Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-21-300-024 HPC Cross Key Location Ring - Replace The Hard Coat, Repair-024 (VRS6171)

Effectivity

FIG/ITEM | PART NO. | |

|---|---|---|

04-750 | 6A2856 | Assembly A |

04-750 | 6A5737 | Assembly B |

04-750 | 6A4179 | Assembly C |

04-750 | 6A5738 | Assembly D |

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

HP Compressor crosskey location ring | QTX or QRK | Nickel based alloy |

General

This repair must only be done when the instruction to do so is given in 72-41-21 Inspection/Check.

The practices and processes referred to in the procedure by the TASK/SUBTASK number are in the SPM.

Price and availability

Refer to International Aero Engines

Related repairs

None.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Lathe | LOCAL | Lathe | ||

| Dial indicator | LOCAL | Dial indicator | ||

| Standard workshop tools | LOCAL | Standard workshop tools | ||

| Milling machine | LOCAL | Milling machine | ||

| Rotary table | LOCAL | Rotary table | Indexing | |

| Abrasive blasting facility | LOCAL | Abrasive blasting facility | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Gloves | LOCAL | Gloves | Clean cotton or polythene | |

| Brush | LOCAL | Brush | Vacuum assisted | |

| Metal spray equipment | LOCAL | Metal spray equipment | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Grinding machine | LOCAL | Grinding machine | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| IAE 3R18633 Grind Fixture | 0AM53 | IAE 3R18633 | 1 | |

| IAE 3R18634 Turn/Grind Fixture | 0AM53 | IAE 3R18634 | 1 | |

| IAE 3R19118 Grind Fixture | 0AM53 | IAE 3R19118 | 1 | |

| IAE 3R19119 Turn/Grind Fixture | 0AM53 | IAE 3R19119 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL | K0993 | CoMat 02-006 | ||

| CoMat 03-239 METAL SPRAYING POWDER, CHROMIUM CARBIDE/NICHROME 75/25, FINE | LOCAL | CoMat 03-239 | ||

| CoMat 03-240 METAL SPRAYING POWDER, CHROMIUM CARBIDE/NICHROME 75/25, FINE | LOCAL | CoMat 03-240 | ||

| CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE | LOCAL | CoMat 05-001 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

NONESafety Requirements

NONEProcedure

Use chemical cleaning equipment.

Refer to TASK 72-41-21-100-000 (CLEANING-000).

Remove the surface protection.

SUBTASK 72-41-21-110-112 Remove the Surface Protection

Use IAE 3R18634 Turn/Grind Fixture 1 off with a lathe and a dial test indicator.

Install the turn/grind fixture onto a lathe and set to turn correctly.

SUBTASK 72-41-21-325-069-A00 Machine to Remove the Hard Coat, Assembly A

Use IAE 3R18634 Turn/Grind Fixture 1 off with a lathe and a dial test indicator.

Install the turn/grind fixture onto a lathe and set to turn correctly.

SUBTASK 72-41-21-325-069-B00 Machine to Remove the Hard Coat, Assembly B

Use IAE 3R19119 Turn/Grind Fixture 1 off, with a lathe and a dial test indicator.

Install the turn/grind fixture onto a lathe and set to turn corrctly.

SUBTASK 72-41-21-325-069-C00 Machine to Remove the Hard Coat, Assembly C

Use IAE 3R19119 Turn/Grind Fixture 1 off, with a lathe and a dial test indicator.

Install the turn/grind fixture onto a lathe and set to turn correctly.

SUBTASK 72-41-21-325-069-D00 Machine to Remove the Hard Coat, Assembly D

Use IAE 3R18633 Grind Fixture 1 off with a milling machine and an indexing rotary table.

Install the grind fixture onto a milling machine.

SUBTASK 72-41-21-322-001-A00 Remove the Hard Coat on the Location Features, Assembly A

Use IAE 3R18633 Grind Fixture 1 off with a milling machine and an indexing rotary table.

Install the grind fixture onto a milling machine.

SUBTASK 72-41-21-322-001-B00 Remove the Hard Coat on the Location Features, Assembly B

Use IAE 3R19118 Grind Fixture 1 off, with a milling machine and an indexing rotary table.

Install the grind fixture onto a milling machine.

SUBTASK 72-41-21-322-001-C00 Remove the Hard Coat on the Location Features, Assembly C

Use IAE 3R19118 Grind Fixture 1 off, with a milling machine and an indexing rotary table.

Install the grind fixture onto a milling machine.

SUBTASK 72-41-21-322-001-D00 Remove the Hard Coat on the Location Features, Assembly D

Refer to the SPM TASK 70-33-59-300-503, SUBTASK 70-33-59-300-008.

Use CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE with abrasive blast facility.

Abrasive blast.

SUBTASK 72-41-21-330-058-A00 Remove the Remaining Hard Coat, Assembly A

Refer to the SPM TASK 70-33-59-300-503, SUBTASK 70-33-59-300-004 or SUBTASK 70-33-59-300-007.

Use chemical cleaning equipment.

Chemically degrade the hard coat.

Refer to the SPM TASK 70-33-59-300-503, SUBTASK 70-33-59-300-008.

Use CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE with abrasive blast facility.

Abrasive blast.

SUBTASK 72-41-21-330-058-B00 Remove the Remaining Hard Coat, Assembly B

Refer to the SPM TASK 70-33-59-300-503, SUBTASK 70-33-59-300-004 or SUBTASK 70-33-59-300-007.

Use chemical cleaning equipment.

Chemically degrade the hard coat.

Refer to the SPM TASK 70-33-59-300-503 SUBTASK 70-33-59-300-008.

Use CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADEblast facility.

Abrasive blast.

SUBTASK 72-41-21-330-058-C00 Remove the Remaining Hard Coat, Assembly C

Refer to the SPM TASK 70-33-59-300-503, SUBTASK 70-33-59-300-004 or SUBTASK 70-33-59-300-007.

Use chemical cleaning equipment.

Chemically degrade the hard coat.

Refer to the SPM TASK 70-33-59-300-503 SUBTASK 70-33-59-300-008<.

Use CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE blast facility.

Abrasive blast.

SUBTASK 72-41-21-330-058-D00 Remove the Remaining Hard Coat, Assembly D

Use penetrant crack test equipment.

Cracks are not permitted.

Refer to the SPM TASK 70-23-01-230-501.

Do a penetrant crack test.

SUBTASK 72-41-21-230-102 Do a Crack Test

Use chemical cleaning equipment.

Refer to the SPM TASK 70-11-01-300-503.

Chemically clean the ring.

SUBTASK 72-41-21-110-113 Chemically Clean

Refer to the SPM TASK 70-12-02-120-501.

Use CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE with an abrasive blast facility.

Abrasive blast the ring on surfaces 'AH'.

SUBTASK 72-41-21-120-059-A00 Abrasive Blast the Ring, Assembly A

Refer to the SPM TASK 70-12-02-120-501.

Use CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE with an abrasive blast facility.

Abrasive blast the ring on surfaces 'AH'.

SUBTASK 72-41-21-120-059-B00 Abrasive Blast the Ring, Assembly B

Refer to the SPM TASK 70-12-02-120-501.

Use CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE with an abrasive blast facility.

Abrasive blast the ring on surfaces 'AH'.

SUBTASK 72-41-21-120-059-C00 Abrasive blast the Ring, Assembly C

Refer to the SPM TASK 70-12-02-120-501.

Use CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE with an abrasive blast facility.

Abrasive blast the ring on surfaces 'AH'.

SUBTASK 72-41-21-120-059-D00 Abrasive Blast the Ring, Assembly D

Refer to SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-026.

Apply a layer of sufficient thickness to get the correct dimensions after the assembly is machined.

Apply the hard coat to surfaces 'AH'.

SUBTASK 72-41-21-340-059-A00 Apply the Hard Coat to the HP Compressor Crosskey Location Ring, Assembly A

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-026.

Apply a layer of sufficient thickness to get the correct dimensions after the assembly is machined.

Apply the hard coat to surfaces 'AH'.

SUBTASK 72-41-21-340-059-B00 Apply the Hard Coat to the HP Compressor Crosskey Location Ring, Assembly B

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-026.

Apply a layer of sufficient thickness to get the correct dimensions after the assembly is machined.

Apply the hard coat to surfaces 'AH'.

SUBTASK 72-41-21-340-059-C00 Apply the Hard Coat to the HP Compressor Crosskey Location Ring, Assembly C

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-026.

Apply a layer of sufficient thickness to get the correct dimensions after the assembly is machined.

Apply the hard coat to surfaces 'AH'.

SUBTASK 72-41-21-340-059-D00 Apply the Hard Coat to the HP Compressor Crosskey Location Ring, Assembly D

Refer to the SPM TASK 70-34-01-340-501.

Use workshop inspection equipment.

Visually examine and measure the dimensions of the hard coat.

SUBTASK 72-41-21-220-251-A00 Examine the Hard Coat, Assembly A

Refer to the SPM TASK 70-34-01-340-501.

Use workshop inspection equipment.

Visually examine and measure the dimensions of the hard coat.

SUBTASK 72-41-21-220-251-B00 Examine the Hard Coat, Assembly B

Refer to the SPM TASK 70-34-01-340-501.

Use workshop inspection equipment.

Visually examine and measure the dimensions of the hard coat.

SUBTASK 72-41-21-220-251-C00 Examine the Hard Coat, Assembly C

Refer to the SPM TASK 70-34-01-340-501.

Use workshop inspection equipment.

Visually examine and measure the dimensions of the hard coat.

SUBTASK 72-41-21-220-251-D00 Examine the Hard Coat, Assembly D

Use IAE 3R18634 Turn/Grind Fixture 1 off with a grinding machine and a dial test indicator.

Install the grind fixture onto a grinding machine and set to turn correctly.

SUBTASK 72-41-21-324-051-A00 Machine the Hard Coat, Assembly A

Use IAE 3R19119 Turn/Grind Fixture 1 off with a grinding machine and a dial test indicator.

Install the grind fixture onto a grinding machine and set to turn correctly.

SUBTASK 72-41-21-324-051-B00 Machine the Hard Coat, Assembly B

Use IAE 3R19119 Turn/Grind Fixture 1 off with a grinding machine and a dial test indicator.

Install the grind fixture onto a grinding machine and set to turn correctly.

SUBTASK 72-41-21-324-051-C00 Examine the Hard Coat, Assembly C

Use IAE 3R19119 Turn/Grind Fixture 1 off, with a grinding machine and a dial test indicator.

Install the grind fixture onto a grinding machine and set to turn correctly.

SUBTASK 72-41-21-324-051-D00 Machine the Hard Coat, Assembly D

Use IAE 3R18633 Grind Fixture 1 off, with a grinding machine and an indexing rotary table.

Install the grind fixture onto a grinding machine.

SUBTASK 72-41-21-324-052-A00 Machine the Hard Coat on the Location Features, Assembly A

Use IAE 3R18633 Grind Fixture 1 off, with a grinding machine and an indexing rotary table.

Install the grind fixture onto a grinding machine and set to turn correctly.

SUBTASK 72-41-21-324-052-B00 Machine the Hard Coat on the Location Features, Assembly B

Refer to Figure.

Use IAE 3R19119 Turn/Grind Fixture 1 off, with a grinding machine and an indexing rotary table.

Install the grind fixture onto a grinding machine and set to turn correctly.

SUBTASK 72-41-21-324-052-C00 Machine the Hard Coat on the Location Features, Assembly C, , 72-41-21-990-073-003and

Use IAE 3R19119 Turn/Grind Fixture 1 off, with a grinding machine and an indexing rotary table.

Install the grind fixture onto a grinding machine and set to turn correctly.

SUBTASK 72-41-21-324-052-D00 Machine the Hard Coat on the Location Features, Assembly D

Refer to the SPM TASK 70-34-01-340-501.

Use workshop inspection equipment.

Visually examine and measure the dimensions of the location features at 'AH'.

SUBTASK 72-41-21-220-053-A00 Examine the Location Features, Assembly A

Refer to the SPM TASK 70-34-01-340-501.

Use workshop inspection equipment.

Visually examine and measure the dimensions of the location features at 'AH'.

SUBTASK 72-41-21-220-053-B00 Examine the Location Features, Assembly B

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Use vibro-engraving equipment.

Mark VRS6171 adjacent to the part number.

SUBTASK 72-41-21-350-083 Identify the Repair

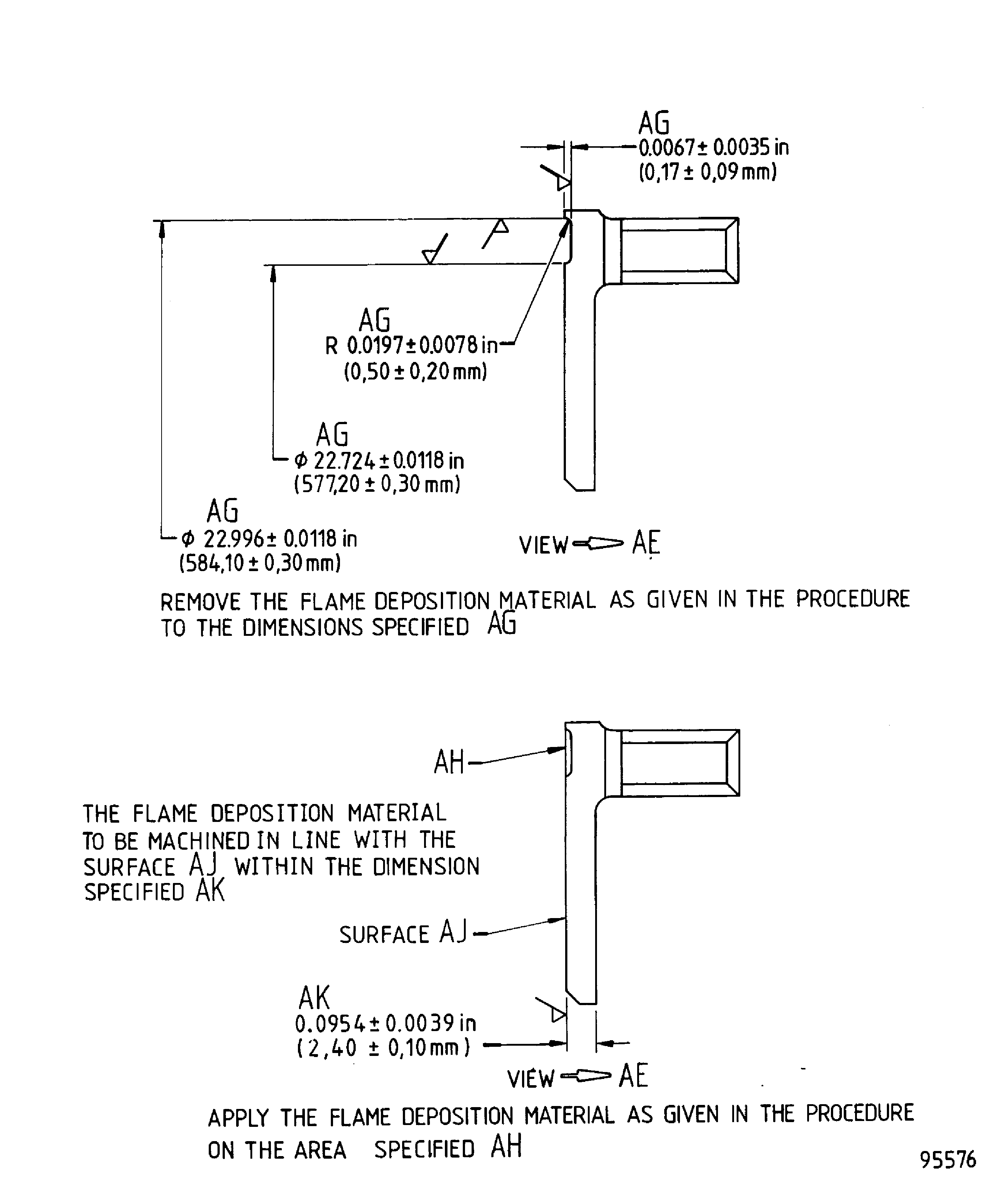

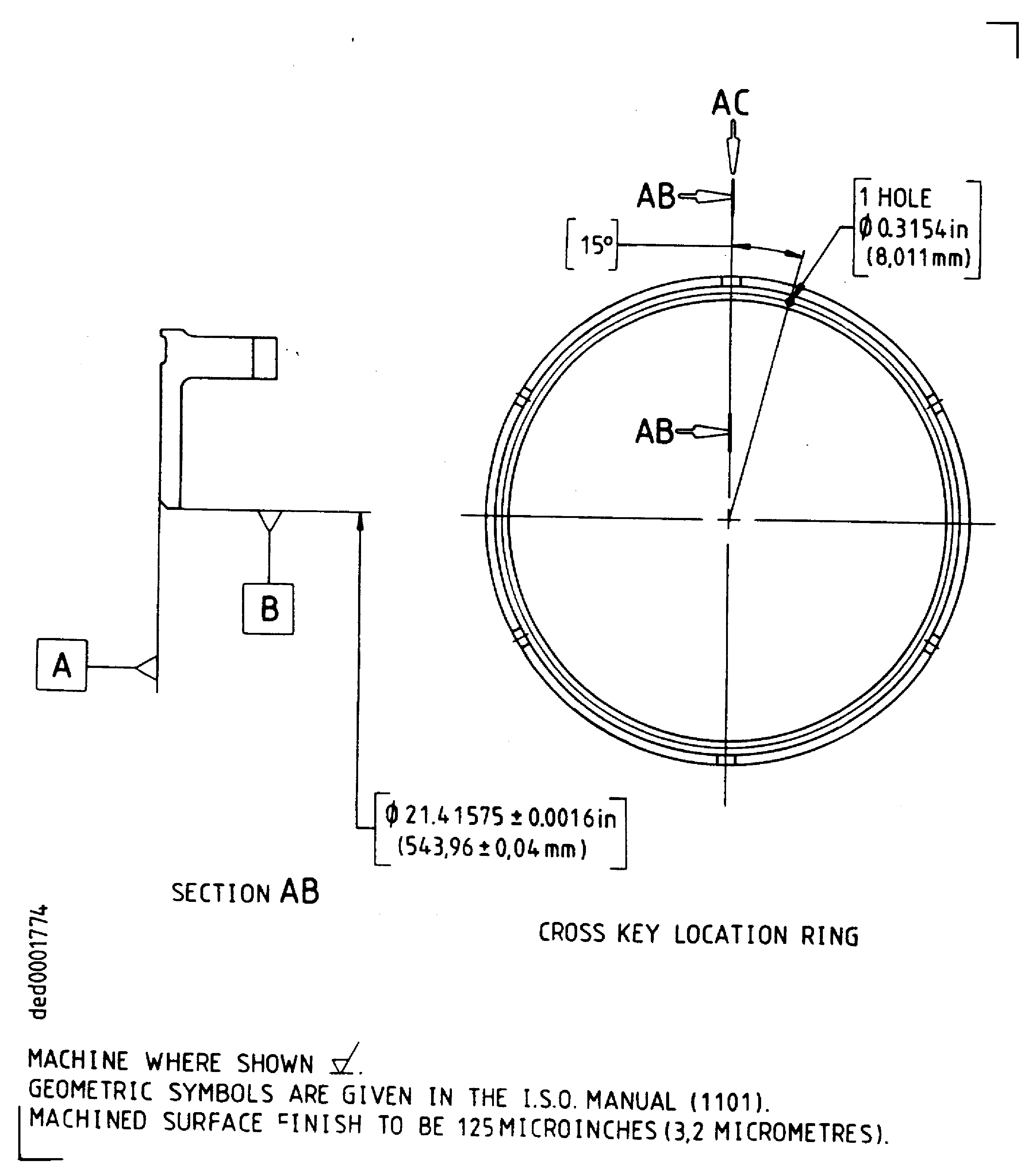

Figure: Repair details and dimensions - Assembly A

Sheet 1

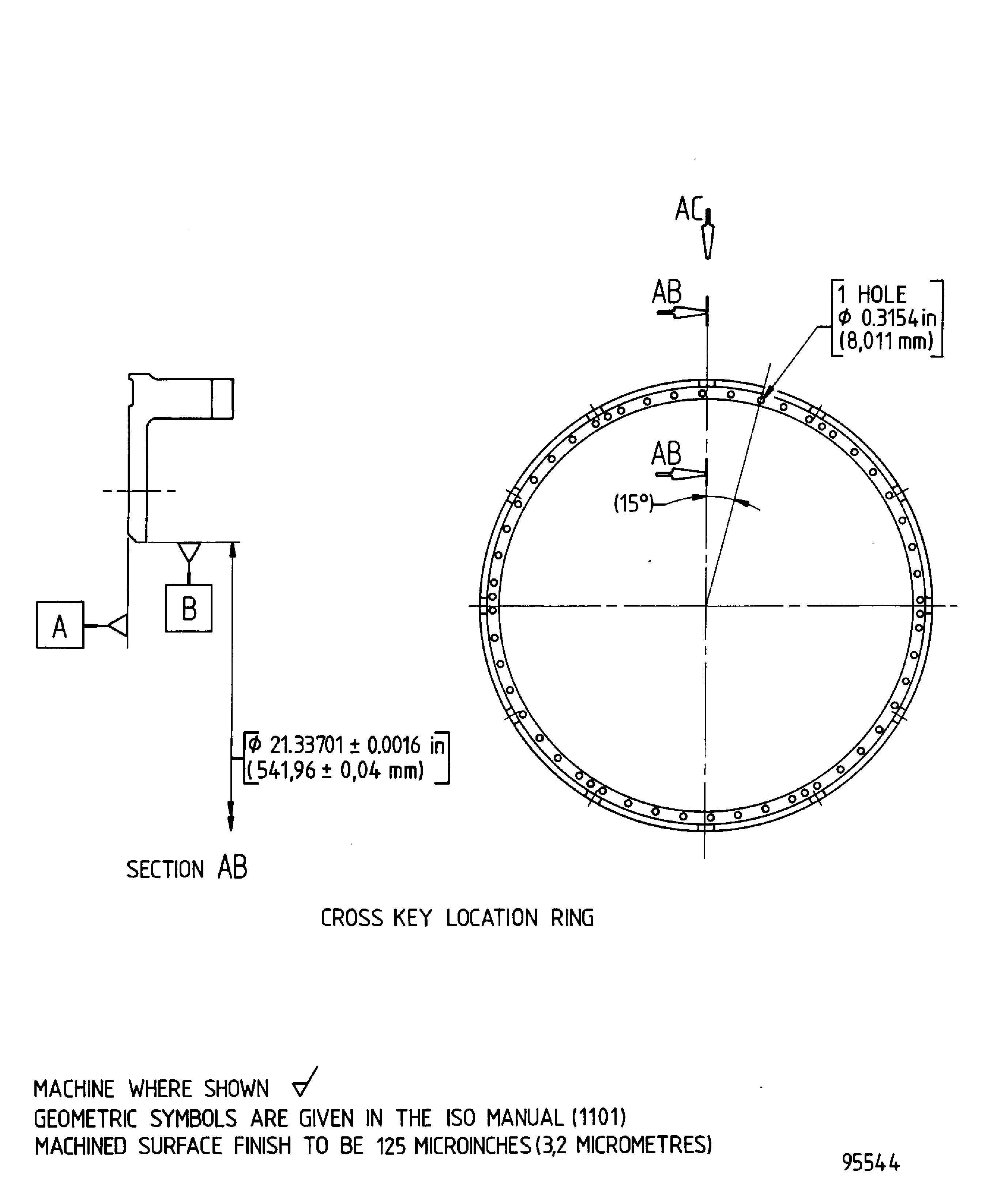

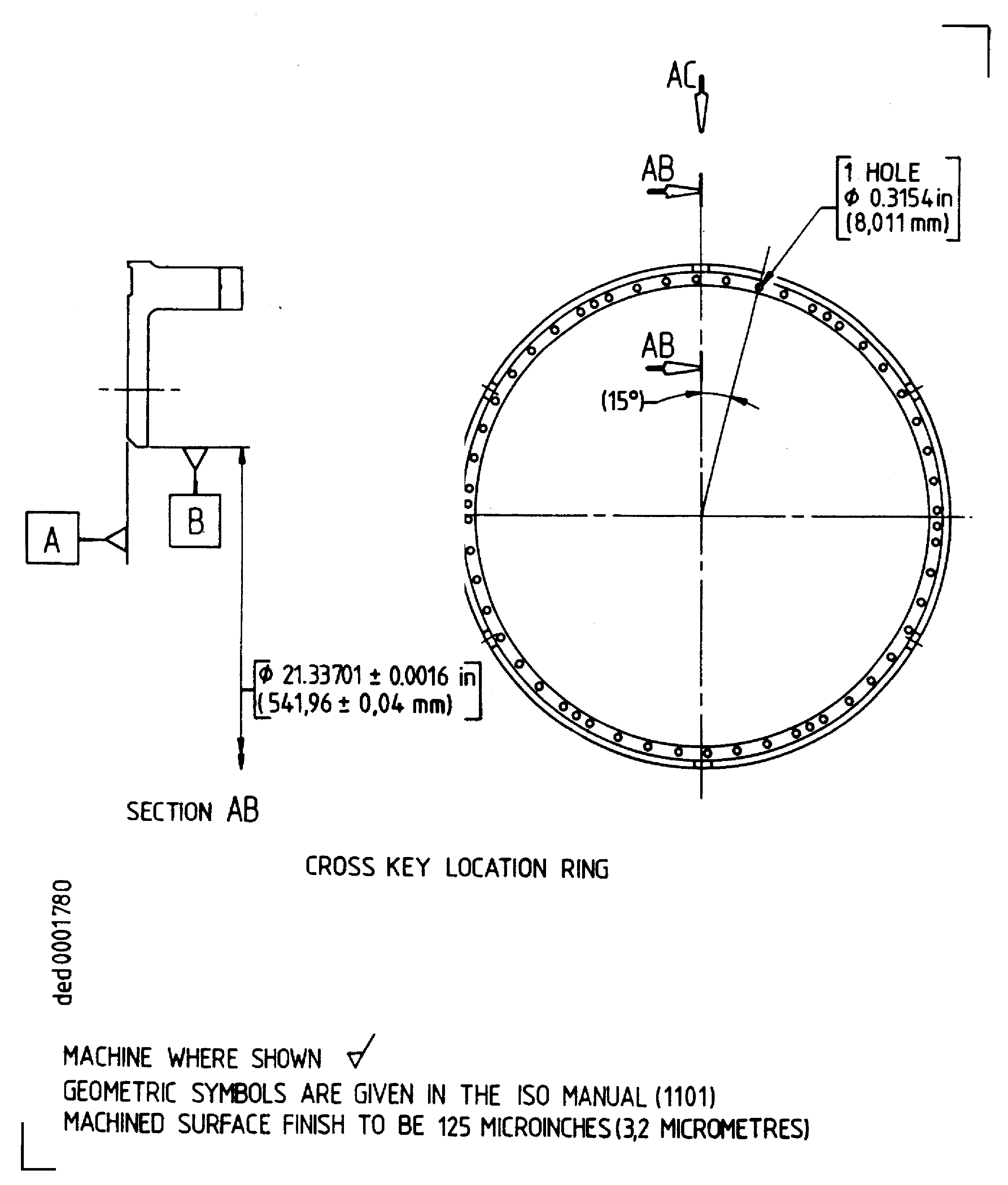

Figure: Repair details and dimensions - Assembly B

Sheet 2

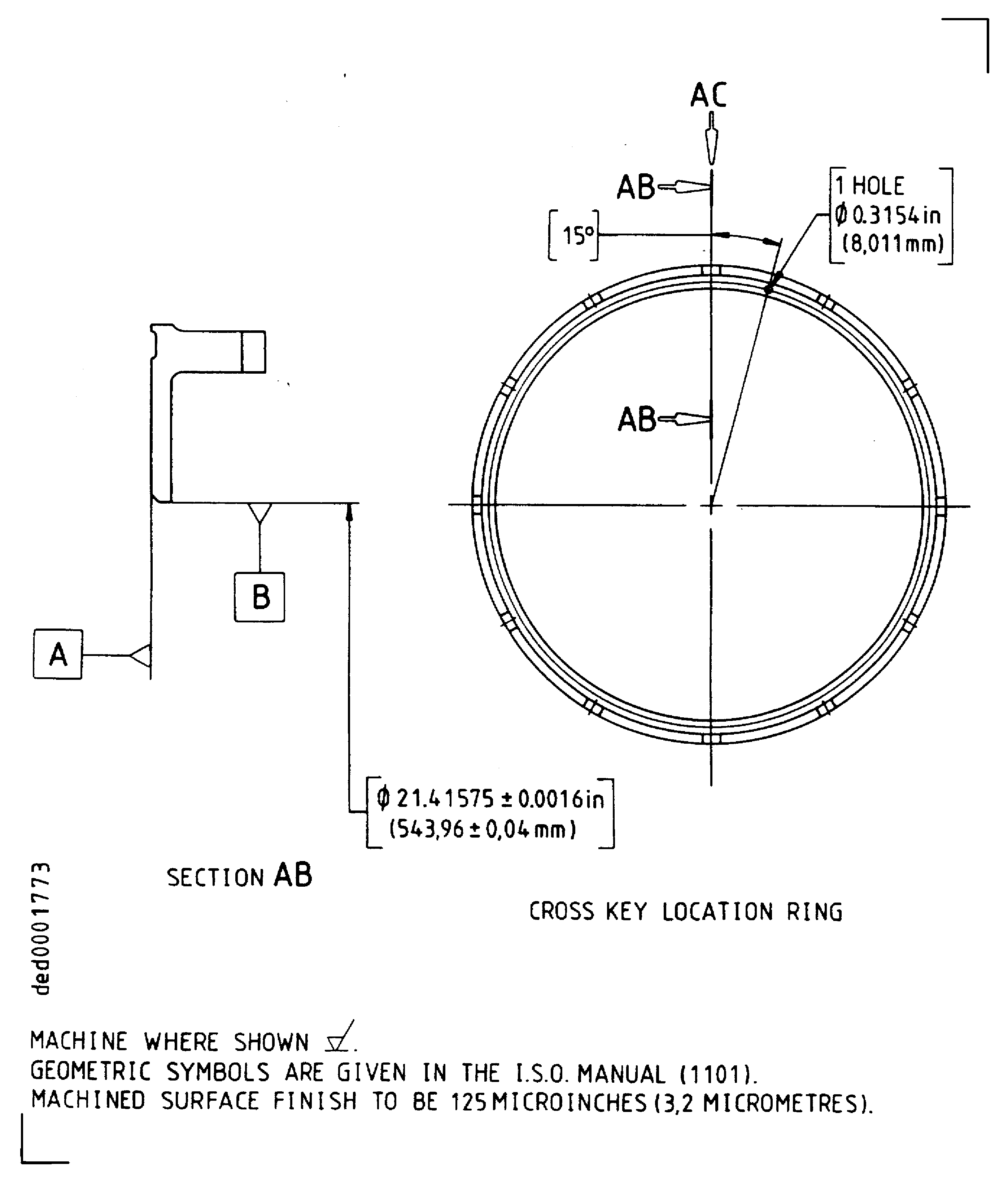

Figure: Repair details and dimensions - Assembly C

Sheet 3

Figure: Repair details and dimensions - Assembly D

Sheet 4

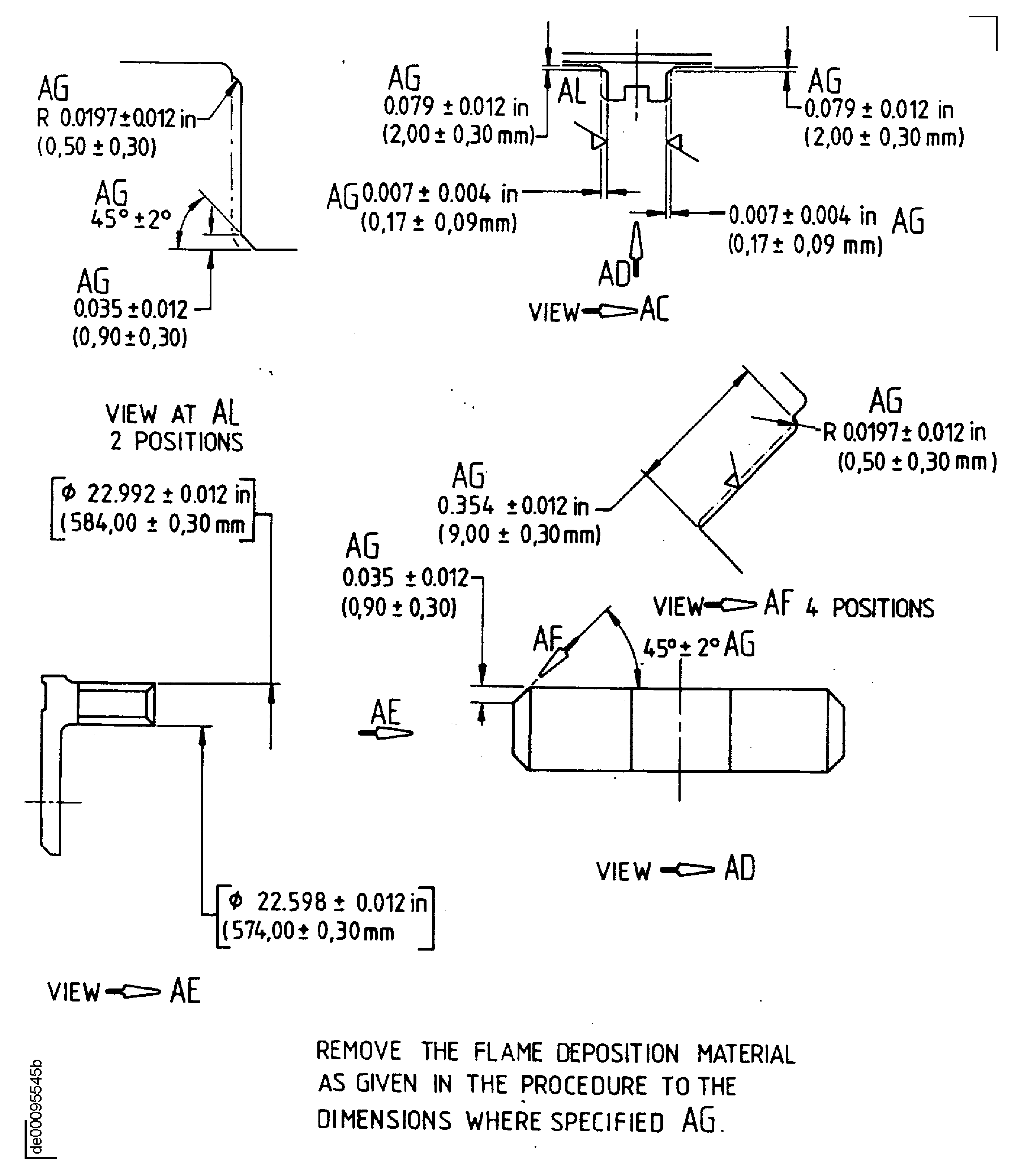

Figure: Repair details and dimensions - Assy's A, B, C and D

Repair details and dimensions - Assy's A, B, C and D

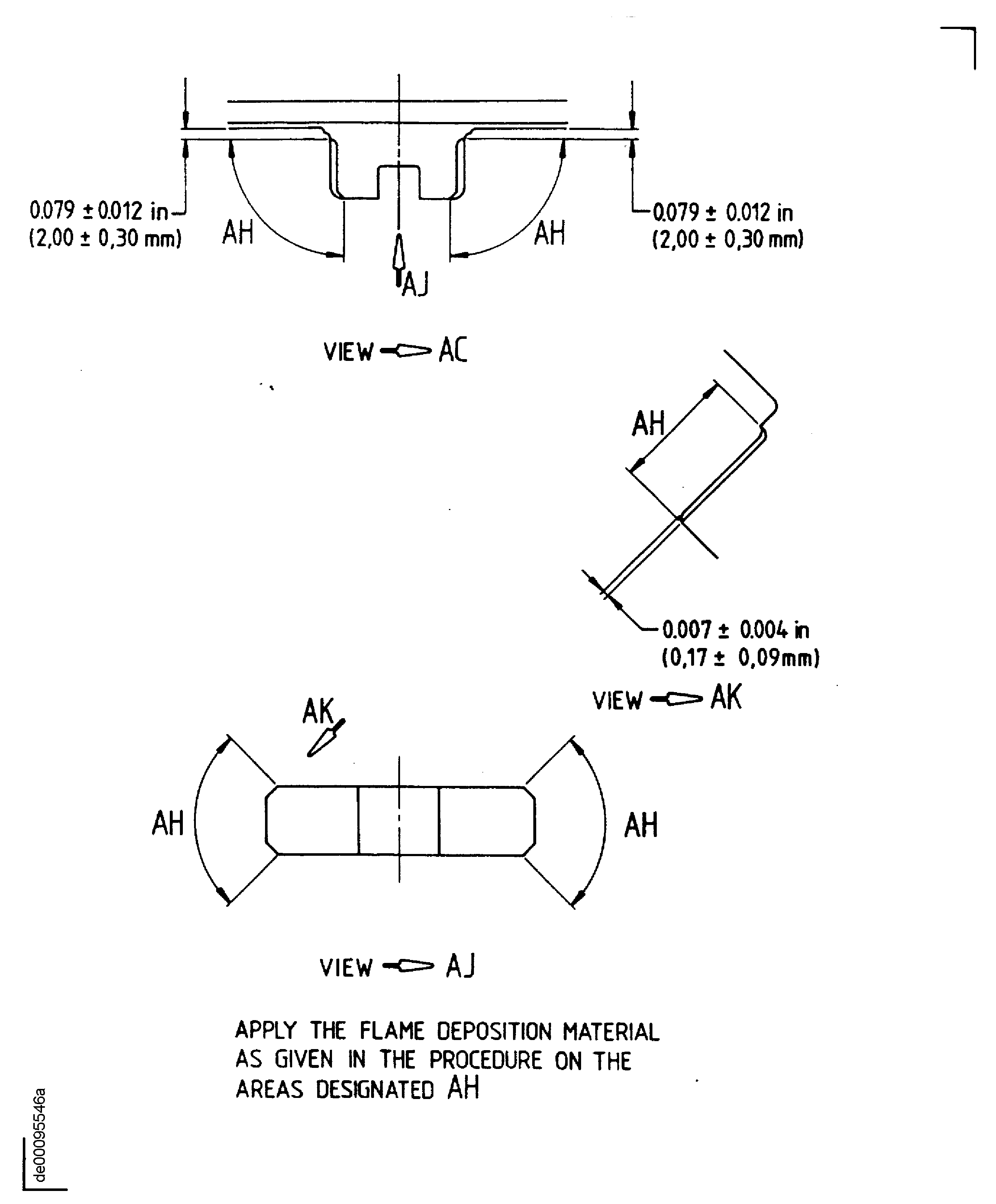

Figure: Repair details and dimensions - Assy's A, B, C and D

Repair details and dimensions - Assy's A, B, C and D

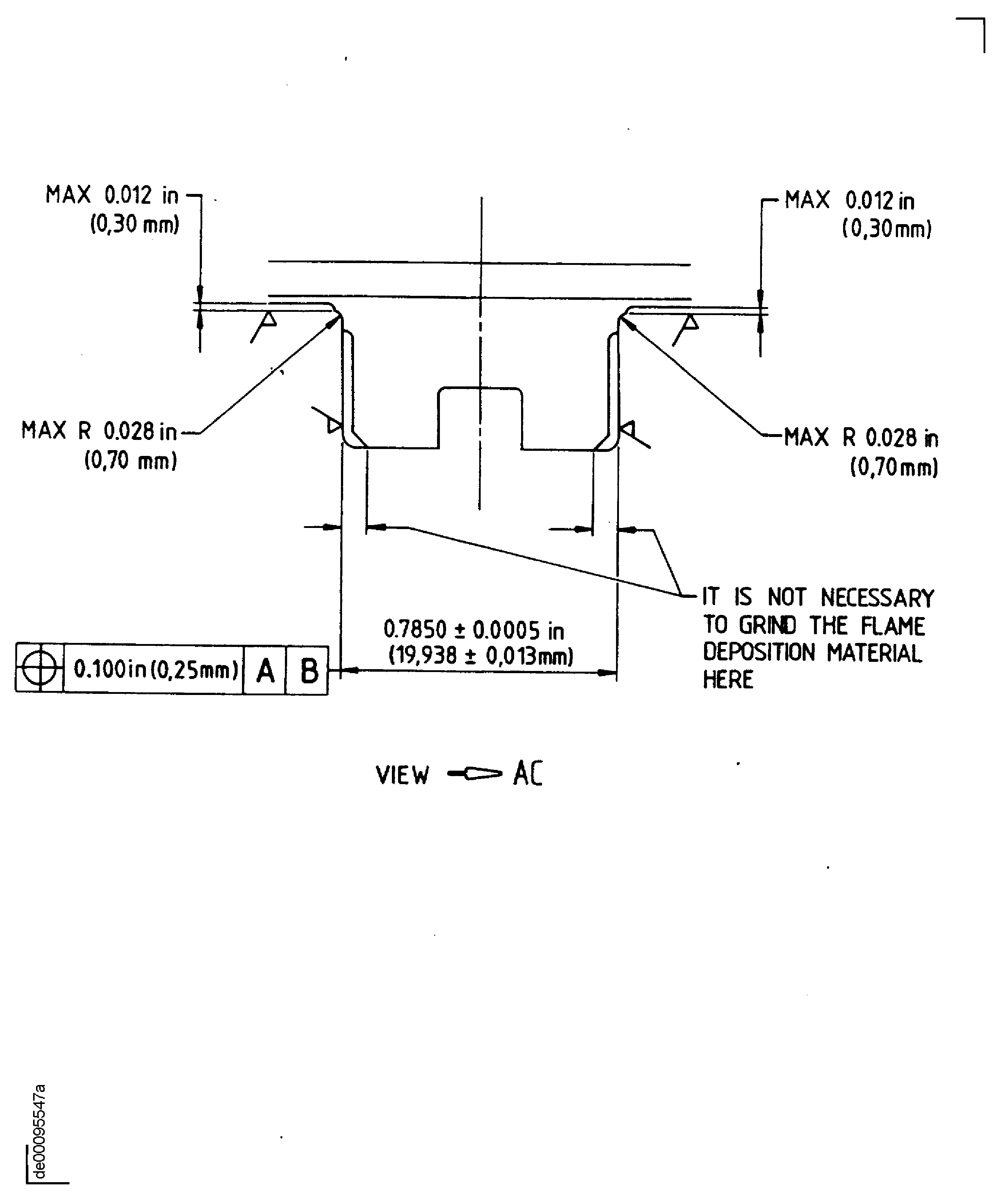

Figure: Repair details and dimensions - Assy's A, B, C and D

Repair details and dimensions - Assy's A, B, C and D

Figure: Repair details and dimensions - Assy's A, B, C and D

Repair details and dimensions - Assy's A, B, C and D