Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-13-300-004 HPC Rear Shaft Heatshield - Repair The Worn Or Damaged Location Diameter, Repair-004 (VRS6379)

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

HP Compressor Rear Shaft Heatshield Assembly | QAH and QAR or QNK and QTE | Nickel base heat resistant alloy |

General

This Repair must only be done when the instruction to do so is given in 72-41-13 Inspection.

This Repair restores the location diameter of the HP Compressor Rear Shaft Heatshield Assembly by metal spray.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and Availability

Refer to International Aero Engines

Related repairs - none

NOTE

Equivalent materials or equipment can be used.

More equipment and materials necessary to do this Repair are in the SPM TASKS given below:

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Grinding machine | LOCAL | Grinding machine | Cylindrical | |

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Dial test indicators | LOCAL | Dial test indicators | ||

| Abrasive blast equipment | LOCAL | Abrasive blast equipment | ||

| Plasma spray equipment | LOCAL | Plasma spray equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY) | LOCAL | CoMat 02-198 | ||

| CoMat 03-265 NICKEL CHROMIUM ALUMINIUMPOWDER | LOCAL | CoMat 03-265 | ||

| CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE | LOCAL | CoMat 05-001 |

Spares

NONESafety Requirements

NONEProcedure

Refer to TASK 72-41-13-100-000 (CLEANING-000).

Use chemical cleaning equipment.

Chemically clean the assembly.

SUBTASK 72-41-13-110-069 Clean the HP Compressor Heatshield Assembly

Refer to the SPM TASK 70-23-01-230-501.

Cracks are not permitted.

Use penetrant crack test equipment.

Do a penetrant crack test on the assembly.

SUBTASK 72-41-13-230-083 Do a Crack Test

Refer to SPM TASK 70-11-03-300-503.

Use chemical cleaning equipment.

Chemically clean the assembly.

SUBTASK 72-41-13-110-070 Clean the HP Compressor Heatshield Assembly

Refer to the SPM TASK 70-23-01-230-501.

Cracks are not permitted.

Use penetrant crack test equipment.

Do a penetrant crack test on the heatshield location diameter.

SUBTASK 72-41-13-230-084 Do a Crack Test

CAUTION

DO NOT TOUCH SURFACE(S) TO BE REPAIRED AFTER THEY ARE CLEANED.

CAUTION

TOO MUCH ABRASIVE BLAST CAN CAUSE DETERIORATION OF THE REPAIRED SURFACE CONDITION AND MUST BE PREVENTED.Refer to Figure.

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-001.

Use CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE, with abrasive blast equipment.

The maximum abrasive blast air pressure must not be more than 60 psi (414 kPa).

Lightly dry blast to prepare the surface for the plasma spray.

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-018.

Use CoMat 03-265 NICKEL CHROMIUM ALUMINIUMPOWDER with plasma spray equipment.

Apply sufficient metal spray powder, to get the correct dimensions when machined, refer to Step

