Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-13-300-024 HPC Rear Shaft - Repair Of The Front Seal, Seal Spacer, And HPT Location Diameter(s) By Chromium Plate, Repair-024 (VRS6509)

Effectivity

FIG/ITEM | PART NO. | ASSEMBLY |

|---|---|---|

01-900 | 6A4151 | A |

01-900 | 6A7708 | C |

01-900 | 6A4158 | B |

01-900 | 6A5868 | B |

01-900 | 6A7712 | D |

01-900 | 6A7714 | D |

General

This TASK gives the procedure to repair the front seal, seal spacer and HPT location diameter(s) by chromium plate on the HP Compressor Rear Shaft Assembly.

This repair must only be done when the instruction to do so is given in the relevant inspection procedures (identified by the applicable part number) located in section 72-41-13.

This repair cannot be applied to a location that has been repaired previously in accordance with VRS6545. If VRS6545 has been previously applied at a repair location, this location should have the coating re-applied in accordance with VRS6545.

To put back the fatigue strength, it is necessary to shot peen surfaces, where the damaged material is removed prior to chromium plating.

This repair can only be done four times on each zone only. You must examine the component to see how many times this repair has been carried out before, refer to Step

Where reference is made to a SUBTASK within a TASK in the form "TASK, SUBTASK" the operator must read and apply the complete TASK. The SUBTASK is listed only when the TASK gives options for the processing of the component. The specified SUBTASK instructs what option must be used during application of the TASK for the successful completion of the Repair Scheme VRS6509.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in SPM.

Price and Availability

Refer to International Aero Engines

Related Repairs - none

NOTE

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical Cleaning Equipment | ||

| Fluorescent penetrant inspection equipment | LOCAL | Fluorescent Penetrant Inspection Equipment | ||

| Grinding Machine | LOCAL | Grinding Machine | Cylindrical | |

| Standard workshop equipment | LOCAL | |||

| Dial test indicator | LOCAL | |||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Shot peening equipment | LOCAL | Automatic | ||

| Chromium Plate equipment | LOCAL | |||

| Binocular inspection equipment | LOCAL | X10 | ||

| Dimensional inspection equipment | LOCAL | |||

| Vibro-peen equipment | LOCAL | |||

| Grinding fixture | LOCAL | Locally made |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-003 ADHESIVE TAPE BLACK WATERPROOF | LOCAL | CoMat 02-003 | ||

| CoMat 02-021 MASKING WAX COMPOUND | 59460 | CoMat 02-021 | ||

| CoMat 02-034 METALLIC MASKING TAPE(LEAD FOIL) | 76381 | CoMat 02-034 | ||

| CoMat 05-029 CAST STEEL SHOT, S110 | LOCAL | CoMat 05-029 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

NONESafety Requirements

NONEProcedure

CAUTION

YOU MUST MAKE SURE THAT THE HP COMPRESSOR REAR SHAFT ASSEMBLY CAN BE REPAIRED.CHECK THE CODE SYMBOL TO MAKE SURE THAT THIS REPAIR CAN BE CARRIED OUT.NOTE

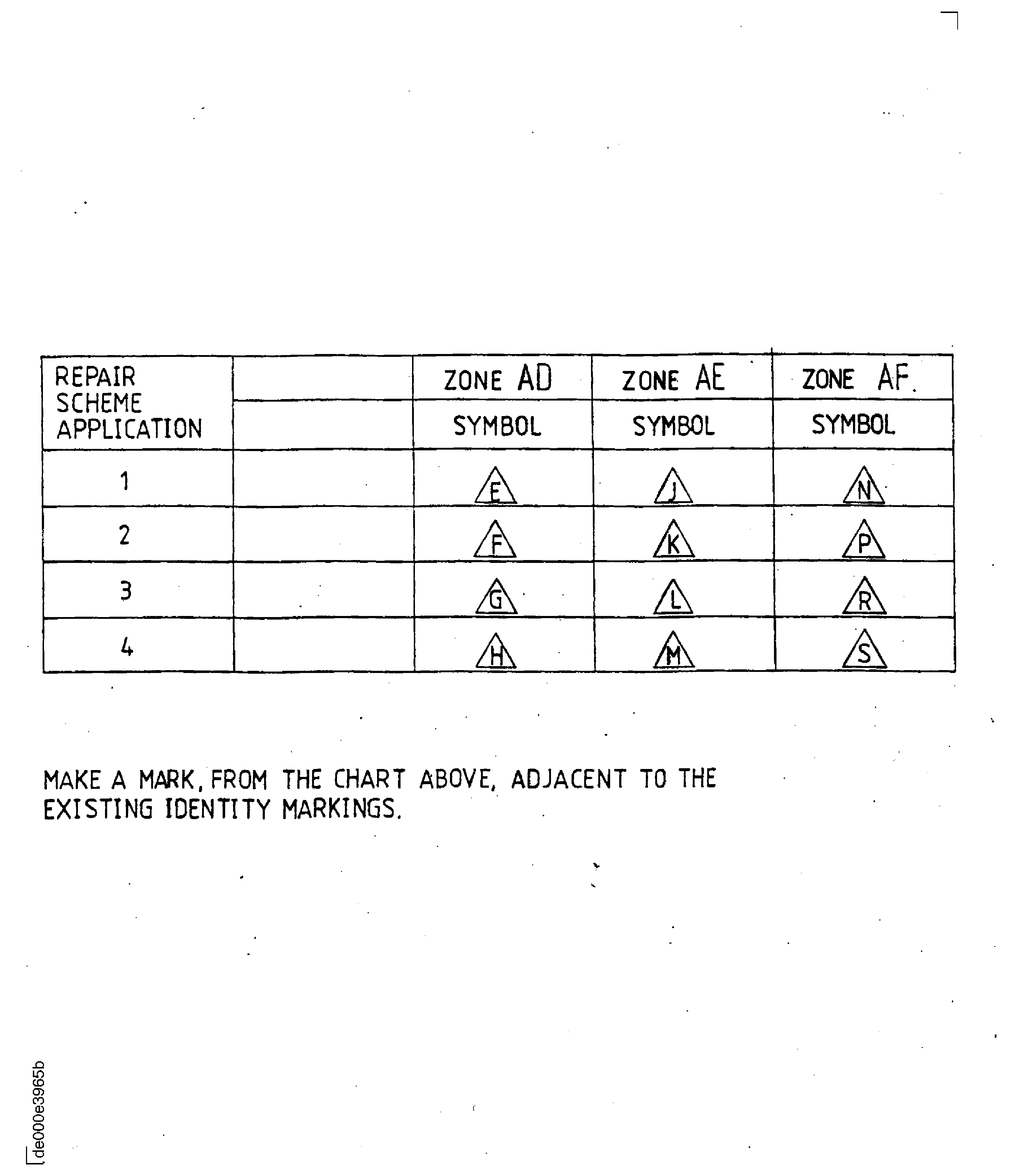

There are three Zones for this repair. They are as follows:(a) Zone AD (Front Seal Diameter)(b) Zone AE (Seal Spacer Diameter)(c) Zone AF (HPT Location Diameter)NOTE

If you see "VRS6509/3" or "VRS6509/4" you cannot carry out this repair again. The HP compressor rear shaft assembly is to be rejected.NOTE

If you see a code symbol (a triangle with a letter in it ) refer to step (1). This is applicable to Zones AD, AE and AF.NOTE

If the identity mark is a triangle with a letter in it you can do this repair unless you see these letters:(a) H for repairs to Zone AD(b) M for repairs to Zone AE(c) S for repairs to Zone AFRefer to Figure.

Keep a record of the identity mark(s) for use with Step

Visually examine the HP Compressor Rear Shaft Assembly, to tell you if this repair has been done before.

SUBTASK 72-41-13-220-152 Make Sure the HP Compressor Rear Shaft Assembly can be Repaired;

Continue with the repair.

If the component is marked with the repair scheme number VRS6545 and one of the suffixes "/21", "/22", "/23", "/24" or "/25":

SUBTASK 72-41-13-220-159 Examine for Previous Applications of VRS6545

Reject.

If the chromium plating from VRS6509 contacts the WC/Co coating applied as part of the relevant service bulletin.

Continue with the repair.

If the chromium plating from VRS6509 does not contact the WC/Co coating applied as part of the relevant service bulletin.

Examine the component to see if it has been repaired in accordance with VRS6509 and reworked in accordance with SB 72-0403 or SB 72-0404.

SUBTASK 72-41-13-220-160 Examine for Combined Application of VRS6509 and SB 72-0403 or SB 72-0404

Refer to TASK 72-41-13-100-000.

Chemically clean the HP Compressor Rear Shaft Assembly.

SUBTASK 72-41-13-110-061 Clean the HP Compressor Rear Shaft Assembly

Refer to SPM TASK 70-23-04-230-501.

Reject.

If cracking is detected.

Continue with the repair.

If no cracking is detected.

Do a local fluorescent penetrant inspection on the applicable diameter.

SUBTASK 72-41-13-230-077 Fluorescent Penetrant Inspect

Refer to SPM TASK 70-33-02-300-503, SUBTASK 70-33-02-300-001.

Chemically strip the chromium plating from the repair location(s).

SUBTASK 72-41-13-330-075 Chemically Strip the Chromium Plating, if Required

Use a locally made Grinding fixture.

Use a cylindrical Grinding Machine and Standard workshop equipment.

Install the fixture into the cylindrical Grinding Machine.

Use a Dial test indicator and Standard workshop equipment.

Make sure that Datums A, B and C are set to turn correctly.

Install the HP Compressor Rear Shaft Assembly on to the fixture and set to turn correctly.

NOTE

There are three diameters. They are at Zones:(a) AD (Front Seal Diameter)(b) AE (Seal Spacer Diameter)(c) AF (HPT Location Diameter)NOTE

If a chromium plate layer has been applied before, make sure all chromium plate is removed.Use a cylindrical Grinding Machine.

Machine only the minimum quantity of material to remove scores or coating.

Grind the applicable diameter(s) to remove all of the damage or existing chromium plating.

SUBTASK 72-41-13-324-053-A00 Grind the HP Compressor Rear Shaft Assembly, if Required

Refer to SPM TASK 70-11-01-300-503.

Chemically clean the HP Compressor Rear Shaft Assembly.

SUBTASK 72-41-13-110-102 Clean the HP Compressor Rear Shaft Assembly

Refer to SPM TASK 70-11-39-300-503.

Cold ferric chloride swab etch the repair area(s) on the HP Compressor Rear Shaft Assembly.

SUBTASK 72-41-13-380-064 Swab Etch

Refer to SPM TASK 70-23-05-230-501.

Reject.

If cracking is detected.

Continue with the repair.

If no cracking is detected.

Do a local fluorescent penetrant inspection on the applicable diameter.

SUBTASK 72-41-13-230-078-A00 Fluorescent Penetrant Inspect

Keep this dimension for use with Step.

Dimensionally inspect the applicable diameter.

SUBTASK 72-41-13-220-153-A00 Dimensionally Inspect the HP Compressor Rear Shaft Assembly

Refer to SPM TASK 70-11-01-300-503.

Chemically clean the assembly.

SUBTASK 72-41-13-110-062 Clean the HP Compressor Rear Shaft Assembly

Use CoMat 02-003 ADHESIVE TAPE BLACK WATERPROOF or a mechanical seal.

Seal the full assembly but for the area to be shot peened.

Refer to SPM TASK 70-38-04-300-503, SUBTASK 70-38-04-300-002.

Use CoMat 05-029 CAST STEEL SHOT, S110 to get an almen intensity of 0.006 in. to 0.009 in. (0.15 mm to 0.23 mm) on 'A' type test strip.

A coverage of 100 percent minimum, 150 percent maximum must be applied.

It is recommended to use a single nozzle with a nozzle to work distance of 4.7 in. (120 mm).

Use automatic Shot peening equipment.

Shot peen the applicable diameter on the HP Compressor Rear Shaft Assembly.

Refer to SPM TASK 70-38-04-300-503, SUBTASK 70-38-04-300-002.

Remove iron contamination after you have shot peened, as necessary.

SUBTASK 72-41-13-380-061-A00 Shot Peen the Repair Area

Refer to SPM TASK 70-38-24-300-503.

Seal areas not to be chromium plated.

SUBTASK 72-41-13-350-073-A00 Seal Surfaces not to be Chromium Plated

Refer to SPM TASK 70-33-02-330-501, SUBTASK 70-33-02-330-018.

Use chromium plating equipment.

Apply sufficient chromium plating to get the correct dimensions when machined, refer to Step.

Chromium plate the assembly on the applicable diameter.

SUBTASK 72-41-13-330-074-A00 Chromium Plate the HP Compressor Rear Shaft Assembly

Use a locally made Grinding fixture.

Use a cylindrical Grinding Machine and Standard workshop equipment.

Install the fixture into the cylindrical Grinding Machine.

Use a Dial test indicator and Standard workshop equipment.

Make sure that Datums A, B and C are set to turn correctly.

Install the HP Compressor Rear Shaft Assembly onto the fixture and set to turn correctly.

Use a cylindrical Grinding Machine.

Machine the applicable diameter.

SUBTASK 72-41-13-324-054-A00 Grind the HP Compressor Rear Shaft Assembly

Refer to SPM TASK 70-11-01-300-503.

Chemically clean the assembly.

SUBTASK 72-41-13-110-063 Clean the HP Compressor Rear Shaft Assembly

Continue with the repair.

If the component has no cracking.

Reject.

If the component has cracking.

Use X10 Binocular inspection equipment.

Visually inspect the HP Compressor Rear Shaft Assembly.

SUBTASK 72-41-13-220-154-A00 Visually and Dimensionally Inspect

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Use Vibro-peen equipment.

Make a mark adjacent to the assembly number.

