Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-13-300-031 HP Compressor Rear Shaft - Repair Surface Damage On The Splines By Hand Dressing - Repair 031 - VRS6516

Effectivity

FIG/ITEM | PART NO | ASSEMBLY |

|---|---|---|

01-900 | 6A4151 | A |

01-900 | 6A4158 | C |

01-900 | 6A5868 | C |

01-900 | 6A7708 | B |

01-900 | 6A7712 | D |

01-900 | 6A7714 | D |

General

This TASK gives the procedure to repair surface damage on the HP Compressor Splines by hand dressing.

This repair must only be done when the instruction to do so is given in the relevant inspection procedures (identified by the applicable part number) located in section 72-41-13.

This repair scheme is written in 3 parts.

PART 1 - Dress to X1 Depth.

Hand dress the HP Compressor Rear Shaft Splines to remove damage to the depth of the damage only.

PART 2 - Dress to X2 Depth.

Hand dress the HP Compressor Rear Shaft Splines to remove damage to twice the depth of the damage.

PART 3 - Dress to remove burrs, raised material and sharp edges.

Hand dress the HP Compressor Rear Shaft Splines to remove burrs, raised material and sharp edges.

The depth of the applied dressing must be in accordance with the instructions in the inspection/check, refer to TASK 72-41-13-200-001-C00 or TASK 72-41-13-200-001-D00 or TASK 72-41-13-200-001-E00 or TASK 72-41-13-200-001-F00.

Where a defect affects more than one surface (i.e. is on an edge or corner) the damage must be assessed using the most conservative limits from the affected surfaces.

If dressing is required on an edge or corner all edges created by the dressing process must be broken to maximum 0.005 in. (0.13 mm).

If the repair is to be applied to a spline which has been dressed previously care must be taken to make sure that the depth of the existing dressed area(s) is not increased by the latest application of the repair.

Power tools or hand held power tools are not to be used to repair the component.

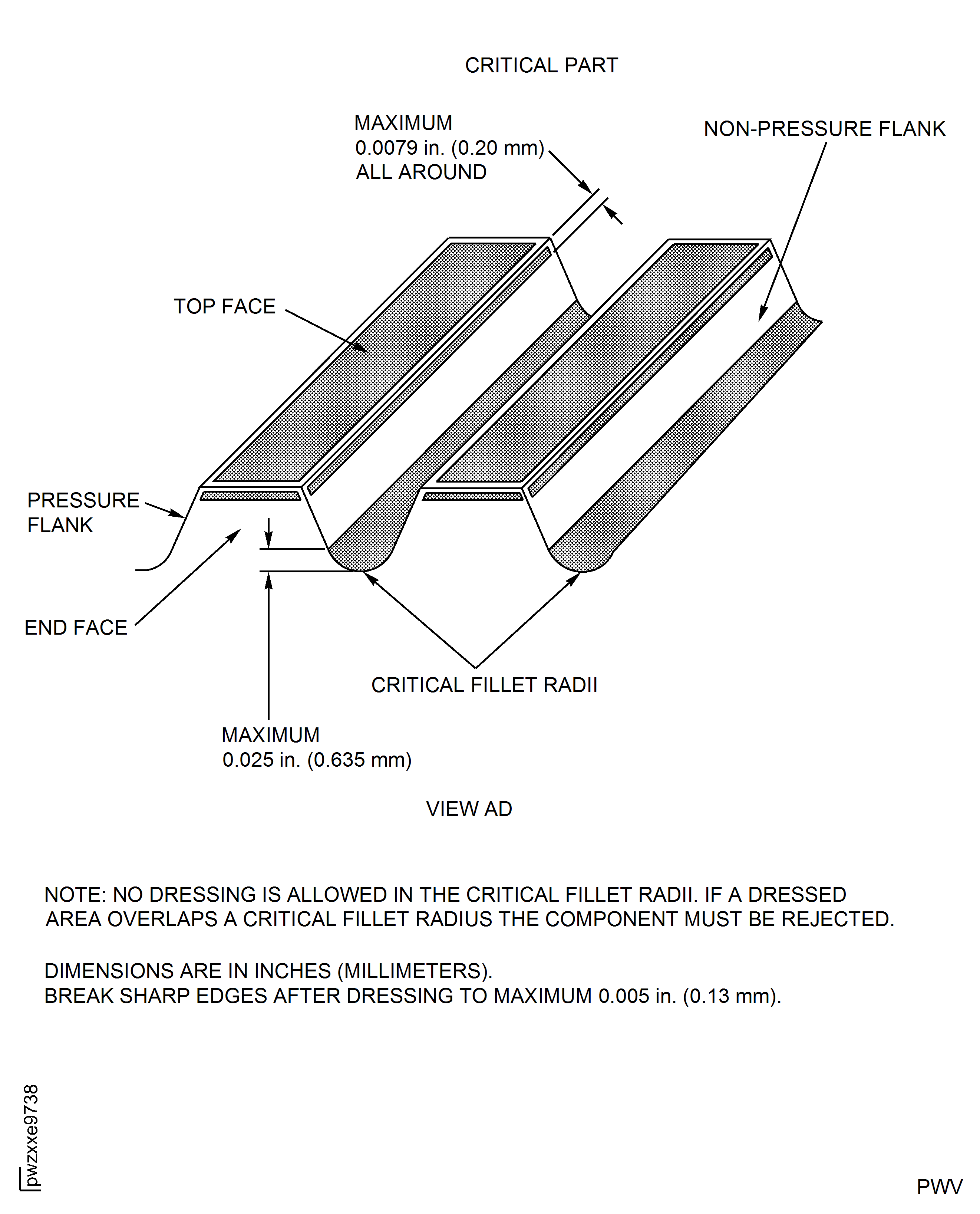

No dressing is allowed in the critical fillet radius, refer to Figure. Polishing in accordance with Part 3 may overlap the critical fillet radius.

TASKS identified by SPM TASK are in the standard practices and processes manual.

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment | ||

| Dimensional inspection equipment | LOCAL | Dimensional inspection equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| Binocular inspection equipment | LOCAL | Binocular inspection equipment | X10 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-096 MARKER PEN | LOCAL | CoMat 02-096 | ||

| CoMat 02-124C MARKING INK | K6858 | CoMat 02-124C | ||

| CoMat 05-074 ALUMINIUM OXIDE ABRASIVE PAPER | 06565 | CoMat 05-074 | ||

| CoMat 05-106 ABRASIVE STONE | K6835 | CoMat 05-106 | ||

| CoMat 05-111 EMERY POLISHING PAPER | 06565 | CoMat 05-111 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

NONESafety Requirements

NONEProcedure

Reject.

