Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-21-300-006 HPC Stage 7 and Stage 8 Rotor Path Case Assembly - Replace The Surface Protection, Repair-006 (VRS6163)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

03-500 | 6A3500 |

03-500 | 6A4310 |

03-500 | 6A4569 |

03-500 | 6A7019 |

03-500 | 6A6548 |

03-500 | 6A7529 |

03-500 | 6A7578 |

03-500 | 6A7624 |

03-500 | 6B1432 |

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

HPC Stage 7 Case Assembly | EAK, EBL or EAE | Corrosion Resistant Steel |

General

This Repair replaces the surface protection on the HPC Stage 7 Case and HPC Stage 8 Rotor Path Case Assembly.

Related repairs - None

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the cleaning and inspection procedures, including any required FPI and other needed repairs, are done before this repair. |

Support Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 06-073 INK, METAL MARKING | LOCAL | CoMat 06-073 | ||

| CoMat 07-035 CORROSION RESISTANT COATING | LOCAL | CoMat 07-035 | ||

| CoMat 07-104 ALUMINIUM HIGH HEAT RESISTANT PAINT | LOCAL | CoMat 07-104 | ||

| CoMat 07-125 LACQUER | 0W199 | CoMat 07-125 | ||

| CoMat 07-175 COATING COMPOUND - ALUMINUM, INORGANIC BINDER | 53012 | CoMat 07-175 |

Spares

NONESafety Requirements

NONEProcedure

Mark the part with VRS6163 adjacent to the assembly part number.

Use vibration peen by SPM TASK 70-09-00-400-501.

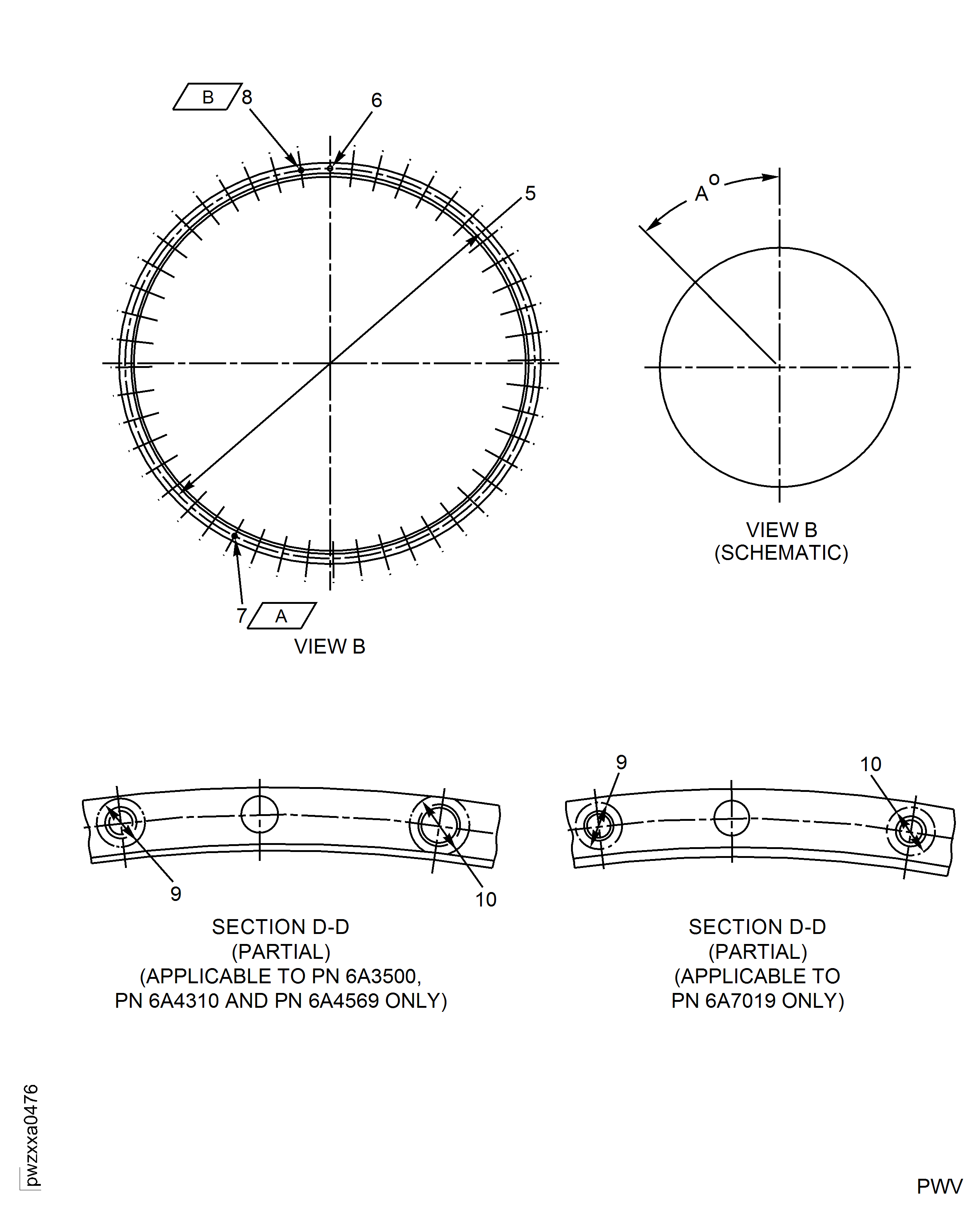

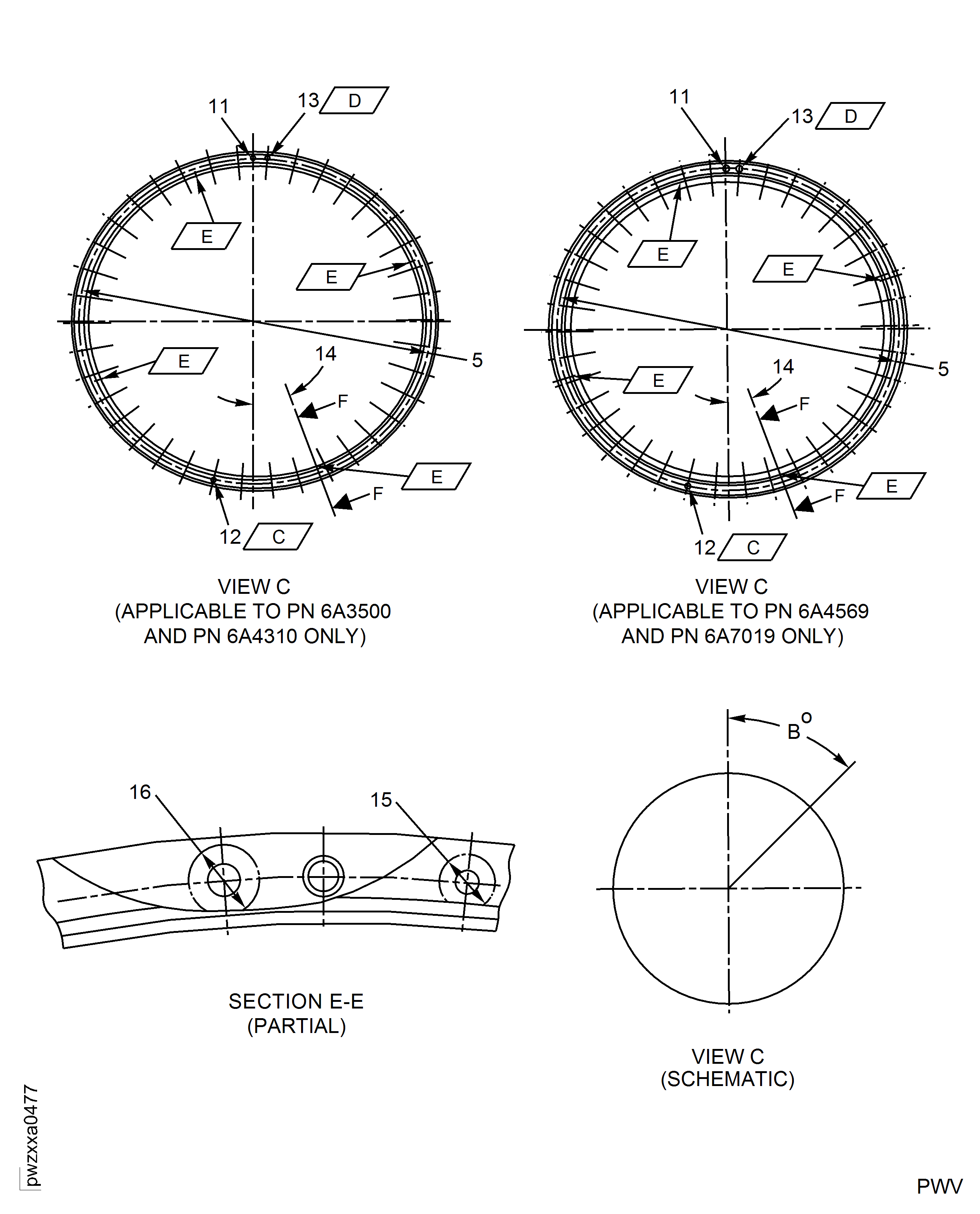

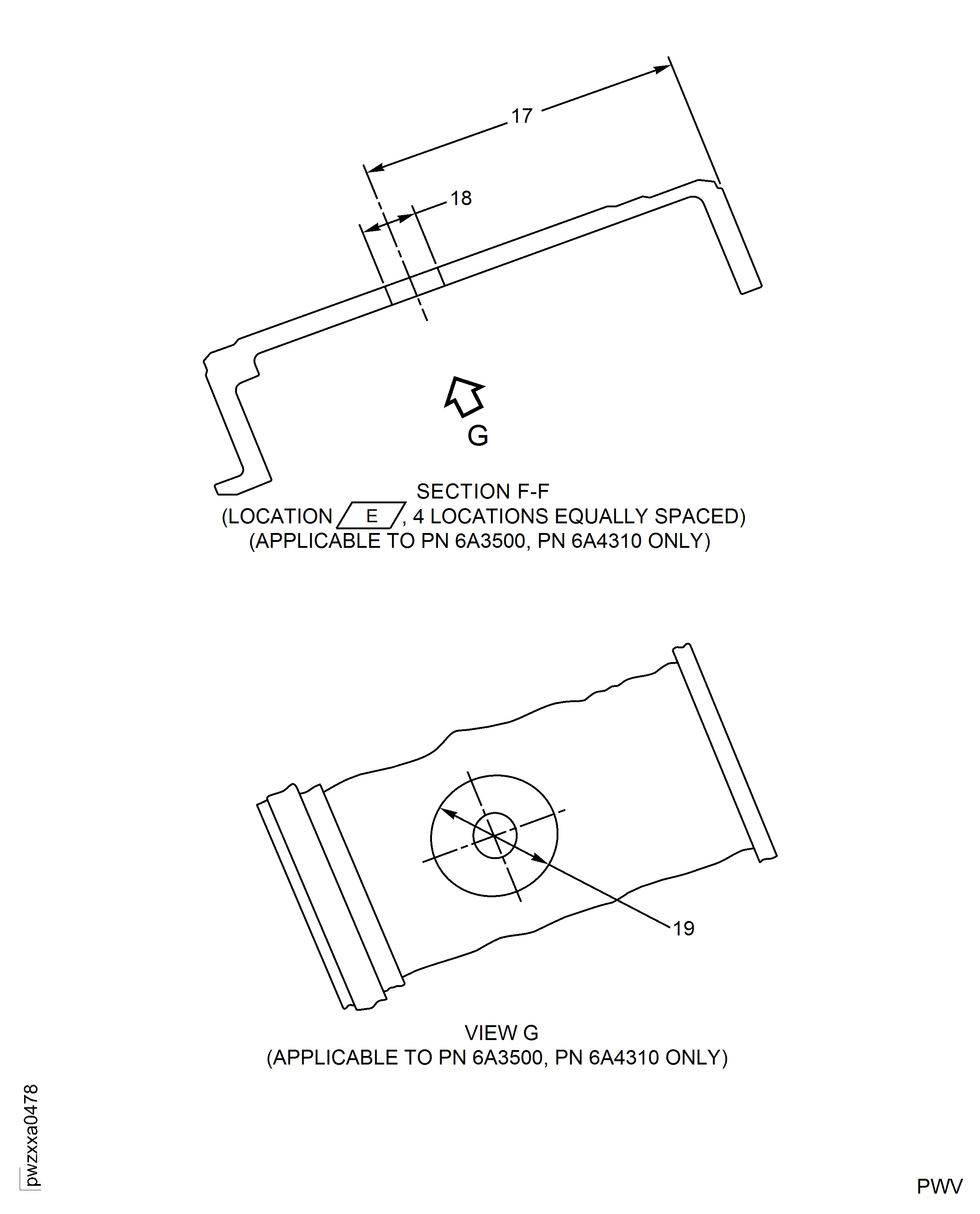

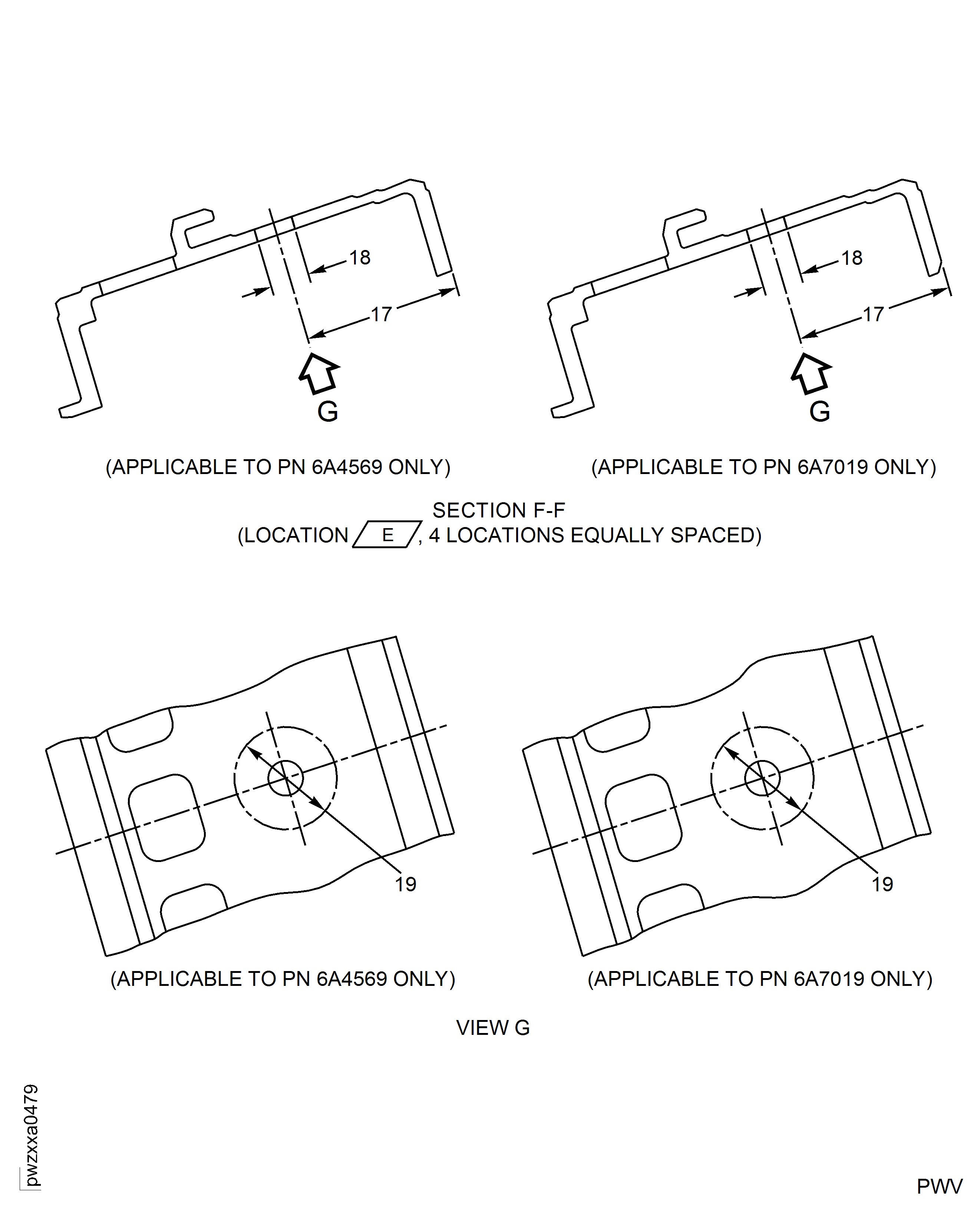

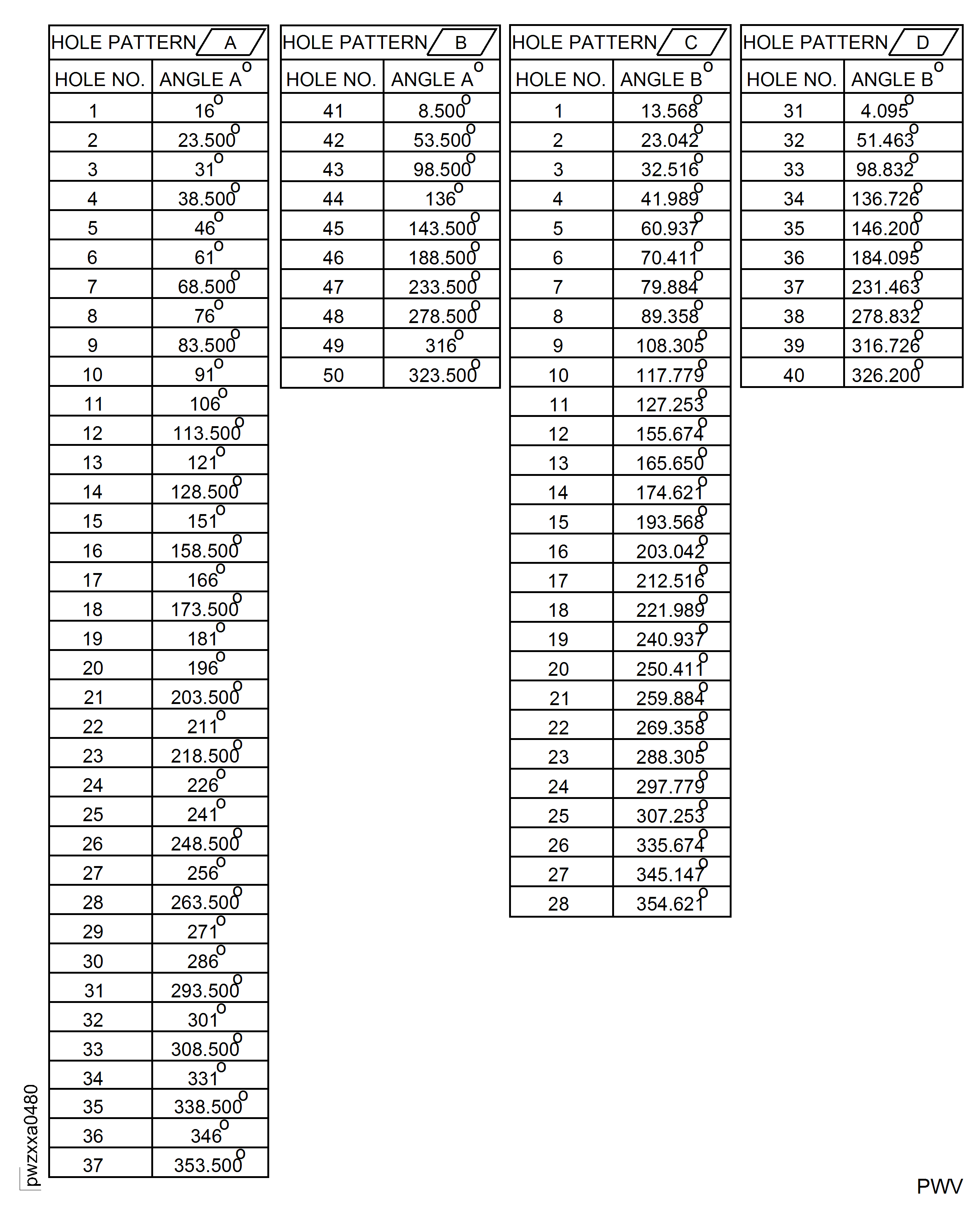

For PN 6A3500, PN 6A4310, PN 6A4569 and PN 6A7019, refer to Figure, Index [4].

For PN 6A6548, PN 6A7529, PN 6A7578 and PN 6A7624, refer to Figure, Index [2].

For PN 6B1432, refer to Figure, Index [2].

SUBTASK 72-41-21-350-282 Mark the Part

For PN 6A3500, PN 6A4310, PN 6A4569 and PN 6A7019, refer to Figure.

For PN 6A6548, PN 6A7529, PN 6A7578 and PN 6A7624, refer to Figure.

For PN 6B1432, refer to Figure.

Use CoMat 07-035 CORROSION RESISTANT COATING (Type A Coating) by SPM TASK 70-38-21-380-501.

For PN 6A3500, PN 6A4310, PN 6A4569 and PN 6A7019, refer to Figure.

For PN 6A6548, PN 6A7529, PN 6A7578 and PN 6A7624, refer to Figure.

For PN 6B1432, refer to Figure.

Use CoMat 07-104 ALUMINIUM HIGH HEAT RESISTANT PAINT (Type A Coating) by SPM TASK 70-38-21-380-501.

For PN 6A3500, PN 6A4310, PN 6A4569 and PN 6A7019, refer to Figure.

For PN 6A6548, PN 6A7529, PN 6A7578 and PN 6A7624, refer to Figure.

For PN 6B1432, refer to Figure.

NOTE

CoMat 07-175 COATING COMPOUND - ALUMINUM, INORGANIC BINDER is a non-chromated alternative to CoMat 07-035 CORROSION RESISTANT COATING and CoMat 07-104 ALUMINIUM HIGH HEAT RESISTANT PAINT.

Prepare the surface and apply surface protection coating and examine the coated surface on the part by one of the following procedures. Refer to Figure, Figure and figure 3. Unless otherwise stated in the figures, apply coat all over the part.

SUBTASK 72-41-21-380-156 Apply Surface Protection

Use temporary marking by SPM TASK 70-09-01-400-501.

CoMat 06-073 INK, METAL MARKING must be completely dry prior to application of CoMat 07-125 LACQUER.

Apply two thin coats of CoMat 07-125 LACQUER to avoid dissolving ink pigment. Allow each layer to dry prior to the next coat.

Heavier application of CoMat 07-125 LACQUER is permitted after the light application of the coating completely dries.

For PN 6A3500, PN 6A4310, PN 6A4569 and PN 6A7019, refer to Figure, Index [4].

For PN 6A6548, PN 6A7529, PN 6A7578 and PN 6A7624, refer to Figure, Index [2].

For PN 6B1432, refer to Figure, Index [2].

Mark the part with VRS6163 adjacent to the assembly part number.