SUBTASK 72-41-13-350-075 Identify the Repair

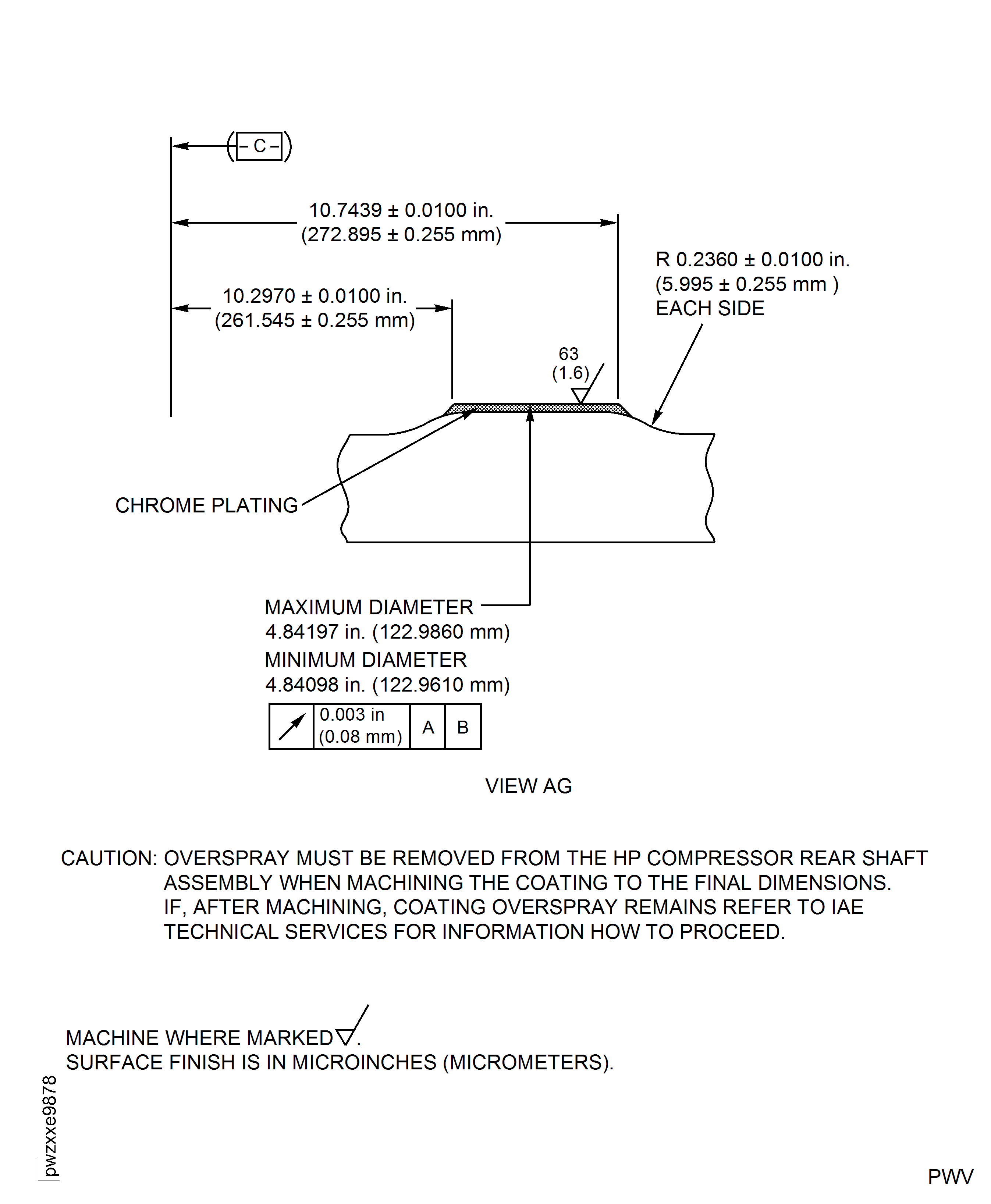

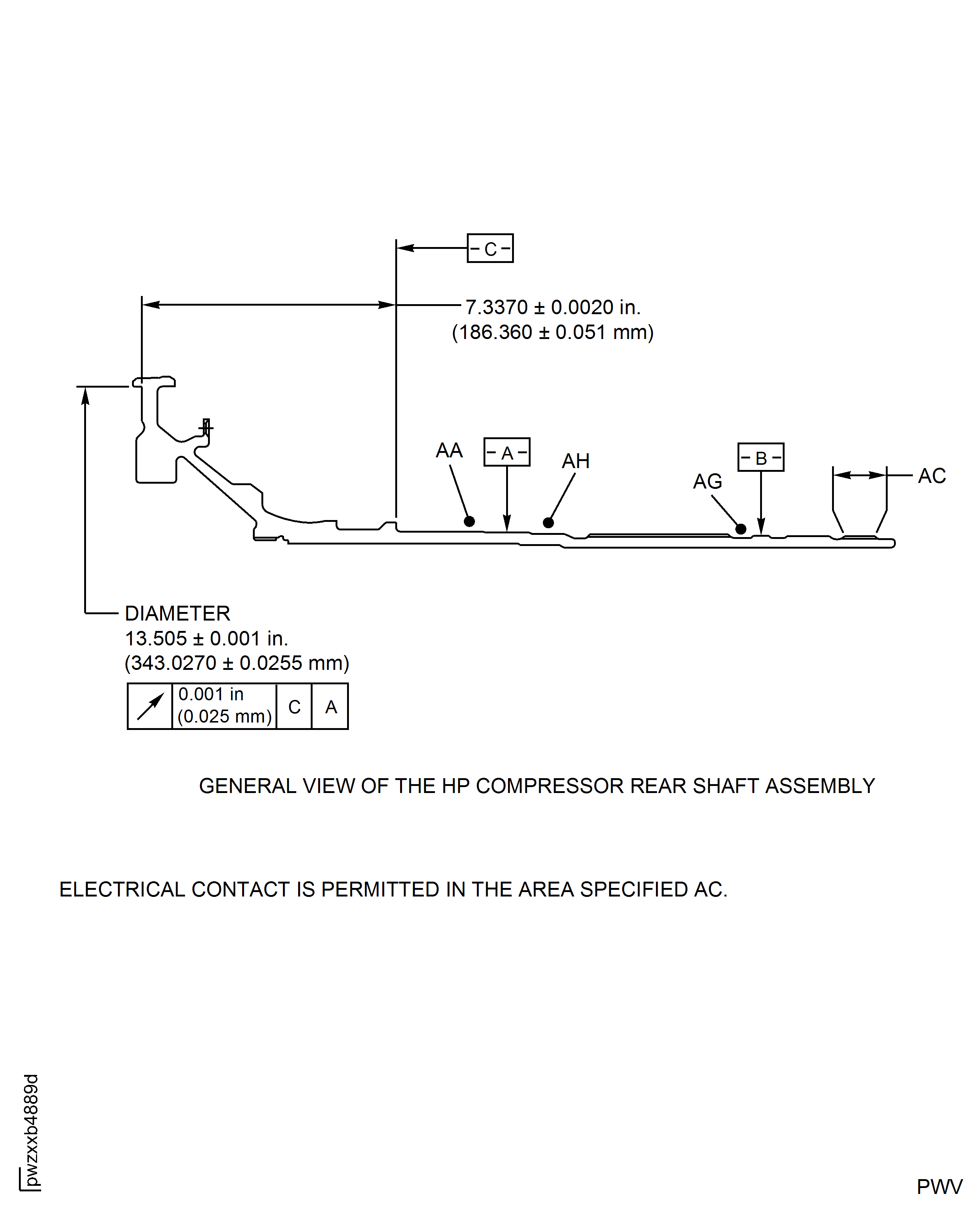

Figure: HP Compressor Rear Shaft Assembly - Repair Details and Dimensions - Assembly A and Assembly C