If the defects are not within the limits or if any of the repair area(s) extend into a critical fillet radius.

Mark the location(s) that are to be repaired and continue with the repair.

If the defects are within the limits and the repair will not extend into a critical fillet radius.

Refer to TASK 72-41-13-200-001-C00 or TASK 72-41-13-200-001-D00 or TASK 72-41-13-200-001-E00 or TASK 72-41-13-200-001-F00.

Examine the damage on the HP Compressor Rear Shaft.

Continue the repair from Step.

lf there is no dot mark on any of the spline end faces.

Examine the spline end faces for a dot mark from a previous repair.

NOTE

The dot mark will only exist if VRS6516 has been applied previously.

SUBTASK 72-41-13-210-001 Examine the HP Compressor Rear Shaft

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

NOTE

To determine the number of the spline being repaired, use the spline with the vibro-peened dot mark as the number 1 spline and count clockwise, viewed from the rear, to the repaired spline.

If this is the first application of VRS6516 vibro-peen a dot mark on the end face of one of the HP Compressor Rear Shaft Splines to act as a reference.

SUBTASK 72-41-13-210-002 Identify a Reference Spline (If Required)

PART 1- DRESS TO X1 DEPTH

Hand Dress the HP Compressor Rear Shaft Splines to remove damage to the depth of the damage only.

Reject.

If the new damage is located at a location which has been dressed previously.

Continue with the repair.

If the dressed area(s) for the new damage will overlap a previously dressed area and the conditions of the above cautions are satisfied.

Determine if the new damage or subsequent dressed area will affect an existing repair.

SUBTASK 72-41-13-350-001 Examine the Component

CAUTION

IF THE DAMAGED AREA OF THE SPLINE(S) HAS BEEN REPAIRED PREVIOUSLY IN ACCORDANCE WITH VRS6516 CARE MUST BE TAKEN TO MAKE SURE THAT THE DEPTH OF THE EXISTING DRESSING IS NOT INCREASED.

CAUTION

IF THE DEPTH OF ANY EXISTING DRESSING WILL BE INCREASED THE COMPONENT MUST BE REJECTED.NOTE

The number(s) or the spline(s) which have been dressed previously were recorded upon successful completion of VRS6516 to make it easier to identify the repair locations.NOTE

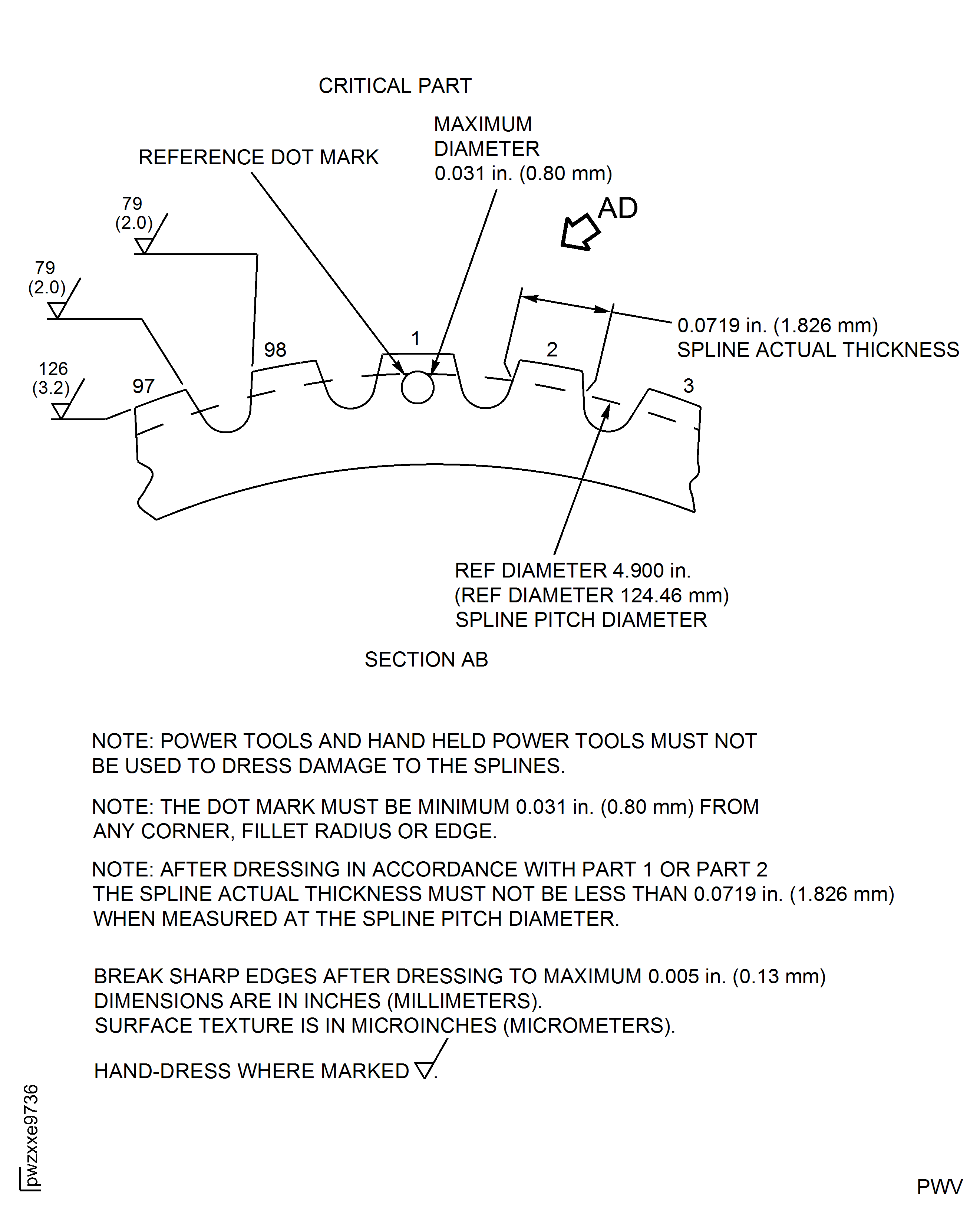

The repaired location(s) on the individual spline(s) and the depth of the dressing were not recorded. Care must be taken during inspection to identify previously repaired locations if further repair is required.Dress to X1 times the depth of the defect only.