SUBTASK 72-41-21-350-283 Mark the Part

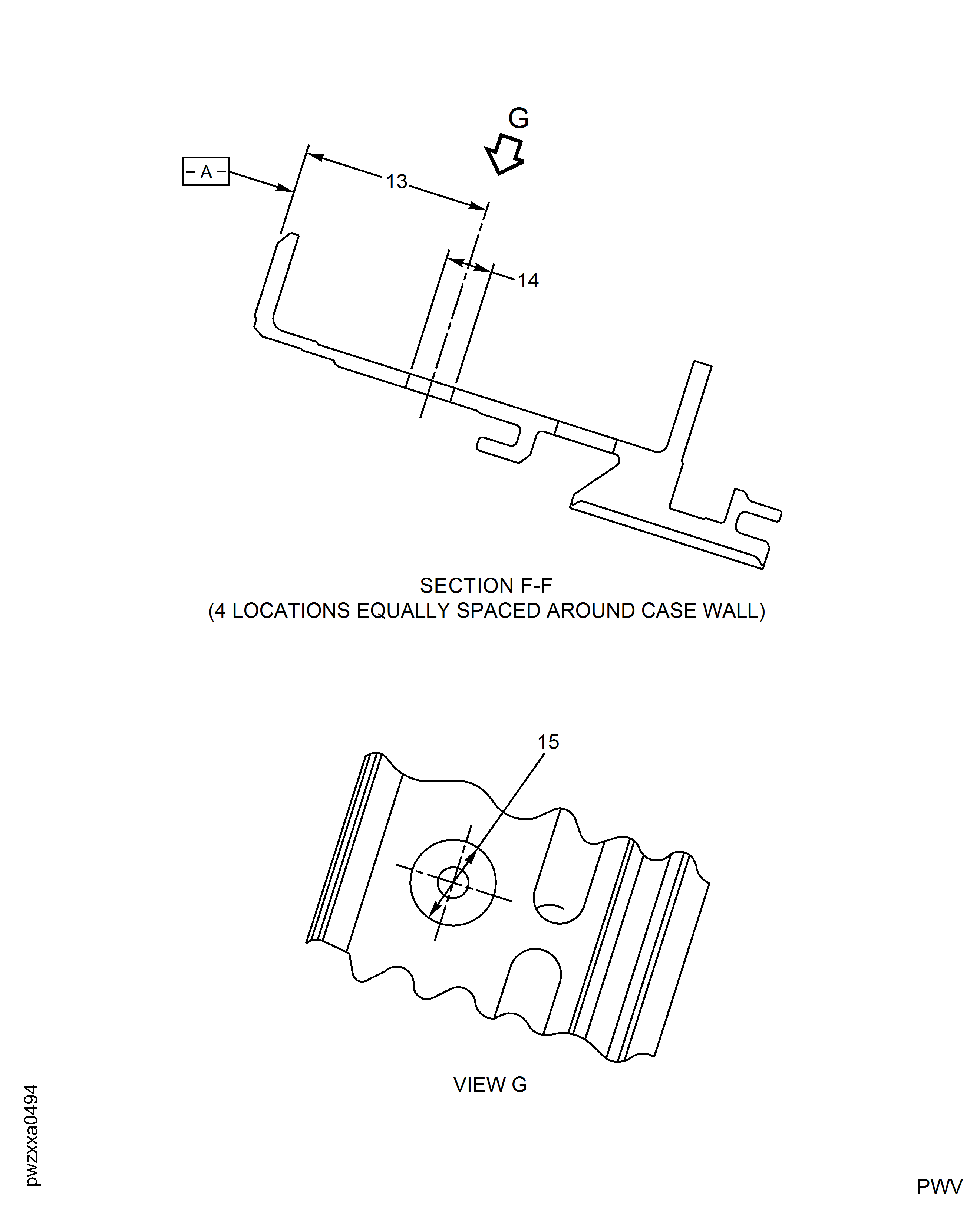

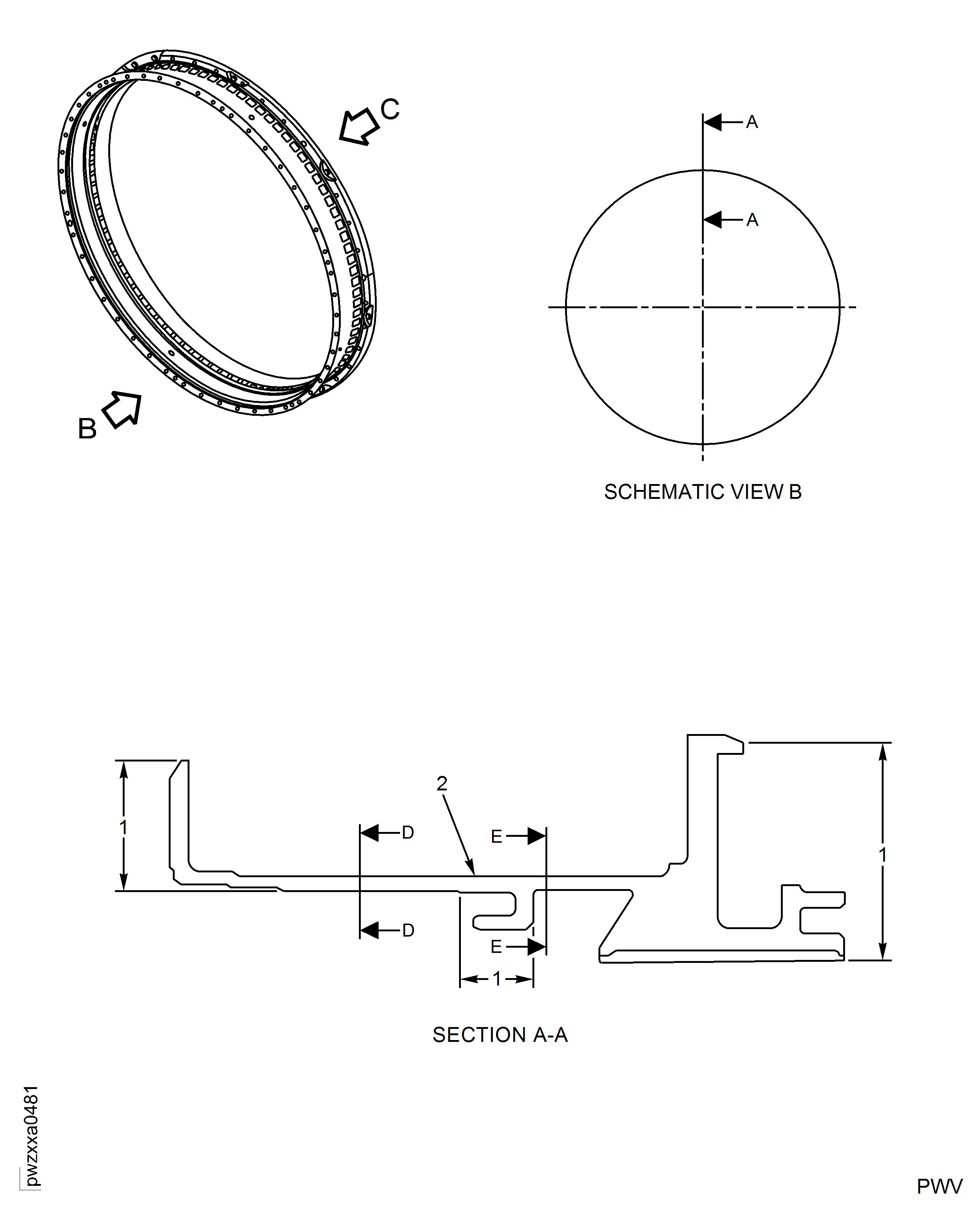

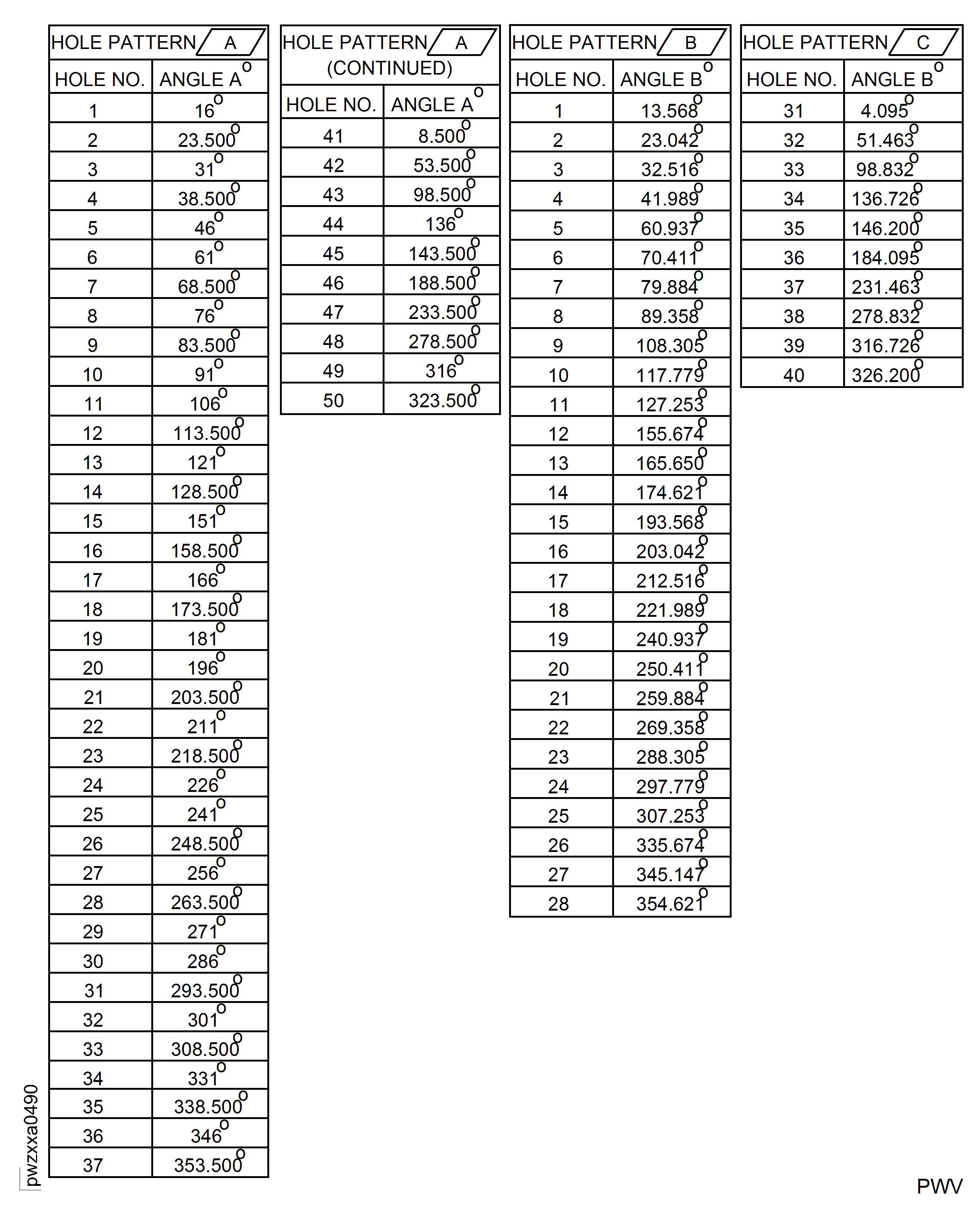

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

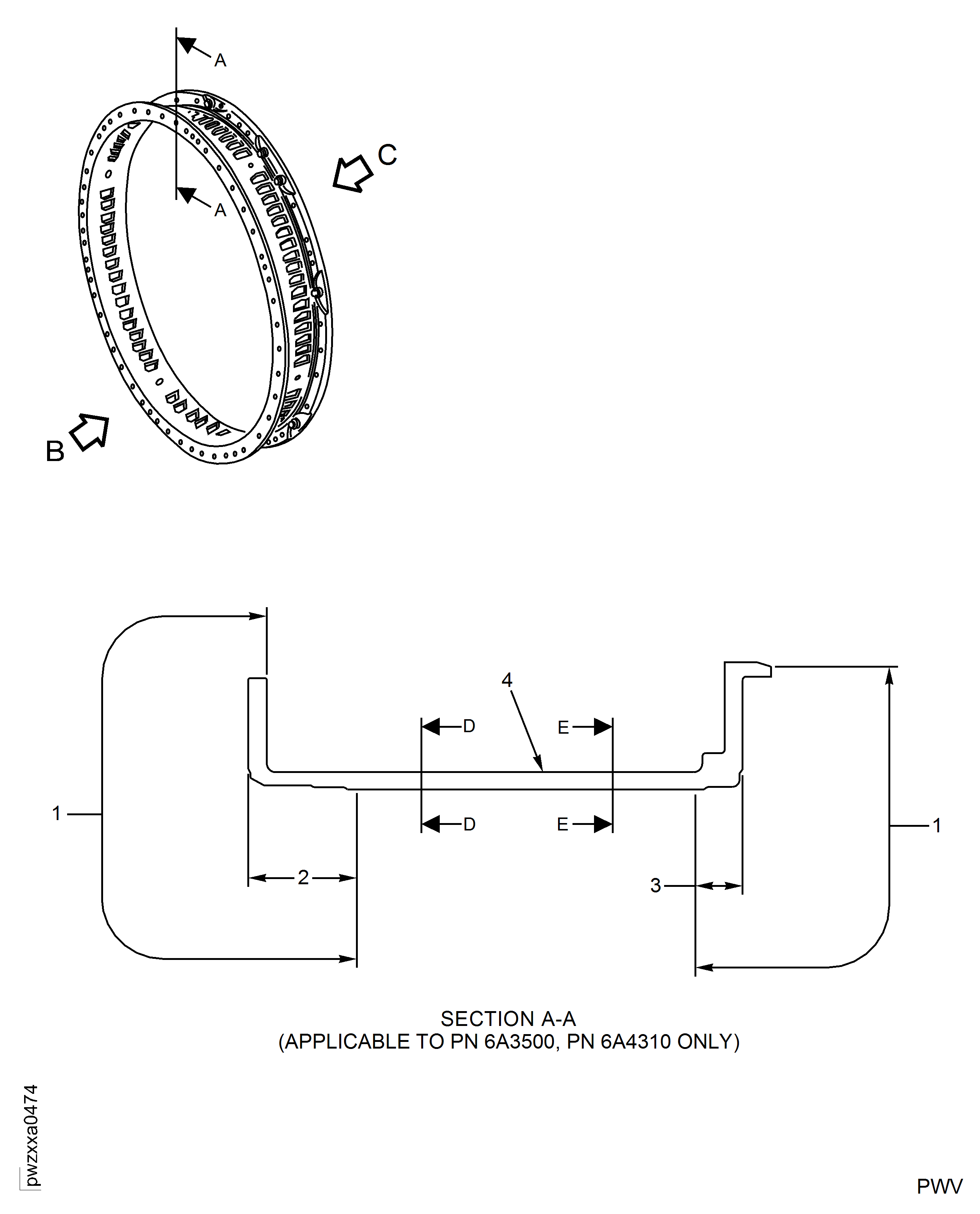

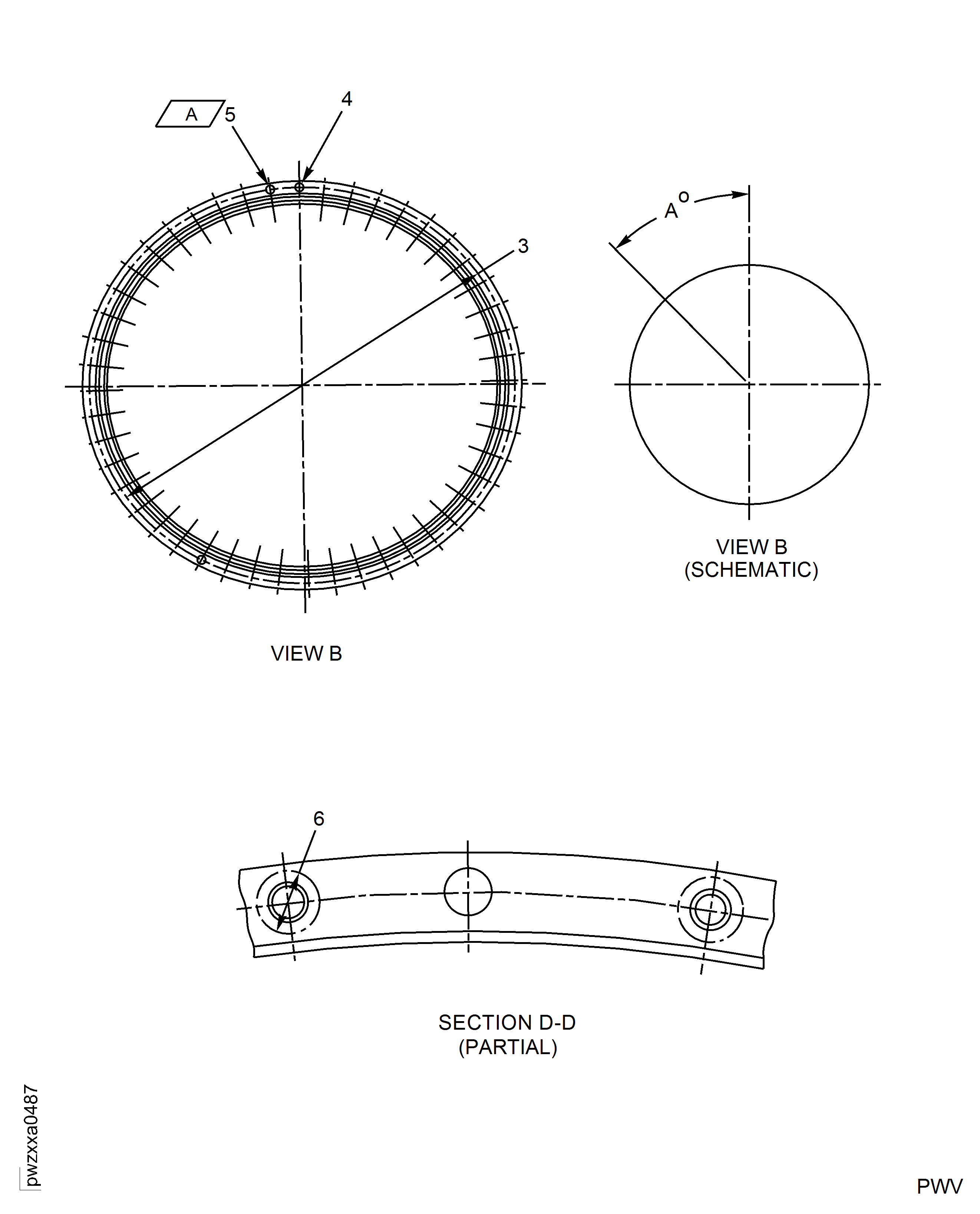

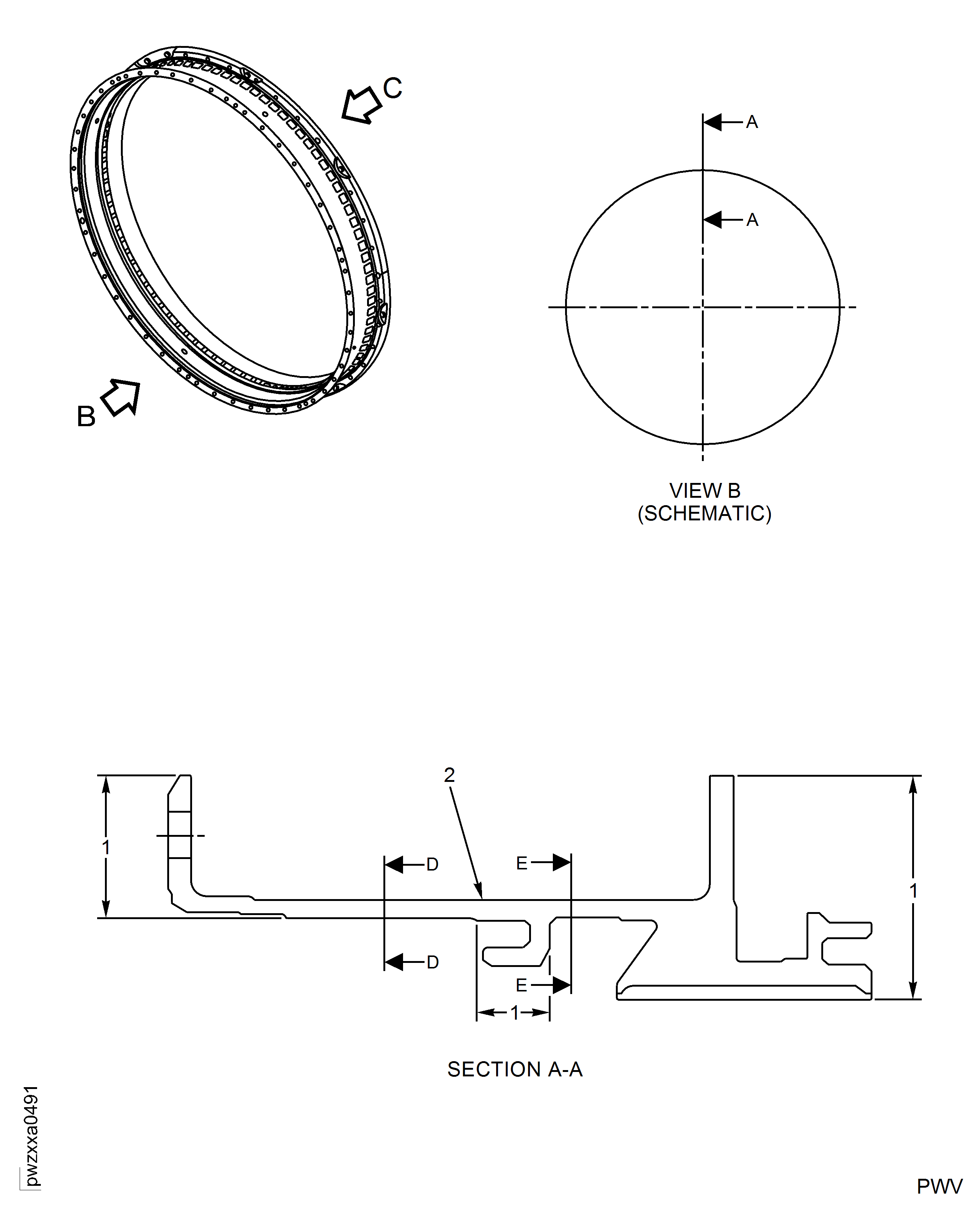

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

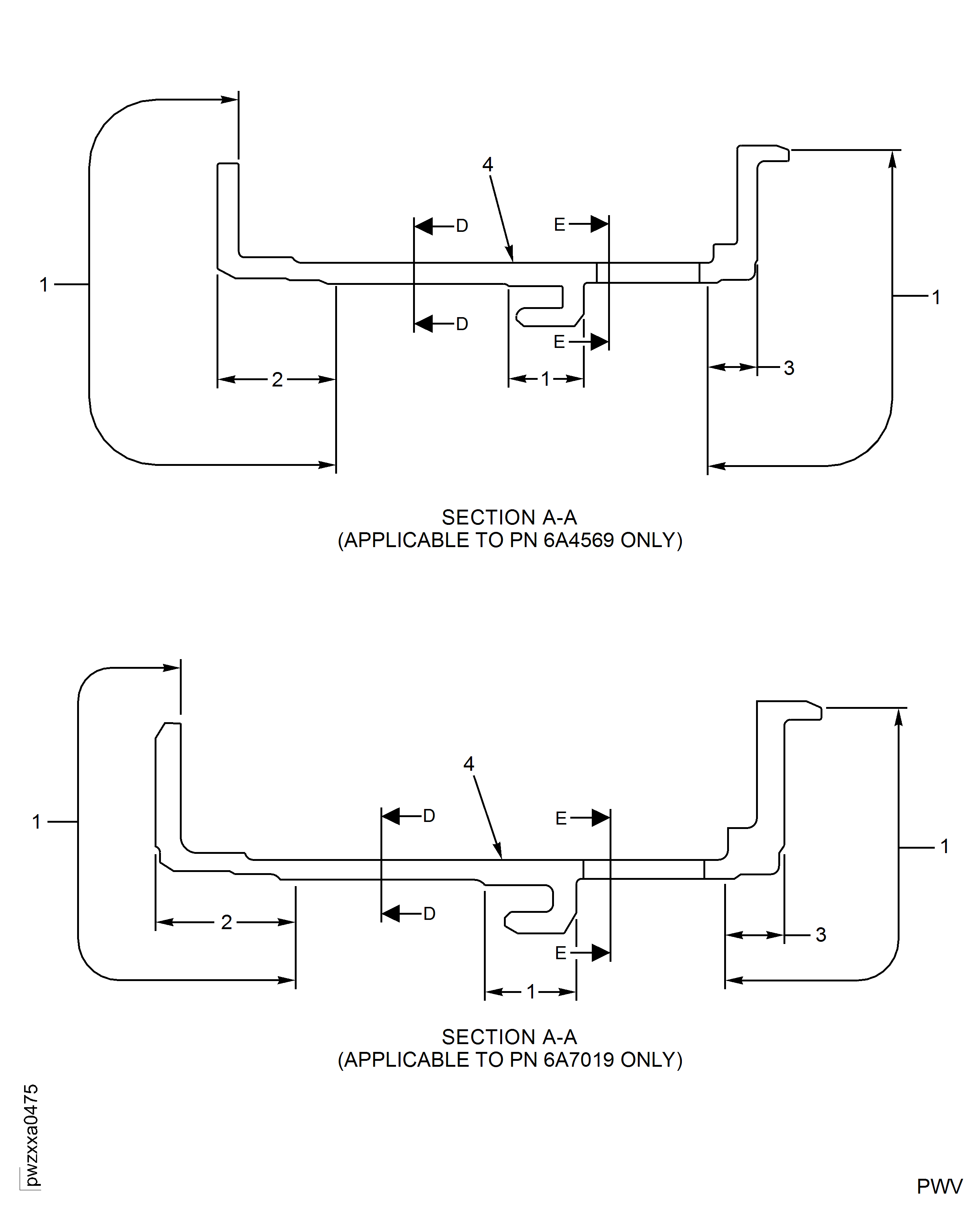

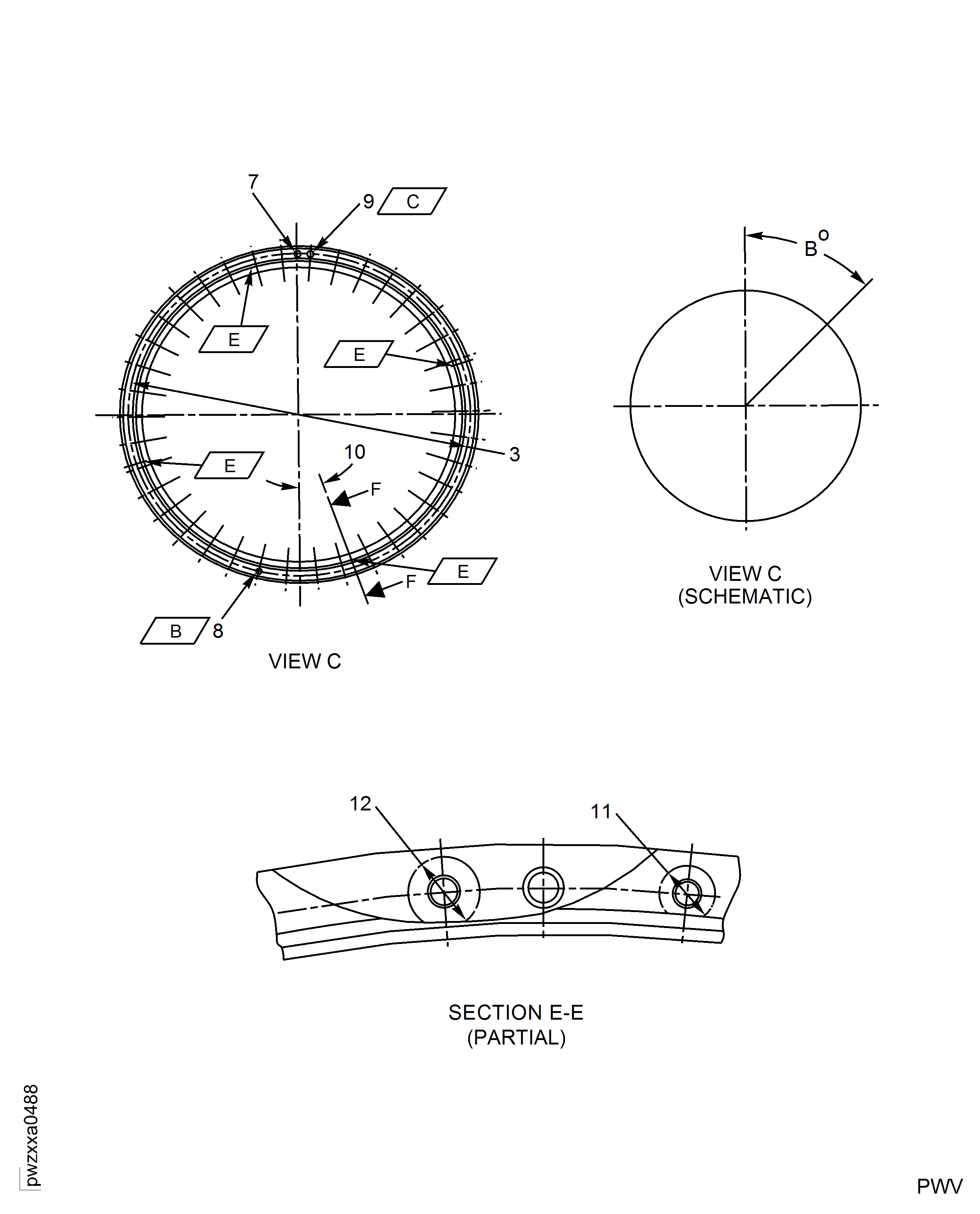

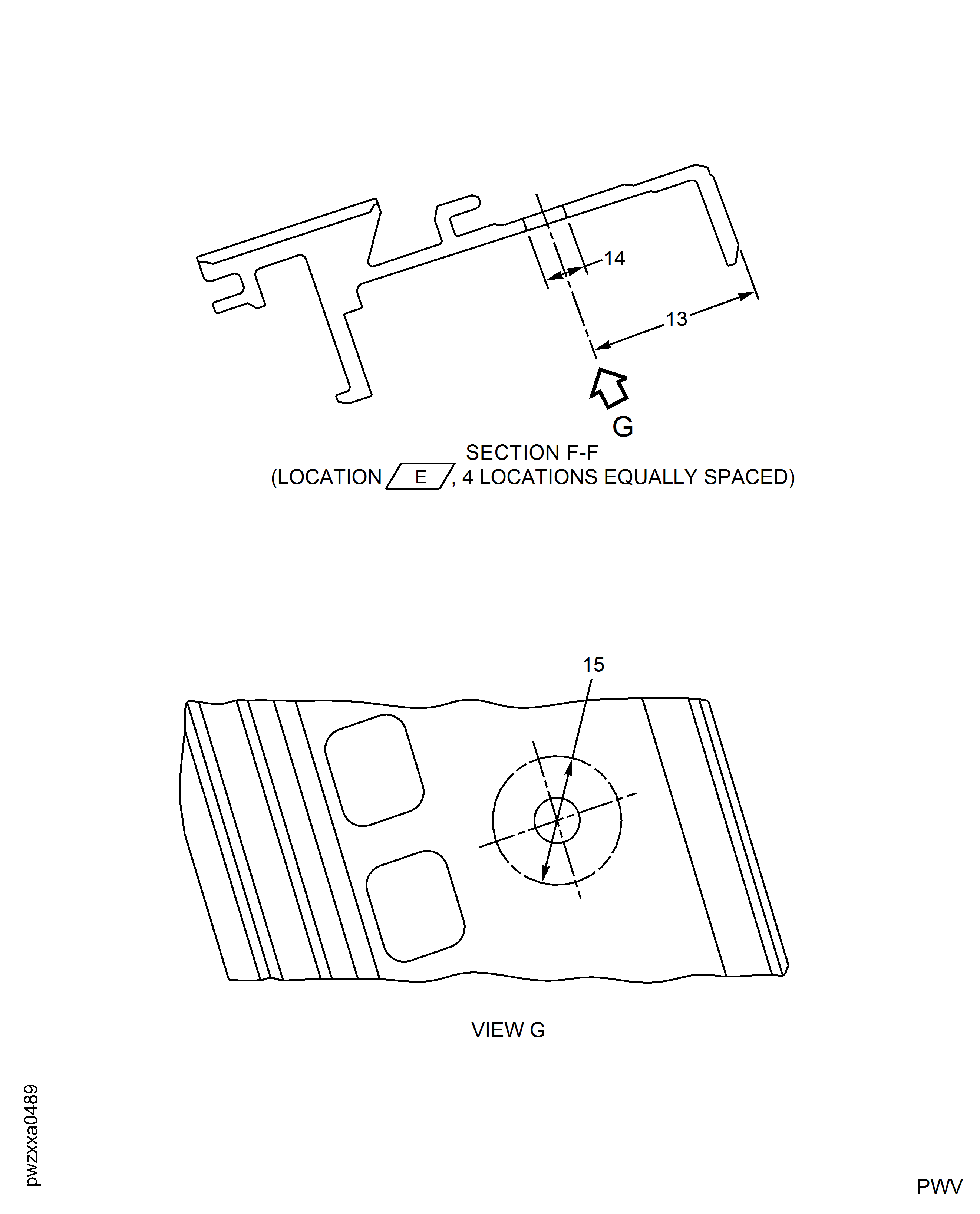

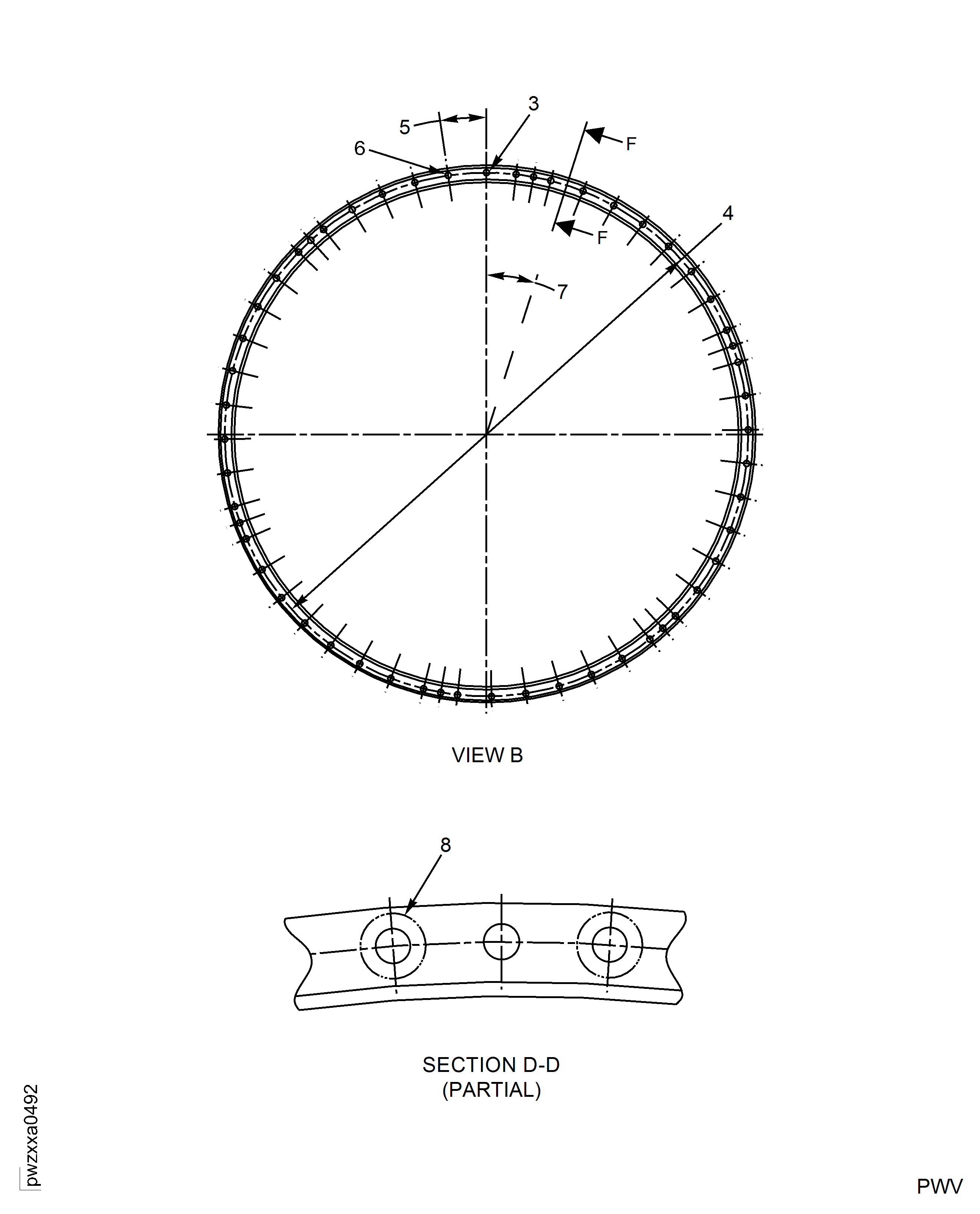

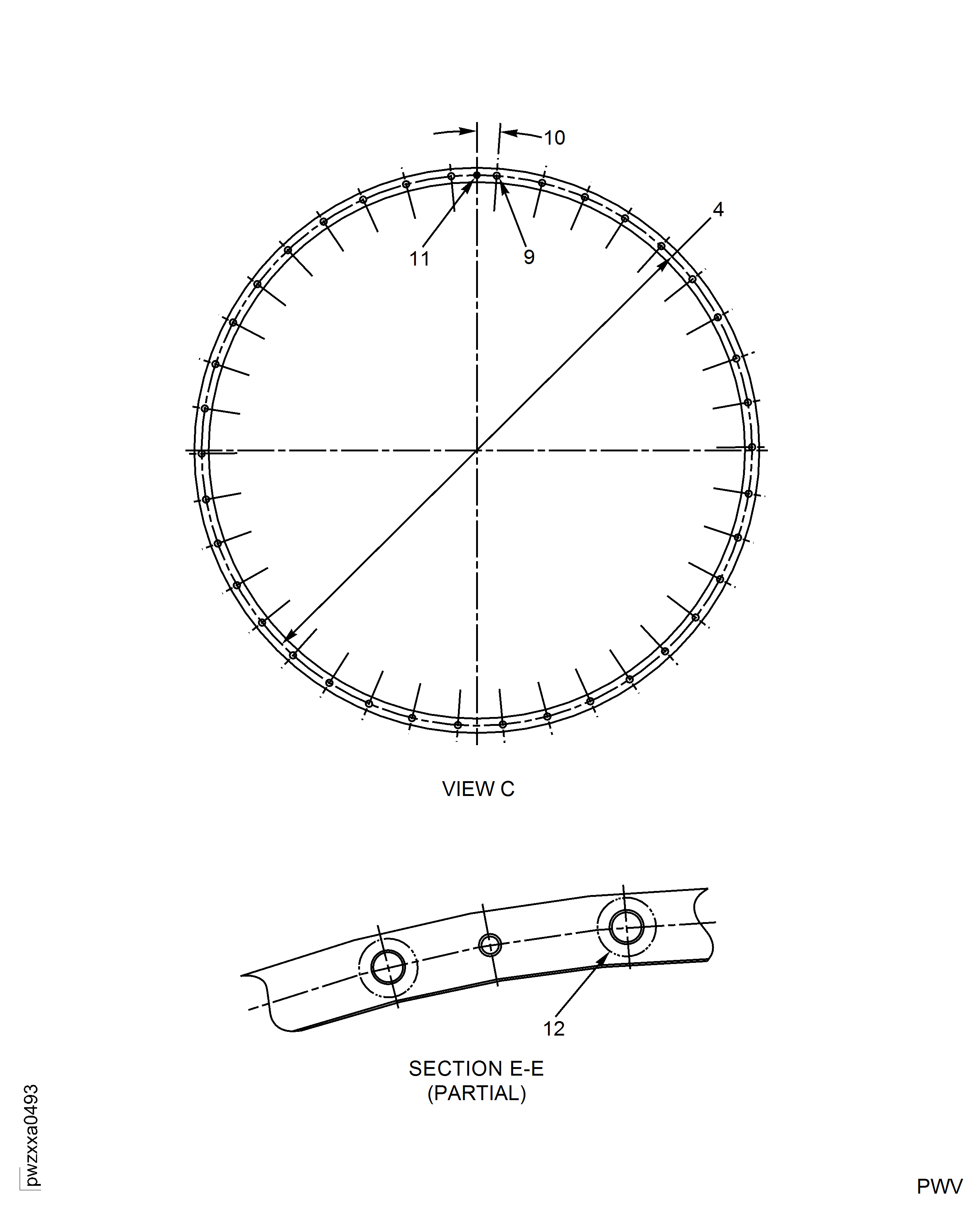

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions