Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-11-840-002-001 HPC Stage 3 - 8 Drum Disk - Machine The Grooves For The Wire Seals, Rework-002 (Method 2) - SBE 72-0161

General

The practices and processes referred to in the procedure by TASK/SUBTASK number are in the SPM.

Refer to the indicated Service Bulletin for specific application requirements.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Centre lathe | LOCAL | Centre lathe | ||

| Milling machine | LOCAL | Milling machine | ||

| Dial test indicators | LOCAL | Dial test indicators | ||

| Standard turning tool | LOCAL | Standard turning tool | ||

| Ball-nosed milling cutter | LOCAL | Ball-nosed milling cutter | ||

| Standard workshop tools | LOCAL | Standard workshop tools | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| Spray gun | LOCAL | Spray gun | ||

| Oven | LOCAL | Oven | ||

| IAE 3R18735 Turning arbor | 0AM53 | IAE 3R18735 | ||

| IAE 3R19100 Front groove tool | 0AM53 | IAE 3R19100 | ||

| IAE 3R19079 Front groove tool | 0AM53 | IAE 3R19079 | ||

| IAE 3R19080 Rear groove tool | 0AM53 | IAE 3R19080 |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

CAUTION

Procedure

Refer to the SPM TASK 70-11-34-300-503.

Clean the disk assembly.

SUBTASK 72-41-11-110-066 Clean the Surfaces

Use IAE 3R18735 Turning arbor 1 off with centre lathe.

Use dial test indicator to ensure disk assembly runs true.

Set up the disk assembly for machining.

Flat surface required to avoid deflection/breakage of fine groove tool during machining.

Refer to Figure.

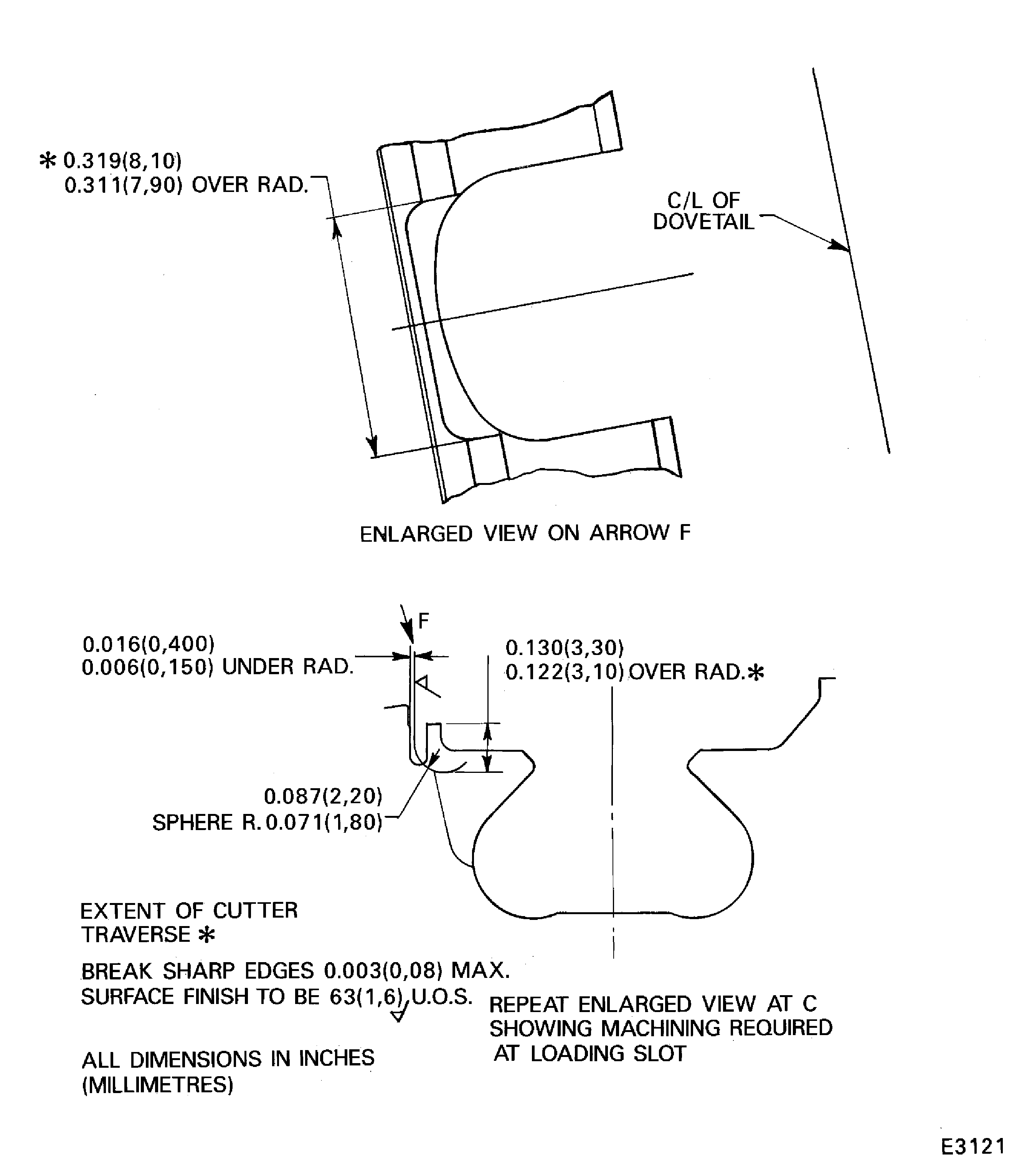

Face off angled surface at the rear of the stage 8 dovetail slot leaving the 0.028 in. (0.72 mm) to 0.032 in. (0.82 mm) dimension intact.

Use IAE 3R19100 Front groove tool 1 off.

