Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-21-840-001 HPC Stage 7 And 8 Rotor Paths - Rework With Reduced Sprayed Thickness Abradable Linings, Rework-001 - SBE 72-0030

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Lathe | LOCAL | Lathe | ||

| Air grinder | LOCAL | Air grinder | ||

| Rotary burr | LOCAL | Rotary burr | ||

| IAE 3R18570 Turning fixture | 0AM53 | IAE 3R18570 | ||

| IAE 3R18232 Lifting beam | 0AM53 | IAE 3R18232 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL | K0993 | CoMat 02-006 | ||

| CoMat 03-036 METAL SPRAYING WIRE, Ni,Al | LOCAL | CoMat 03-036 | ||

| CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) | IE200 | CoMat 03-038 | ||

| CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5) | 00741 | CoMat 03-089 | ||

| CoMat 03-090 METAL SPRAYING POWDER Ni/Al (95/5) | 0AM53 | CoMat 03-090 | ||

| CoMat 03-235 DELETED | 0AM53 | CoMat 03-235 | ||

| CoMat 03-236 METAL SPRAYING POWDER-ALUMINUM | LOCAL | CoMat 03-236 | ||

| CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE | LOCAL | CoMat 05-001 | ||

| CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE | LOCAL | CoMat 05-003 | ||

| CoMat 07-035 CORROSION RESISTANT COATING | LOCAL | CoMat 07-035 | ||

| CoMat 07-036 ALUMINIUM HIGH HEAT RESISTANT PAINT | 0AM53 | CoMat 07-036 | ||

| CoMat 07-037 CORROSION RESISTANT TOUCH-UP COATING | LOCAL | CoMat 07-037 | ||

| CoMat 07-038 AIR DRYING ENAMEL | K3504 | CoMat 07-038 |

Spares

NONESafety Requirements

NONEProcedure

Use lathe, IAE 3R18570 Turning fixture 1 off and IAE 3R18232 Lifting beam 1 off.

Set the machine correctly.

Assemble the fixture on to the machine.

SUBTASK 72-41-21-325-065 Machine the Abradable Lining

Refer to the SPM TASK 70-33-63-300-503.

Remove the remaining lining material.

SUBTASK 72-41-21-330-057 Chemically Remove the Lining Material

NOTE

This SUBTASK is an alternative to SUBTASK 72-41-21-350-090 and Step.Refer to the SPM TASK 70-12-02-120-501.

Remove the remaining lining material.

SUBTASK 72-41-21-120-057 Abrasive Blast the Lining Material

NOTE

This SUBTASK is an alternative to SUBTASK 72-41-21-350-090 and Step.Refer to the SPM TASK 70-34-01-340-501 and Figure and Figure.

Visually and dimensionally inspect.

SUBTASK 72-41-21-220-237 Inspect the Lining

Refer to the SPM TASK 70-23-01-230-501.

Do a penetrant crack test.

SUBTASK 72-41-21-230-100-001 Do a Crack Test

Refer to the SPM TASK 70-23-03-230-501.

Do a penetrant crack test.

SUBTASK 72-41-21-230-100-002 Do a Crack Test

Refer to the SPM TASK 70-11-01-300-503.

Remove the grease.

SUBTASK 72-41-21-110-111 Clean the Part

Use CoMat 02-001 ADHESIVE TAPE (MASKING) or locally manufactured fixture.

Put covers on the areas not to be sprayed.

Refer to the SPM TASK 70-12-02-120-501.

Remove the covers when the blasting is completed.

Do not touch the area which had been blasted.

Abrasive blast.

SUBTASK 72-41-21-120-058 Abrasive Blast

Use CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL or locally manufactured fixture.

Put the covers on the areas not to be sprayed.

Refer to the SPM TASK 70-34-01-340-501.

For powder feed plasma spray gun use CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) or CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5) or CoMat 03-090 METAL SPRAYING POWDER Ni/Al (95/5).

Preheat the seal ring to 221 to 257 deg F (105 to 125 deg C).

Use spray gun with feed off.

Apply the bond coat.

Spray data for metco 3MB powder feed plasma spray gun.

Gun

Metco 3MB

Cathode

3M11A

Nozzle

3M7AGH

Distibution ring

3A275A

Powdr port

No. 2

Primary gas flow tube

2M164

Secondary gas flow tube

2M166

Gases:

Arc primary

Argon

Pressure

100 psi

Arc secondary

Hydrogen

Pressure

50 psi

Gas flow Metco flow meter setting:

Primary

80

Secondary

15

Power settings:

Current

500 amps

Voltage

61-75 volts

Powder control:

Carrier gas flow meter

37

Setting

Powder feed rate

67-69 gms/min

Spray distance

4-7 ins.

Spray thickness

0.004 -0.007 ins.

SUBTASK 72-41-21-340-057-001 Apply the Bond Coat

Use CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL or locally manufactured fixture.

Put the covers on the areas not to be sprayed.

Refer to the SPM TASK 70-34-01-340-501.

For powder feed plasma burner use CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) or CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5) or CoMat 03-090 METAL SPRAYING POWDER Ni/Al (95/5).

Preheat the seal ring to 221 to 257 deg F (105 to 125 deg C).

Use gun with feed off.

Apply the bond coat.

Spray data for plasma technik plasma burner.

Gun

Plasma Technik F4

Nozzle dia

6.0 mm

Powder injector dia

1.8 mm

Injector angle

90 degrees

Powder gage

6.0 mm

Arc primary gas

Argon

Flow rate litres/min

55

Arc secondary gas

Hydrogen

Flow rate litres/min

9.5

Power supply

600 amps

Carrier gas litres/min

3.5

Powder spreader type

L

Powder feed rate grams/min

50

Spray distance

5.5 ins.

Spray thickness

0.004-0.007 ins.

SUBTASK 72-41-21-240-057-002 Apply the Bond Coat

Use CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL or locally manufacatured fixture.

Put the covers on the area not to be sprayed.

Refer to the SPM TASK 70-34-01-340-501.

For wire feed combustion spray use CoMat 03-036 METAL SPRAYING WIRE, Ni,Al.

Preheat the seal ring to 221 to 257 deg F (105 to 125 deg C).

Use spray gun with feed off.

Apply the bond coat.

Spray data for metco 10E or 12E wire feed combustion spray gun.

Gun

Metco 10E or 12E

Nozzle diameter

3.0 mm

Air cap

C

Gas pressures

Acetylene

10 psi

Oxygen

30 psi

Air

65 psi or 75 psi

Gas flows Metco flow meter setting

Acetylene

33

Oxygen

46

Air

49 or 65

Spray distance

5-7 ins.

Wire diameter

0.125 ins.

Deposition per pass

0.001 ins.

Spray thickness

0.004-0.007 ins.

SUBTASK 72-41-21-340-057-003 Apply the Bond Coat

Refer to the SPM TASK 70-34-01-340-501.

Remove covers after spraying is completed.

Apply the abradable lining.

Spray data for metco 3MB powder feed plasma spray gun.

Gun

Metco 3MB

Cathode

3M11A

Nozzle

3M7AGH

Distribution ring

3A275A

Powder port

No.1

Primary gas flow tube

2M164

Secondary gas flow tube

2M166

Gases:

Arc primary

Argon

Pressure

100 psi

Arc Secondary

Hydrogen

Pressure

50 psi

Gas flow Metco flow meter setting:

Primary

150

Secondary

5

Power settings:

Current

500 amps

Voltage

55-70 volts

Powder control:

Carrier gas flow meter

setting

37

Powder feed rate

49-50 gms/min

Spray distance

4-6 ins.

Spray thickness

See illustrations

SUBTASK 72-41-21-340-058-001 Apply the Abradable Lining

Refer to the SPM TASK 70-34-01-340-501.

Remove covers after spraying is completed.

Apply the abradable lining.

Spray data for plasma technick plasma burner.

Gun

Plasma Technik F4

Nozzle dia

6.0 mm

Powder injector dia

1.8 mm

Injector angle

+15 degrees

Powder gage

6.0 mm

Arc primary gas

Argon

Flow rate litres/min

38

Arc secondary gas

Hydrogen

FLow rate litres/min

12

Power supply

500 amps

Carrire gas litres/min

5.0

Powder spreader type

L

Powder feed rate grams/min

35

Spray distance

6-7 ins

Spray thickness

See illustrations

SUBTASK 72-41-21-340-058-002 Apply the Abradable Lining

Refer to the SPM TASK 70-34-01-340-501.

Visually inspect the sprayed coating on the ring.

Refer to the SPM TASK 70-34-01-340-501.

Average hardness must be 70-80 R15Y outer limits 65 min 85 max.

Hardness test the sprayed coating.

SUBTASK 72-41-21-220-238 Inspect the Lining

Refer to the SPM TASK 70-09-00-400-501.

NUMBER BEFORE: 6A3652 .

NEW NUMBER: 6A4101.

NUMBER BEFORE: 6A3652.

NEW NUMBER: 6A4102.

Vibration peen the new part number adjacent to the assembly part number.

SUBTASK 72-41-21-350-085 Identify the Reworked Rotor Path with the New Part Number

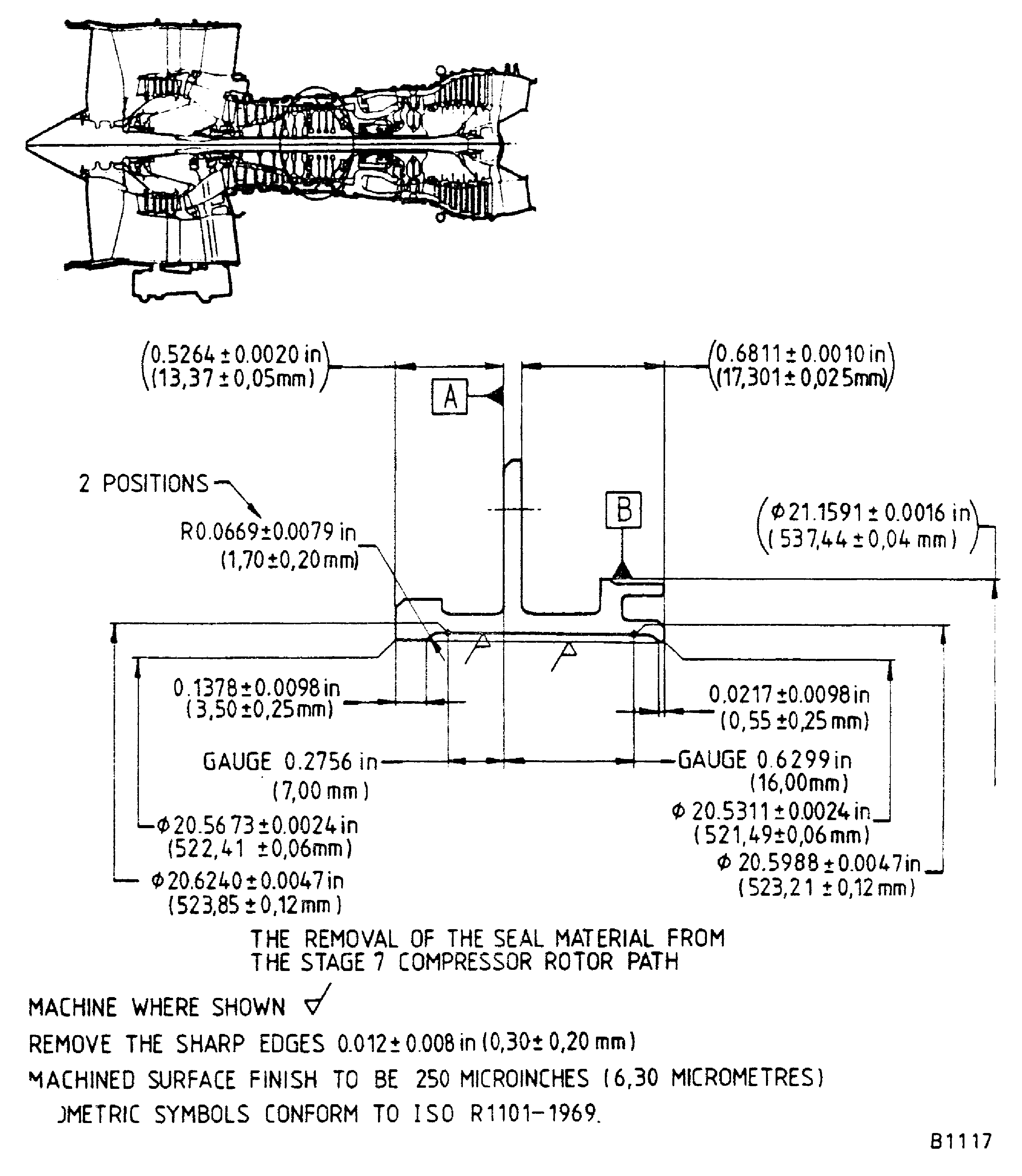

Figure: Rework of HP compressor stage 7 rotor path

Rework of HP compressor stage 7 rotor path

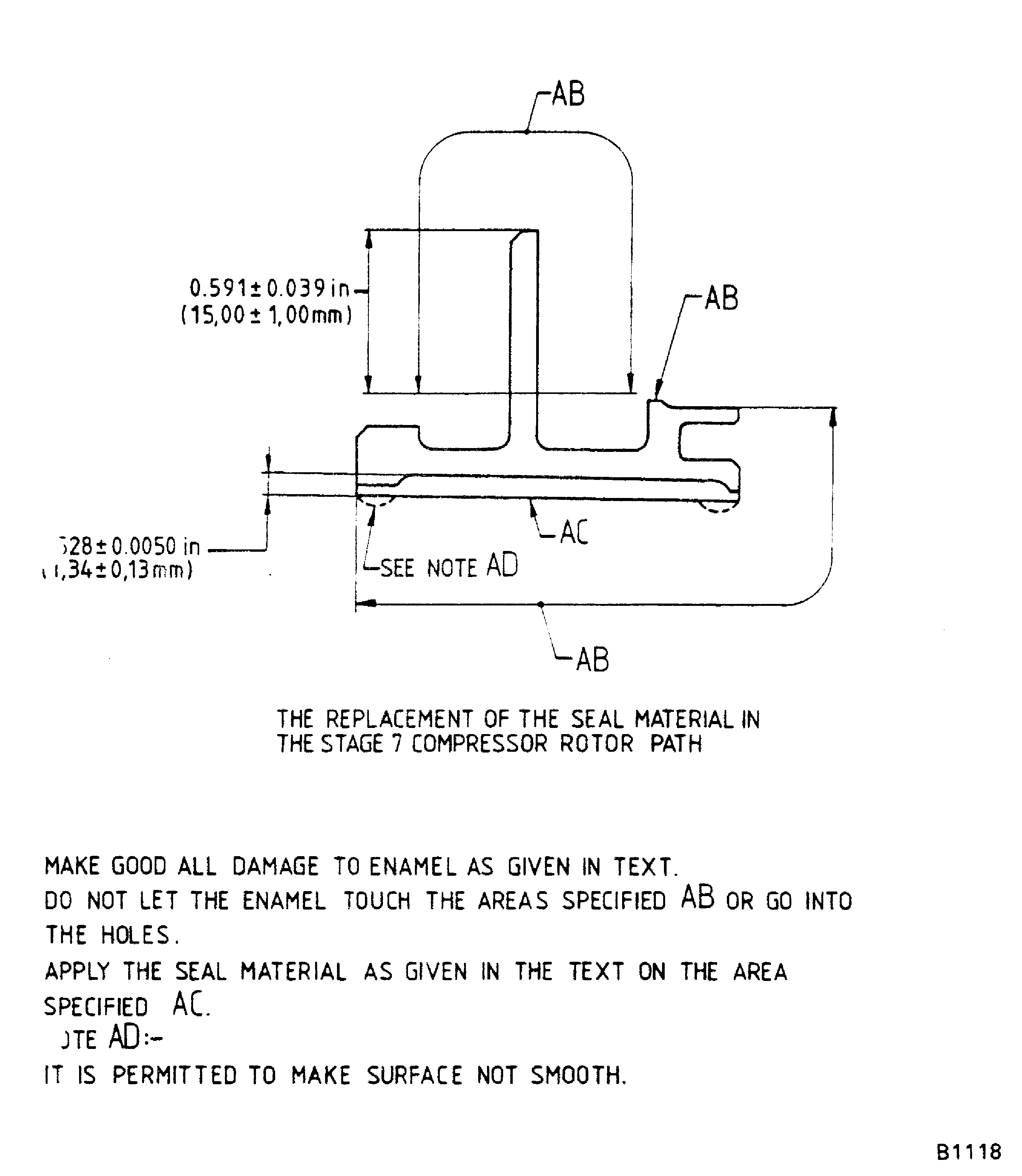

Figure: Rework of HP compressor stage 7 rotor path abradable lining

Rework of HP compressor stage 7 rotor path abradable lining

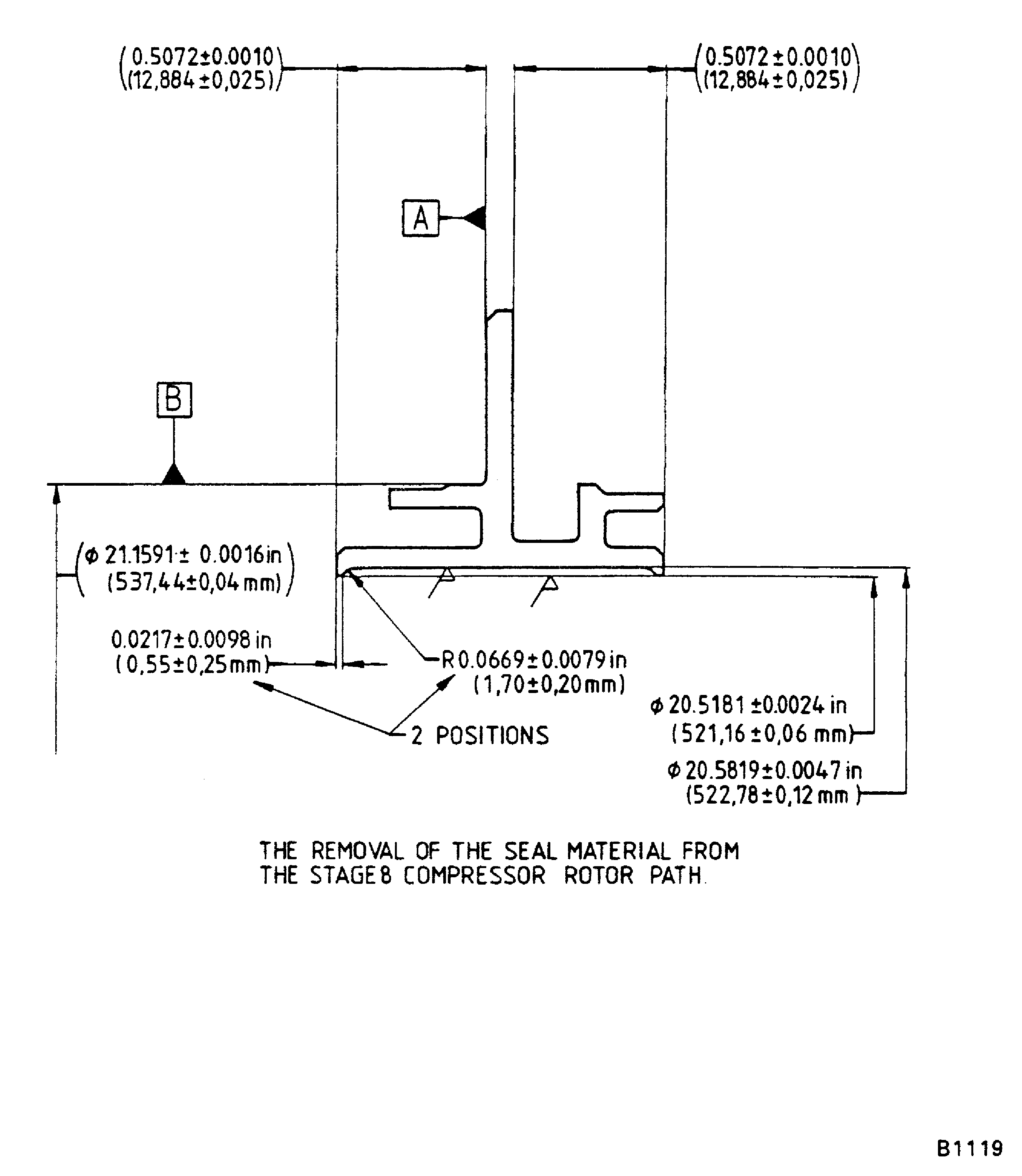

Figure: Rework of HP compressor stage 8 rotor path abradable lining

Rework of HP compressor stage 8 rotor path abradable lining

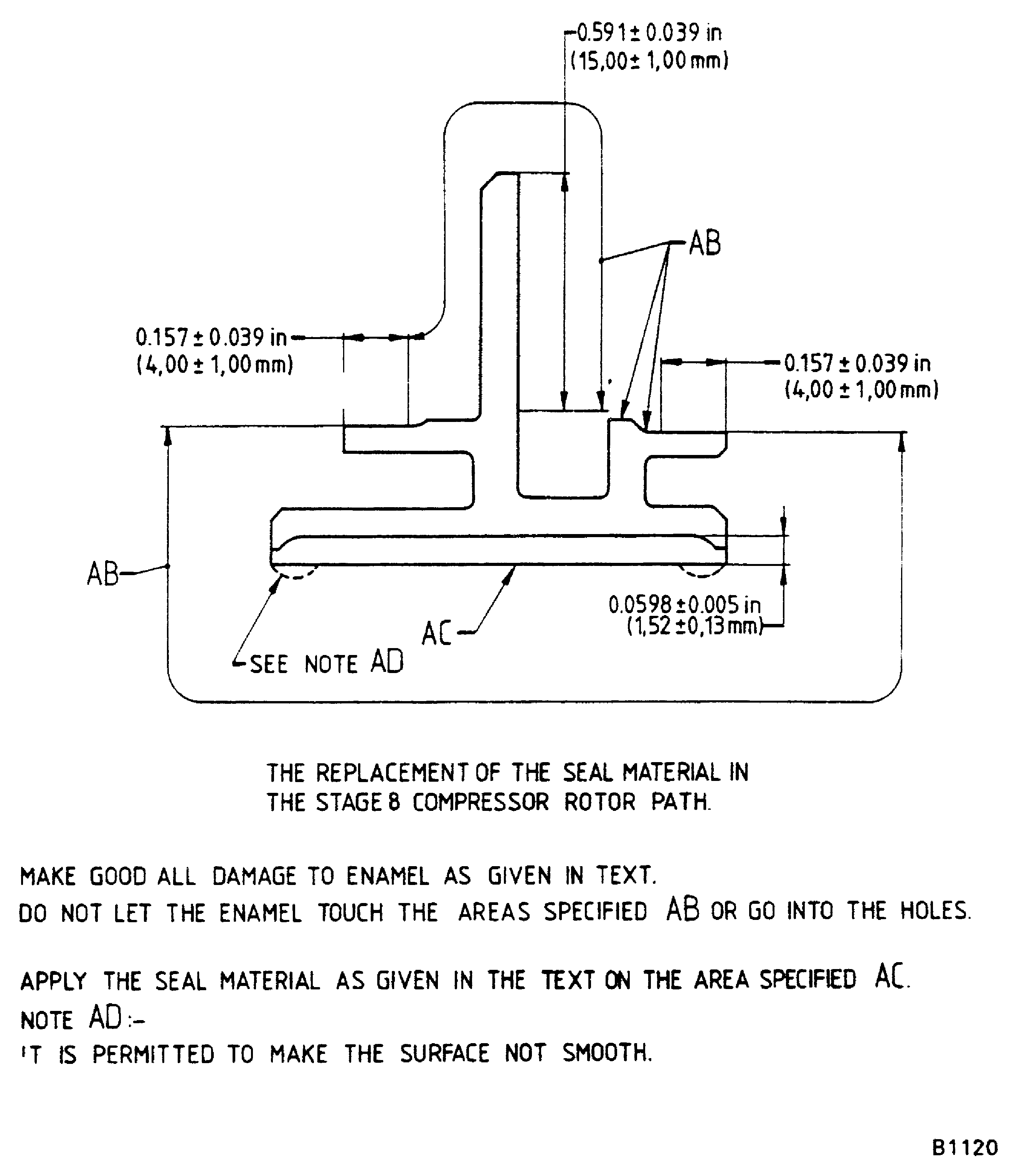

Figure: Rework of HP compressor stage 8 rotor path abradable lining

Rework of HP compressor stage 8 rotor path abradable lining