Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-30-300-001 HPC Front Case And Vane Assembly - HPC Front Case Assembly Hand Cropping Of Replacement Stage 6 Vanes, Repair-001 (VRS6520)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-350 | 6A4231 |

01-350 | 6A7424 |

01-350 | 6A7481 |

01-350 | 6A8767 |

01-400 | 6A4230C01 |

01-400 | 6A7423C01 |

01-400 | 6A7482C01 |

01-400 | 6A8765 |

01-448 | 6A4230C01 |

01-448 | 6A7423C01 |

01-448 | 6A7482C01 |

01-448 | 6A8765 |

01-450 | 6A4230C02 |

01-450 | 6A7423C02 |

01-450 | 6A7482C02 |

01-450 | 6A8766 |

General

This TASK gives the procedure to replace (by hand cropping) individual HP compressor stator vanes for stage 6 on an assembled front case.

As each stator vane is removed its location in the assembly must be recorded.

There is no requirement to measure stator to rotor drum clearance when performing this repair procedure.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and Availability

Refer to International Aero engines

Related Repairs

None

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Hand held mechanical cutters | LOCAL | Hand held mechanical cutters | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Soft jaw fixture | LOCAL | Soft jaw fixture | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-296 HEAT SHRINKABLE TUBING | LOCAL | CoMat 02-296 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-082 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-082 | ||

| CoMat 05-127 ABRASIVE PAD | LOCAL | CoMat 05-127 | ||

| CoMat 05-140 ABRASIVE STONE SILICON CARBIDE | LOCAL | CoMat 05-140 | ||

| CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) | LOCAL | CoMat 06-063 | ||

| CoMat 02-096 MARKER PEN | LOCAL | CoMat 02-096 |

Spares

NONESafety Requirements

NONEProcedure

Refer to TASK 72-41-30-040-001-B00.

Remove the damaged vane.

SUBTASK 72-41-30-350-001 Remove the Damaged Vane

Locate the damaged vane.

Remove the nearest adjacent serviceable vane.

Refer to TASK 72-41-30-040-001-B00.

Remove the nearest serviceable vane.

Refer to SPM TASK 70-11-34-300-503.

Clean the nearest serviceable vane.

SUBTASK 72-41-30-350-002 Remove, Clean and Measure the Nearest Serviceable Vane

Hand crop the tip of the vane.

Make sure that the tip is dressed in the direction from the leading edge tip to the trailing edge tip.

If necessary, use mechanical hand cutters, smooth hand metal file and/or CoMat 05-140 ABRASIVE STONE SILICON CARBIDE silicon abrasive stone.

Make sure that you get the dimensional limits set in Step.

Remove tip material by cropping.

Blend and polish the replacement new vane tip.

Make sure that the tip is dressed in the direction from the leading edge tip to the trailing edge tip.

Use CoMat 05-020 WATERPROOF SILICON CARBIDE waterproof silicon carbide paper, CoMat 05-082 WATERPROOF SILICON CARBIDE waterproof silicon carbide paper and CoMat 05-127 ABRASIVE PAD scotch brite.

Make sure that you get the dimensional limits set in Step.

Blend and polish the replacement new vane tip.

SUBTASK 72-41-30-350-003 Crop the Replacement New Vane

CAUTION

IF YOU USE MECHANICAL CUTTERS ON THE VANE, MAKE LIGHT CUT TO PREVENT OVERHEATING OF THE MATERIAL.Refer to SPM TASK 70-11-39-300-503, SUBTASK 70-11-39-300-001.

Do a local swab etch of the cropped area.

SUBTASK 72-41-30-110-055 Swab Etch the Cropped Area

Refer to SPM TASK 70-23-01-230-501.

Cracks are not permitted.

If you find cracks, do the SUBTASK 72-41-30-220-059 thru Step again with a new replacement vane.

Locally crack test the cropped area.

SUBTASK 72-41-30-230-001 Crack Test the Cropped Area

Refer to SPM TASK 70-11-03-300-503.

Clean the replacement new vane.

SUBTASK 72-41-30-110-056 Clean the Replacement New Vane

Use workshop inspection equipment.

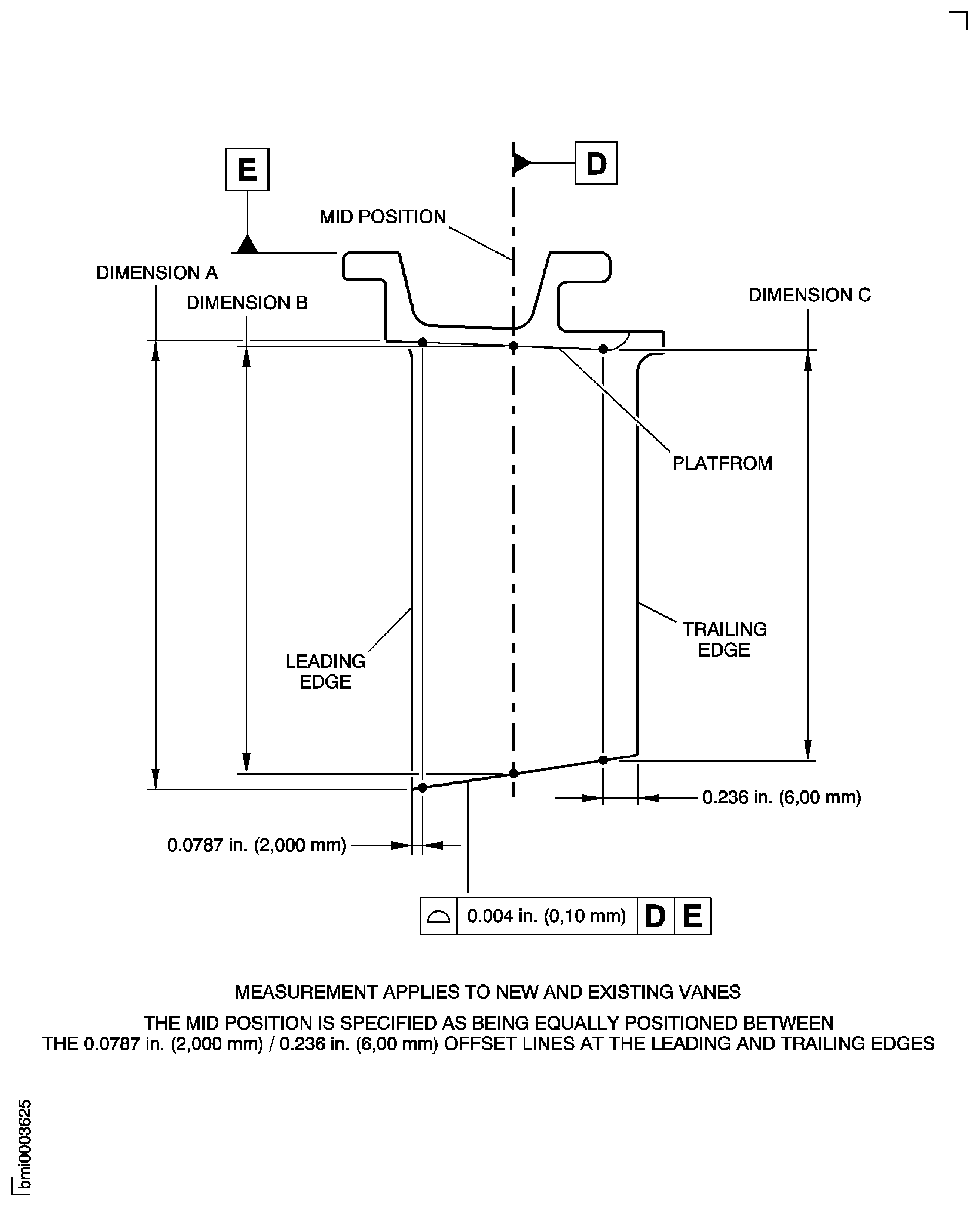

Measure the vane length at three positions given in figure.

Make sure the vane length is within 0.002 in. (0.05 mm) of the adjacent serviceable vane length measured in Step para D.

.

Dimensionally examine the replacement new vane.

SUBTASK 72-41-30-220-511 Dimensionally Examine the Replacement New Vane

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Use vibro-engraving equipment.

Mark the symbol 20 inside a triangle adjacent to the part number.

Mark the repair symbol adjacent to the part number.

SUBTASK 72-41-30-350-004 Identify the Replacement New Vane

Refer to TASK 72-41-30-440-000.

Install the replacement new vane in original vane set.

SUBTASK 72-41-30-350-005 Install the Replacement New Vane

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions