Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-14-300-008 HPC Rear Rotating Air Seal - Repair The Damaged Rub Track By Metal Spray, Repair-008 (VRS 6505)

Material of component

RR | ||

|---|---|---|

DESCRIPTION | SYMBOL | MATERIAL |

HP compressor rear | QDY | Waspaloy heat |

rotating air seal | resisting alloy, | |

vacuum melted |

General

This Repair must only be done when the instruction to do so is given in 72-41-14 Inspection/Check.

This Repair replaces a damaged rub track on the HP compressor rear rotating air seal, by metal spray.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and availability

Refer to International Aero Engines.

Repair facilities

The Source Demonstration requirements of the Repair means that any facility not authorized to accomplish this Repair, either utilize the Authorized Repair Vendors listed below or contact the IAE Repair Development Group to determine if a qualification program can be initiated at their facility.

IAE - International Aero Engines AG

400 Main Street

East Hartford CT 06108

U.S.A.

ATTN: Manager, Repair Services

Authorized Repair Vendors for the Repair VRS6505 are listed below:

General Plasma Inc.

12 Windsor Road

EAST WINDSOR CT 06088

USA

ATTN: Director, Quality Assurance

MTU Maintenance GmbH

Flughafen Hannover

Munchner Strasse 31

Postfach 1720

D3012 LANGENHAGEN

Germany

ATTN: Manager, Quality Assurance

Rolls-Royce Aero-Engine Services Ltd

Component Refurbishment

Mavor Avenue

Nerston

EAST KILBRIDE

Glasgow G74 4PY

Scotland

ATTN: Manager, Engine Component Repair Development

Ishikawajima - Harima Heavy Industries Co Ltd

Aero-Engine and Space Operations

Mizuho Aero-Engine Works

229, Tonogaya

Mizuho - Machi

Mishitama - Gun

TOKYO, 190-12

Japan

ATTN: Manager, Engine Component Repair Development

The designation by IAE of an Authorized Repair Vendor indicates that the Repair Vendor has demonstrated the necessary capability to enable it to carry out the listed repair work. However, IAE makes no warranties or representations concerning the qualifications or quality standards of the Repair Vendors to carry out the repair work, and accepts no responsibility whatsoever for any work that may be carried out by a Repair Vendor other than when IAE is listed as the Repair Vendor. Authorized Repair Vendors do not act as agents or representatives of IAE.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Abrasive blast equipment | LOCAL | Abrasive blast equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Metal spray equipment | LOCAL | Metal spray equipment | ||

| Plasma Tecnik F4 MB Gun | LOCAL | Plasma Tecnik F4 MB Gun | ||

| Grinding machine | LOCAL | Grinding machine | ||

| Dial test indicators | LOCAL | Dial test indicators | ||

| Lathe | LOCAL | Lathe | ||

| Tufnol block | LOCAL | Tufnol block | ||

| Brush | LOCAL | Brush | ||

| Surface measuring equipment | LOCAL | Surface measuring equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| IAE 3R19128 grind fixture | 0AM53 | IAE 3R19128 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-025 NITRIC ACID HNO3, TECHNICAL GRADE | LOCAL | CoMat 01-025 | ||

| CoMat 02-019 TAPE, ADHESIVE PAPER HEAT RESISTING MASKING | 94960 | CoMat 02-019 | ||

| CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) | IE200 | CoMat 03-038 | ||

| CoMat 03-043 METAL SPRAYING POWDER,Al OXIDE | LOCAL | CoMat 03-043 | ||

| CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE | LOCAL | CoMat 05-001 | ||

| CoMat 05-118 DIAMOND LAPPING COMPOUND,SLURRY, SPRAY, OR SUSPENSION | 4S8W0 | CoMat 05-118 | ||

| CoMat 10-105 LAPPING FLUID | LOCAL | CoMat 10-105 | ||

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 |

Spares

NONESafety Requirements

NONEProcedure

Refer to TASK 72-41-14-100-000 (CLEANING-000).

Use chemical cleaning equipment.

Chemically clean.

SUBTASK 72-41-14-110-057 Clean the HP Compressor Rear Rotating Air Seal

CAUTION

REMOVE THE TOP COAT ONLY, THE BLAST OPERATION MUST STOP WHEN THE WHITE TOP COAT IS REMOVED. FAILURE TO STOP THE BLAST OPERATION AS SPECIFIED CAN RESULT IN SUBSEQUENT ENGINE FAILURE.NOTE

It is permitted to loosen the rub track top coat in part, to let the Nitric Acid by capillary action, release both top and bond coats.Refer to the SPM TASK 70-12-02-120-501.

Use CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE with abrasive blast equipment.

Lightly dry blast to loosen the rub track top coat.

SUBTASK 72-41-14-120-052 Loosen the Rub Track Top Coat

Refer to the SPM TASK 70-33-59-300-503.

Use CoMat 01-025 NITRIC ACID HNO3, TECHNICAL GRADE with chemical cleaning equipment.

Put the HP compressor rear rotating air seal into the nitric acid solution and keep below the surface until the bubbles stop.

Remove the rub track coating.

SUBTASK 72-41-14-330-051 Chemically Remove the Rub Track Coating

Use penetrant crack test equipment.

Discard the HP compressor rear rotating air seal, if cracked.

Refer to the SPM TASK 70-23-04-230-501.

Do a penetrant crack test.

SUBTASK 72-41-14-230-059 Do a Crack Test

Refer to the SPM TASK 70-12-02-120-501.

Use CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE with abrasive blast equipment.

Lightly dry blast to prepare the surface for the rub track coating.