Use non-powered hand tools and/or CoMat 05-106 ABRASIVE STONE and CoMat 05-074 ALUMINIUM OXIDE ABRASIVE PAPER

Remove the minimum amount of material necessary to remove the defect(s).

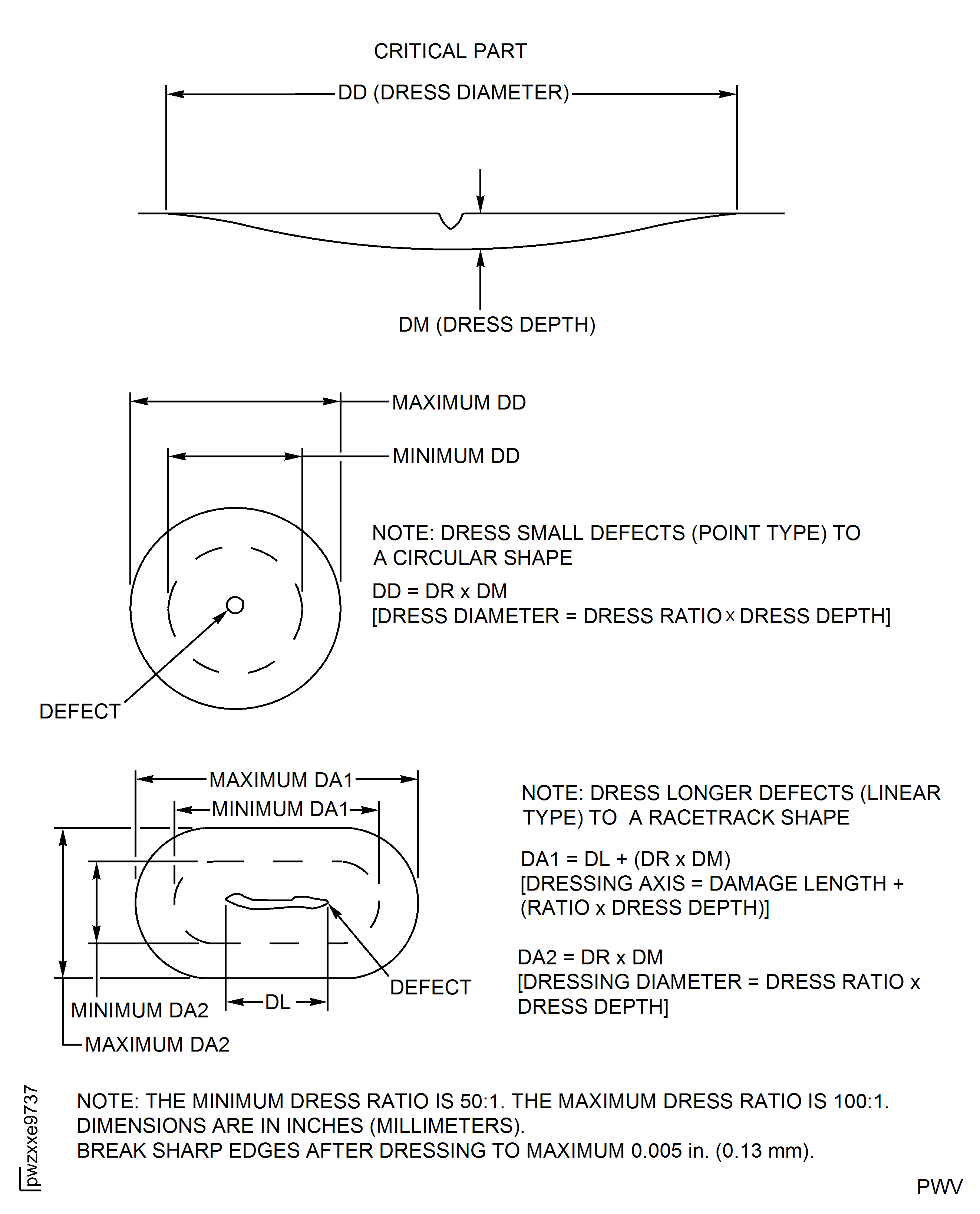

The minimum dress ratio is 50 to 1. The maximum dress ratio is 100 to 1.

Make sure that radii or chamfers affected by the repair do not decrease in size due to the repair.

NOTE

Defects positioned next to each other can be treated as a single defect providing the maximum length-depth ratio is maintained. In case of a combination of defects next to each other which must be dressed to Part 1 and Part 2 where the dressed areas will overlap, the repair must be accomplished in accordance with Part 2.

Hand dress to remove damage from the HP Compressor Rear Shaft Splines.

SUBTASK 72-41-13-350-002 Hand Dress the Identified Defect(s)

CAUTION

DO NOT USE POWER TOOLS OR HAND HELD POWER TOOLS TO REPAIR THE HP COMPRESSOR REAR SHAFT SPLINES.

CAUTION

MAKE SURE THAT ALL BURRS CREATED BY THE DRESSING PROCESS ARE REMOVED.Reject.

If the dressed area overlaps a critical fillet radius.

Reject.

If the dressed areas are in excess of the limits.

Reject.

lf the spline is reduced beyond the minimum actual spline thickness.

Continue with the repair.

If all of the indications of damage have been removed and the repair(s) are within the limits and the spline is not less than the minimum actual spline thickness.

Dimensionally inspect the repaired area(s) of the HP Compressor Rear Shaft Splines.

SUBTASK 72-41-13-220-001 Dimensionally Inspect the Repaired Areas

Refer to SPM TASK 70-11-39-300-503, SUBTASK 70-11-39-300-001.

Cold ferric chloride swab etch the repair areas on the HP Compressor Rear Shaft Splines.

SUBTASK 72-41-13-110-001 Swab Etch the Repair Area(s)

Refer to SPM TASK 70-23-05-230-501, SUBTASK 70-23-05-230-002.

Reject.

If cracking is detected.

Continue with the repair.

If no cracking is detected.

Inspect for cracking at the repair area on the HP Compressor Rear Shaft Splines using fluorescent penetrant inspection.

SUBTASK 72-41-13-230-001 Fluorescent Penetrant Inspect

Hand polish the repair areas.

The surface texture of the repair area(s) on the flanks must be 80 microinches (2.0 micrometres) or better.