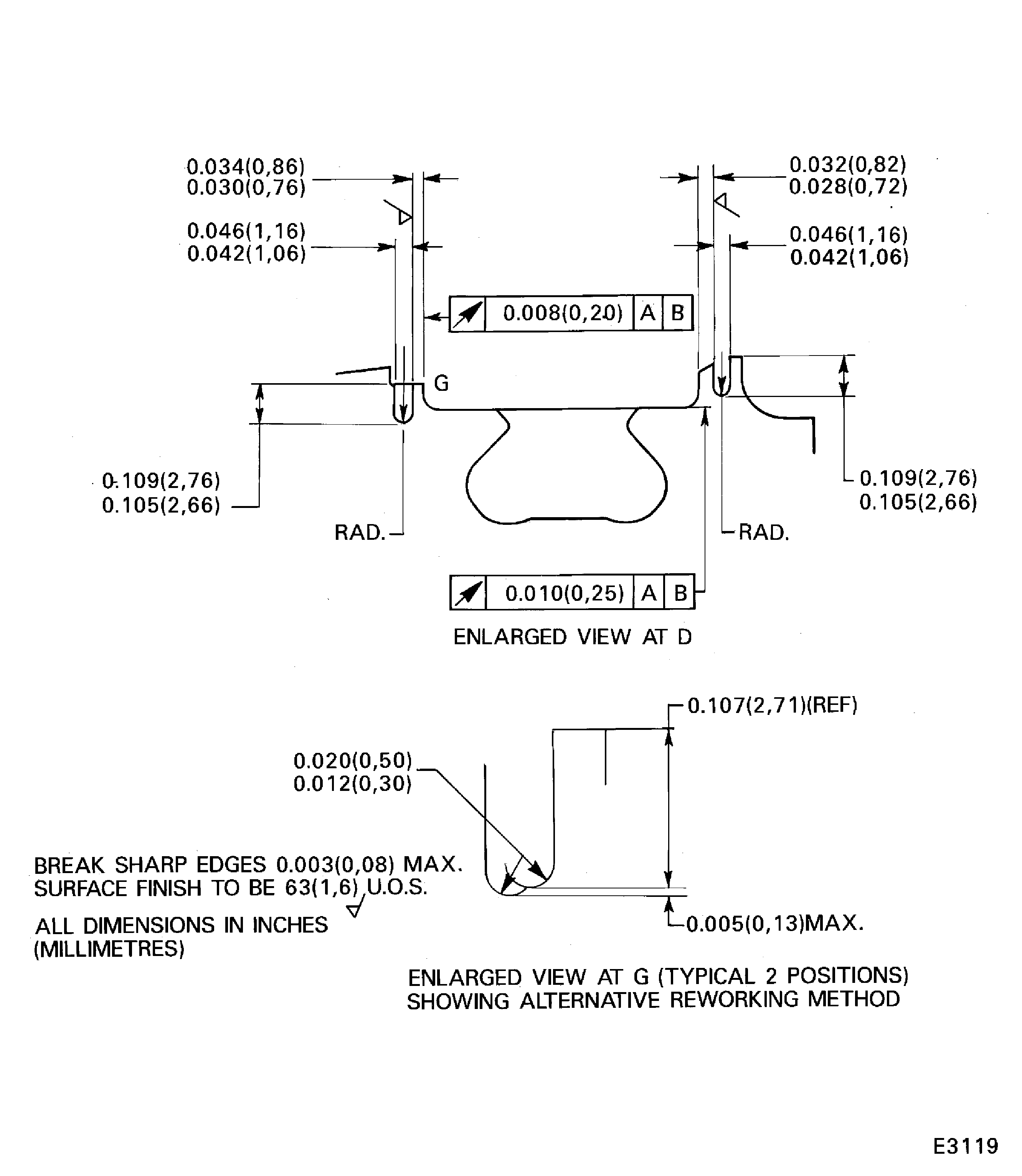

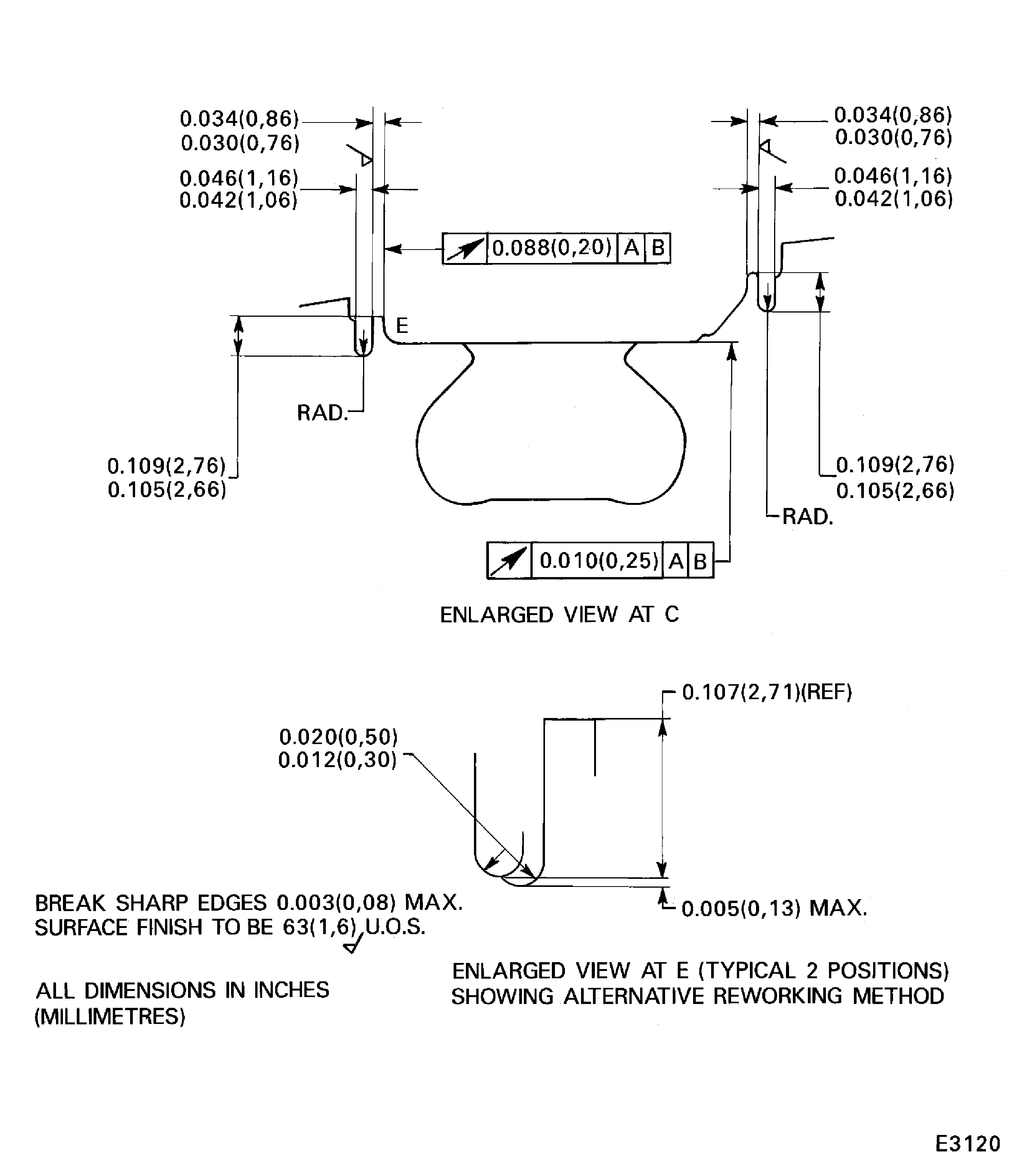

Machine the damping wire location slots at the front of stages 7 and 8 blade root location slots.

Use IAE 3R19079 Front groove tool 1 off and IAE 3R19080 Rear groove tool 1 off as applicable.

NOTE

Do not machine to full depth of above, allowance for final machining is required.Machine the damping wire location slots at the front and rear of stages 7 and 8 blade root location slots.

SUBTASK 72-41-11-320-052 Machine the Damping Wire Location Slots

Refer to the SPM TASK 70-11-14-300-503.

Chemically clean the machined surfaces in preparation for crack test.

Refer to the SPM TASK 70-11-08-300-503.

Swab etch machined surfaces.

SUBTASK 72-41-11-110-067 Clean the Surfaces

Refer to the SPM TASK 70-23-04-230-501.

Reject if cracked.

Do a penetrant crack test.

SUBTASK 72-41-11-230-072 Do a Crack Test

Refer to TASK 72-41-11-100-001-B00, SUBTASK 72-41-11-110-057.

Clean the disk assembly.

SUBTASK 72-41-11-110-068 Clean the Disk Assembly

Refer to the SPM TASK 70-09-00-400-501.

NUMBER BEFORE 6A4189.

NEW NUMBER 6A5594.

NUMBER BEFORE 6A3934.

NEW NUMBER 6A5592.

NUMBER BEFORE 6A3936.

NEW NUMBER 6A5659.

Replace the part number with the new part number.

SUBTASK 72-41-11-350-072 Identify the Reworked Part with the New Part Number

Figure: Rework of existing compressor shaft assembly (stage 8)

Rework of existing compressor shaft assembly (stage 8)

Figure: Rework of existing compressor shaft assembly (stage 7)

Rework of existing compressor shaft assembly (stage 7)

Figure: Rework of existing compressor shaft assembly (stage 7)

Rework of existing compressor shaft assembly (stage 7)