Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

72-41-23-300-026 Repair Damaged Helicoil Or Thinwall lnsert(s) In The HP Compressor Rear Outer Case Assembly By Replacement, Repair-026 (VRS6540)

Material of components

DESCRIPTION | SYMBOL | MATERIAL |

|---|---|---|

HP Compressor, Rear Outer Case Assembly | EEJ Or ENH | Corrosion resistant steel Chrome cobalt molybdenum electro flux remelted steel |

General Data

This repair must only be done when the instruction to do so is given in VRS6306.

This repair is to replace the thinwall insert(s), when the insert holes are damaged with oversized inserts.

Price and availability

Refer to International Aero Engines (IAE).

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Approved workshop equipment | LOCAL | Approved workshop equipment |

Consumables, Materials and Expendables

NONESpares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| INSERT - SCREW THREAD | U1653 | AS52761 | ||

| INSERT - SCREW THREAD | U1653 | AS52762 | ||

| Thinwall Insert | LOCAL | AS62142 | 80 | ASSEMBLY-A |

| Thinwall Insert | LOCAL | AS62143 | 20 | ASSEMBLY-A |

Safety Requirements

NONEProcedure

Indicate damaged hole within 0.005 in. (0.127 mm) DOTP and machine minor diameter through one wall to diameter 0.367 in. - 0.372 in. (9.322 mm - 9.45 mm) and tap hole for 0.4219-20 UNS- 3B Mod threads through one wall.

Machine countersink to a maximum of diameter 0.463 in. (10.92 mm) x 120 degrees +/- 2 degrees.

Machine counter bore diameter 0.421 in. - 0.426 in. (10.69 mm -10.82 mm) to a depth of 0.111 in. - 0.131 in. (2.82 mm - 3.33 mm) within 0.006 in. (0.152 mm) true position to the machined hole and with a 90 degrees +/- 5 degrees chamfer on the bottom of the counter bore after depth has been achieved.

Machine 32 serrations with a maximum diameter of 0.442 in. (11.23 mm). The 32 serrations are to be broached in counter bore using a wobble broach with the cutting tool offset by 1 degrees to the broaching tool body to a depth of 0.091 in. - 0.111 in. (2.31 mm - 2.82 mm) within 0.006 in. (0.152 mm) true position to the machined hole and a maximum bottom corner radius of 0.010 in. (0.254 mm).

For AS52761 INSERT - SCREW THREAD, 02-432 machine to accept oversized insert as follows:

Machine AS52761 holes to accept AS62142 as necessary.

Indicate damaged hole within 0.005 in. (0.127 mm) DOTP and machine minor diameter through one wall to diameter 0.436 in. - 0.441 in. (11.07 mm - 11.20 mm) and tap hole for 0.4844-20 UNS- 3B Mod threads through one wall.

Machine countersink to a maximum of diameter 0.530 in. (13.462 mm) x 120 degrees +/- 2 degrees.

Machine counter bore diameter 0.483 in. - 0.488 in. (12.27 mm - 12.40 mm) to a depth of 0.115 in. - 0.135 in. (2.92 mm - 3.43 mm) within 0.006 in. (0.152 mm) true position to the machined hole and with a 90 degrees +/- 5 degrees chamfer on the bottom of the counter bore after depth has been achieved.

Machine 37 serrations with a maximum diameter of 0.512 in. (13.00 mm). The 37 serrations are to be broached in counter bore using a wobble broach with the cutting tool offset by 1 degrees to the broaching tool body to a depth of 0.095 in. - 0.115 in. (2.413 mm - 2.921 mm) within 0.006 in. (0.152 mm) true position to the machined hole and a maximum bottom corner radius of 0.010 in. (0.254 mm).

For AS52762 INSERT - SCREW THREAD, 02-433 machine to accept oversized insert as follows:

Machine AS52762 holes to accept AS62143 as necessary.

Use a soft, clean cloth and remove loose material with air.

Clean the machined hole.

SUBTASK 72-41-23-350-135 Machine for Thinwall lnsert(s) Assembly-A

Refer to SPM TASK 70-23-01-230-501.

Use penetrant crack test equipment.

Cracks are not permitted.

Do a penetrant crack test in the area of repair.

SUBTASK 72-41-23-230-071 Do a Crack Test, Assembly-A

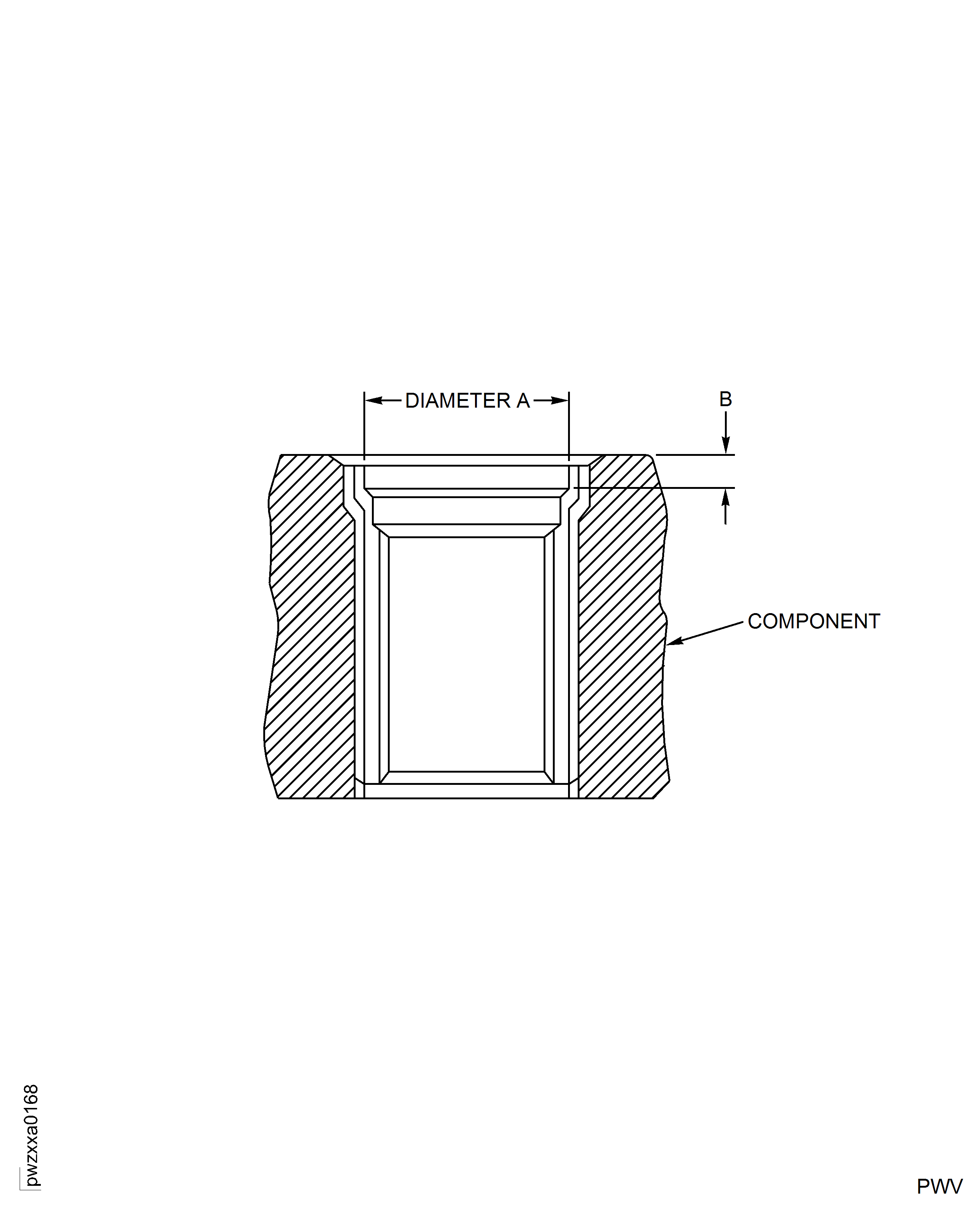

Refer to Figure.

Use installation tool part number WSDW - 225 for AS62142 as necessary and Diameter A to be a minimum of 0.355 in. (9.02 mm) and Dimension B to be a minimum of 0.071 in. (1.80 mm) deep after swaging. Technicut after swage gauge tool No. is WSSG - 225.

Use installation tool part number WSDW- 231 for AS62143 as necessary and Diameter A to be a minimum of 0.427 in. (10.85 mm) and Dimension B to be a minimum of 0.075 in. (1.91 mm) deep after swaging. Technicut after swage gauge tool No. is WSSG - 231.

Refer to SPM TASK 70-35-26-300-501, SUBTASK 70-35-26-350-001 except as follows:

Install the thinwall insert(s).

SUBTASK 72-41-23-350-136 Install the Thinwall lnsert(s), Assembly-A

Refer to Figure.

For AS62142 Diameter A to be a minimum of 0.355 in. (9.02 mm) and Dimension B to be a minimum of 0.071 in. (1.80 mm) deep after swaging. Technicut after swage gauge tool No. is WSSG - 225.

For AS62143 Diameter A to be a minimum of 0.427 in. (10.85 mm) and Dimension B to be a minimum of 0.075 in. (1.91 mm) deep after swaging. Technicut after swage gauge tool No. is WSSG - 231.

Refer to SPM TASK 70-35-26-300-501, SUBTASK 70-35-26-350-001 except as follows:

Examine the thinwall insert(s).

SUBTASK 72-41-23-220-140 Examine the Thinwall lnsert(s), Assembly-A

Figure: Case Assembly, Rear Outer - Repair Details and Dimensions

Case Assembly, Rear Outer - Repair Details and Dimensions