NOTE

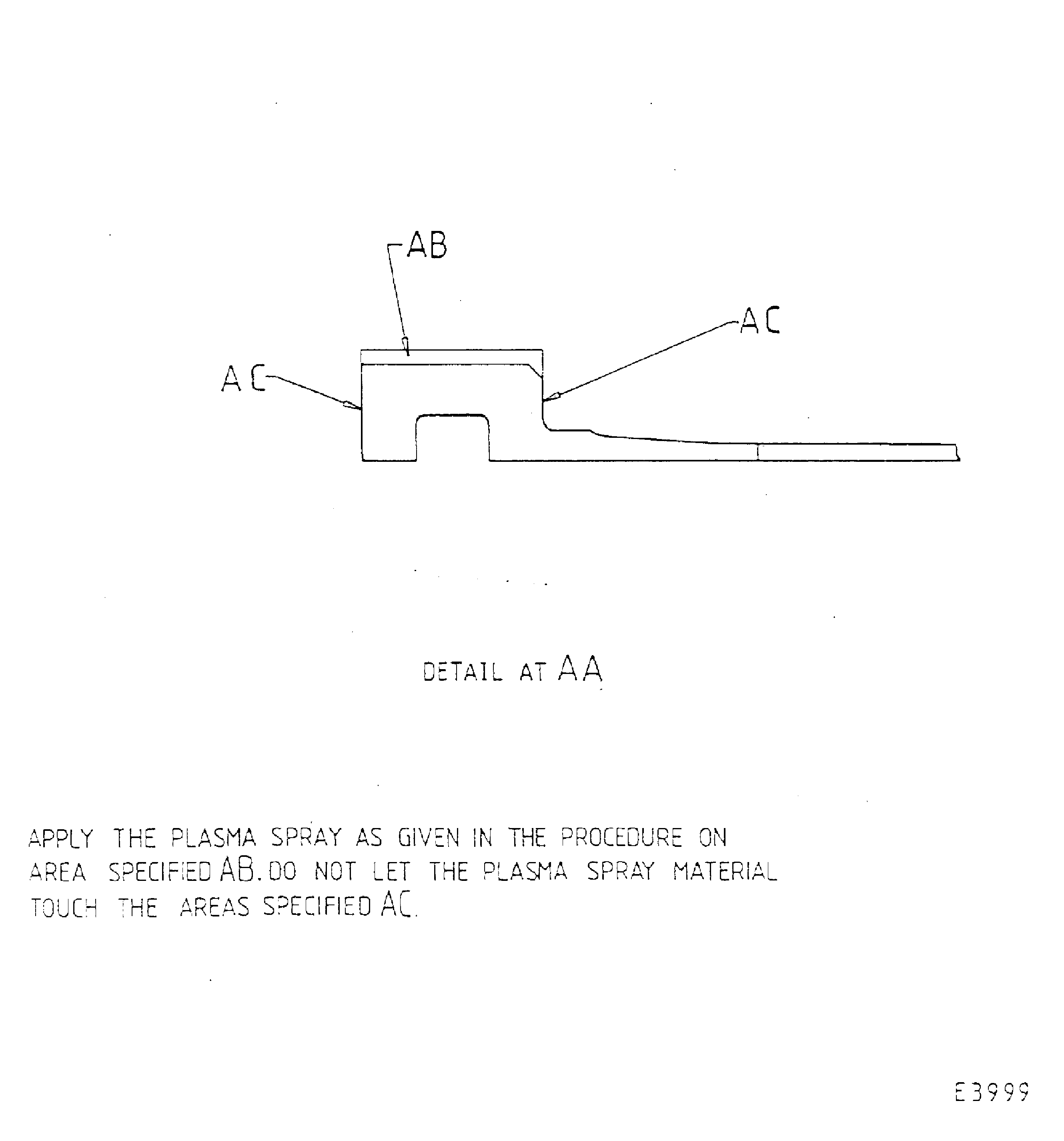

When plasma spray equipment is used, the CoMat 03-265 NICKEL CHROMIUM ALUMINIUMPOWDER is self-bonding.Apply the plasma spray to the heatshield location diameter, at position AB.

SUBTASK 72-41-13-340-055 Apply the Plasma Spray to the Surface(s) to be Repaired

Refer to Figure.

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-002.

Visually examine the plasma sprayed coat.

SUBTASK 72-41-13-220-163 Visually Examine

Refer to SPM TASK 70-11-03-300-503.

Use chemical cleaning equipment.

Chemically clean the assembly.

SUBTASK 72-41-13-110-070 Clean the HP Compressor Heatshield Assembly

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Use vibrating marking pencil.

Make a mark VRS6379 adjacent to the assembly number.

SUBTASK 72-41-13-350-077 Identify the Repair

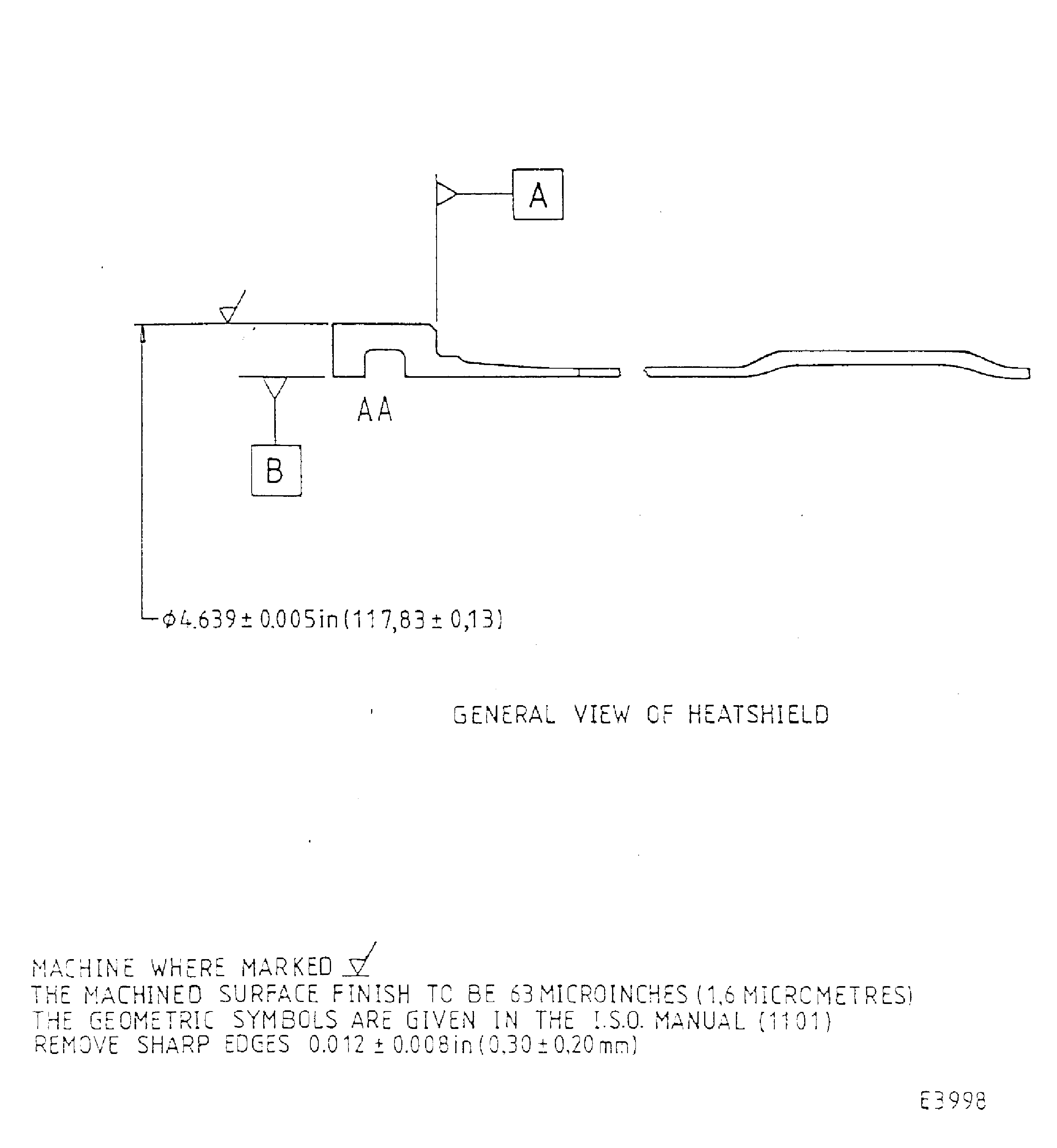

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions