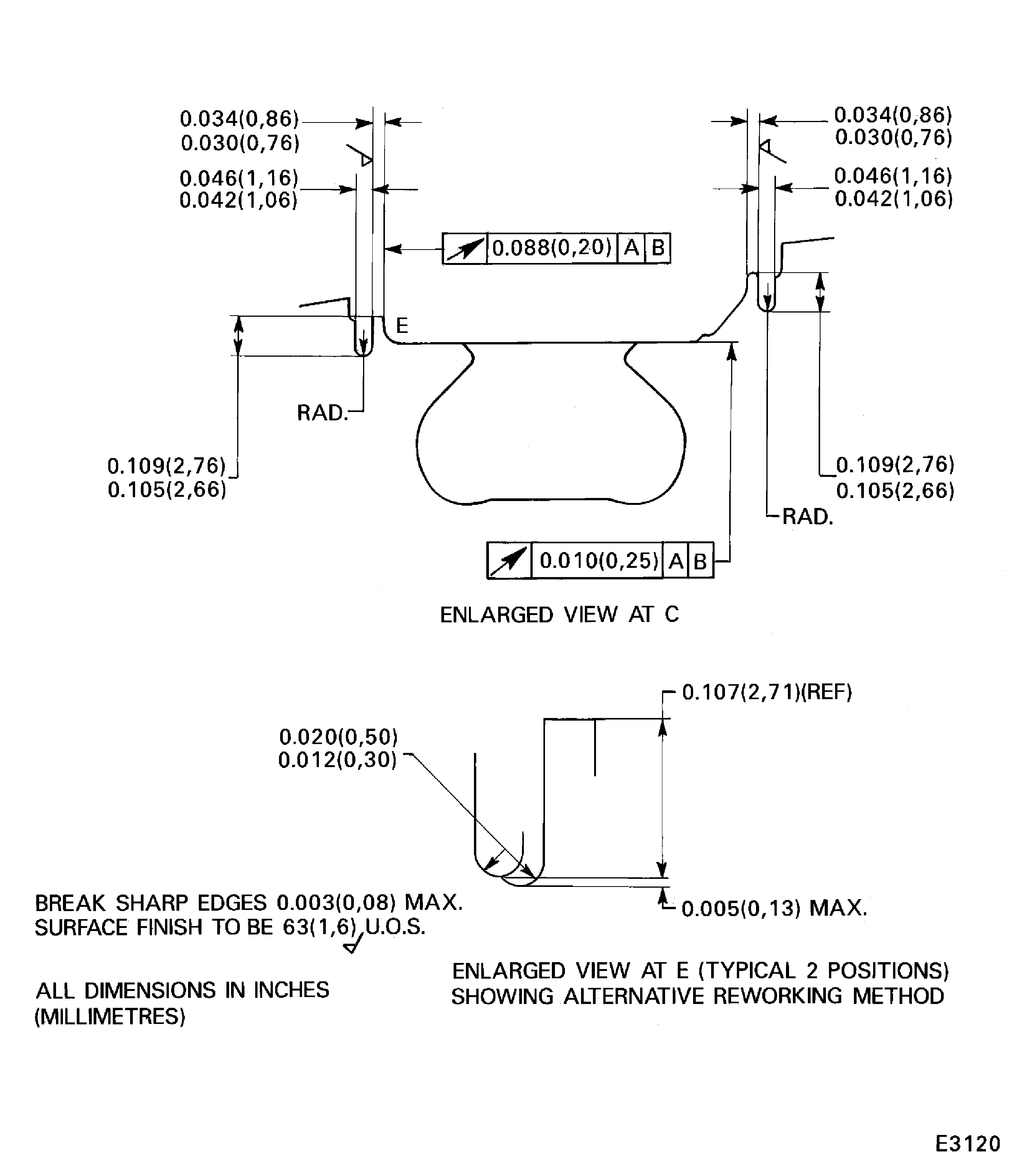

Figure: Rework of stage 3 to 8 disk assembly

Rework of stage 3 to 8 disk assembly

Figure: Rework of HP compressor rotor assembly

Rework of HP compressor rotor assembly

Figure: Rework of existing compressor shaft assembly (stage 8)

Rework of existing compressor shaft assembly (stage 8)

Figure: Rework of existing compressor shaft assembly (stage 7)

Rework of existing compressor shaft assembly (stage 7)

Figure: Rework of existing compressor shaft assembly (stage 7)

Rework of existing compressor shaft assembly (stage 7)