The surface texture of the repair area(s) on the top face must be 126 microinches (3.2 micrometres) or better.

Polish the repair area(s) on the HP Compressor Rear Shaft Splines.

SUBTASK 72-41-13-350-003 Polish the Repair Area

CAUTION

DO NOT USE POWER TOOLS OR HAND HELD POWER TOOLS TO REPAIR THE HP COMPRESSOR REAR SHAFT.NOTE

The SUBTASK only needs to be applied if the contact surface of the pressure flank or a combination of the pressure flank and the top face has been dressed in accordance with Part 1 or Part 2 of VRS6516. If the non-pressure flank or just the top face has been dressed then this SUBTASK need not be applied.There must be a minimum of 90% bedding of the pressure flank of the repaired spline(s) after all dressing is complete.

Reject.

lf there is less than 90% bedding of the contact surface on the pressure flank.

Continue with the repair.

lf there is more than 90% bedding of the contact surfaces on the pressure flank.

Do a bedding check (blue bed check) of the contact surface of the pressure flank of the repaired spline(s).

SUBTASK 72-41-13-220-002 Bedding Check the Contact Surface (If Required)

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Vibro-peen VRS6516 at the indicated location(s) on the HP Compressor Rear Shaft.

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

To determine the spline number, use the spline with the vibro-peened dot mark as number 1 and count clockwise, viewed from the rear, to the repaired spline(s).

Vibro-peen the number of the repaired spline(s) adjacent to the repair scheme number at the indicated location.

NOTE

It will only be required to remove raised material, burrs and/or sharp edges from the dot mark location if this is the first application of VRS6516.

Remove raised material, burrs and/or sharp edges at the vibro-peen marking area and the dot mark.

SUBTASK 72-41-13-350-004 Identify the Repair

PART 2-DRESS TO X2 DEPTH

Hand dress the HP Compressor Rear Shaft Splines to remove damage to twice the depth of the damage

Reject.

If the new damage is located at a location which has been dressed previously.

Continue with the repair.

If the dressed area(s) for the new damage will overlap a previously dressed area and the conditions of the above cautions are satisfied.

Determine if the new damage or subsequent dressed area will affect an existing repair.

SUBTASK 72-41-13-210-003 Examine the Component

CAUTION

IF THE DAMAGED AREA OF THE SPLINE(S) HAS BEEN REPAIRED PREVIOUSLY IN ACCORDANCE WITH VRS6516 CARE MUST BE TAKEN TO MAKE SURE THAT THE DEPTH OF THE EXISTING DRESSING IS NOT INCREASED.

CAUTION

IF THE DEPTH OF ANY EXISTING DRESSING WILL BE INCREASED THE COMPONENT MUST BE REJECTED.NOTE

The number(s) or the spline(s) which have been dressed previously were recorded upon successful completion of VRS6516 to make it easier to identify the repair locations.NOTE

The repaired location(s) on the individual spline(s) and the depth of the dressing were not recorded. Care must be taken during inspection to identify previously repaired locations if further repair is required.Dress to X2 times the depth of the defect only.

Use non-powered hand tools and/or CoMat 05-106 ABRASIVE STONE and CoMat 05-074 ALUMINIUM OXIDE ABRASIVE PAPER.

The minimum dress ratio is 50 to 1. The maximum dress ratio is 100 to 1.

Make sure that radii or chamfers affected by the repair do not decrease in size due to the repair.

NOTE

Defects positioned next to each other can be treated as a single defect providing the maximum length-depth ratio is maintained. In case of a combination of defects next to each other which must be dressed to Part 1 and Part 2 where the dressed areas will overlap, the repair must be accomplished in accordance with Part 2.

Hand dress to remove damage from the HP Compressor Rear Shaft Splines.

SUBTASK 72-41-13-350-005 Hand Dress the Identified Defect(s)

CAUTION

DO NOT USE POWER TOOLS OR HAND HELD POWER TOOLS TO REPAIR THE HP COMPRESSOR REAR SHAFT SPLINES.

CAUTION

MAKE SURE THAT ALL BURRS CREATED BY THE DRESSING PROCESS ARE REMOVED.Reject.

If the dressed area(s) overlaps a critical fillet radius.

Reject.

If the dressed area(s) are in excess of twice the limits in the Inspection/Check.

Reject.

lf the spline is reduced beyond the minimum actual spline thickness.

Continue with the repair.

If all of the indications of damage have been removed, the repair(s) are within the limits and the spline is not less than the minimum actual spline thickness.

Dimensionally inspect the repaired area(s) of the HP Compressor Rear Shaft Splines.

SUBTASK 72-41-13-220-003 Dimensionally Inspect the Repaired Areas

Refer to SPM TASK 70-11-39-300-503, SUBTASK 70-11-39-300-001.

Cold ferric chloride swab etch the repair areas on the HP Compressor Rear Shaft Splines.

SUBTASK 72-41-13-110-002 Swab Etch the Repair Area(s)

Refer to SPM TASK 70-23-05-230-501, SUBTASK 70-23-05-230-002.

Reject.

If cracking is detected.

Continue with the repair.

If no cracking is detected.

Inspect for cracking at the repair area on the HP Compressor Rear Shaft Splines using fluorescent penetrant inspection.

SUBTASK 72-41-13-230-002 Fluorescent Penetrant Inspect

Hand polish the repair areas.

The surface texture of the repair area(s) on the flanks must be 80 microinches (2.0 micrometres) or better.

The surface texture of the repair area(s) on the top face must be 126 microinches (3.2 micrometres) or better.

Polish the repair area(s) on the HP Compressor Rear Shaft Splines.

SUBTASK 72-41-13-350-006 Polish the Repair Area(s)

CAUTION

DO NOT USE POWER TOOLS OR HAND HELD POWER TOOLS TO REPAIR THE HP COMPRESSOR REAR SHAFT.NOTE

The SUBTASK only needs to be applied if the contact surface of the pressure flank or a combination of the pressure flank and the top face has been dressed in accordance with Part 1 or Part 2 of VRS6516. If the non-pressure flank or just the top face has been dressed then this SUBTASK need not be applied.There must be a minimum of 90% bedding of the pressure flank of the repaired spline(s) after all dressing is complete.

Reject.

lf there is less than 90% bedding of the contact surface on the pressure flank.

Continue with the repair.

lf there is more than 90% bedding of the contact surfaces on the pressure flank.