SUBTASK 72-41-14-120-053 Prepare the Surface for Repair

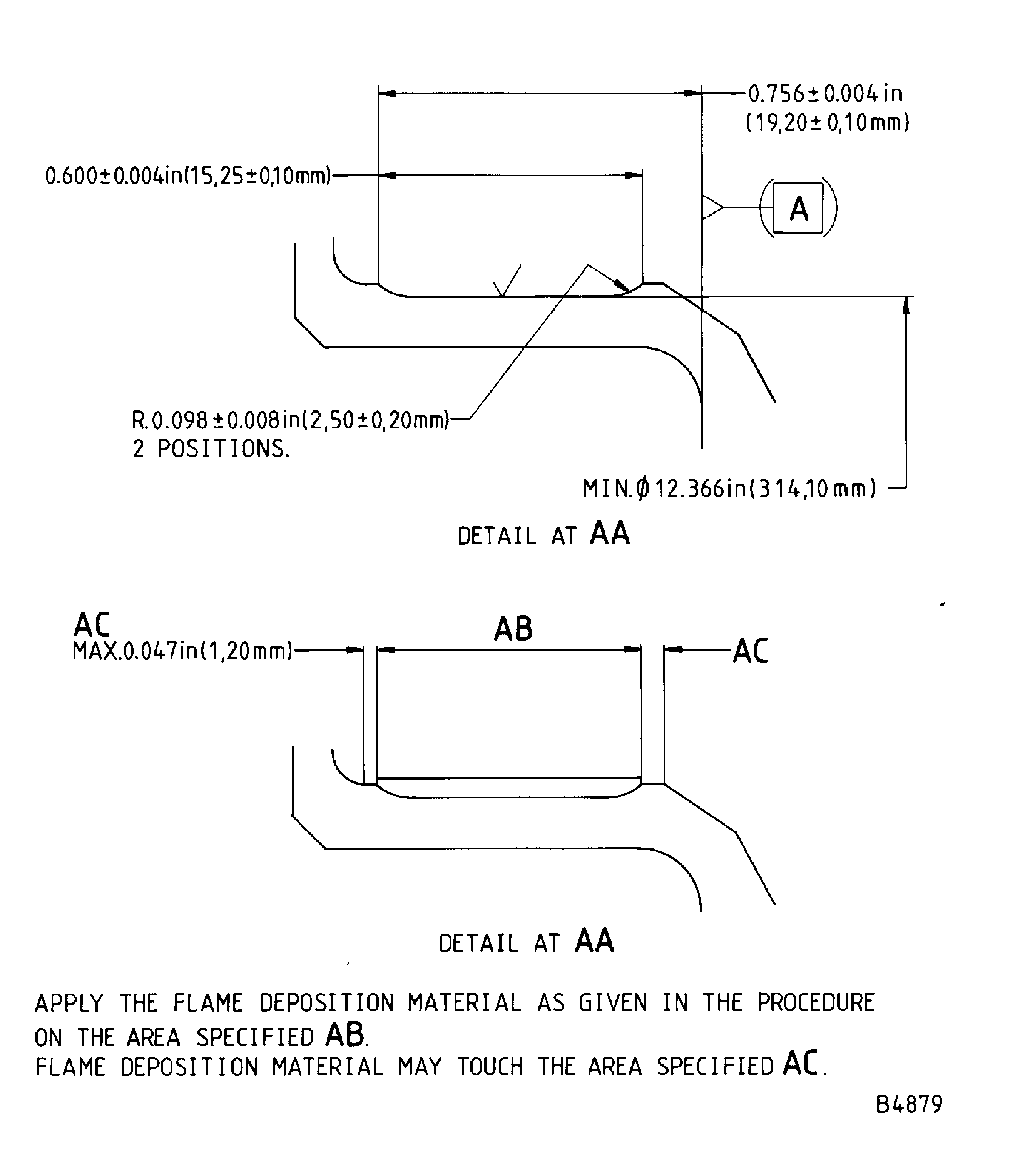

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-025.

Use CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) with metal spray equipment and a Plasma Tecnik F4 MB spray gun or equivalent.

Apply a thickness of 0.003 to 0.005in. (0.076 to 0.127 mm).

Apply the bond coat to the rub track groove.

Refer to TASK 70-34-01-340-501, SUBTASK 70-34-01-340-013.

Use CoMat 03-043 METAL SPRAYING POWDER,Al OXIDE with metal spray equipment and a Plasma Tecnik F4 MB spray gun or equivalent.

Apply a layer of sufficient thickness to get the correct dimensions after the HP compressor rear rotating air seal rub track is machined.

Apply the top coat to the rub track groove.

SUBTASK 72-41-14-340-052 Apply the Rub Track Coating

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-002.

Visually examine the rub track coating.

SUBTASK 72-41-14-220-081 Visually Examine

Use a dial test indicator.

