Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-21-300-012 HPC Stage 9 Rotor Path Ring - Replace The Lining, Repair-012 (VRS6021)

General

This Repair must only be done when the instruction to do so is given in inspection procedures (identified by the applicable part number) located in section 72-41-21.

This TASK gives the procedure to replace the damaged rotor path linings on the HP compressor stage 9 rotor path ring.

TASKS identified by SPM TASK are in the Standard Practices and Processes Manual (SPM).

Price and availability

Refer to International Aero Engines

Related repairs - none

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Abrasive Blast Equipment | LOCAL | Abrasive Blast Equipment | ||

| Air Operated Grinder | LOCAL | Air Operated Grinder | ||

| Chemical Cleaning Equipment | LOCAL | Chemical Cleaning Equipment | ||

| Dial Test Indicator | LOCAL | Dial Test Indicator | ||

| Hardness Tester | LOCAL | Hardness Tester | ||

| Lathe | LOCAL | Lathe | ||

| Masking fixture | LOCAL | Masking fixture | Locally Made | |

| Metal Spray Equipment | LOCAL | Metal Spray Equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant Crack Test Equipment | ||

| Rotary Burr | LOCAL | Rotary Burr | ||

| Vibro-engraving equipment | LOCAL | Vibro-engraving equipment | ||

| Workshop Inspection Equipment | 0AM53 | Workshop Inspection Equipment | ||

| IAE 3R18232 Lifting beam | 0AM53 | IAE 3R18232 | ||

| IAE 3R18570 Turning fixture | 0AM53 | IAE 3R18570 | Assembly A | |

| IAE 3R19081 Turning fixture | 0AM53 | IAE 3R19081 | Assembly B |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL | K0993 | CoMat 02-006 | ||

| CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY) | LOCAL | CoMat 02-198 | ||

| CoMat 03-036 METAL SPRAYING WIRE, Ni,Al | LOCAL | CoMat 03-036 | ||

| CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) | IE200 | CoMat 03-038 | ||

| CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5) | 00741 | CoMat 03-089 | ||

| CoMat 03-090 METAL SPRAYING POWDER Ni/Al (95/5) | 0AM53 | CoMat 03-090 | ||

| CoMat 03-238 METAL SPRAY POWDER, Ni-Cr-Al | LOCAL | CoMat 03-238 | ||

| CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE | LOCAL | CoMat 05-003 | ||

| CoMat 05-015 ABRASIVE MEDIUM, ALUMINUM OXIDE | LOCAL | CoMat 05-015 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Set to turn correctly.

Use a Dial Test Indicator.

Use IAE 3R18232 Lifting beam1 off and IAE 3R18570 Turning fixture 1 off with a lathe.

Assemble the fixture on the machine.

SUBTASK 72-41-21-325-054-A00 Remove the Abradable Lining, Assembly A

Refer to Figure.

Use IAE 3R18232 Lifting beam 1 off and IAE 3R19081 Turning fixture 1 off with a lathe.

Set to turn correctly.

Use a Dial Test Indicator.

Assemble the fixture on the machine.

SUBTASK 72-41-21-325-054-B00 Remove the Abradable Lining, Assembly B

Set to turn correctly.

Use a Dial Test Indicator.

Assemble the fixture on the machine.

SUBTASK 72-41-21-325-054-C00 Remove the Abradable Lining, Assembly C and Assembly D

Use an Air Operated Grinder with a rotary burr or applicable alternatives.

You must not remove material from the rotor path ring.

Remove the lining material.

SUBTASK 72-41-21-350-059 Remove the Remaining Lining

Refer to the SPM TASK 70-33-59-300-503, SUBTASK 70-33-59-300-002.

Chemically remove the lining material.

SUBTASK 72-41-21-330-052 Remove the Remaining Lining

Use CoMat 02-001 ADHESIVE TAPE (MASKING) or CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL or CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY) or a locally made fixture.

Seal the surfaces not to be repaired.

Refer to the SPM TASK 70-12-02-120-501.

Lightly dry blast the repaired area(s) to fully remove the lining.

SUBTASK 72-41-21-120-052 Abrasive Blast the Repair Area(s)

Refer to the SPM TASK 70-11-39-300-503, SUBTASK 70-11-39-300-001.

Swab etch the repaired area(s).

SUBTASK 72-41-21-110-124 Cold Ferric Chloride Etch

Refer to the SPM TASK 70-23-05-230-501.

No cracks are permitted.

Do a penetrant crack test of the repaired area(s).

SUBTASK 72-41-21-230-079 Do a Crack Test

Refer to the SPM TASK 70-11-03-300-503.

Chemically clean the rotor path ring.

SUBTASK 72-41-21-110-106 Clean the Rotor Path Ring

Use CoMat 02-001 ADHESIVE TAPE (MASKING) or CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL or CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY) or a locally made fixture.

Seal the surfaces not to be repaired.

SUBTASK 72-41-21-350-060 Seal Surfaces not to be Repaired

Refer to the SPM TASK 70-12-02-120-501.

Abrasive blast the area(s) to be repaired.

SUBTASK 72-41-21-120-064 Clean the Area(s) to be Sprayed

CAUTION

DO NOT TOUCH AREA(S) TO BE REPAIRED AFTER THEY ARE CLEANED.

CAUTION

TOO MUCH ABRASIVE BLAST CAN CAUSE DETERIORATION OF THE PREPARED SURFACE CONDITION AND MUST BE PREVENTED.Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-025 and SUBTASK 70-34-01-340-010.

For the powder feed plasma spray gun, use CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5), CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5) or CoMat 03-090 METAL SPRAYING POWDER Ni/Al (95/5).

Alternatively for the wire feed combustion spray gun, use CoMat 03-036 METAL SPRAYING WIRE, Ni,Al.

Pre-heat the seal ring to 221 deg F to 257 deg F (105 deg C to 125 deg C).

Apply a thickness of 0.004 in.to 0.007 in. (0.10 mm to 0.18 mm).

Apply the bond coat.

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-029.

Apply abradable lining.

SUBTASK 72-41-21-340-052 Apply the Abradable Lining

Refer to the SPM TASK 70-34-01-340-501.

Visually examine the sprayed coating on the ring.

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-004.

The average hardness must be 45 to 55 R15Y outer limits 40 minimum to 60 maximum.

Use a Hardness Tester.

Hardness test the sprayed coating.

SUBTASK 72-41-21-220-211 Examine the Rotor Path Lining

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Identify VRS6021 adjacent to the part number.

SUBTASK 72-41-21-350-062 Identify the Repair

Refer to TASK 72-41-20-440-006 (ASSEMBLY-006).

Machine and examine the rotor path ring lining.

SUBTASK 72-41-21-325-056 Machine and Examine the Rotor Path Ring Lining

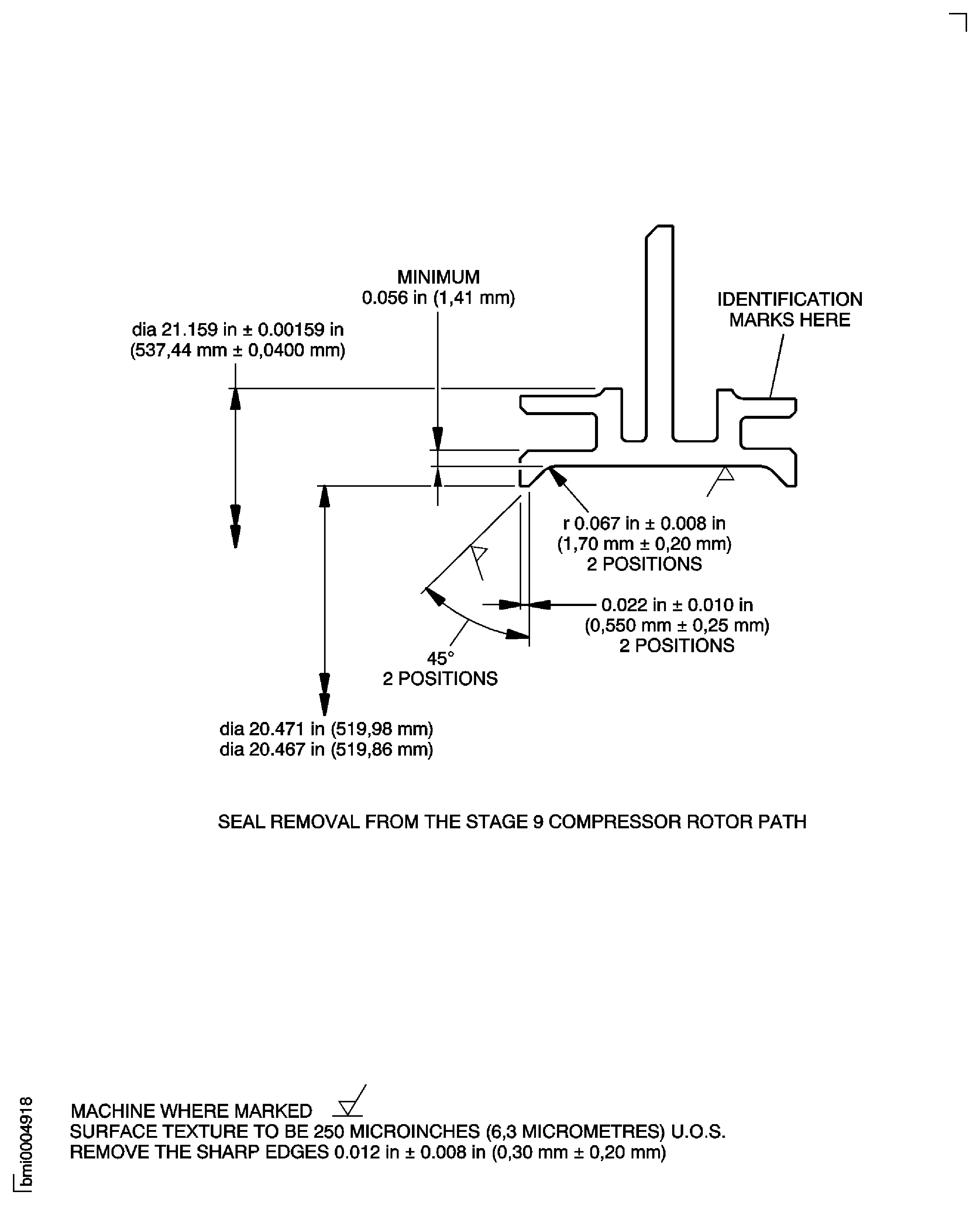

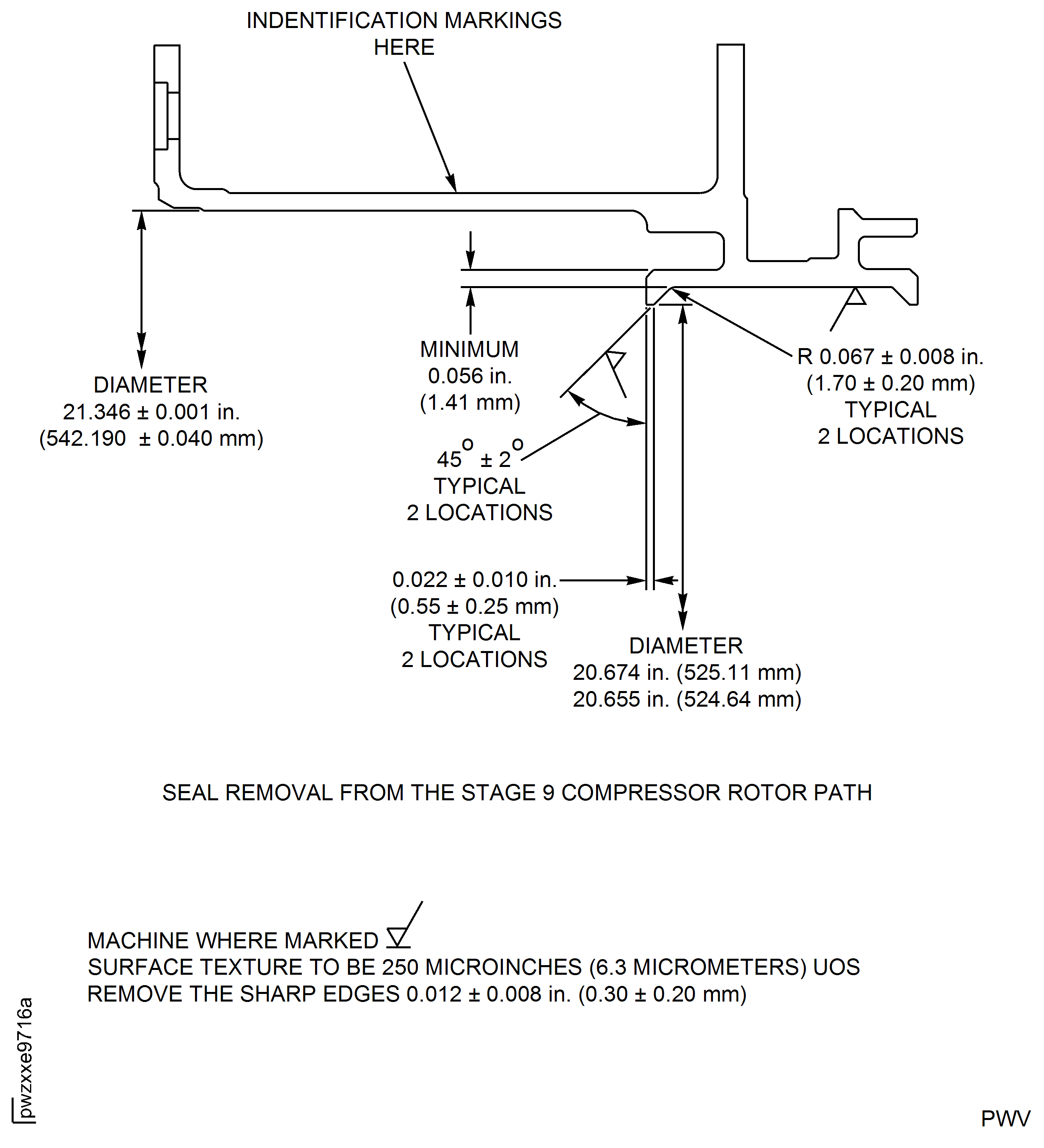

Figure: Repair Details and Dimensions - Assembly A

Repair Details and Dimensions - Assembly A

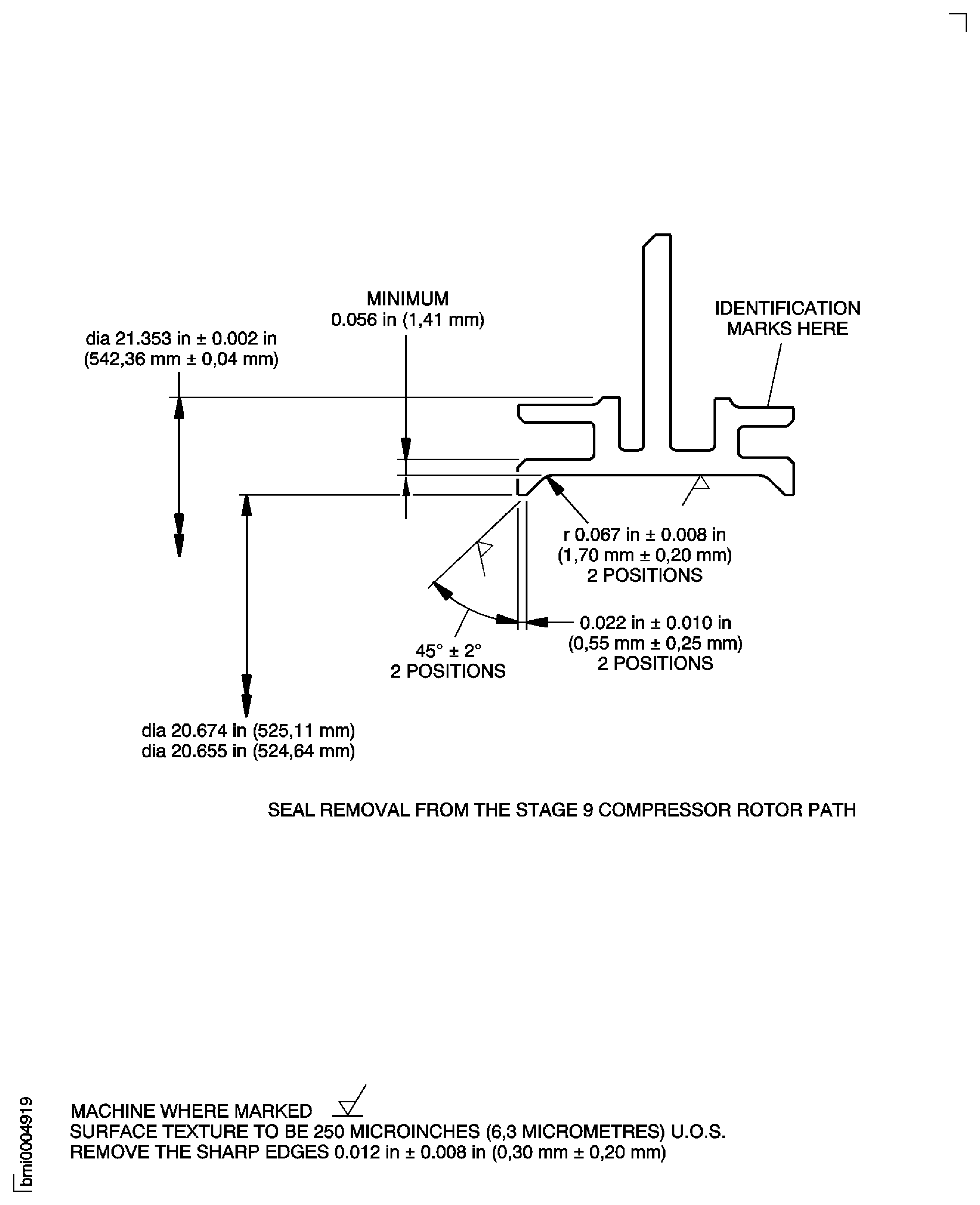

Figure: Repair Details and Dimensions - Assembly B

Repair Details and Dimensions - Assembly B

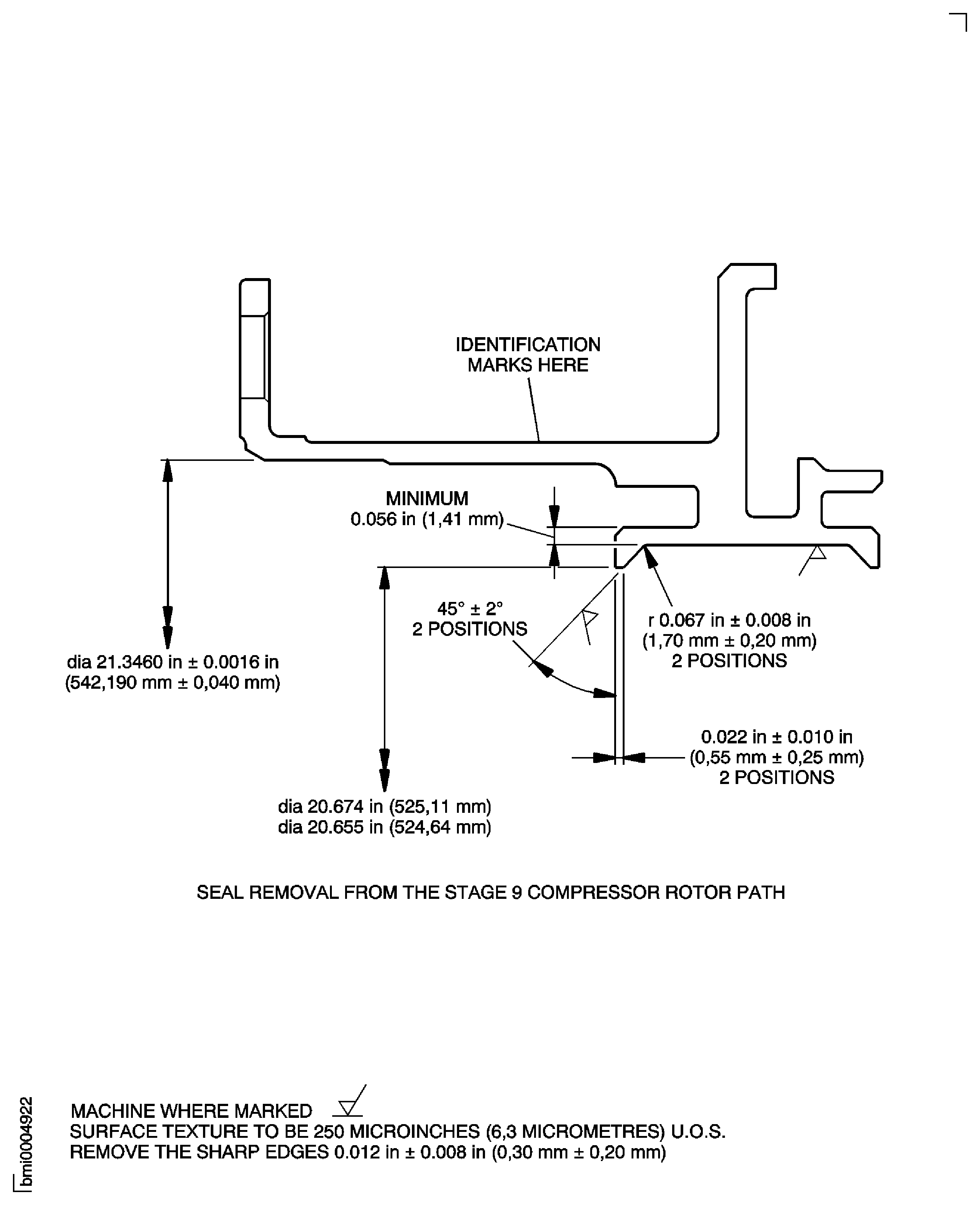

Figure: Repair Details and Dimensions - Assembly C

Repair Details and Dimensions - Assembly C

Figure: Repair Details and Dimensions - Assembly D

Repair Details and Dimensions - Assembly D

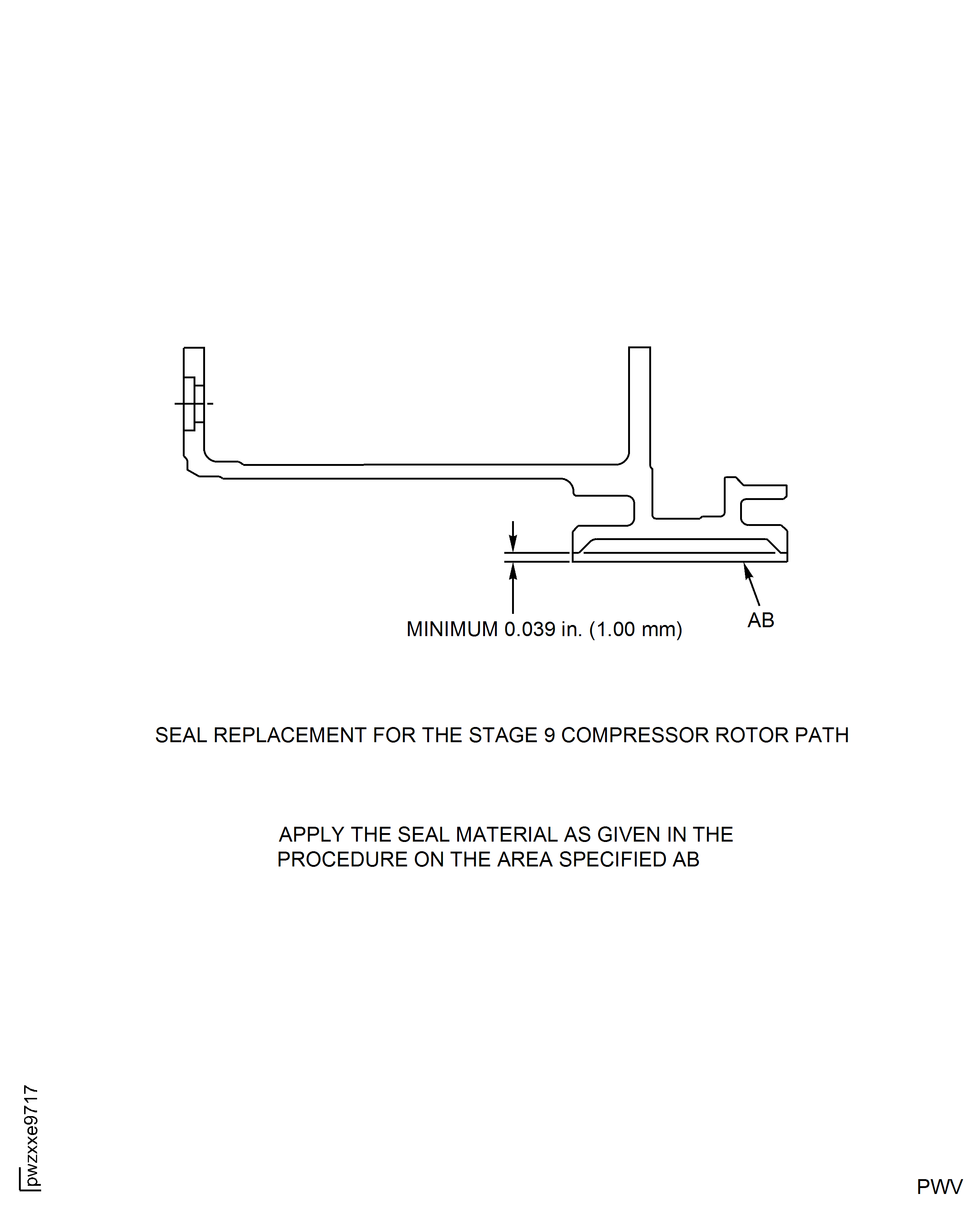

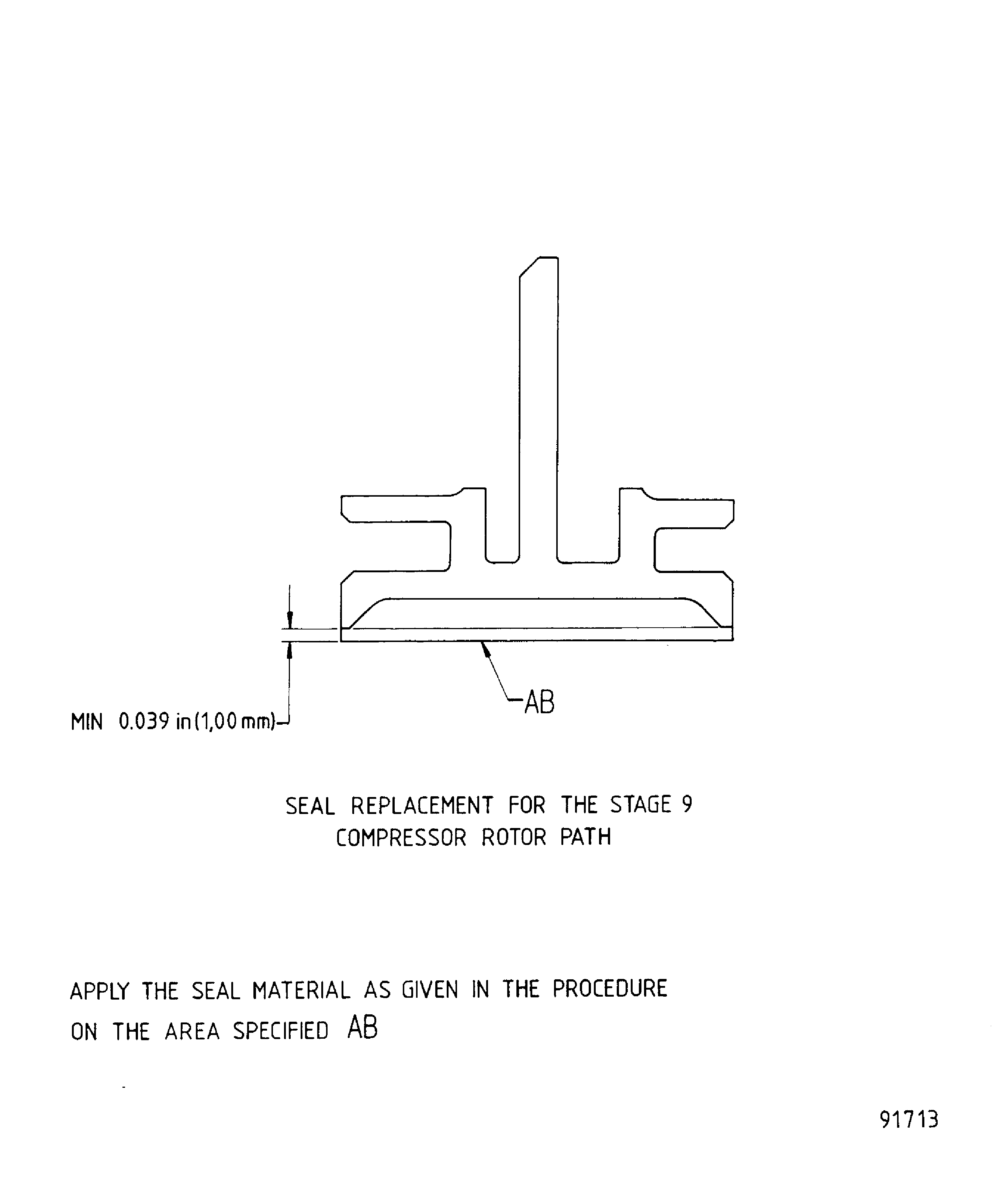

Figure: Repair details and dimensions - Assembly A and Assembly B

Repair details and dimensions - Assembly A and Assembly B

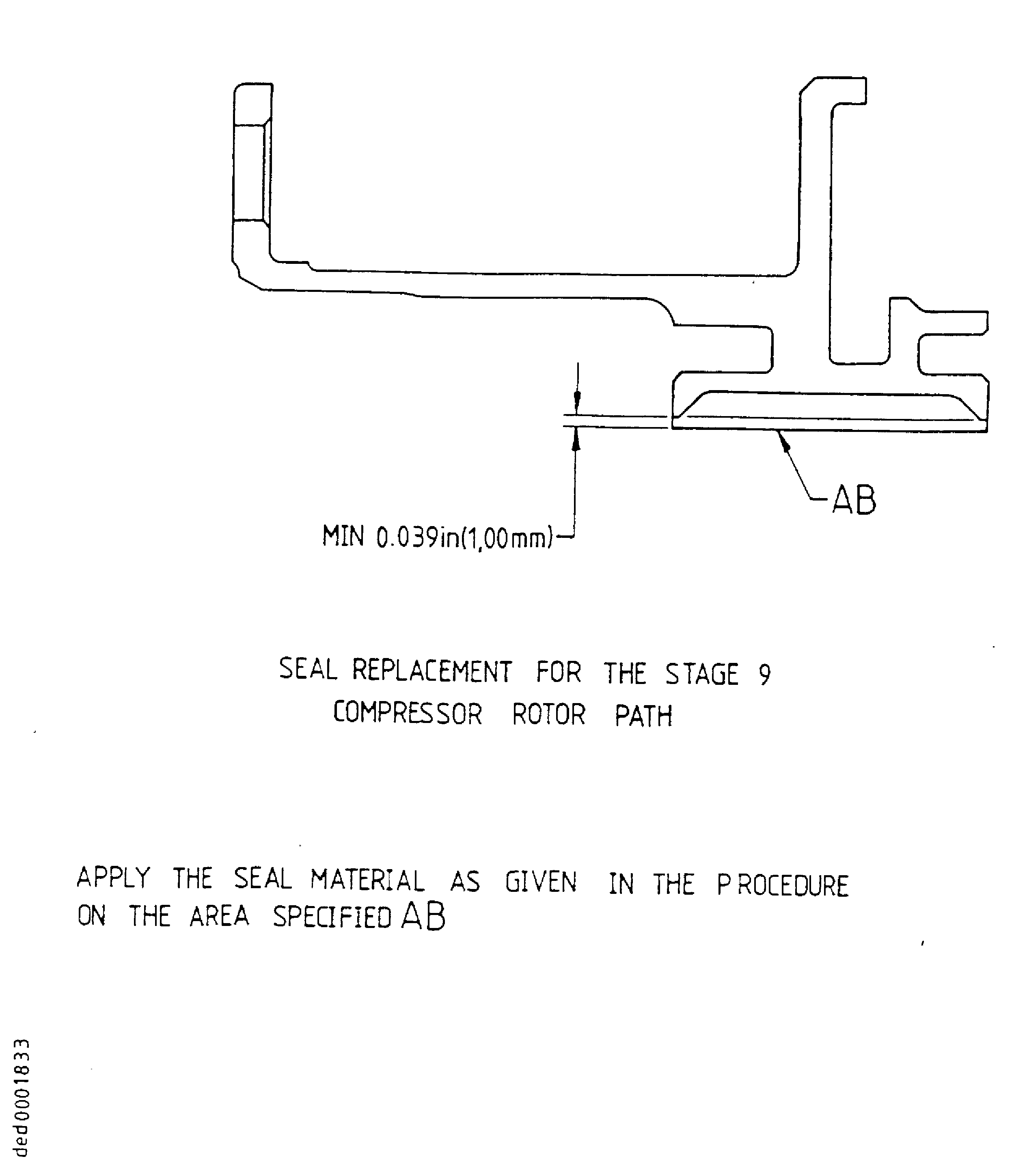

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

Figure: Repair Details and Dimensions - Assembly D

Repair Details and Dimensions - Assembly D