Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-21-300-036 HPC Stage 8 Case - Replace The Shank Nuts On The Stage 8 Case And Stage 9 Rotor Path Assembly, Repair-036 (VRS6218)

Material of component

PART IDENT | MATERIAL |

HP compressor case assembly | Heat resisting alloy |

Nut self locking shank |

General

This repair must only be done when the instruction is given in 72-41-21 Inspection/Check.

This repair has been issued for HP compressor stage 8 case assembly and stage 9 rotor path assembly shank nut damage.

The practices and processes referred to in the procedure by the TASK/SUBTASK number are in SPM.

Price and Availability

Refer to International Aero Engines

Related Repairs - None

NOTE

NOTE

It is possible that some materials in the consumable materials chart cannot be used for some or all of the necessary applications. Before you use the materials, make sure the types, quantities and applications of the materials necessary are legally permitted in your location. All persons must obey all applicable federal, state, local and provincial laws and regulations when it is necessary to work with these materials.

To identify the consumable materials, refer to the Overhaul Processes and Consumables Index (PCI).

Other necessary consumable materials are referred to in the SPM TASKS.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Drill | LOCAL | Drill | 5.7 mm (0.224 in.) diameter | |

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Dimensional inspection equipment | LOCAL | Dimensional inspection equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| IAE 3R18591 Swage bush | 0AM53 | IAE 3R18591 | 1 | |

| IAE 3R18592 Tool bolt | 0AM53 | IAE 3R18592 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Nut self locking shank | AS44750 | A/R |

Safety Requirements

NONEProcedure

Use a drilling machine and a 5.7 mm (0.224 in.) diameter drill.

Refer to SPM TASK 70-35-11-300-501, SUBTASK 70-35-11-350-001.

Drill the flare until the nut is released. Remove the nut.

SUBTASK 72-41-21-350-080 Remove Damaged Shank Nuts

Make sure the shank nut is installed correctly.

Refer to the SPM TASK 70-35-11-300-501, SUBTASK 70-35-11-350-001.

Install the new nut into the hole.

Use IAE 3R18591 Swage bush 1 off and IAE 3R18592 Tool bolt tool bolt 1 off.

Hold nut and swage the flange.

SUBTASK 72-41-21-350-212 Install the new Shank Nuts

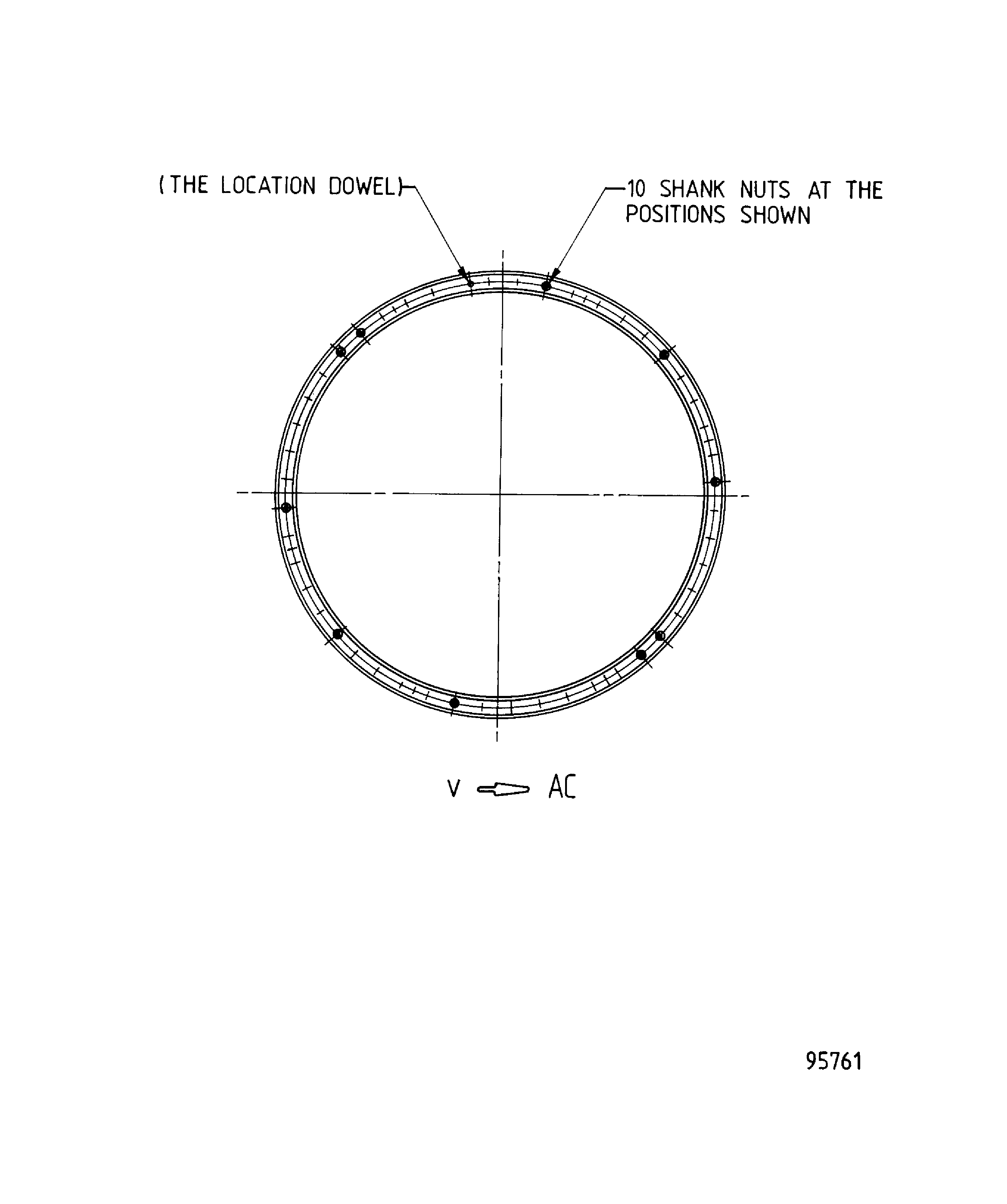

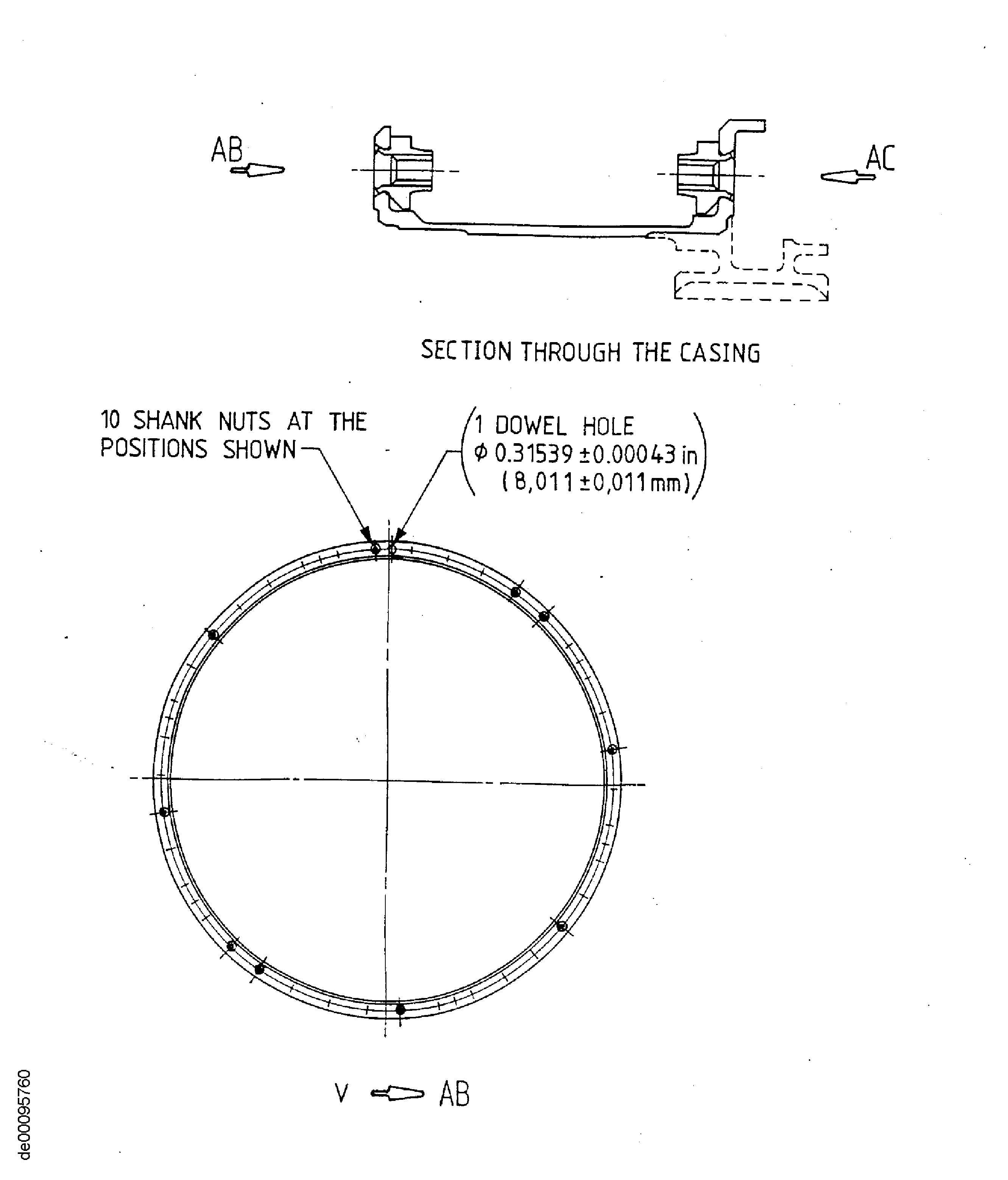

Figure: Repair Details and Dimensions - Assembly A and Assembly B

Repair Details and Dimensions - Assembly A and Assembly B

Figure: Repair Details and Dimensions - Assembly C

Repair Details and Dimensions - Assembly C

Figure: Repair Details and Dimensions - Assembly A, Assembly B and Assembly C

Sheet 1

Figure: Repair Details and Dimensions - Assembly A, Assembly B and Assembly C

Sheet 2