Do a bedding check (blue bed check) of the contact surface of the pressure flank of the repaired spline(s).

SUBTASK 72-41-13-220-004 Bedding Check the Contact Surface (If Required)

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Vibro-peen VRS6516 at the indicated location(s) on the HP Compressor Rear Shaft.

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

To determine the spline number, use the spline with the vibro-peened dot mark as number 1 and count clockwise, viewed from the rear, to the repaired spline(s).

Vibro-peen the number of the repaired spline(s) adjacent to the repair scheme number at the indicated location.

NOTE

It will only be required to remove raised material, burrs and/or sharp edges from the dot mark location if this is the first application of VRS6516.

Remove raised material, burrs and/or sharp edges at the vibro-peen marking area and at the dot mark.

SUBTASK 72-41-13-350-007 Identify the Repair

PART 3 - Dress to Remove Burrs, Raised Material and Sharp Edges.

Hand dress the HP Compressor Rear Shaft Splines to remove burrs, raised material and sharp edges.

Dress to remove burrs, raised material and sharp edges from the defect/repair area only.

If the dressed area overlaps a corner or chamfer make the edges of the polished area smooth.

Make sure that radii or chamfers affected by the repair do not decrease in size due to the repair.

Use non-powered hand tools and/or CoMat 05-106 ABRASIVE STONE and CoMat 05-074 ALUMINIUM OXIDE ABRASIVE PAPER.

Hand dress to remove burrs, raised material and/or sharp edges from the HP Compressor Rear Shaft splines.

SUBTASK 72-41-13-350-008 Dress the Burrs, Raised Material and/or Sharp Edges at the Repair Area

CAUTION

DO NOT USE POWER TOOLS OR HAND HELD POWER TOOLS TO REPAIR THE HP COMPRESSOR REAR SHAFT.

CAUTION

MAKE SURE THAT ALL OF THE BURRS CREATED BY THE REPAIR PROCESS ARE REMOVED.Reject.

lf all of the damage burrs, raised material and sharp edges have not been removed or if the repair area(s) does not have a smooth profile.

Continue with the repair.

If all of the damage burrs, raised material and sharp edges have been removed and the repair area(s) has a smooth profile.

Make sure that all of the burrs, raised material and sharp edges have been removed and that the repair area(s) has a smooth profile.

Examine the repaired area(s) of the HP Compressor Rear Shaft Splines.

Accept.

If the dressed area overlaps another dressed area.

Reject.

If the dressed area overlaps a critical fillet radius.

SUBTASK 72-41-13-220-005 Examine the Dressed Areas

Refer to SPM TASK 70-11-39-300-503, SUBTASK 70-11-39-300-001.

Cold ferric chloride swab etch the repair areas on the HP Compressor Rear Shaft Splines.

SUBTASK 72-41-13-110-003 Swab Etch the Repair Area(s)

Refer to SPM TASK 70-23-05-230-501, SUBTASK 70-23-05-230-002.

Reject.

If cracking is detected.

Continue with the repair.

If no cracking is detected.

Inspect for cracking at the repair area on the HP Compressor Rear Shaft Splines using fluorescent penetrant inspection.

SUBTASK 72-41-13-230-003 Fluorescent Penetrant Inspect

Hand polish to achieve the required surface texture.

The surface texture of the repair area(s) on the flanks must be 80 microinches (2.0 micrometres) or better.

The surface texture of the repair area(s) on the top face must be 126 microinches (3.2 micrometres) or better.

Hand polish the repair area(s).

SUBTASK 72-41-13-350-008 Polish the Repair Area

Make sure that all of the burrs, raised material and sharp edges have been removed and that the repair area(s) has a smooth profile and that the required surface finish has been achieved.

Reject.

lf all of the damage burrs, raised material and sharp edges have not been removed, if the repair area(s) does not have a smooth profile or if the required surface finish has not been achieved.

Continue with the repair.

If all of the damage burrs, raised material and sharp edges have been removed, the repair area(s) has a smooth profile and if the required surface finish has been achieved.

Examine the polished area(s) of the HP Compressor Rear Shaft Splines.

Accept.

If the polished area overlaps another polished area or a critical fillet radius.

SUBTASK 72-41-13-220-006 Examine the Polished Areas

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Vibro-peen VRS6516 at the indicated location(s) on the HP Compressor Rear Shaft.

NOTE

It will only be required to remove raised material, burrs and/or sharp edges from the dot mark location if this is the first application of VRS6516.

Remove raised material, burrs and/or sharp edges at the vibro-peen marking area and at the dot mark.

SUBTASK 72-41-13-350-009 Identify the Repair

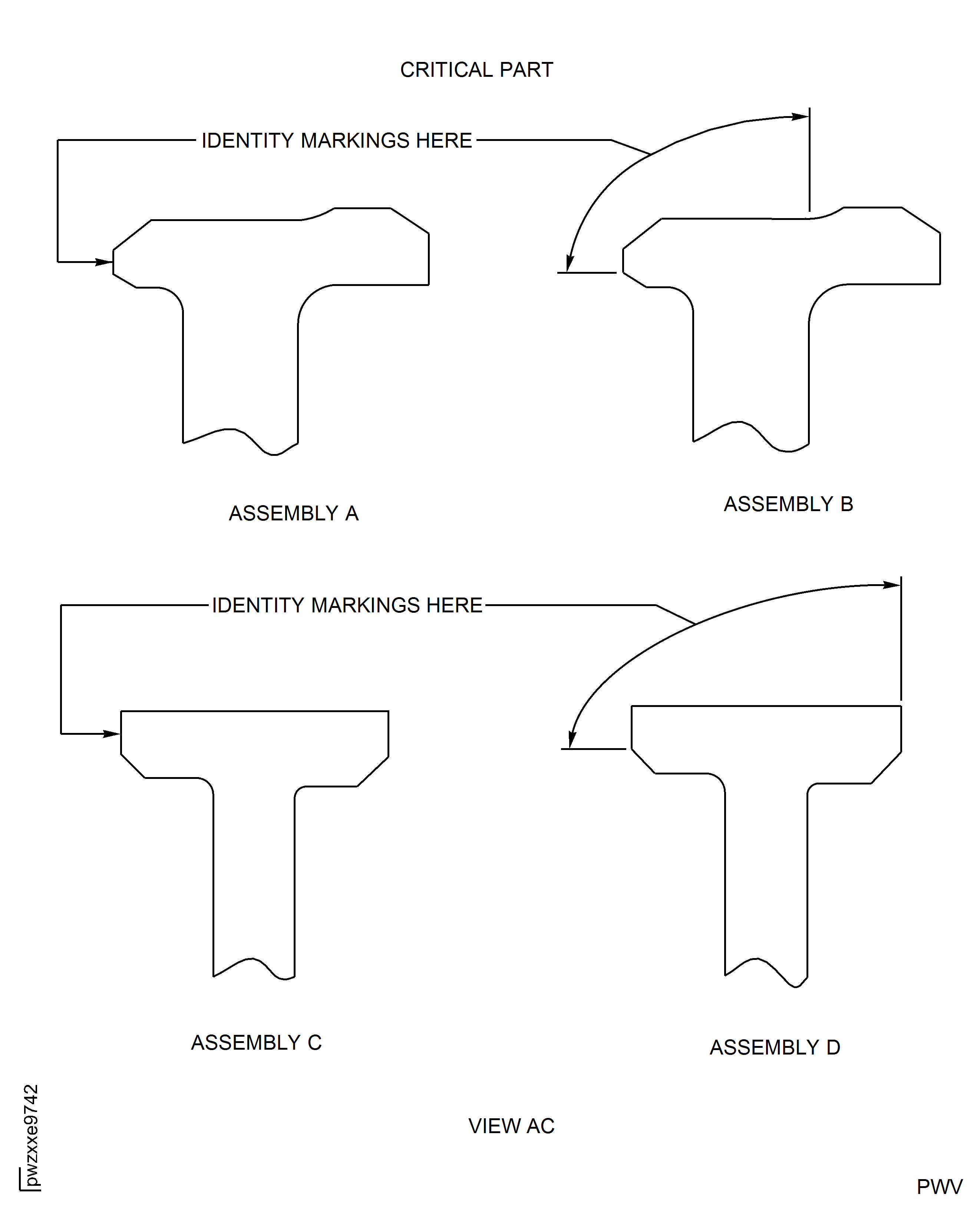

Figure: HP Compressor Rear Shaft Splines - Component Details - Assemblies A, B, C and D

HP Compressor Rear Shaft Splines - Component Details - Assemblies A, B, C and D

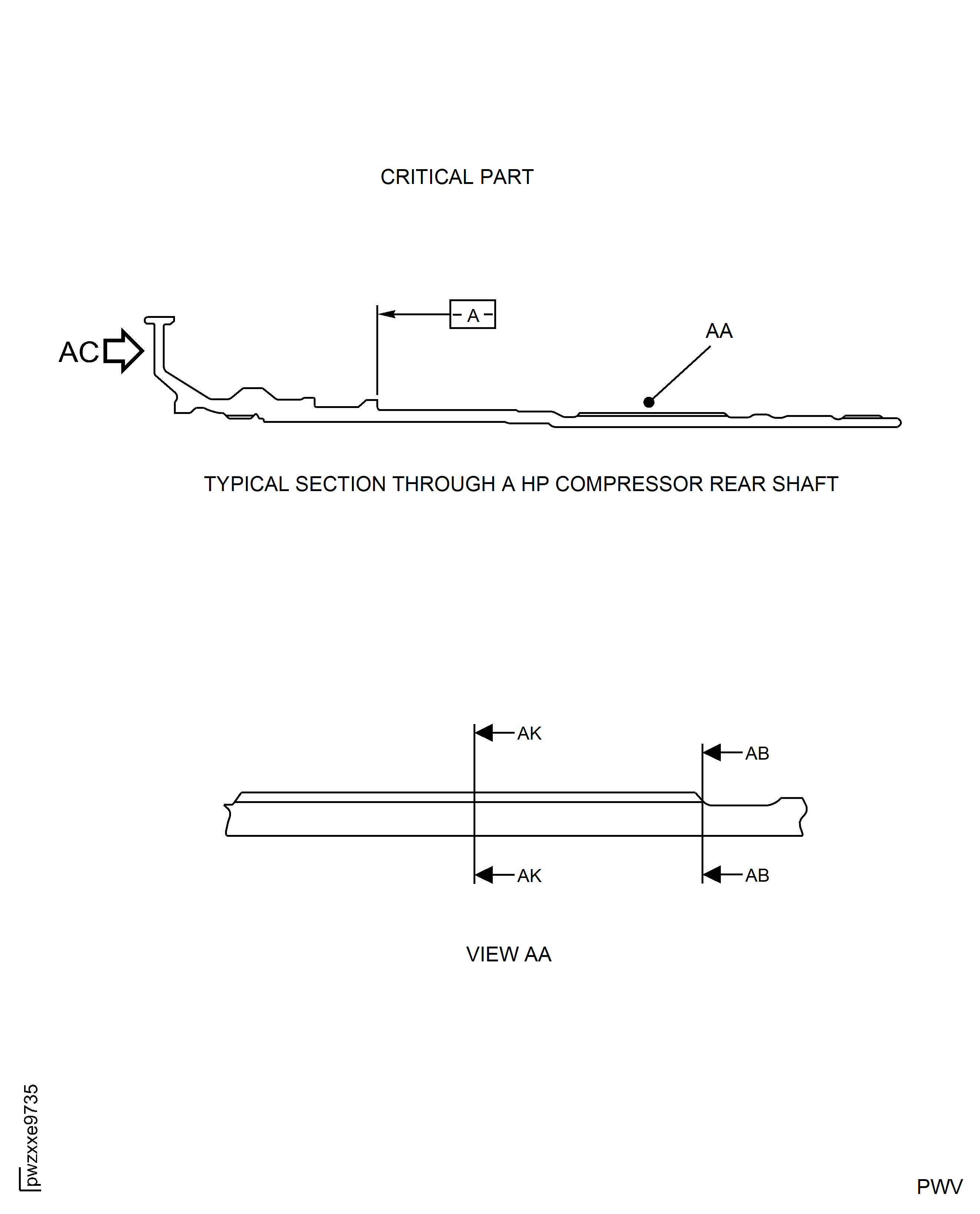

Figure: HP Compressor Rear Shaft Splines - Dot Marking Location and Repair Details - Assemblies A, B, C and D

HP Compressor Rear Shaft Splines - Dot Marking Location and Repair Details - Assemblies A, B, C and D

Figure: HP Compressor Rear Shaft Splines - Dressing Ratios and Shapes - Assemblies A, B, C and D

HP Compressor Rear Shaft Splines - Dressing Ratios and Shapes - Assemblies A, B, C and D

Figure: HP Compressor Rear Shaft Splines - Repair Areas and Locations - Assemblies A, B, C and D

HP Compressor Rear Shaft Splines - Repair Areas and Locations - Assemblies A, B, C and D

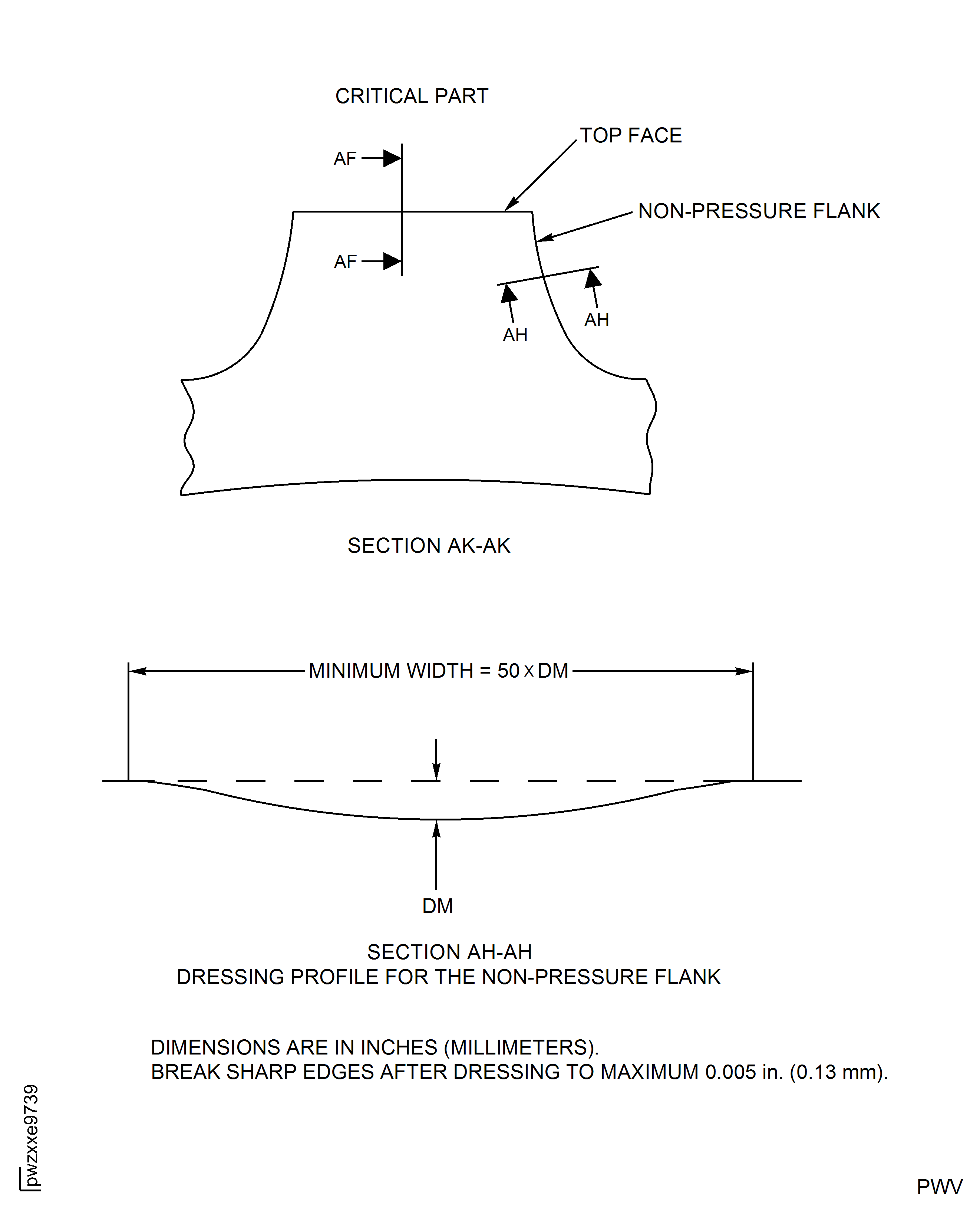

Figure: HP Compressor Rear Shaft Splines - Dressing Details and Dimensions - Assemblies A, B, C and D

HP Compressor Rear Shaft Splines - Dressing Details and Dimensions - Assemblies A, B, C and D

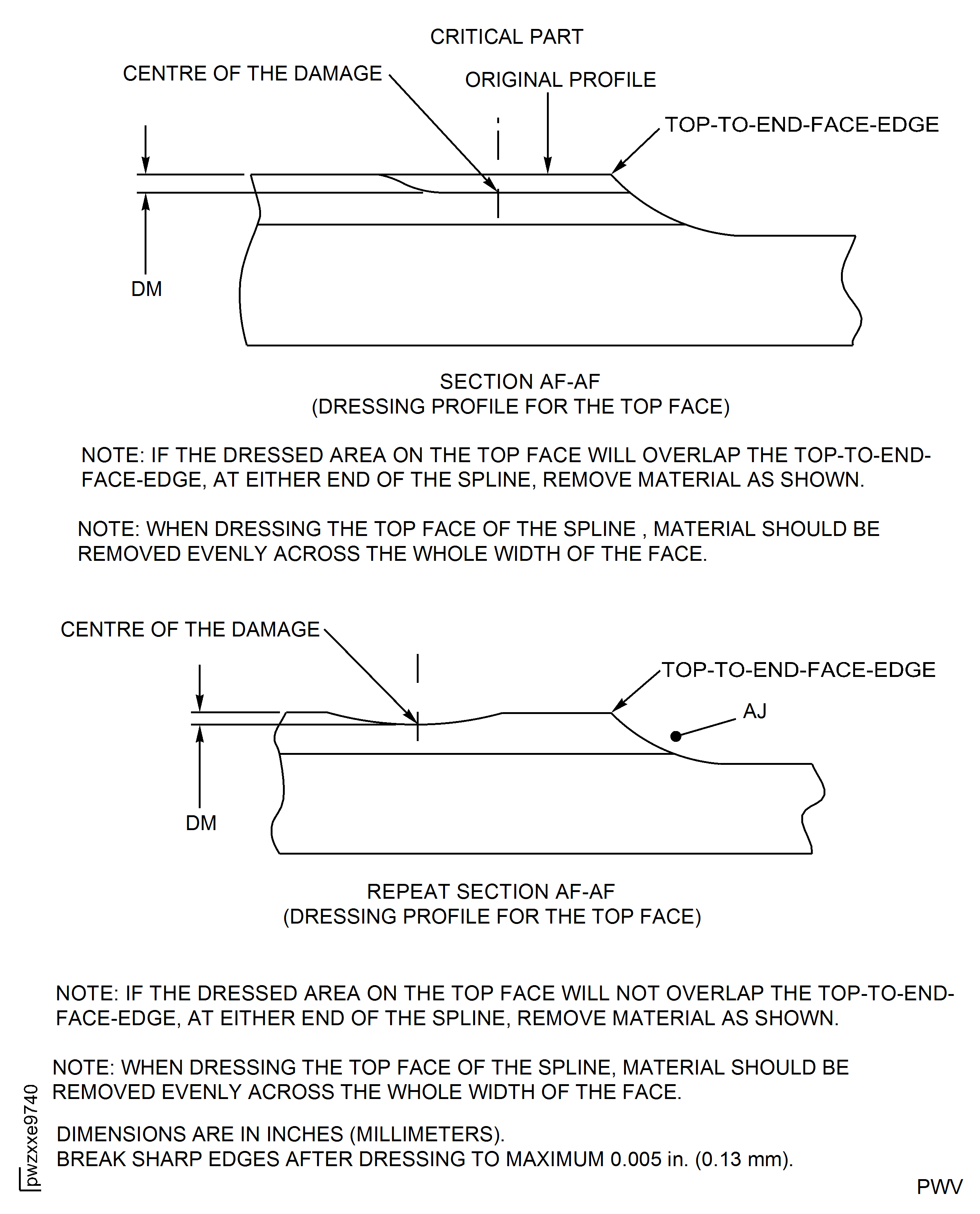

Figure: HP Compressor Rear Shaft Splines - Dressing Details for the Top Face - Assemblies A, B, C and D

HP Compressor Rear Shaft Splines - Dressing Details for the Top Face - Assemblies A, B, C and D

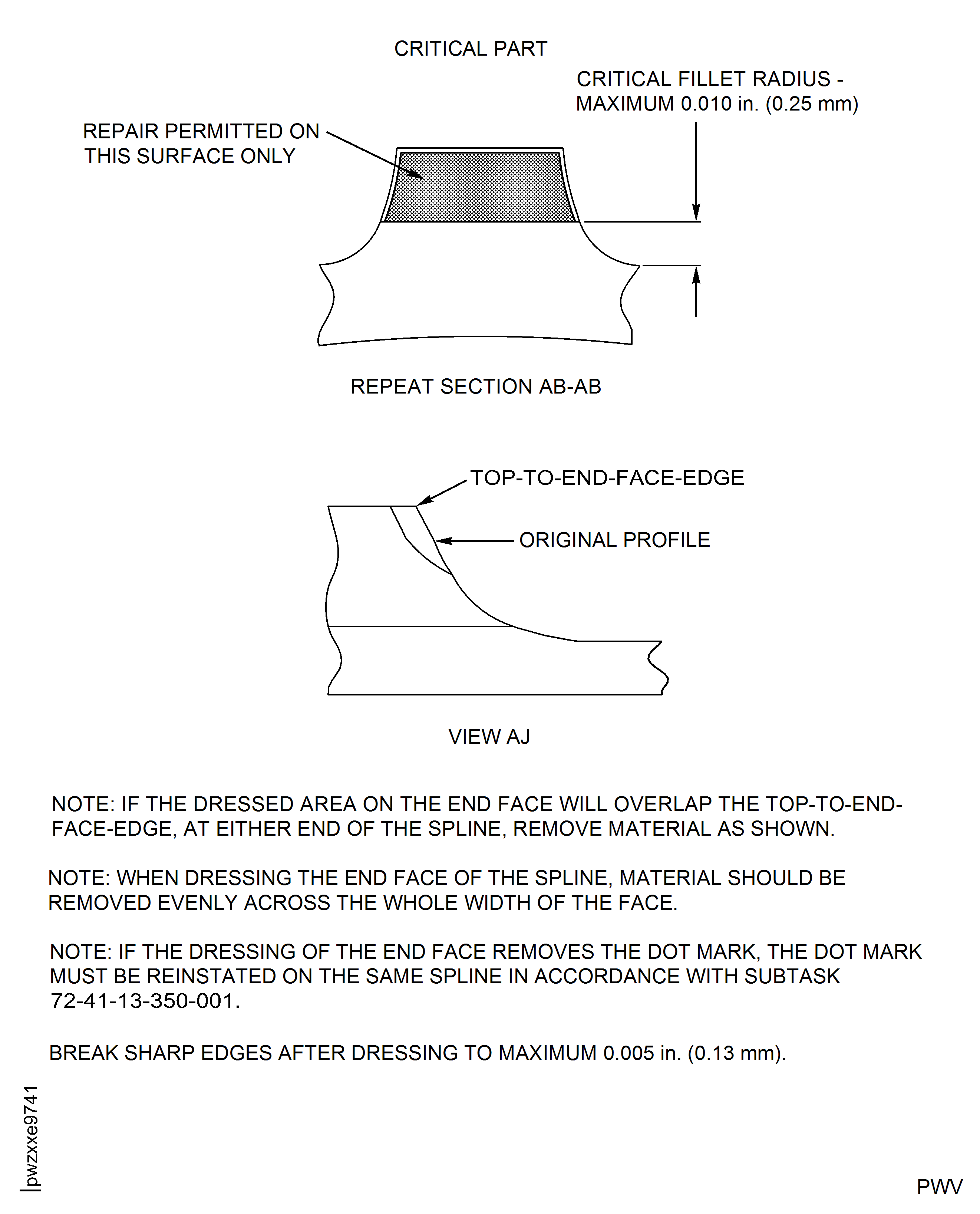

Figure: HP Compressor Rear Shaft Splines - Dressing Details for the End Face - Assemblies A, B, C and D

HP Compressor Rear Shaft Splines - Dressing Details for the End Face - Assemblies A, B, C and D

Figure: HP Compressor Rear Shaft Splines - Identity Marking Location - Assemblies A, B, C and D

HP Compressor Rear Shaft Splines - Identity Marking Location - Assemblies A, B, C and D