Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-15-300-005 HPC Stage 7 Rotor Blade - Repair Damage By Material Removal, Repair-005 (VRS6013)

Effectivity

FIG/ITEM | PART NO. | ASSEMBLY |

|---|---|---|

02-270 | 6A3246 | A |

02-270 | 6A4905 | B |

02-270 | 6A5588 | A |

02-270 | 6A6462 | B |

02-270 | 6A6493 | A |

02-270 | 6A8314 | B |

02-270 | 6A8743 | B |

02-285 | 6A3247 | A |

02-285 | 6A4906 | B |

02-285 | 6A5589 | A |

02-285 | 6A6463 | B |

02-285 | 6A6494 | A |

02-285 | 6A8315 | B |

02-285 | 6A8744 | B |

02-300 | 6A3245C01 | A |

02-300 | 6A4907C01 | B |

02-300 | 6A5584C01 | A |

02-300 | 6A6469C01 | B |

02-300 | 6A6492C01 | A |

02-300 | 6A8312 | B |

02-300 | 6A8741 | B |

02-315 | 6A3245C01 | A |

02-315 | 6A4907C01 | B |

02-315 | 6A5584C01 | A |

02-315 | 6A6469C01 | B |

02-315 | 6A6492C01 | A |

02-315 | 6A8312 | B |

02-315 | 6A8741 | B |

02-316 | 6B1495 | B |

02-317 | 6A3245C02 | A |

02-317 | 6A4907C02 | B |

02-317 | 6A5584C02 | A |

02-317 | 6A6469C02 | B |

02-317 | 6A6492C02 | A |

02-317 | 6A8313 | B |

02-317 | 6A8742 | B |

Material of component

PART IDENT | RR SYMBOL | MATERIAL |

HP Compressor Stage 7 Rotor Blade | TDY or TTX | Titanium alloy |

General

This TASK gives the procedure to repair surface damage on the HP Compressor Stage 7 Rotor Blade by material removal.

This repair must only be done when the instruction to do so is given in the relevant inspection procedures (identified by the applicable part number) located in section 72-41-15.

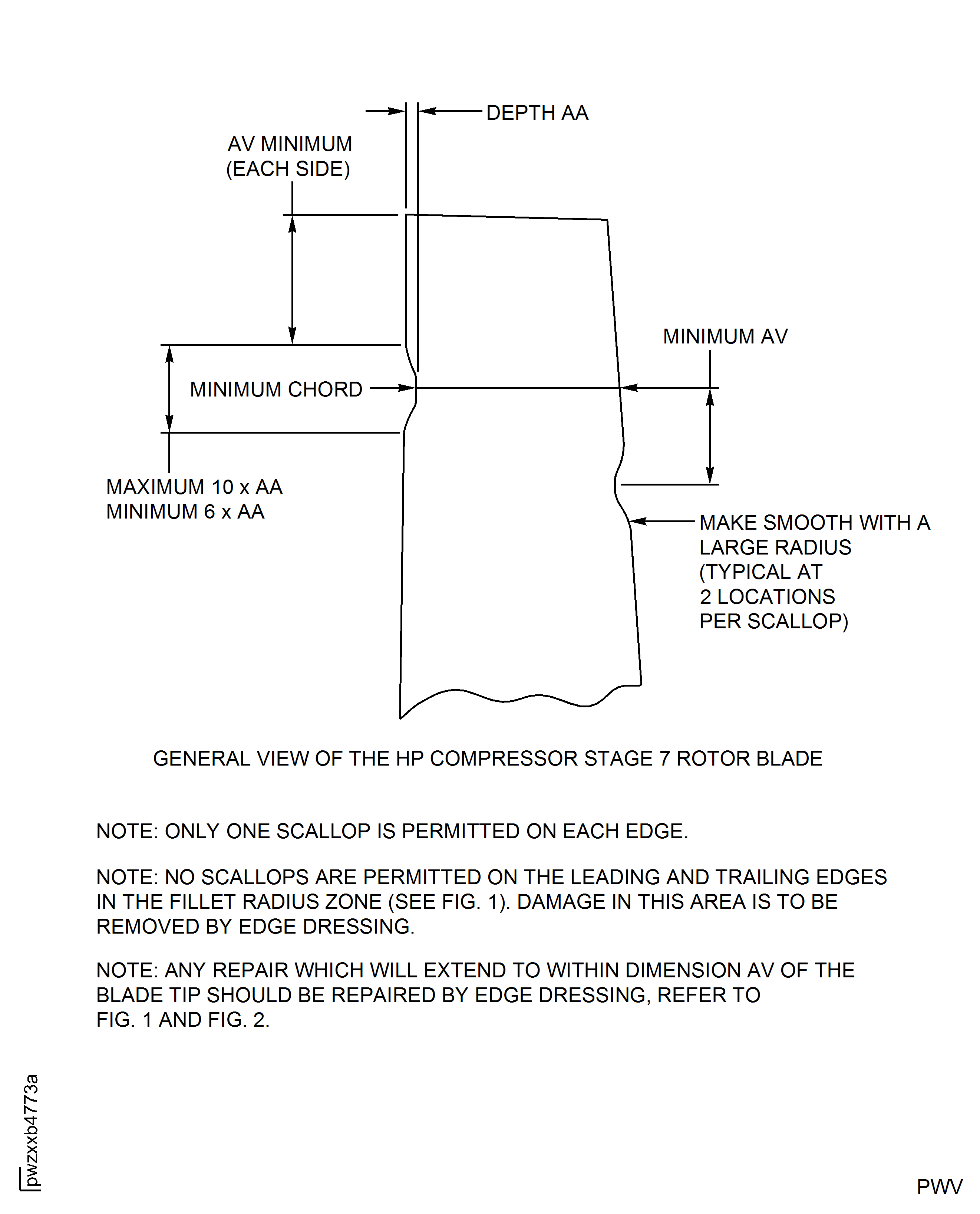

You can mix a scallop and edge dressing to a given HP Compressor Stage 7 Rotor Blade, if the maximum limit for any one of these is not exceeded.

Rotor blades must be repaired as soon as damage or wear is monitored, to get back HP compressor efficiency and extend the rotor blade life.

Material removal from the HP Compressor Stage 7 Rotor Blade airfoil fillet radius is not permitted.

When the depth of the dressed material is more than 0.002 in. (0.05 mm) it is necessary to glass bead peen the HP Compressor Stage 7 Rotor Blade to restore the airfoil surface condition, refer to Repair, VRS6150 TASK 72-41-15-300-040 (REPAIR-040).

Where reference is made to a SUBTASK within a TASK in the form "TASK, SUBTASK" the operator must read and apply the complete TASK. The SUBTASK is listed only when the TASK gives options for the processing of the component. The specified SUBTASK instructs what option must be used during application of the TASK for the successful completion of the repair scheme VRS6013.

The practices and processes referred to in the procedure by the TASK/SUBTASK number are in the SPM.

Related Repairs

HP Compressor - Stage 3 to 12 - Rotor Blades - Restore Airfoil Surface condition, refer to Repair, VRS6150 TASK 72-41-15-300-040 (REPAIR-040).

NOTE

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure all the necessary cleaning and inspection procedures are done before this repair. |

Support Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

This subtask has been deleted.

SUBTASK 72-41-15-110-185 Chemically Clean (DELETED)

This subtask has been deleted.

SUBTASK 72-41-15-230-131 Do a Crack Test (DELETED)

This subtask has been deleted.

SUBTASK 72-41-15-220-587 Visually Examine (DELETED)

Refer to SPM TASK 70-35-03-300-501.

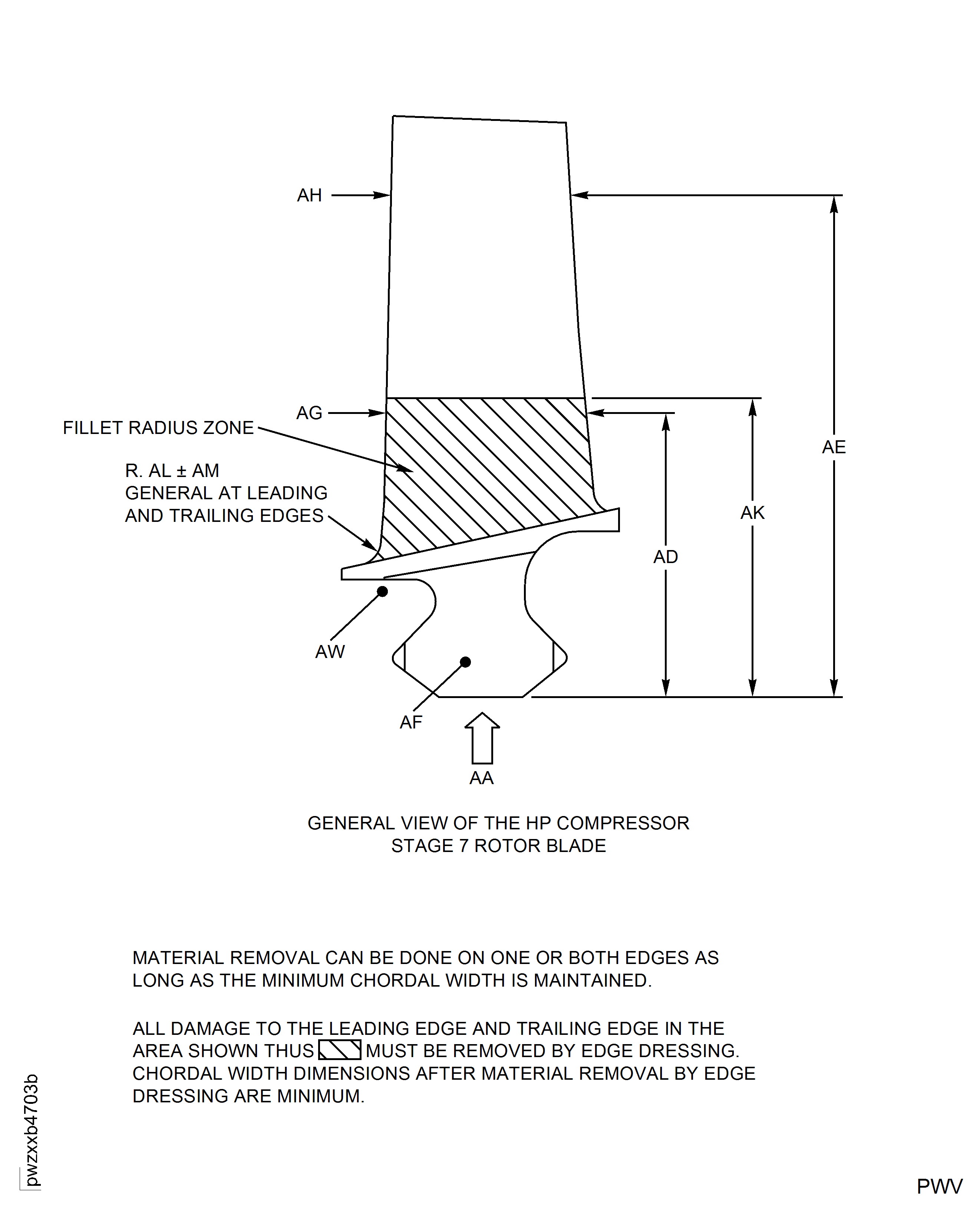

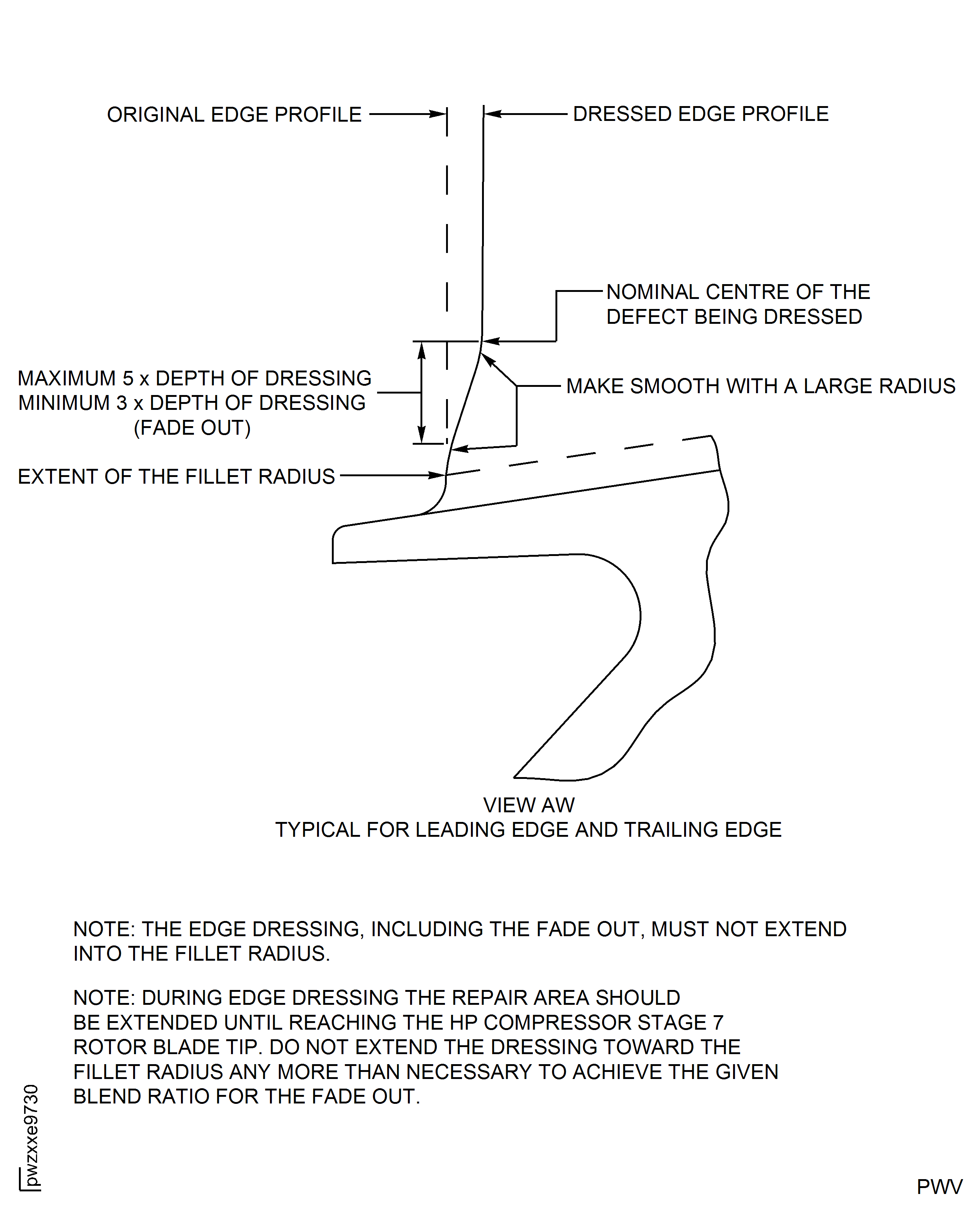

Remove damage on the leading or trailing edge of the HP Compressor Stage 7 Rotor Blade by blending.

The maximum depth of blending on the airfoil surface must not be more than 0.005 in. (0.13 mm).

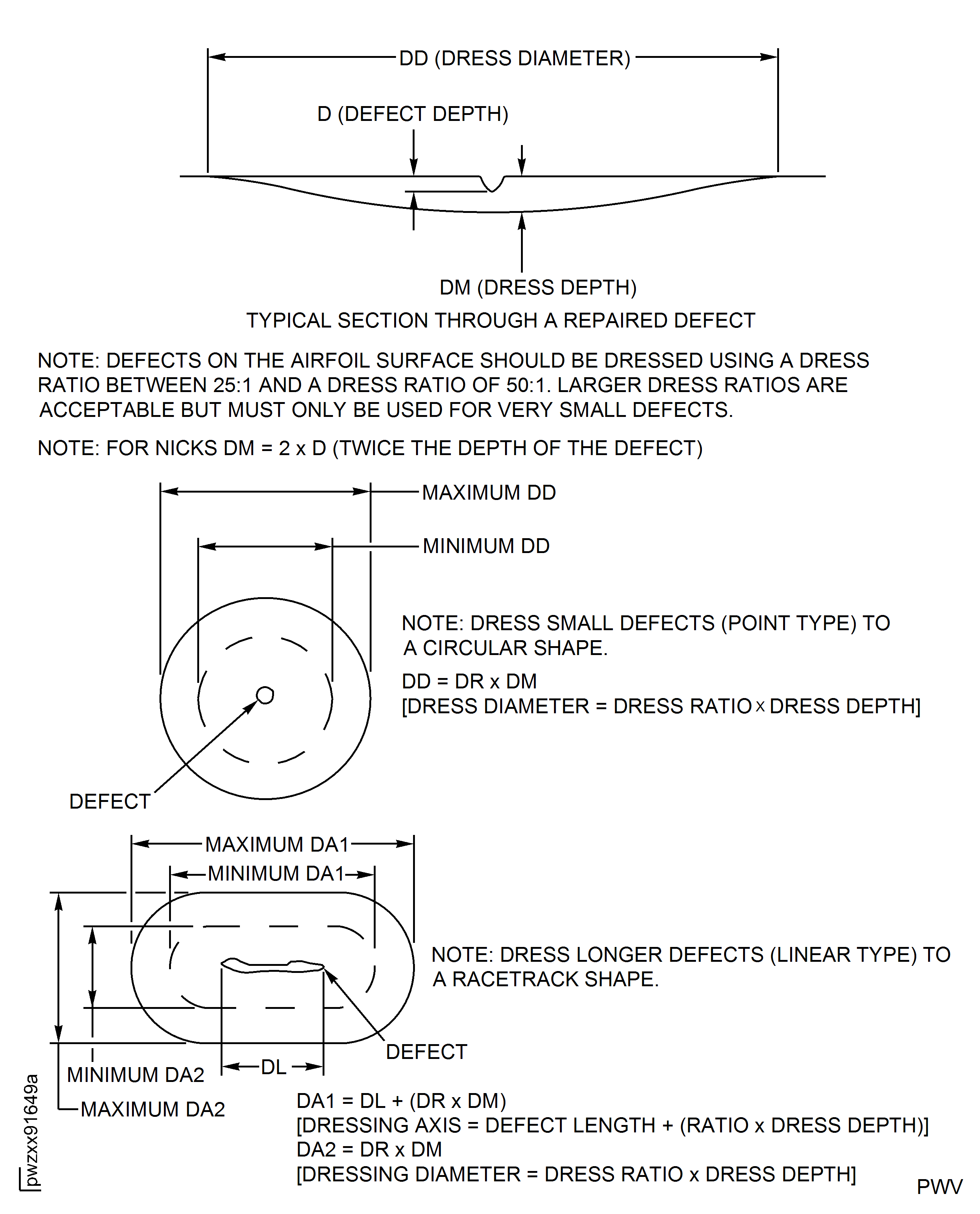

The diameter of the blend area (blend ratio) must be between 25 and 50 times the depth of the blended area. Larger blend ratios are acceptable but must only be used for very small defects.

Impact damage, such as nicks, must be blended to twice the depth of the defect.

Remove damage on the HP Compressor Stage 7 Rotor Blade airfoil surface by blending.

SUBTASK 72-41-15-350-063 Blend to Remove the Damaged Material

This subtask has been deleted.

SUBTASK 72-41-15-350-057-B00 Remove Damage from the HP Compressor Rotor Blade(s), Stage 7, Assembly B (DELETED)

Make sure that all of the defect(s) have been removed from the component.

Do a visual inspection of the HP Compressor Stage 7 Rotor Blade.

Discard the blades, if more than the limits specified.

Do a dimensional inspection of the HP Compressor Stage 7 Rotor Blade.

SUBTASK 72-41-15-220-165 Visually and Dimensionally Inspect

This subtask has been deleted.

SUBTASK 72-41-15-220-165-B00 Examine the Repaired HP Compressor Rotor Blade(s), Stage 7, Assembly B (DELETED)

Refer to SPM TASK 70-11-08-300-503.

Clean and swab etch the repaired area(s).

SUBTASK 72-41-15-110-120 Do a Swab Etch

Refer to SPM TASK 70-23-05-230-501, ultra high sensitivity. Cracks are not permitted.

Do a penetrant crack test on the repair areas by one of the procedures that follow:

Refer to SPM TASK 70-23-04-230-501.

SUBTASK 72-41-15-230-065 Do a Crack Test

Refer to Repair, VRS6150 TASK 72-41-15-300-040 (REPAIR-040).

NOTE

This SUBTASK, to restore the surface condition, is only necessary if the depth of material removal is greater than 0.002 in. (0.05 mm).Restore the HP Compressor Stage 7 Rotor Blade surface condition.

SUBTASK 72-41-15-380-057 Restore the Airfoil Surface Condition

Polish the repair area to remove scratches and to achieve a surface finish of 10 microinches (0.25 micrometers).

Use suitable silicon carbide abrasive papers to achieve the given surface finish.

Polish the repair area on the HP Compressor Stage 7 Rotor Blade.

SUBTASK 72-41-15-350-005 Polish the Repair Area

CAUTION

TITANIUM COMPONENT - ONLY USE SILICON CARBIDE ABRASIVE STONES, WHEELS AND PAPERS TO DRESS, BLEND AND POLISH THE COMPONENT.

CAUTION

TITANIUM COMPONENT- THE MAXIMUM SPEED FOR MECHANICAL TOOLS MUST NOT EXCEED 1000 REVOLUTIONS PER MINUTE.

CAUTION

TITANIUM COMPONENT - MAKE SURE THAT DURING MATERIAL REMOVAL, BLENDING TO MAKE SMOOTH AND POLISHING THAT NO SPARKS ARE PRODUCED.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOUR TO DARKER THAN A LIGHT STRAW COLOUR THE COMPONENT MUST BE REJECTED.

CAUTION

TITANIUM COMPONENT - AVOID BUILD UP OF HEAT BY APPLYING ONLY GENTLE PRESSURE AND KEEPING THE TOOL SPEED AS LOW AS POSSIBLE. USE TECHNIQUES WHICH ALLOW FOR PROGRESSIVE WEAR OF THE DRESSING MEDIA TO PRESENT A CONTINUALLY FRESH CUTTING SURFACE TO THE WORK PIECE.

CAUTION

TITANIUM COMPONENT - DO NOT DWELL ON ONE AREA OF THE COMPONENT.

