Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-13-840-002 HPC Rear Shaft - Rework The Shaft For A Revised No. 4 Bearing Location Coating, Rework-002 - SBE 72-0403

General

The practices and procedures referred to in the procedure by the TASK number are in the SPM.

Refer to the indicated Service Bulletin for specific application requirements.

Estimated man-hours for this Rework is 14 hours.

Repair Facilities

This is a Source Demonstrated Rework which can only be done by approved vendors.

The Source Demonstration requirements of this rework means that any facility not authorized to accomplish this rework either utilize the Authorized Repair Vendors listed below or contact IAE Technical Services to determine if a qualification program can be initiated at their facility.

IAE - INTERNATIONAL AERO ENGINES AG

C/O ROLLS-ROYCE PLC

P.O. BOX 31

DERBY

DE24 8BJ

ENGLAND

ATTN: Manager Technical Services

Authorized Rework Vendors for the Rework are listed below:

ROLLS-ROYCE - AERO REPAIR AND OVERHAUL

Mavor Avenue

Nerston

East Kilbride

Glasgow G74 4 PY

Scotland

The designation by IAE of an authorized Rework Vendor indicates that the Rework Vendor has demonstrated the necessary capability to enable it to carry out the listed Rework. However, IAE makes no warranties or representations concerning the qualifications or quality standards of the Rework Vendors to carry out the Rework, and accepts no responsibility whatsoever for any work that may be carried out by a Rework Vendor, other than when IAE is listed as the Rework Vendor. Authorized Rework Vendors do not act as agents or representatives of IAE.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Grinding fixture | LOCAL | Grinding fixture | Locally made | |

| Grinding fixture | LOCAL | Grinding fixture | Cylindrical | |

| Dial test indicators | LOCAL | Dial test indicators | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Binoculars | LOCAL | Binoculars | 10x | |

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 06-003 DELETED | 0AM53 | CoMat 06-003 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

NONESafety Requirements

NONEProcedure

Refer to the SPM TASK 70-11-01-300-503. Use chemical cleaning equipment.

Chemically clean the HP compressor rear shaft assembly.

SUBTASK 72-41-13-110-081 Chemically Clean the HP Compressor Rear Shaft Assembly

Refer to Figure and Figure. Refer to the SPM TASK 70-11-39-300-503, SUBTASK 70-11-39-300-001. Use chemical cleaning equipment.

Cold ferric chloride etch surface AB on the HP compressor rear shaft.

SUBTASK 72-41-13-110-082 Cold Ferric Chloride Etch Surface AB on the HP Compressor Rear Shaft

Refer to Figure and Figure. Refer to the SPM TASK 70-23-05-230-501. Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY), with penetrant crack test equipment. Cracks are not permitted.

Do a Local Penetrant Crack Test on Surface AB of the HP Compressor Rear Shaft.

SUBTASK 72-41-13-230-093 Do a Local Penetrant Crack Test on Surface AB of the HP Compressor Rear Shaft

Refer to Figure and Figure. Use CoMat 06-003 DELETED or a mechanical seal. Patch mask all identification marks and symbols.

Seal the full assembly but for the area which is to be shot peened.

SUBTASK 72-41-13-120-053 Shot Peen the Surface AB on the HP Compressor Rear Shaft

Refer to the SPM TASK 70-11-26-300-503, SUBTASK 70-11-26-300-002.

Chemically Clean the Repaired Area.

SUBTASK 72-41-13-110-083 Chemically Clean the Repaired Area

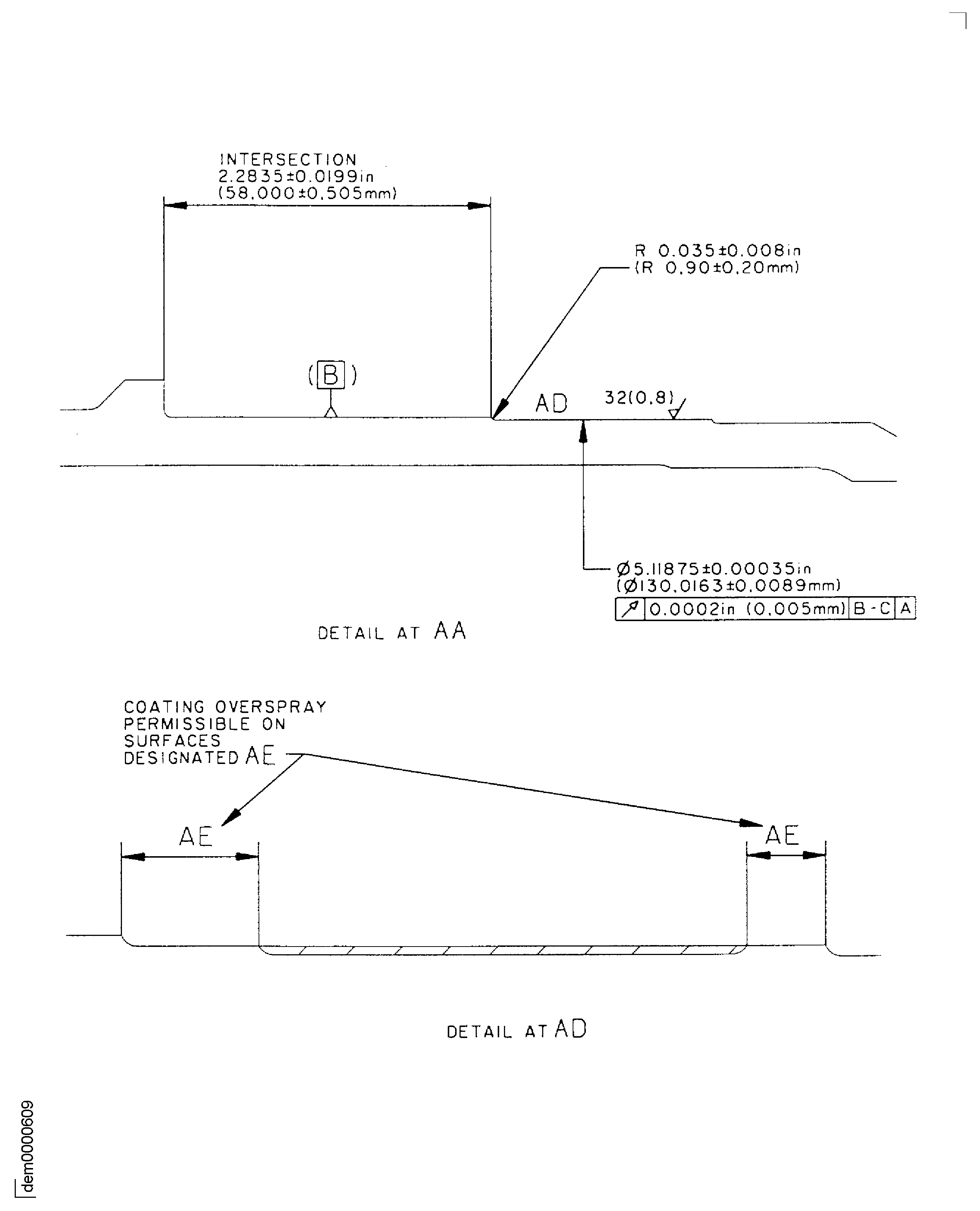

Figure: Rework details and dimensions

Rework details and dimensions

Figure: Rework details and dimensions

Rework details and dimensions