HP Compressor Rear Shaft Assembly - Repair Details and Dimensions - Assembly A and Assembly C

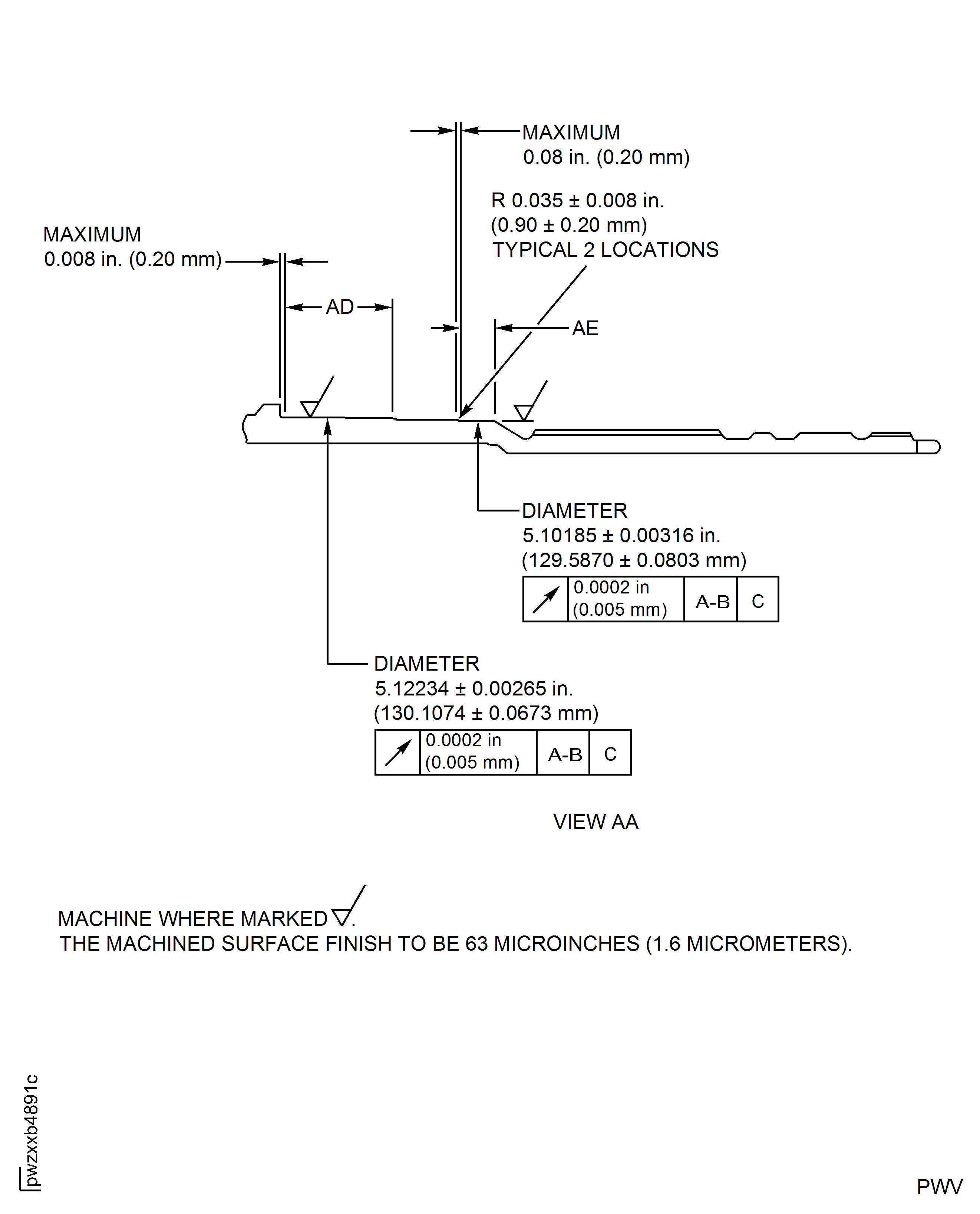

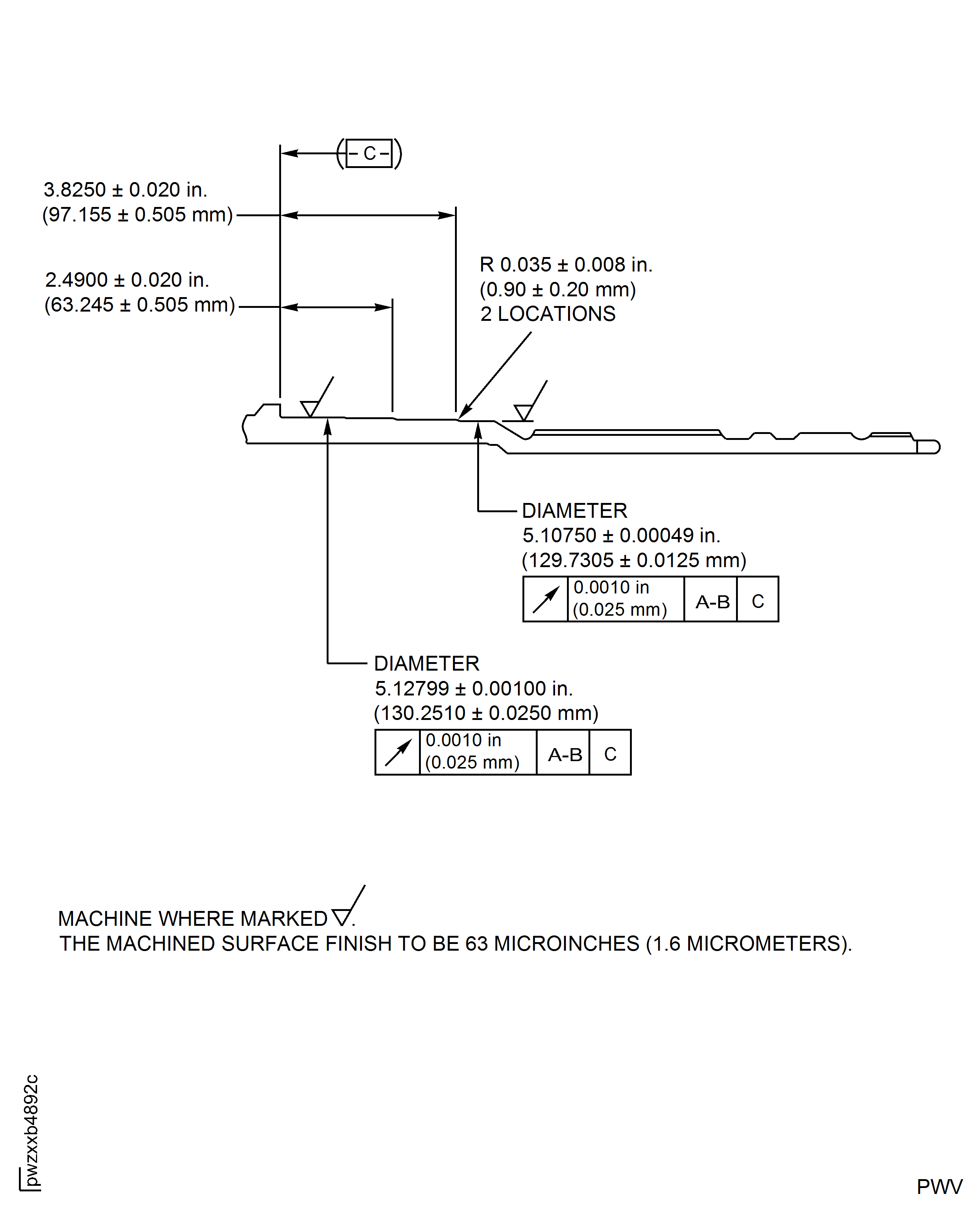

Figure: HP Compressor Rear Shaft Assembly - Repair Details and Dimensions - Assembly B and Assembly D

HP Compressor Rear Shaft Assembly - Repair Details and Dimensions - Assembly B and Assembly D

Figure: HP Compressor Rear Shaft Assembly - Repair Details and Dimensions - Assembly A and Assembly B

HP Compressor Rear Shaft Assembly - Repair Details and Dimensions - Assembly A and Assembly B

Figure: HP Compressor Rear Shaft Assembly - Repair Details and Dimensions - Assembly A and Assembly B

HP Compressor Rear Shaft Assembly - Repair Details and Dimensions - Assembly A and Assembly B

Figure: HP Compressor Rear Shaft Assembly - Repair Details and Dimensions - Assembly A and Assembly B

HP Compressor Rear Shaft Assembly - Repair Details and Dimensions - Assembly A and Assembly B

Figure: HP Compressor Rear Shaft Assembly - Repair Details and Dimensions - Assembly A and Assembly B

HP Compressor Rear Shaft Assembly - Repair Details and Dimensions - Assembly A and Assembly B

Figure: HP Compressor Rear Shaft Assembly - Repair Details and Dimensions - Assembly A and Assembly B

HP Compressor Rear Shaft Assembly - Repair Details and Dimensions - Assembly A and Assembly B

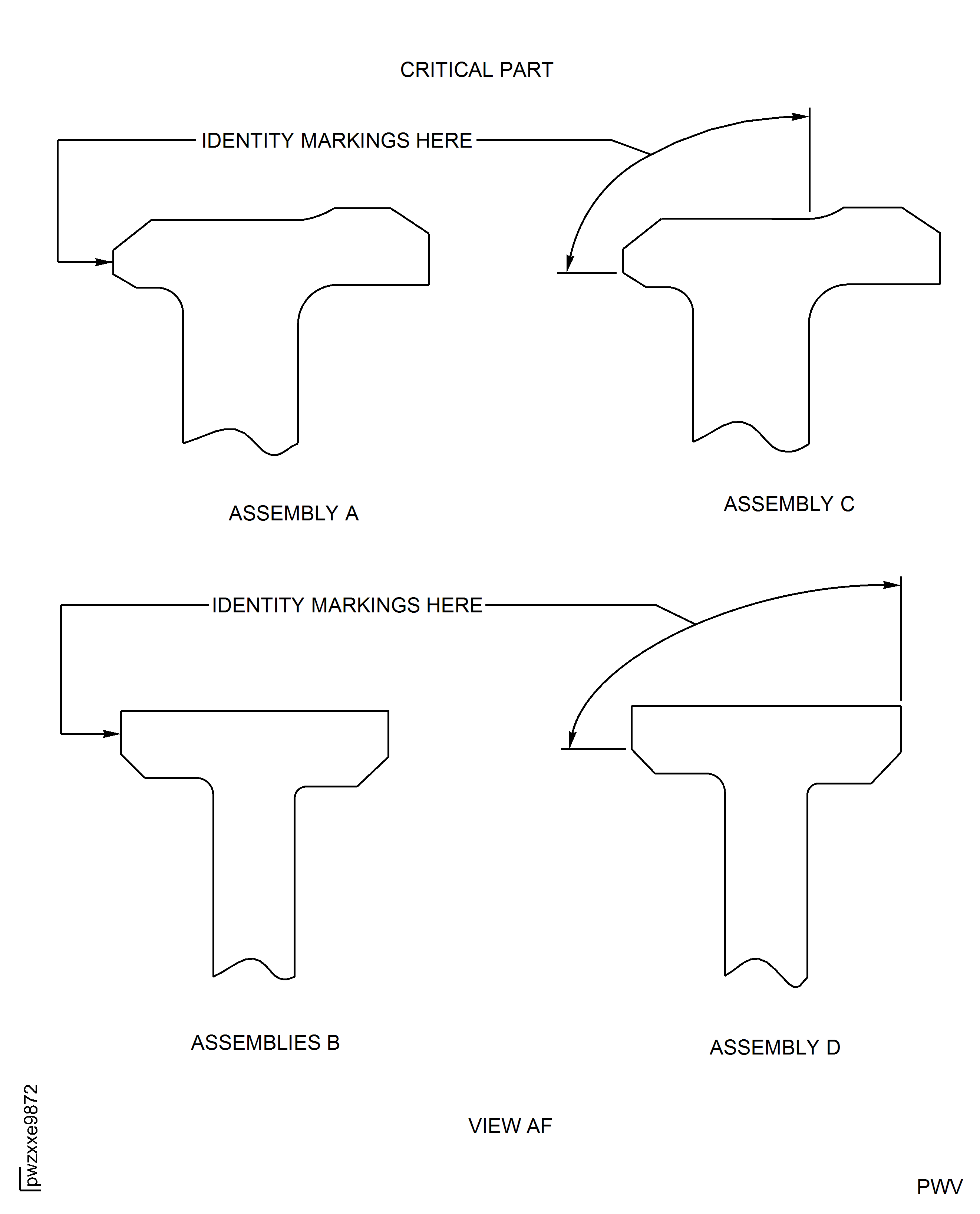

Figure: HP Compressor Rear Shaft Assembly - Identity Marking Locations Details - Assembly A, Assembly B, Assembly C and Assembly D

HP Compressor Rear Shaft Assembly - Identity Marking Locations Details - Assembly A, Assembly B, Assembly C and Assembly D

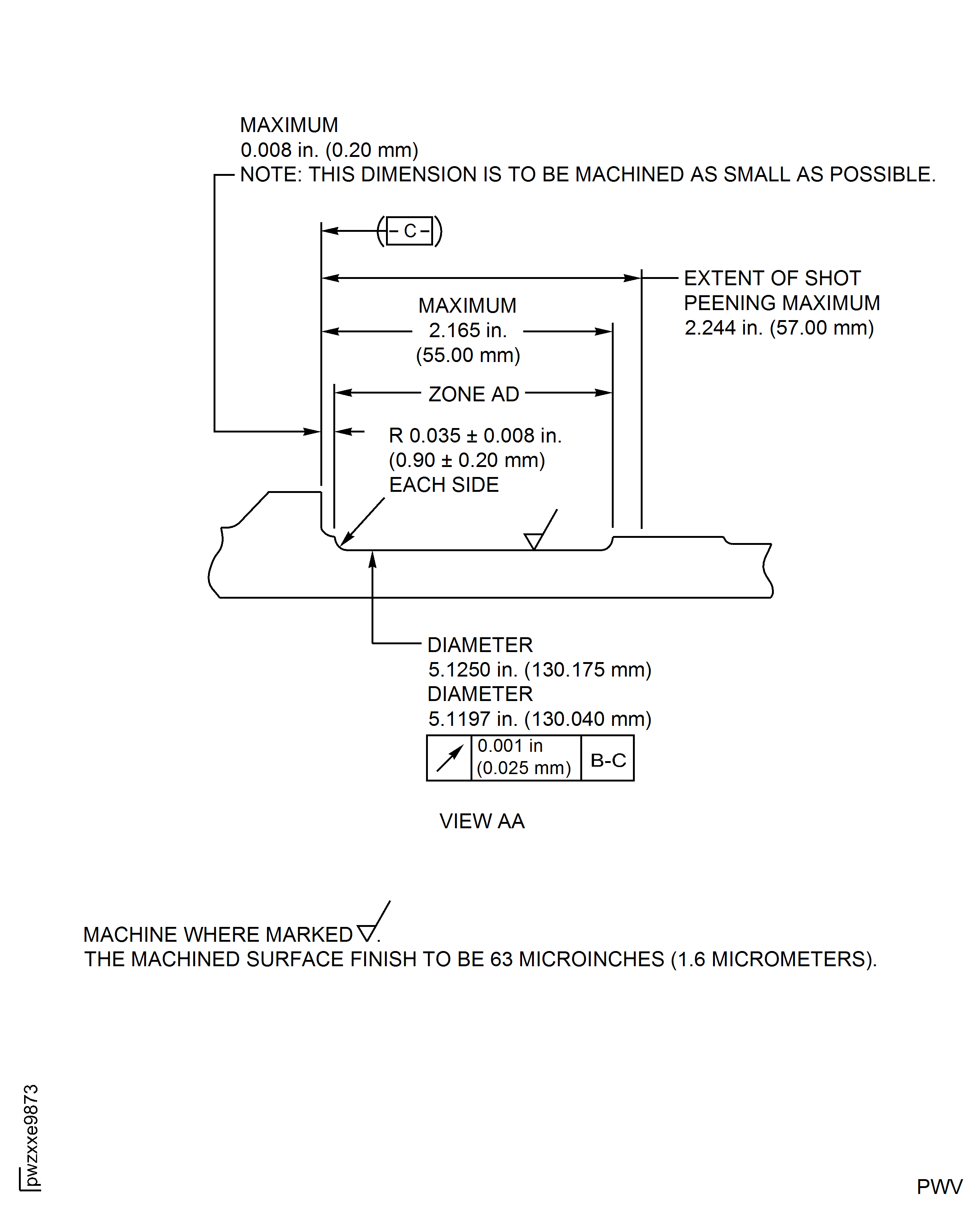

Figure: HP Compressor Rear Shaft Assembly - Zone AD Pre-Coating Dimensions - Assembly C and Assembly D

HP Compressor Rear Shaft Assembly - Zone AD Pre-Coating Dimensions - Assembly C and Assembly D

Figure: HP Compressor Rear Shaft Assembly - Zone AD Final Dimensions - Assembly C and Assembly D

HP Compressor Rear Shaft Assembly - Zone AD Final Dimensions - Assembly C and Assembly D

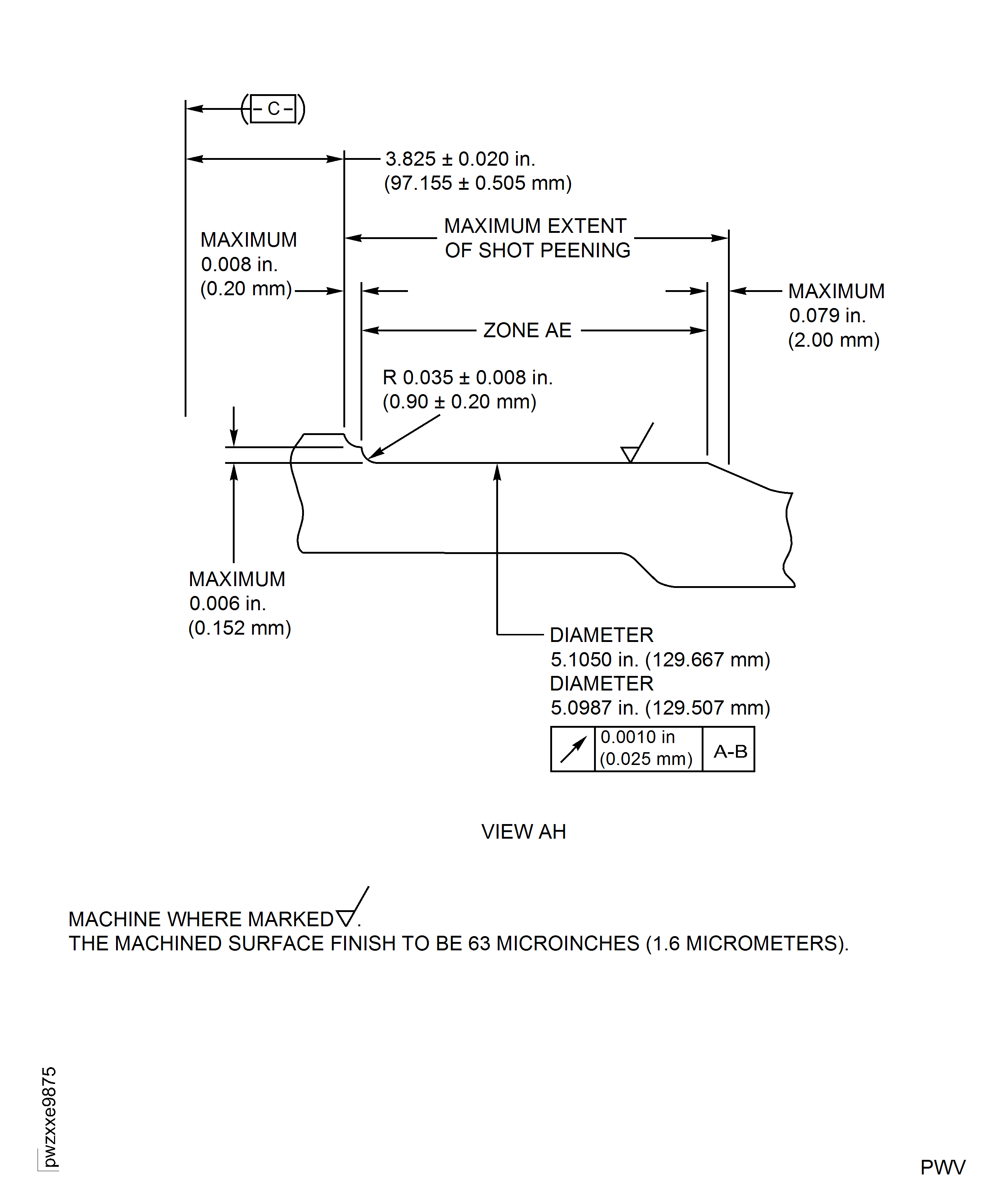

Figure: HP Compressor Rear Shaft Assembly - Zone AE Pre-Coating Dimensions - Assembly C and Assembly D

HP Compressor Rear Shaft Assembly - Zone AE Pre-Coating Dimensions - Assembly C and Assembly D

Figure: HP Compressor Rear Shaft Assembly - Zone AE Final Dimensions - Assembly C and Assembly D

HP Compressor Rear Shaft Assembly - Zone AE Final Dimensions - Assembly C and Assembly D

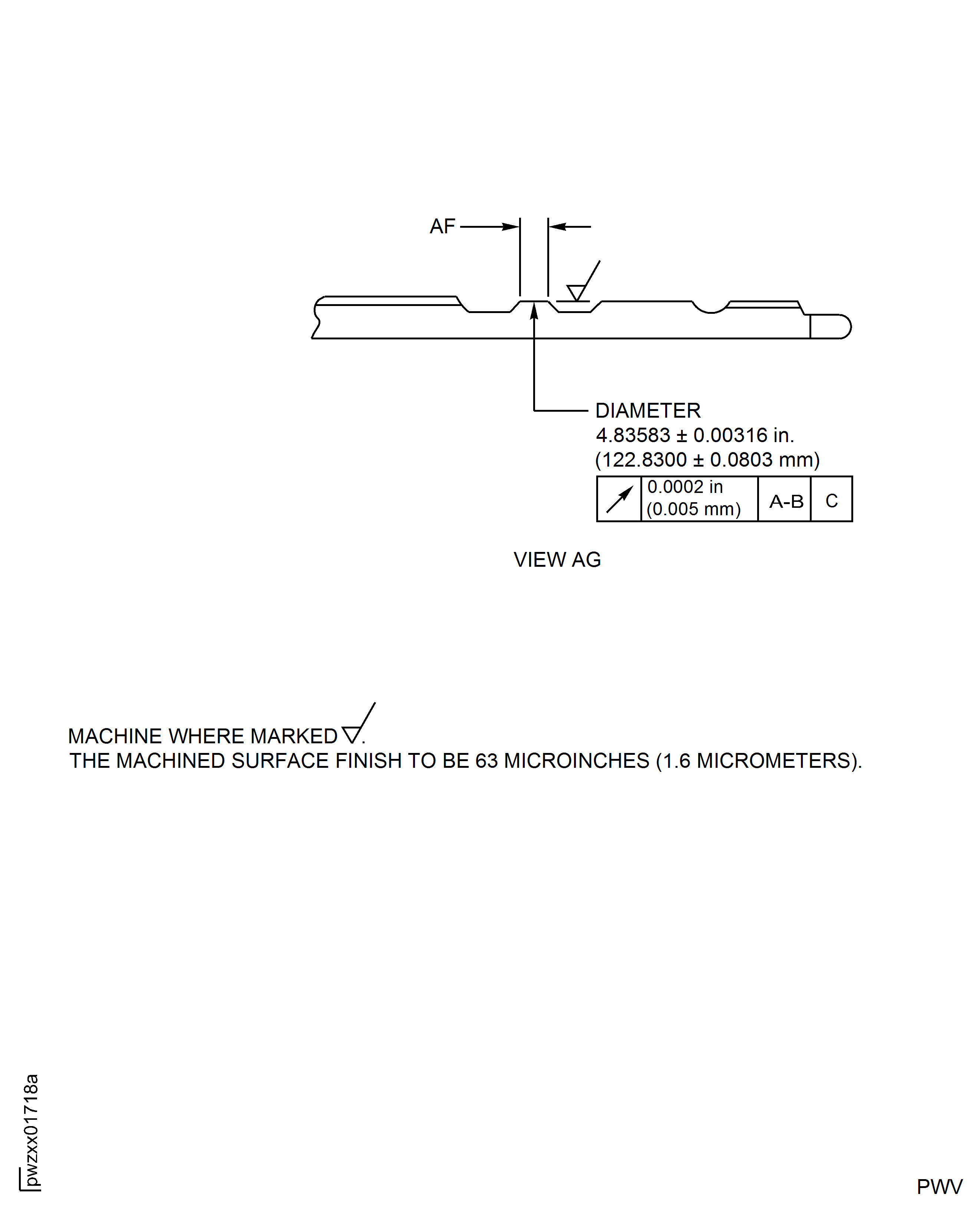

Figure: HP Compressor Rear Shaft Assembly - Zone AF Pre-Coating Dimensions - Assembly C and Assembly D

HP Compressor Rear Shaft Assembly - Zone AF Pre-Coating Dimensions - Assembly C and Assembly D

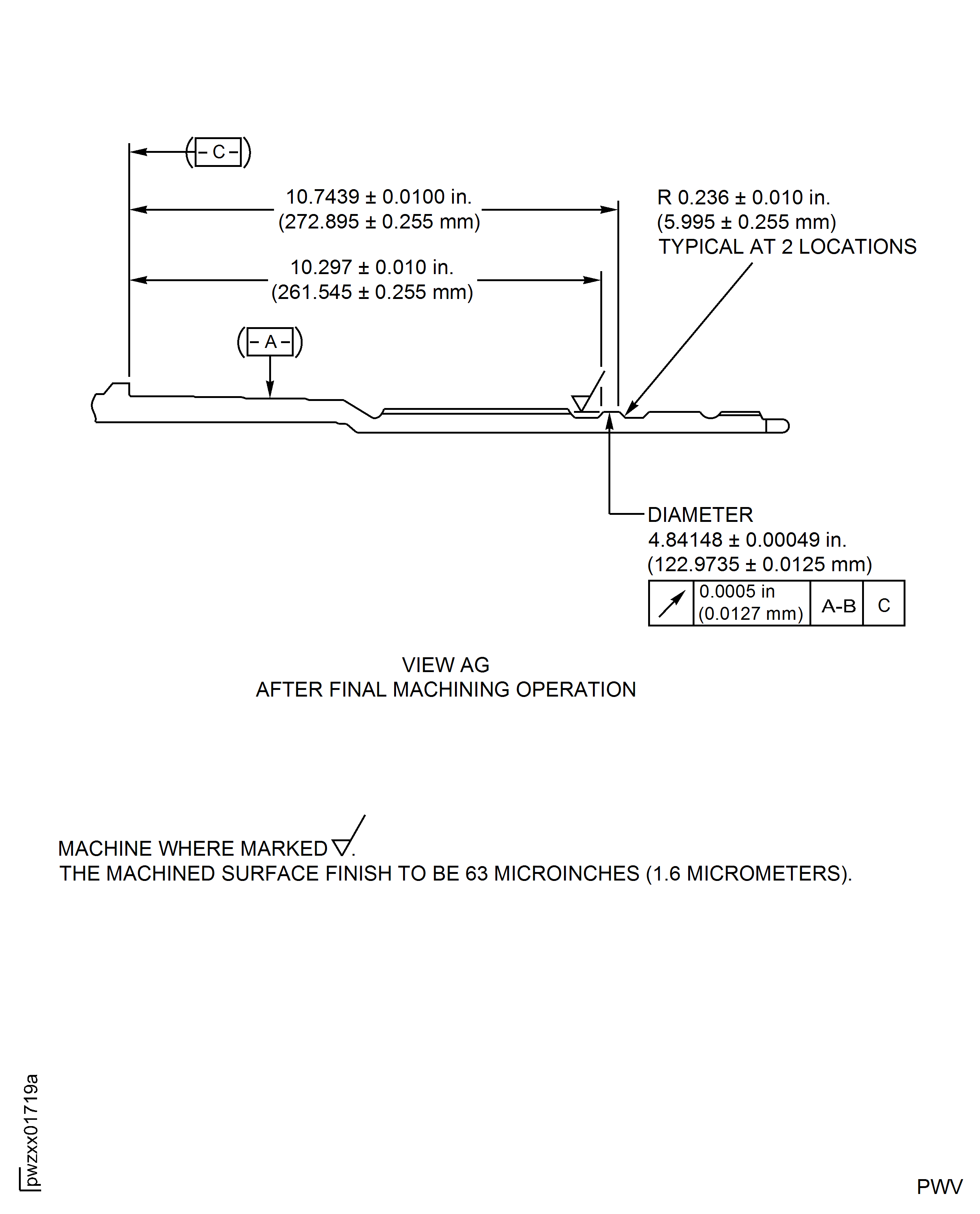

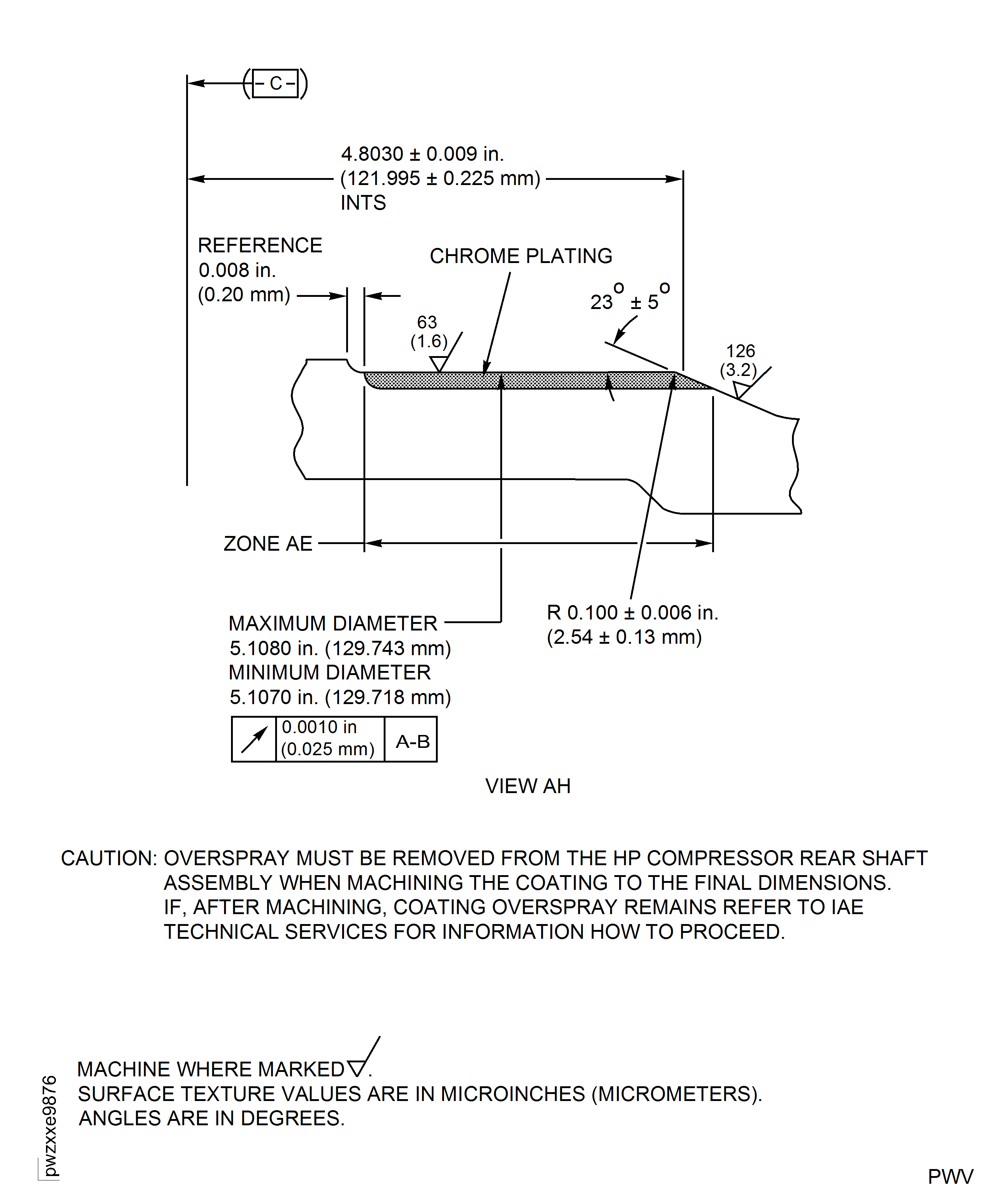

Figure: HP Compressor Rear Shaft Assembly - Zone AF Final Dimensions - Assembly C and Assembly D

HP Compressor Rear Shaft Assembly - Zone AF Final Dimensions - Assembly C and Assembly D