CAUTION

TITANIUM COMPONENT - DRESS WHERE POSSIBLE IN A CIRCULAR MOTION.NOTE

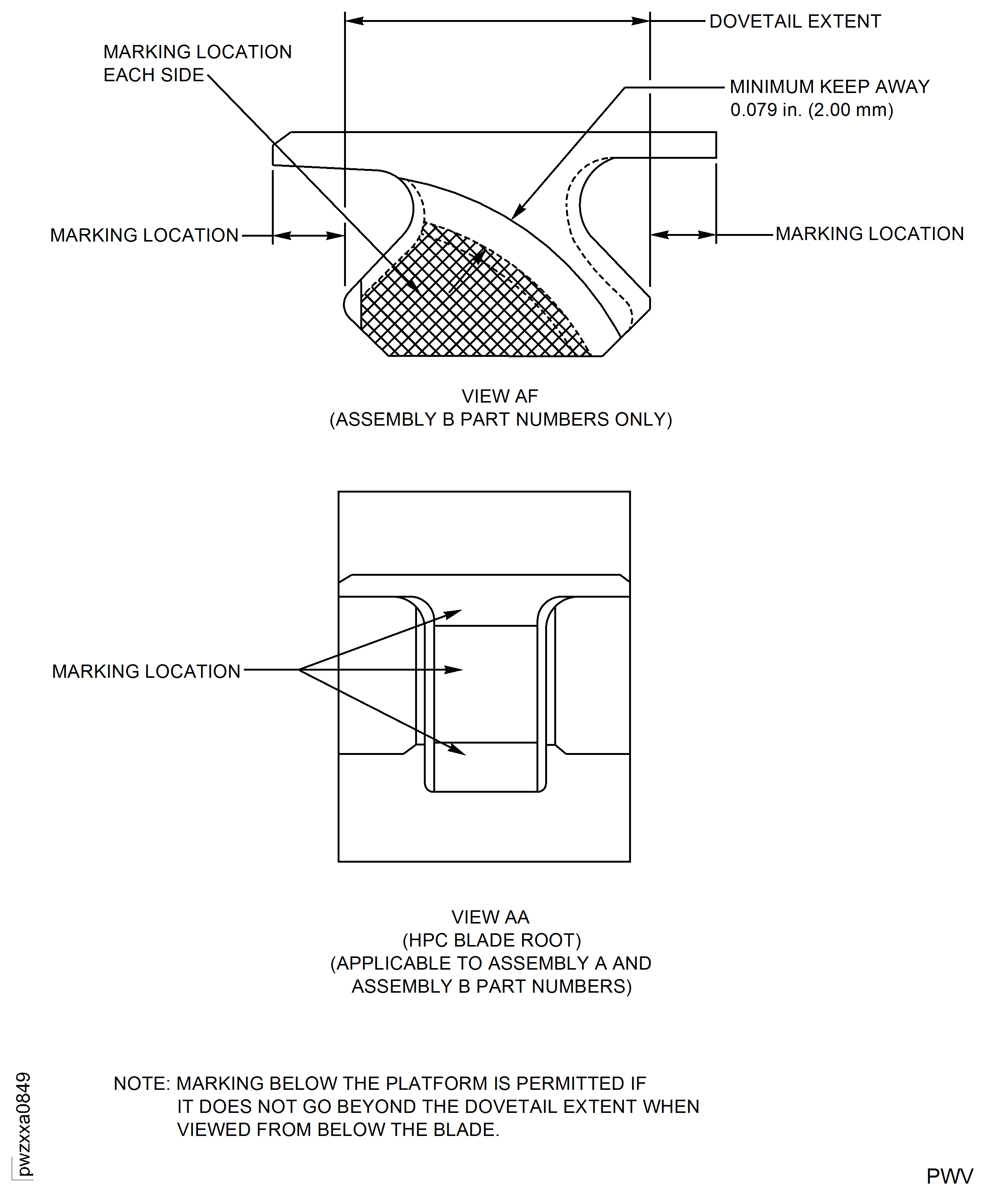

This SUBTASK only needs to be applied if Step has not been applied.For Assembly A and Assembly B, refer to Figure.

NOTE

If the HP Compressor Stage 7 Rotor Blade is already identified with the repair scheme identification symbol 26 from a previous repair application, further identification is not necessary.Refer to SPM TASK 70-09-00-400-501.

Use vibration peen method.

Vibro-peen 26 at one of the indicated locations on the HP Compressor Stage 7 Rotor Blade.

SUBTASK 72-41-15-350-006 Identify the Repair

Figure: HP Compressor Stage 7 Rotor Blade - Leading And Trailing Edge Blending Details And Dimensions - Assembly A And Assembly B

HP Compressor Stage 7 Rotor Blade - Leading And Trailing Edge Blending Details And Dimensions - Assembly A And Assembly B

Figure: HP Compressor Stage 7 Rotor Blade - Leading And Trailing Edge Dressing Details - Assembly A And Assembly B

HP Compressor Stage 7 Rotor Blade - Leading And Trailing Edge Dressing Details - Assembly A And Assembly B

Figure: HP Compressor Stage 7 Rotor Blade - Leading And Trailing Edge Scalloping Details And Dimensions - Assembly A And Assembly B

HP Compressor Stage 7 Rotor Blade - Leading And Trailing Edge Scalloping Details And Dimensions - Assembly A And Assembly B

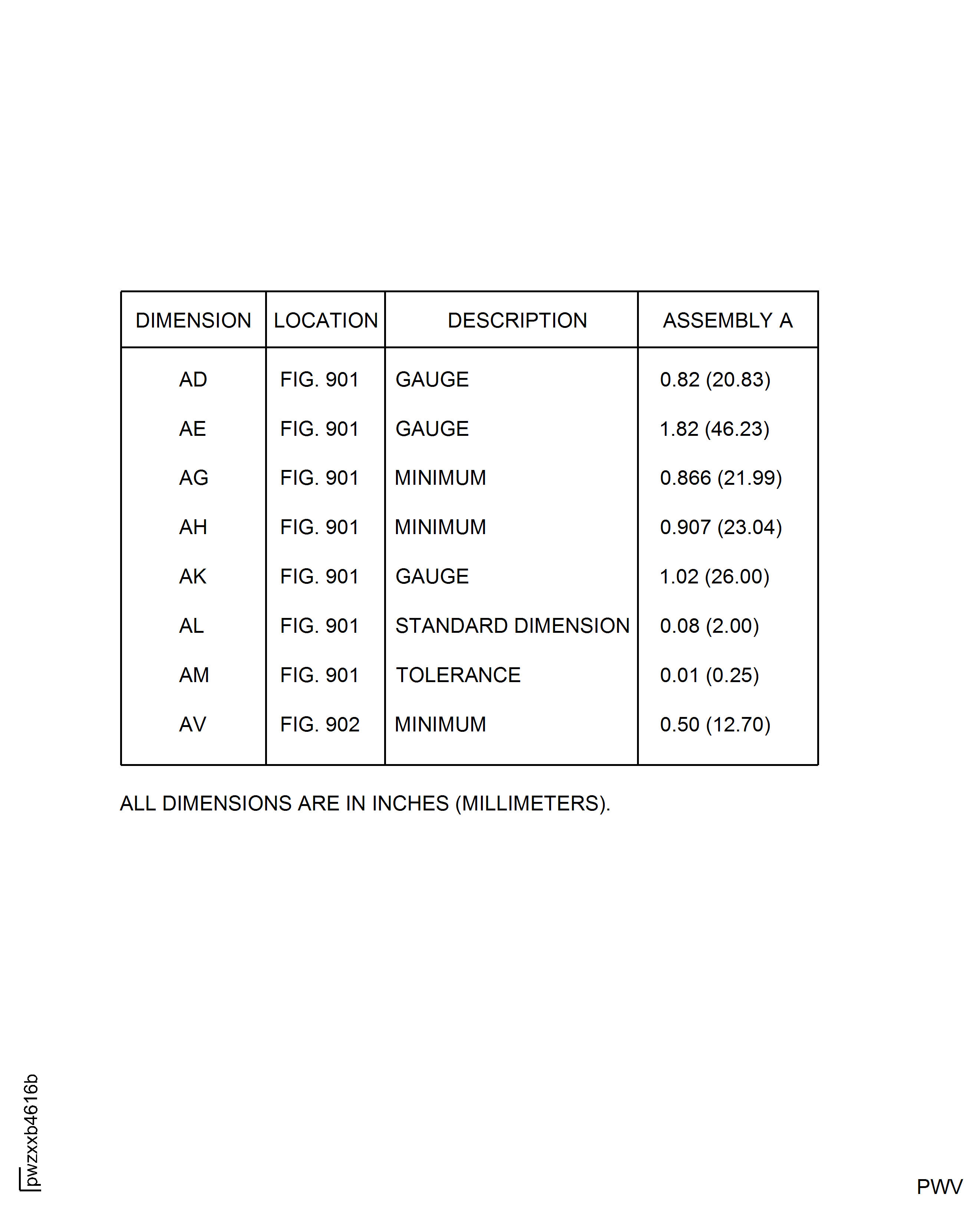

Figure: HP Compressor Stage 7 Rotor Blade - Repair Dimensions - Assembly A

HP Compressor Stage 7 Rotor Blade - Repair Dimensions - Assembly A

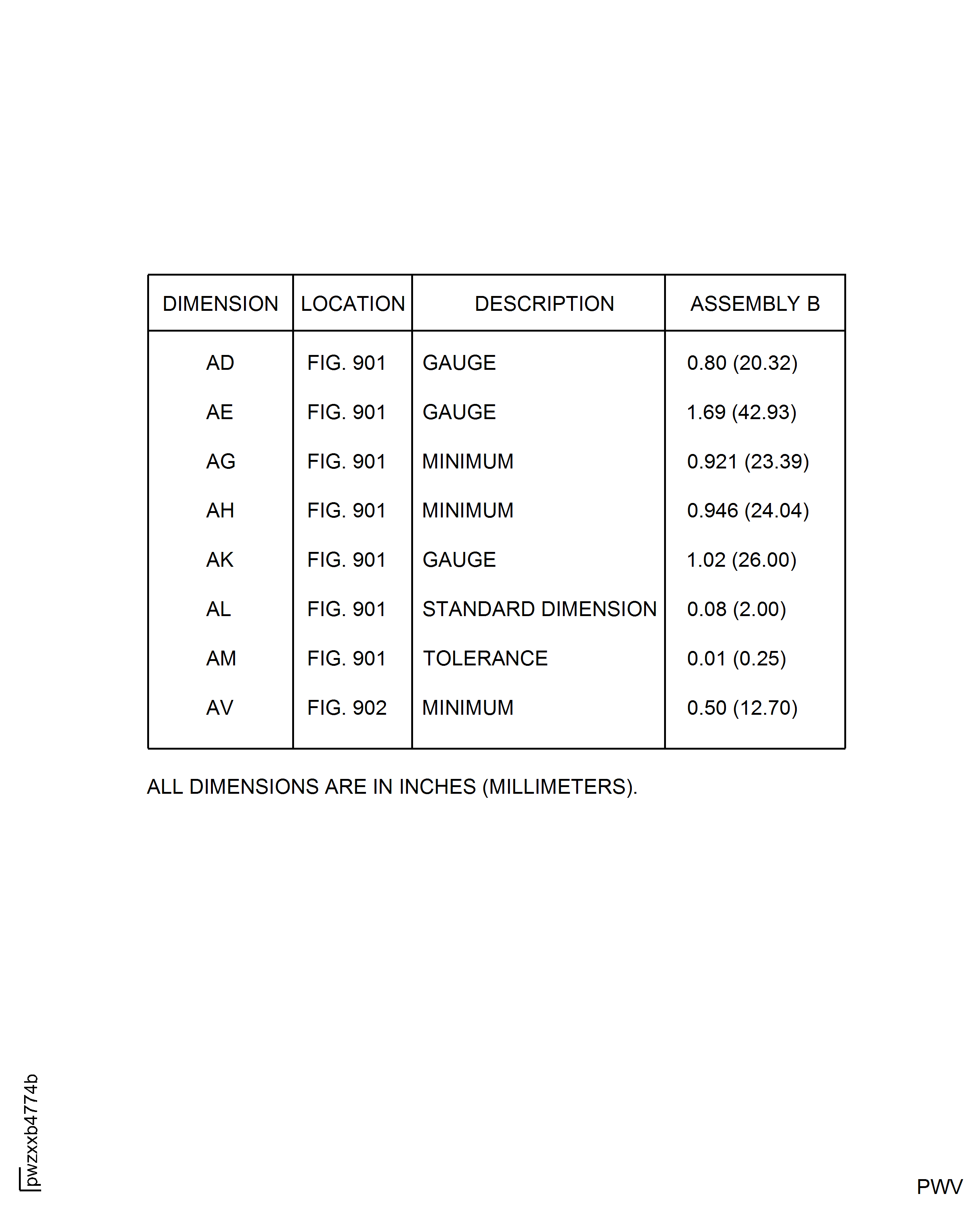

Figure: HP Compressor Stage 7 Rotor Blade - Repair Dimensions - Assembly B

HP Compressor Stage 7 Rotor Blade - Repair Dimensions - Assembly B

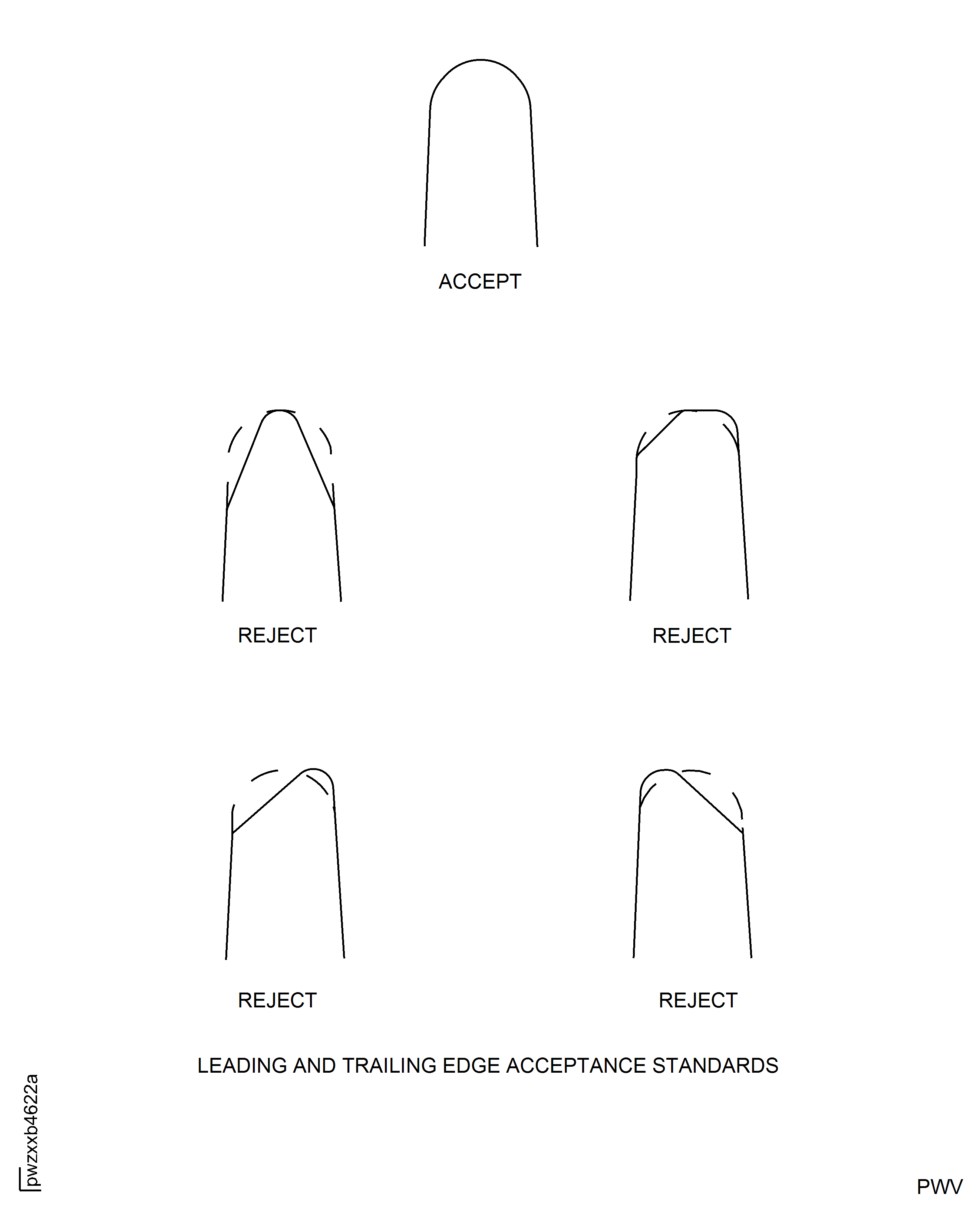

Figure: HP Compressor Stage 7 Rotor Blade - Repaired Leading And Trailing Edge Details - Assembly A And Assembly B

HP Compressor Stage 7 Rotor Blade - Repaired Leading And Trailing Edge Details - Assembly A And Assembly B

Figure: HP Compressor Stage 7 Rotor Blade - Airfoil Surface Dressing - Repair Details And Dimensions - Assembly A And Assembly B

HP Compressor Stage 7 Rotor Blade - Airfoil Surface Dressing - Repair Details And Dimensions - Assembly A And Assembly B

Figure: HP Compressor Stage 7 Rotor Blades - Marking Locations

HP Compressor Stage 7 Rotor Blades - Marking Locations