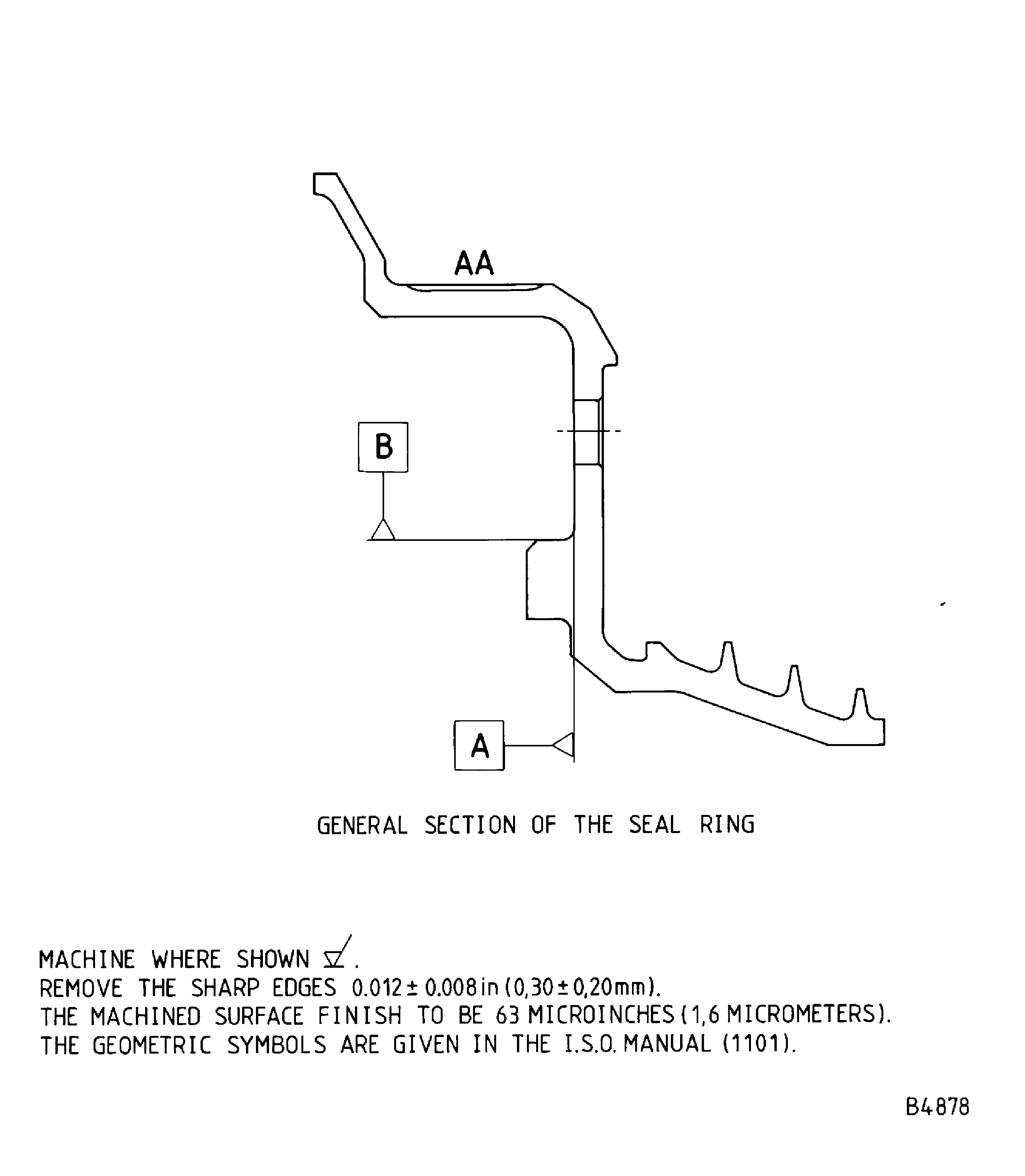

Make sure the HP compressor rear rotating air seal datum points A and B, turn correctly.

Use IAE 3R19128 grind fixture 1 off, or a locally made grind fixture, with a grinding machine.

Set up the HP compressor rear rotating air seal to be machined, to turn correctly.

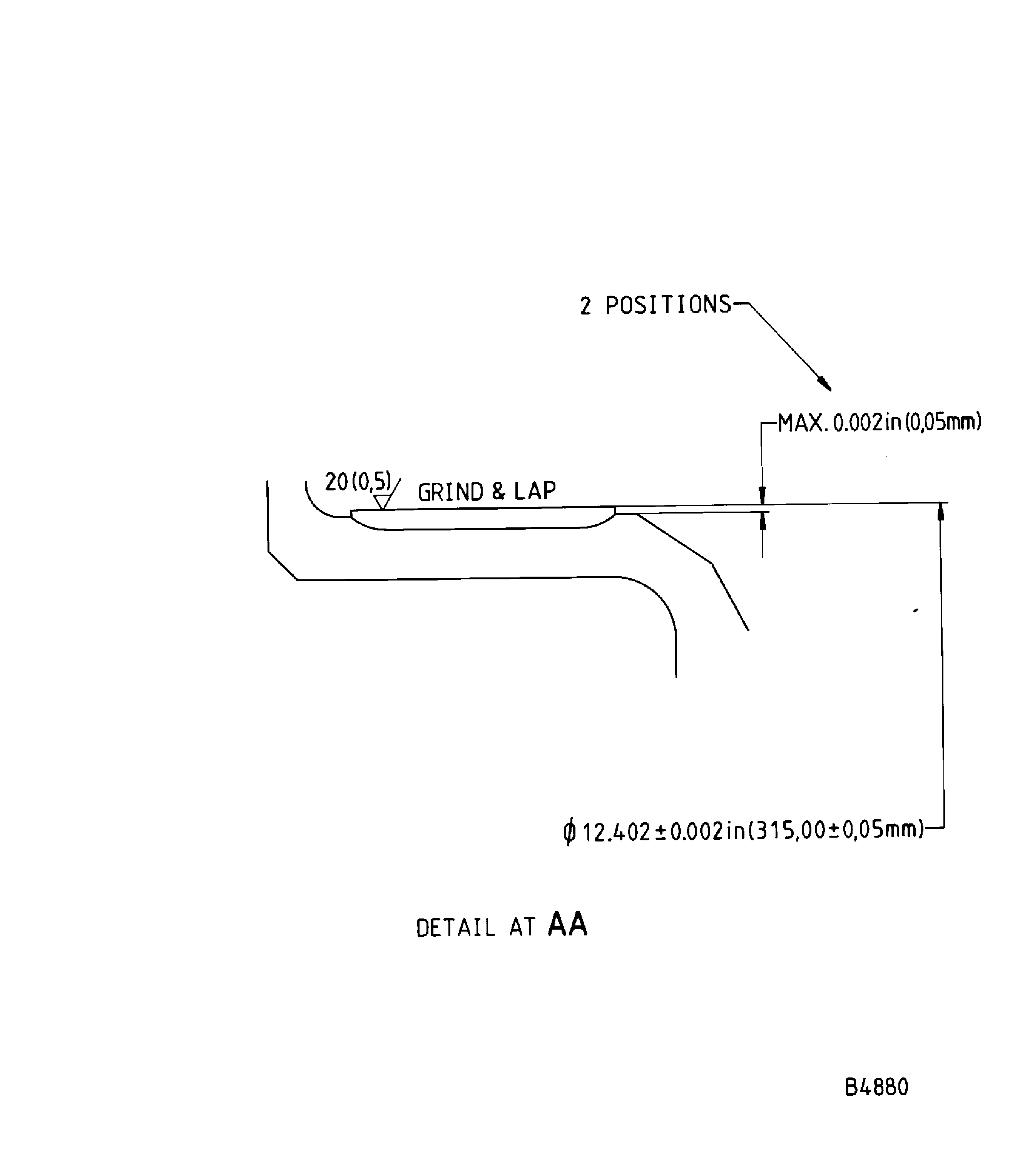

Refer to Figure.

GRINDING DATA

Wheel

Standard 120 Grit

Wheel speed

3000rpm

Feed

Manual

NOTE

The information given above is for guidance only. Local conditions and equipment can change.

Grind the rub track coating on the HP compressor rear rotating air seal, to the given dimensions.

SUBTASK 72-41-14-324-053 Machine the Rub Track Coating

Use a dial test indicator.

Make sure the HP compressor rear rotating air seal datum points A and B, turn correctly.

Use IAE 3R19128 grind fixture 1 off, and a locally made grind fixture, with a lathe.

Set up the HP compressor rear rotating air seal, to turn correctly.

Keep the rub track coating well lubriacted during the lapping operation.

Most times you can get the necessary surface finish in one cycle.

The information given above is for guidance only. Local conditions and equipment can change.

Lubricate the rub track coating with CoMat 10-105 LAPPING FLUID or equivalent.

Apply a large quantity of the fluid with a brush.

Load the Tufnol block into contact with the rub track coating surface and apply a 0.020 in. (0.508 mm) feed depth on the cross-slide indicator of the lathe.

Turn the work for 20 minutes, to get the necessary surface finish.

Use a Tufnol block.

Apply lapping paste, CoMat 05-118 DIAMOND LAPPING COMPOUND,SLURRY, SPRAY, OR SUSPENSION or a 20 micro inch (0.5 micron) equivalent, to a Tufnol block.

NOTE

Lap the machined rub track coating, to get a good surface finish.

SUBTASK 72-41-14-325-051 Lap the Rub Track Coating

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-002.

Visually examine the rub track coating.

Use surface measuring equipment.

If necessary, do Step again.

A surface finish of 20 micro in. (0.5 microns) has to be achieved.

Examine the surface finish of the rub track coating.

SUBTASK 72-41-14-220-082 Examine the Repaired Rub Track

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Vibro-engrave VRS6505 adjacent to the part number.

SUBTASK 72-41-14-350-062 Identify the Repair

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions