Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-41-30-040-001-B00 HPC Front Case And Vane Assembly - Disassemble The HP Compressor Upper And Lower Half Front Cases, Disassembly-001

General

Refer to TASK 72-41-00-040-001-B00 to disassemble the HP compressor assembly.

Fig/item numbers in parentheses in the procedure agree with those used in the EIPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the EIPC.

Apply the approved CoMat 10-058 PENETRATING OIL before the removal of threaded parts. Let the parts soak before removal.

Discard all rubber seal rings and cotter pins removed in this procedure.

Remove and discard the lockwire before the part is disconnected.

Refer to the SPM TASK 70-09-00-400-501 for the procedure to make identification marks.

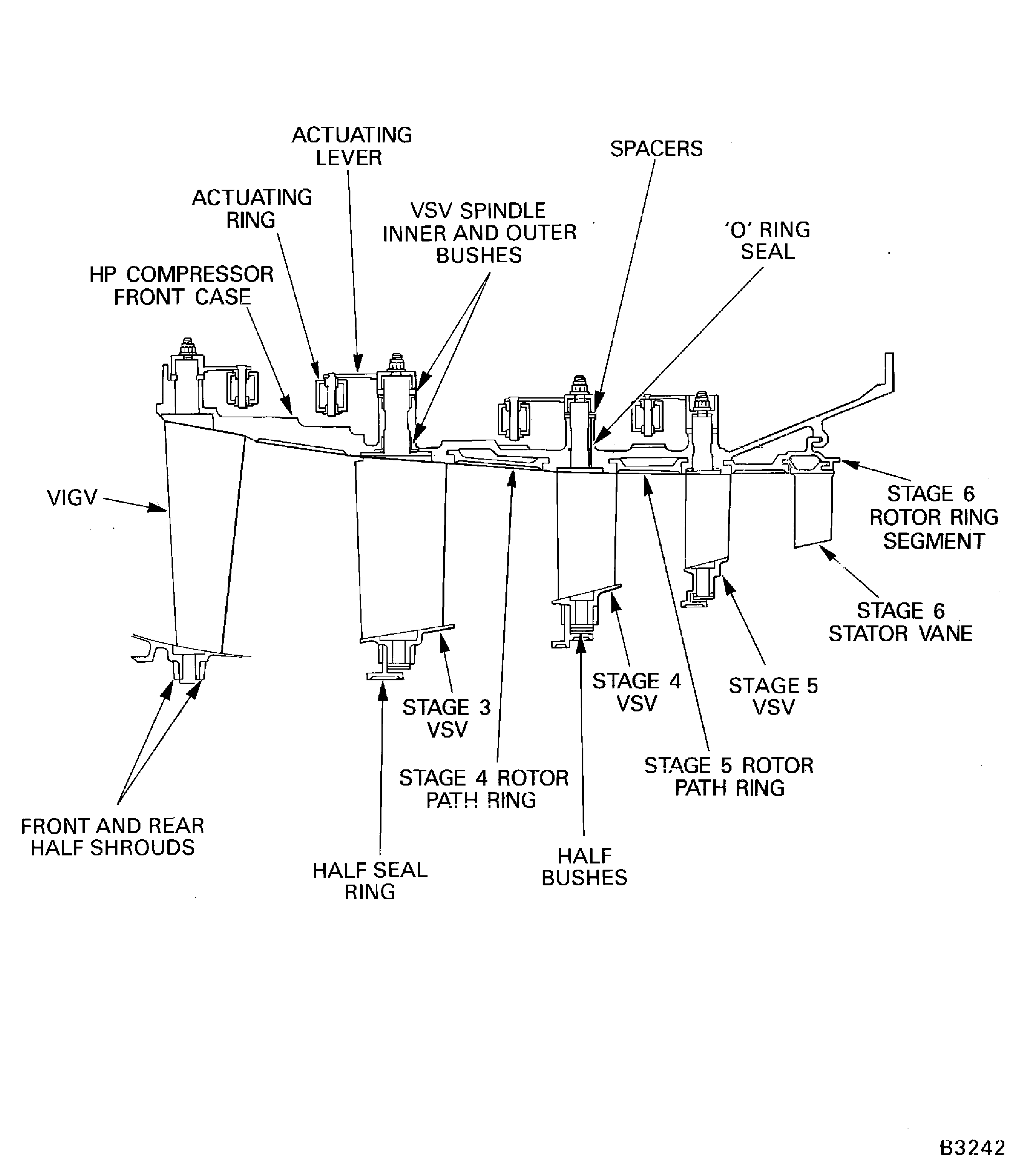

Refer to Figure for a sectional view of the HP compressor front case.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Vibration peening equipment | LOCAL | Vibration peening equipment | ||

| IAE 1R18264 Removal punch | 0AM53 | IAE 1R18264 | 1 | |

| IAE 1R18265 Removal punch | 0AM53 | IAE 1R18265 | 1 | |

| IAE 1R18266 Impact extractor | 0AM53 | IAE 1R18266 | 1 | |

| IAE 1R18289 Bushing extractor | 0AM53 | IAE 1R18289 | 1 | |

| IAE 1R18290 Removal extractor | 0AM53 | IAE 1R18290 | 1 | |

| IAE 1R18648 Puller extractor | 0AM53 | IAE 1R18648 | 1 | |

| IAE 1R18819 Bushing extractor | 0AM53 | IAE 1R18819 | 1 | |

| IAE 1R18820 Bushing extractor | 0AM53 | IAE 1R18820 | 1 | |

| IAE 1R18821 Bushing extractor | 0AM53 | IAE 1R18821 | 1 | |

| IAE 1R18822 Bushing extractor | 0AM53 | IAE 1R18822 | 1 | |

| IAE 1R18823 Bushing extractor | 0AM53 | IAE 1R18823 | 1 | |

| IAE 1R19559 Extractor inner clamp | 0AM53 | IAE 1R19559 | 1 | |

| IAE 1R19560 Impact extractor adapter | 0AM53 | IAE 1R19560 | 1 | |

| IAE 1R18270 Removal adapter | 0AM53 | IAE 1R18270 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-058 PENETRATING OIL | X222X | CoMat 10-058 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

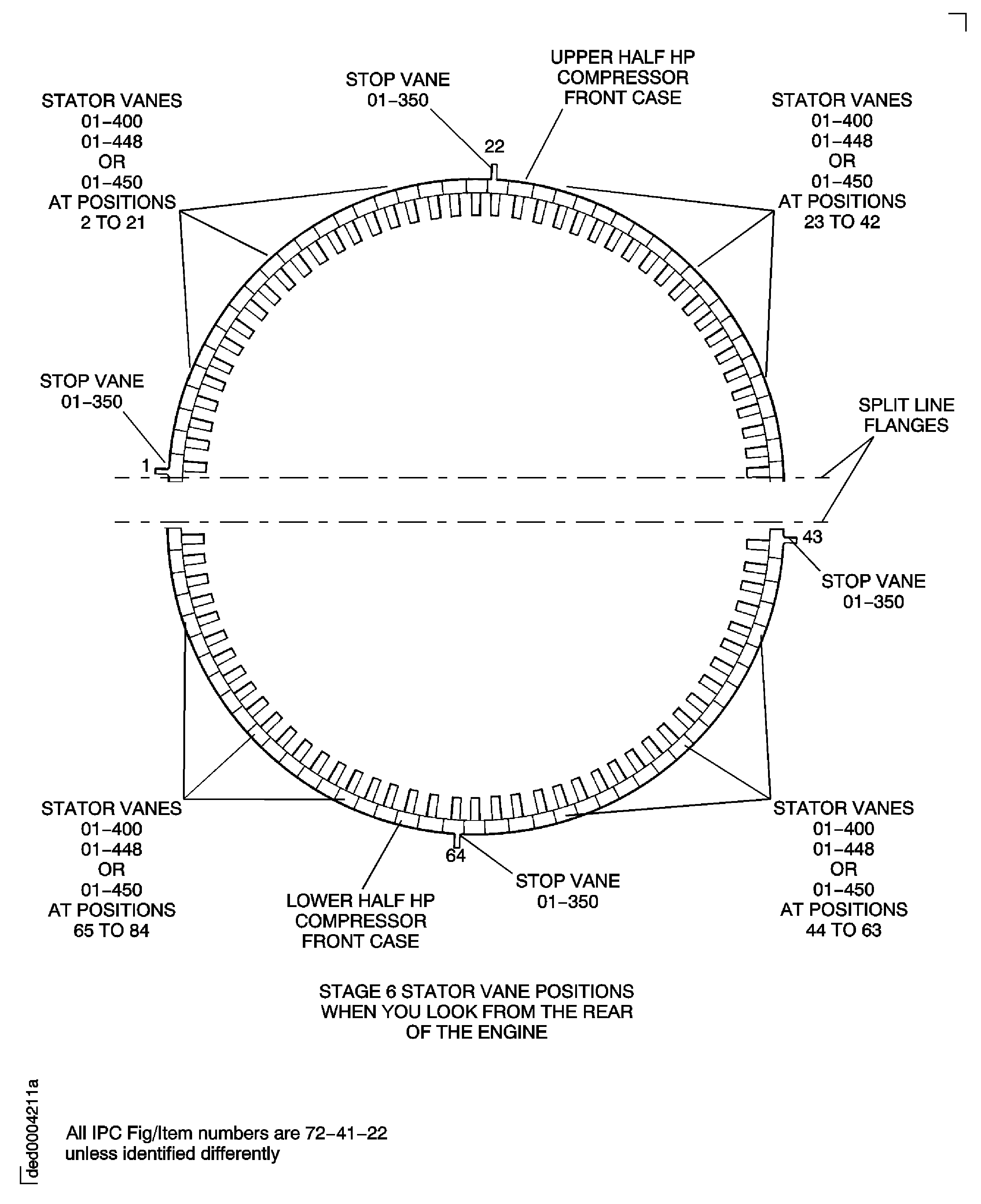

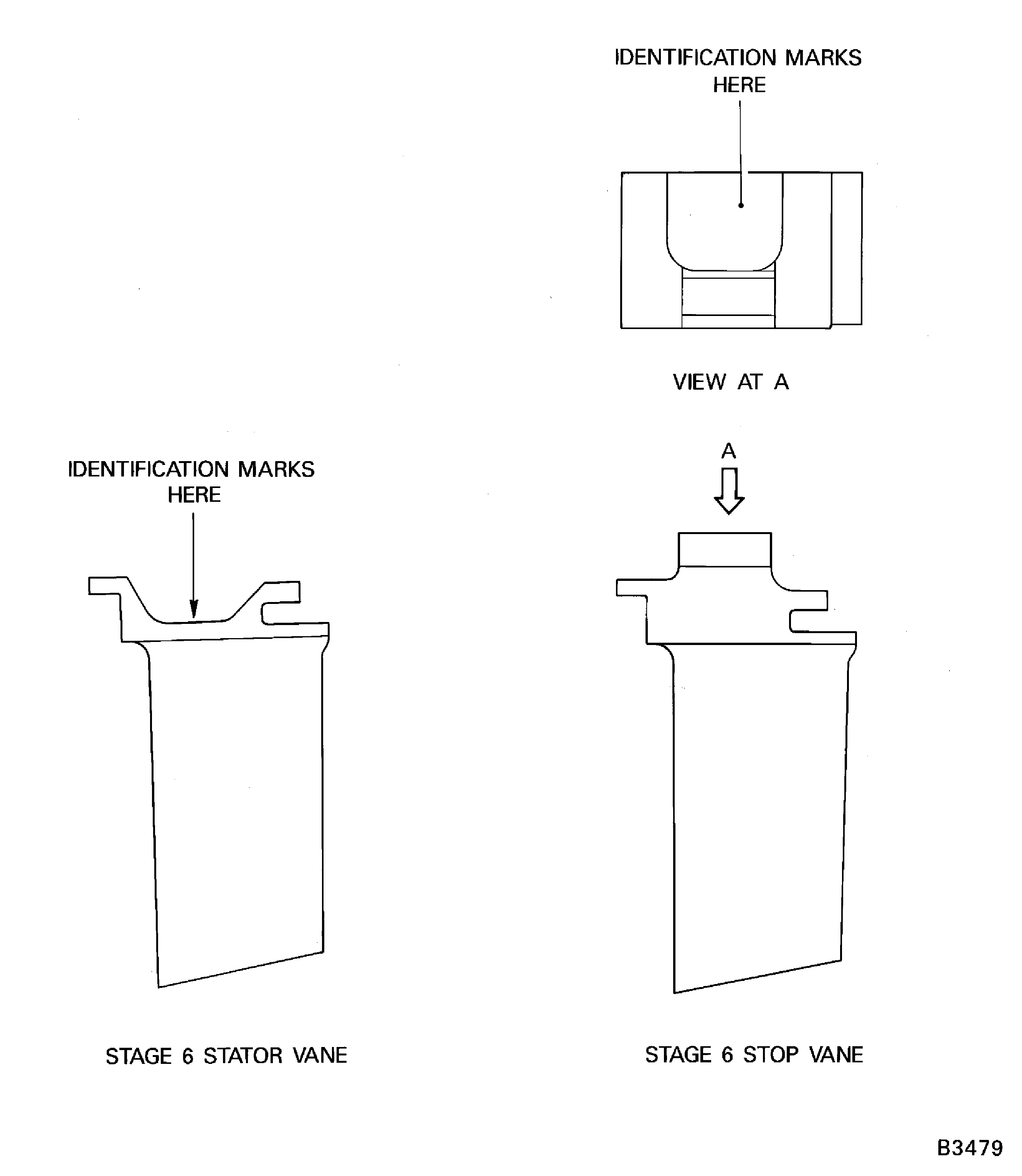

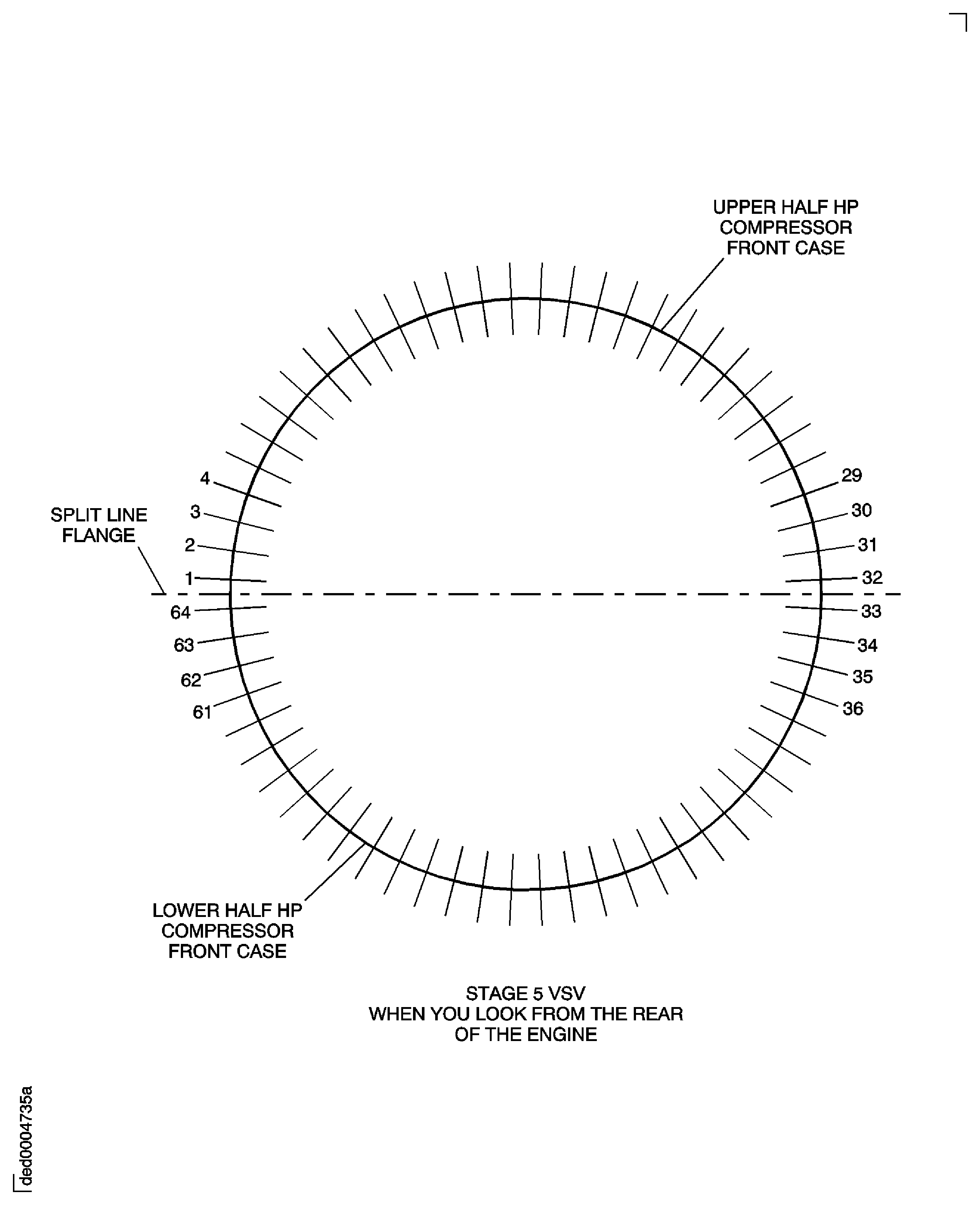

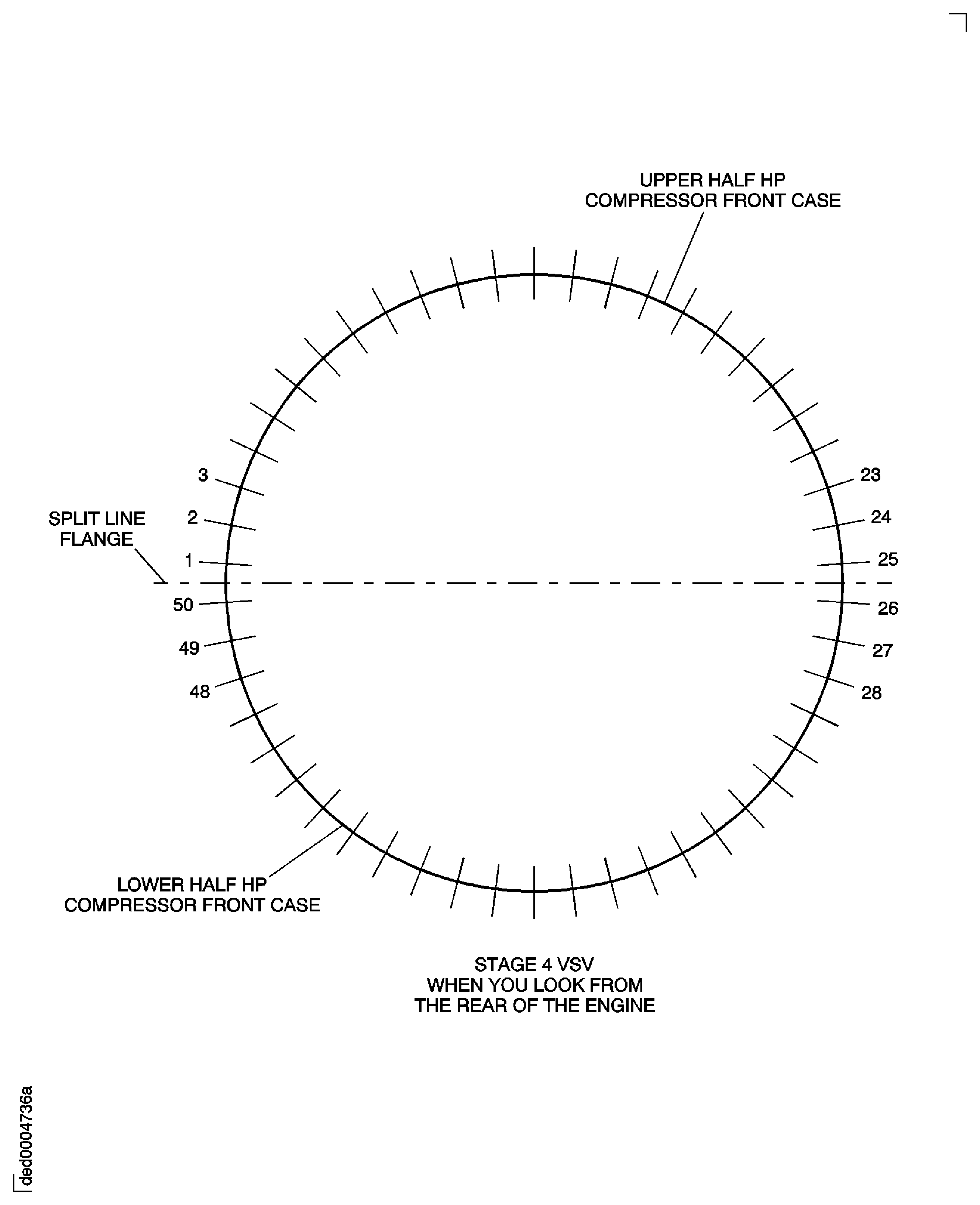

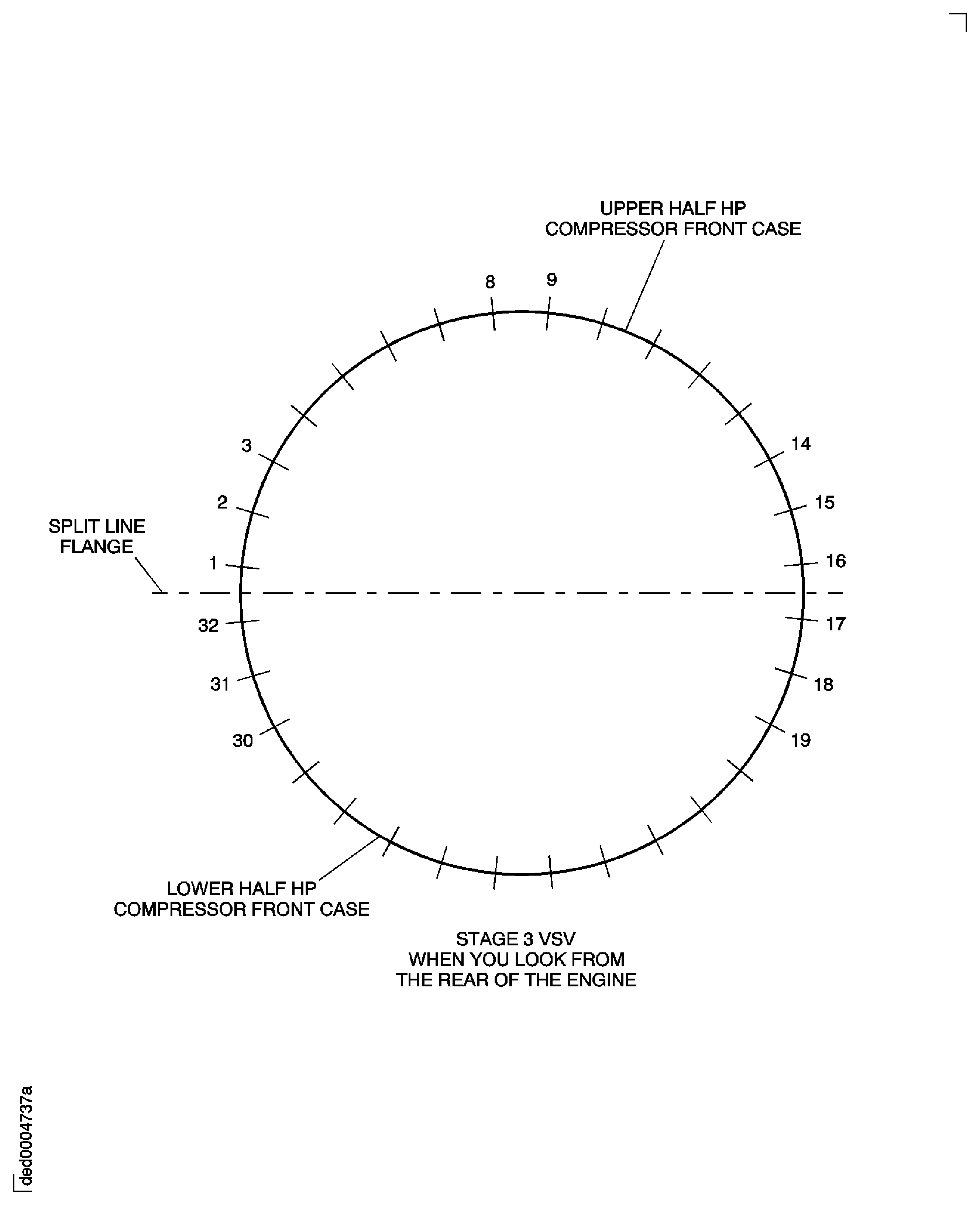

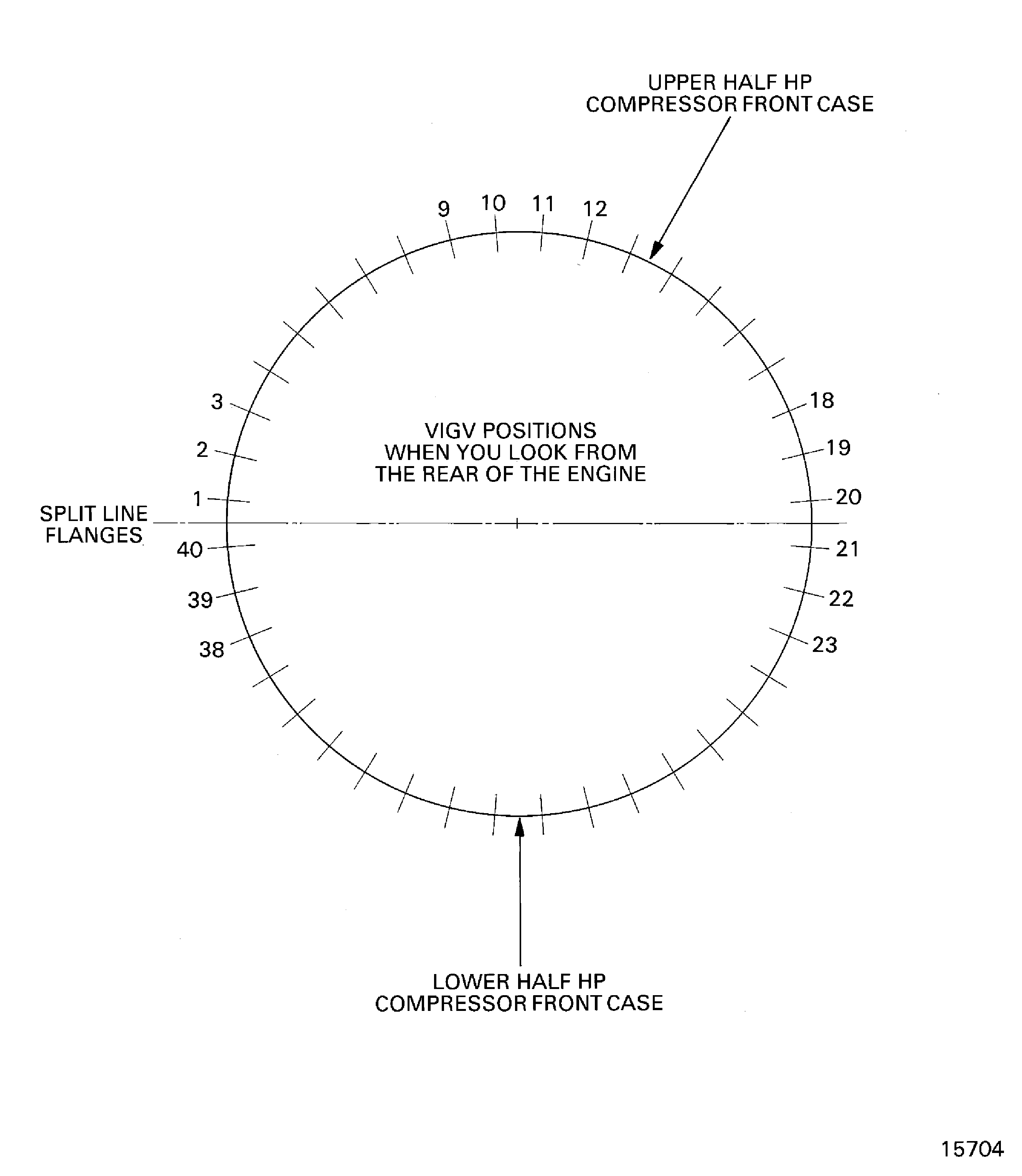

Identify each stator vane with its position number as the vanes are removed. Use vibration peening equipment to identify the vanes. Refer to Figure for the position for identification marks.

Remove the stop vane at position 1 and the stator vanes at positions 2 to 21.

NOTE

The stop vane at position 22 is removed in Step.

Remove the stop vane and stator vanes from the upper half HP compressor front case.

SUBTASK 72-41-30-040-059 Remove the Stage 6 Stator Vanes

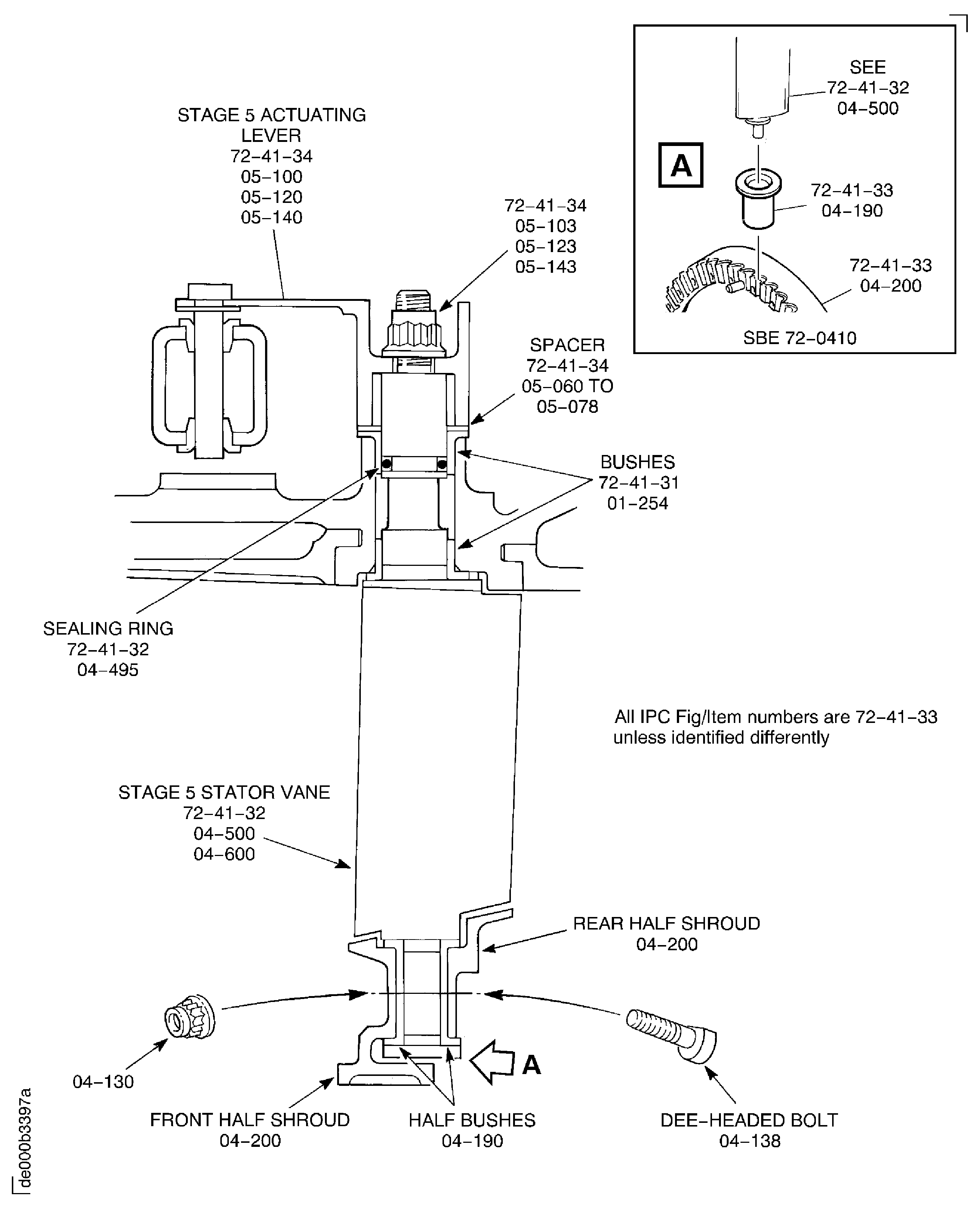

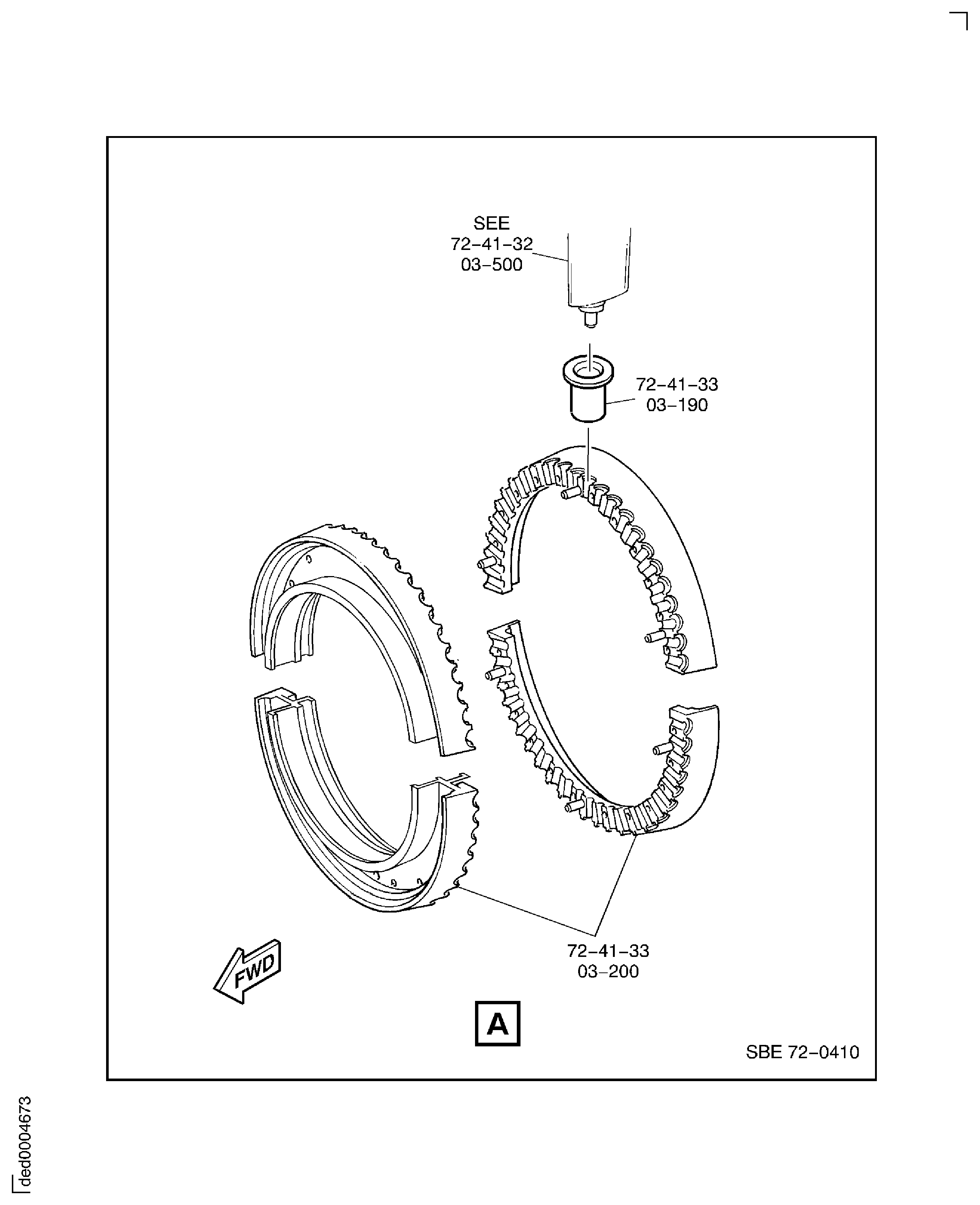

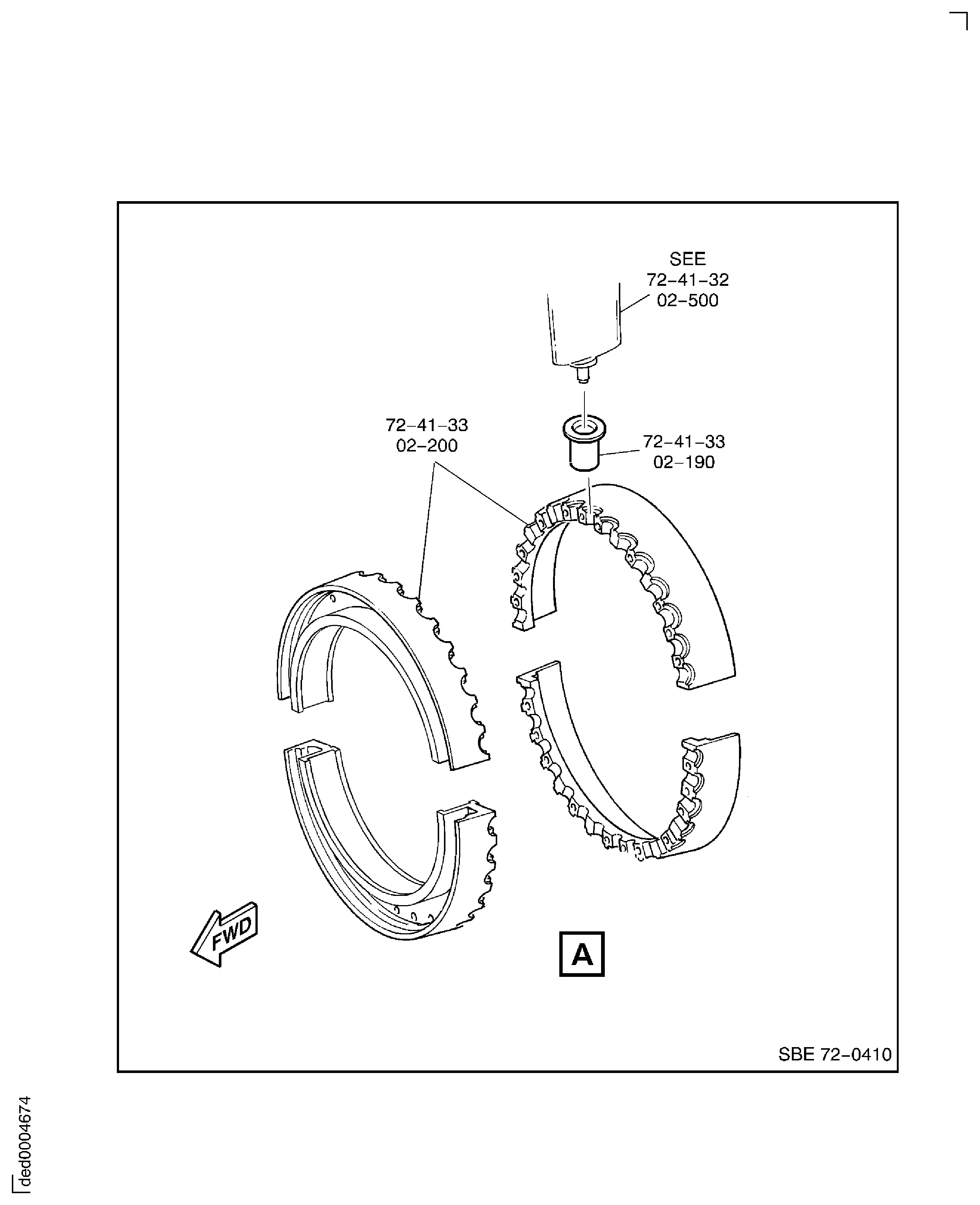

SBE 72-0410: HP compressor variable inner shrouds - Introduction of revised one piece bushes

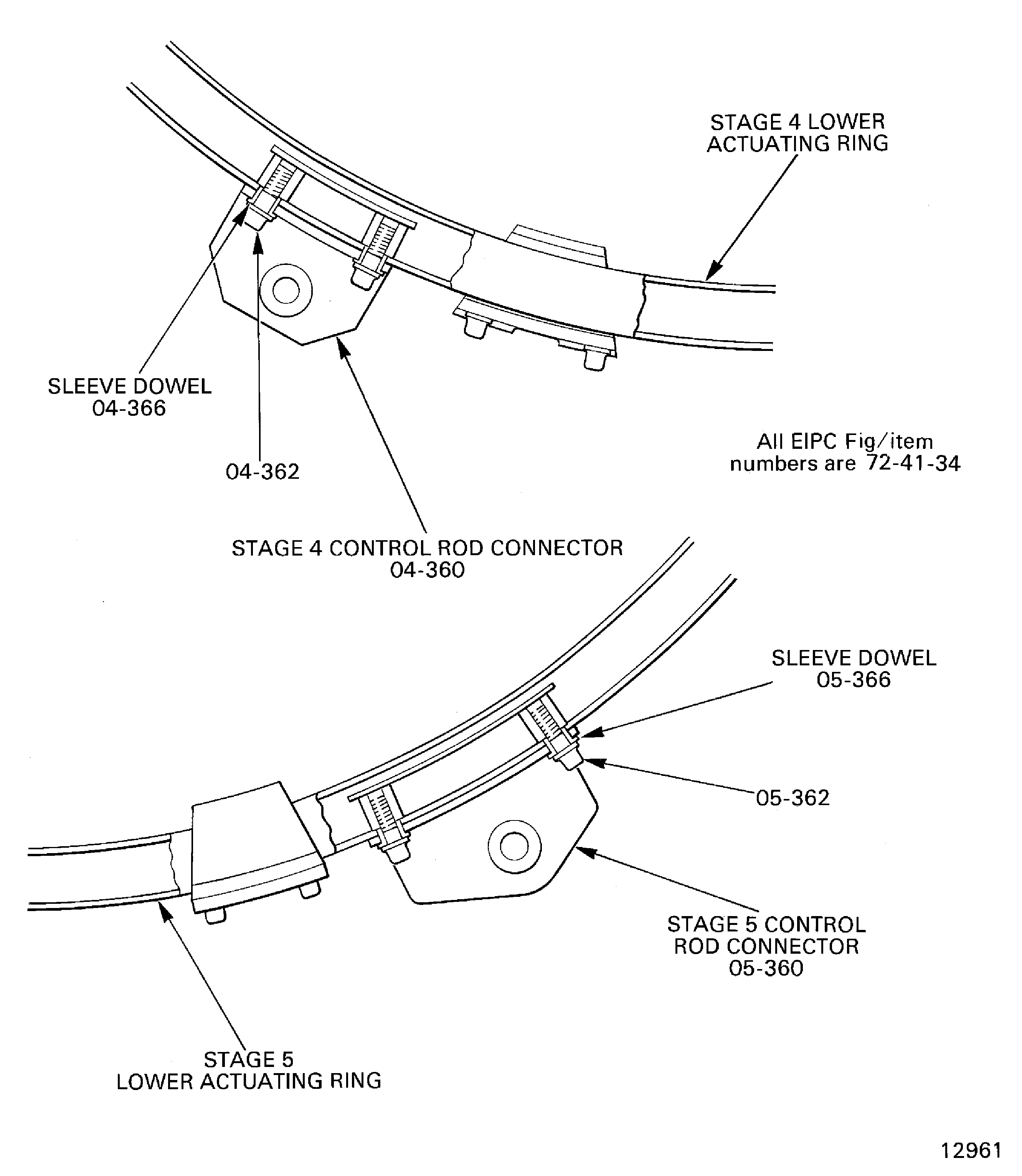

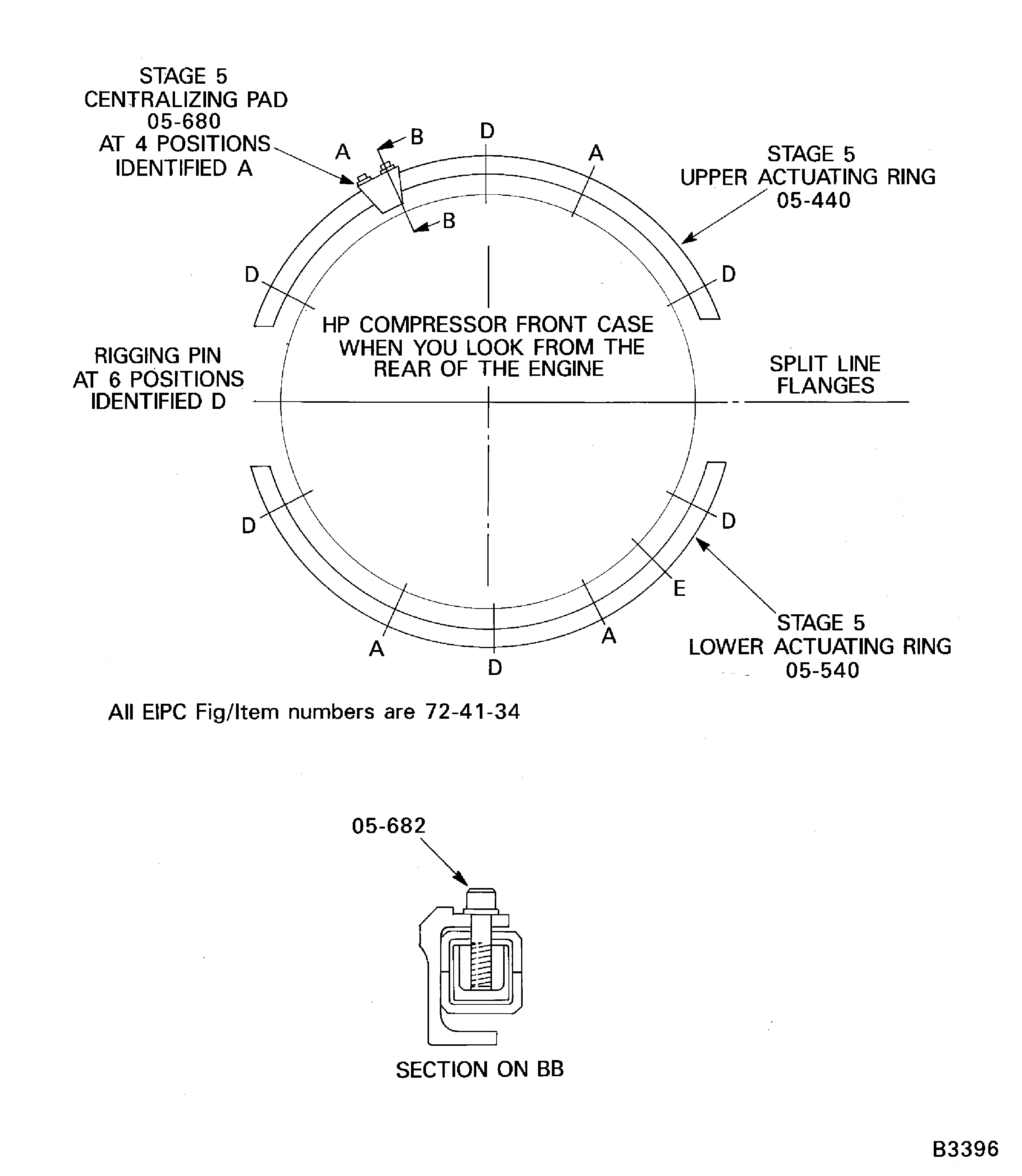

SBE 72-0385, SBE 72-0416: Introduction of revised actuating rings with increased dowel locations.

Pre SBE 72-0385, SBE 72-0416: Remove the stage 5 upper actuating ring and the actuating levers.

SBE 72-0385, SBE 72-0416: Remove the stage 5 upper actuating ring and the actuating levers.

Remove the stage 5 upper actuating ring from the upper half HP compressor front case.

Pre SBE 72-0385, SBE 72-0416: Remove the stage 5 lower actuating ring and the actuating levers.

SBE 72-0385, SBE 72-0416: Remove the stage 5 lower actuating ring and the actuating levers.

Remove the stage 5 lower actuating ring from the lower half HP compressor front case.

Pre SBE 72-0410: Remove the front and rear half shroud with the half bushes.

SBE 72-0410: Remove the front and rear half shroud with the one piece bushes.

Remove the stage 5 stator vanes from the upper half HP compressor front case.

NOTE

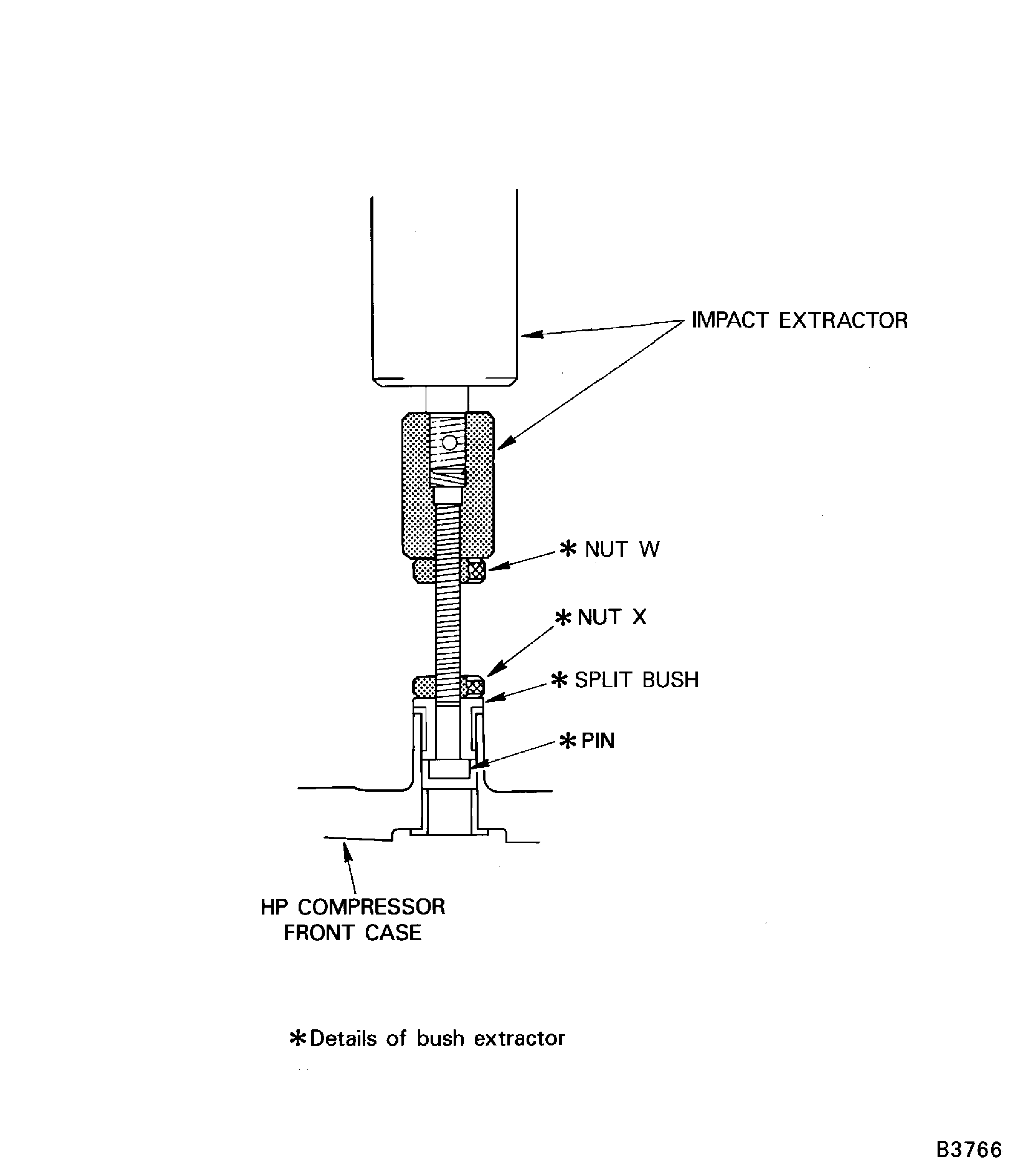

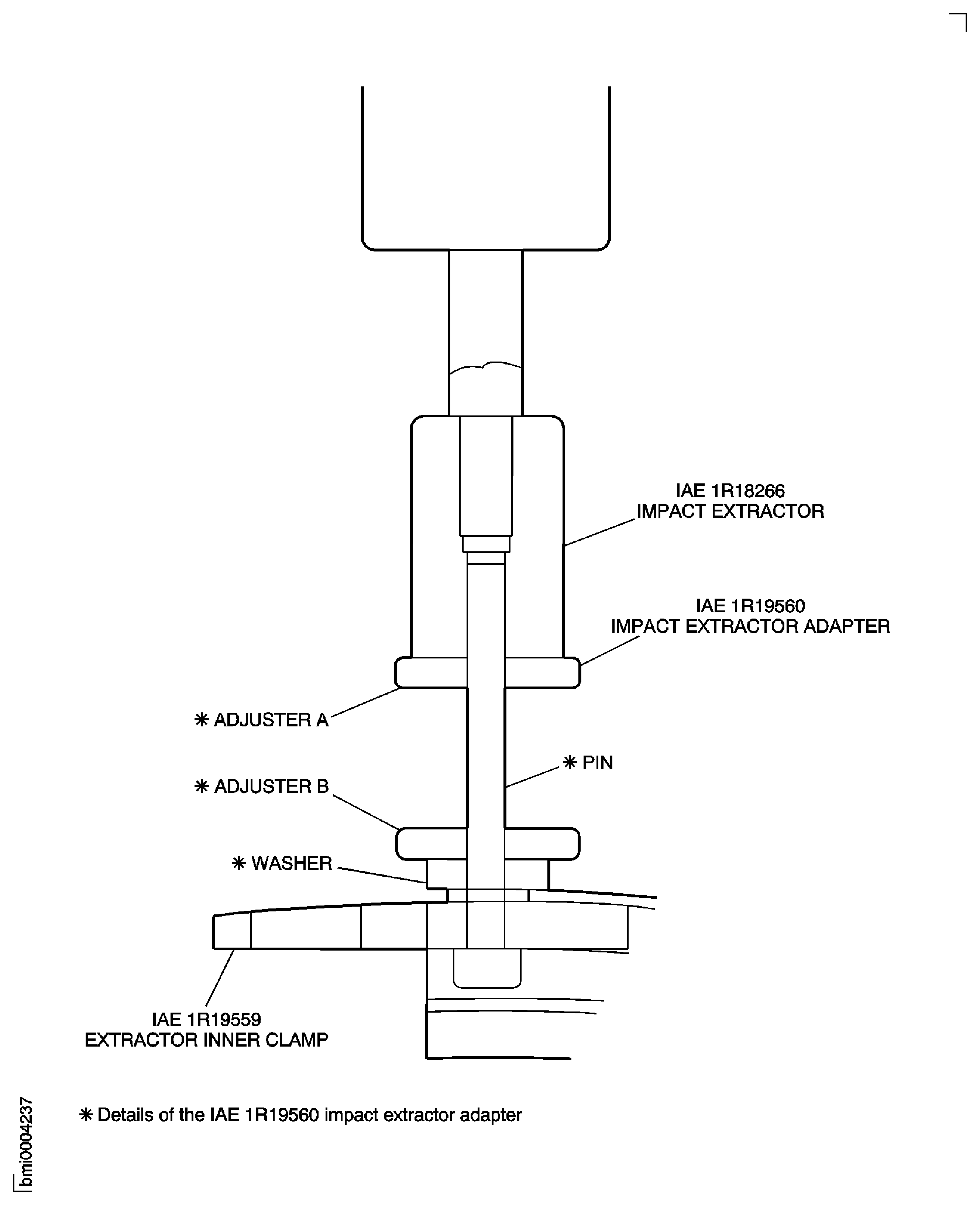

The bolts are a close tolerance fit and must not be turned during their removal.Install the IAE 1R19559 Extractor inner clamp 1 off on the body. Tighten the clamp.

Install the IAE 1R18266 Impact extractor 1 off on the pin.

Tighten the adjuster A to attach the IAE 1R18266 Impact extractor to the pin.

Use the IAE 1R18266 Impact extractor to remove the bush.

Use IAE 1R19560 Impact extractor adapter 1 off to remove the 64 stage 5 stator vane outer bushes.

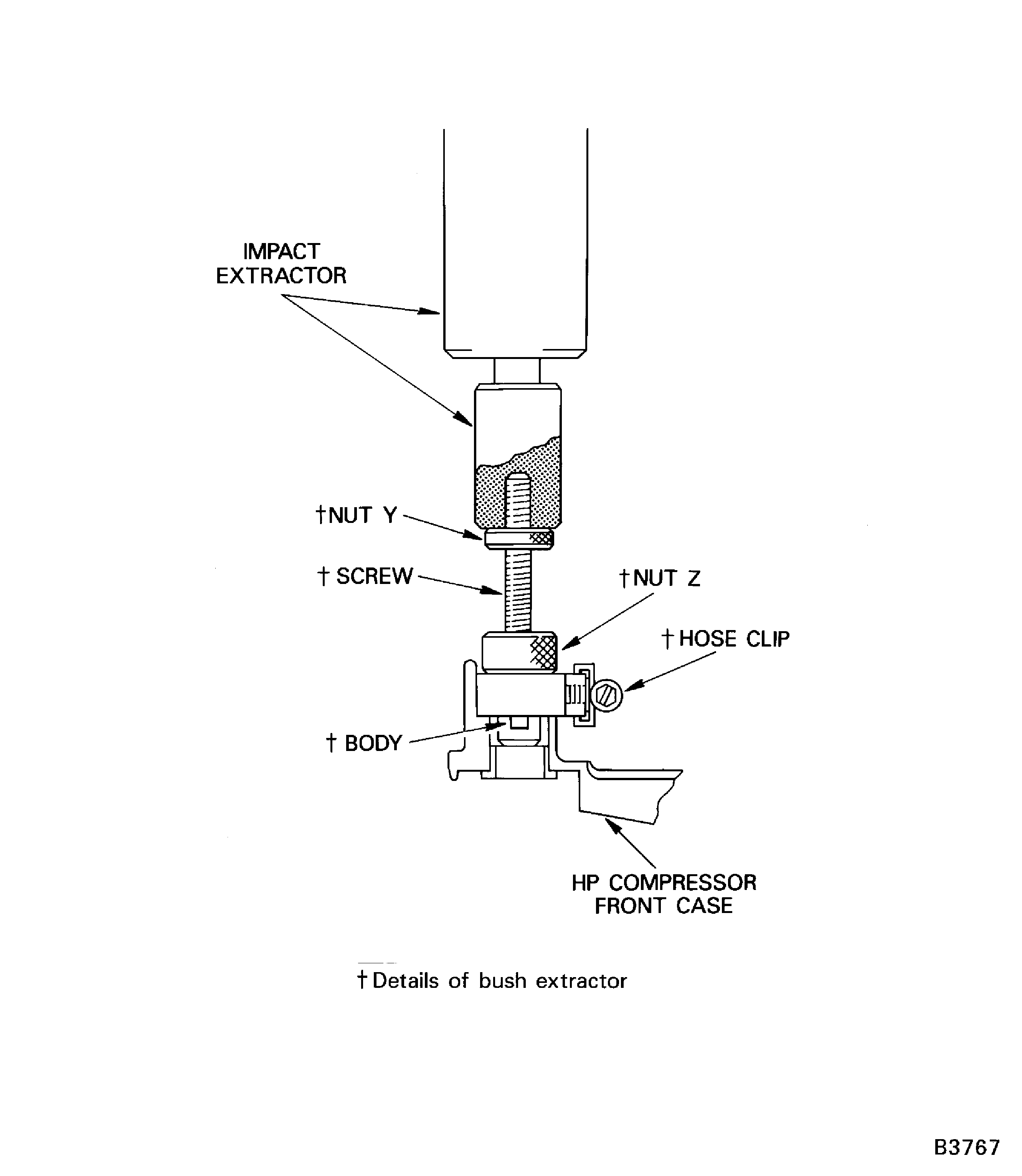

Pre SBE 72-0385, SBE 72-0416: Remove the stage 5 stator vane outer bushes.

Install IAE 1R18266 Impact extractor 1 off, on the pin.

Use IAE 1R18823 Bushing extractor 1 off to remove the four outer bushes at the four long bosses.

Install IAE 1R18266 Impact extractor 1 off, on the screw.

Use IAE 1R18821 Bushing extractor 1 off to remove the remaining 60 outer bushes.

SBE 72-0385, SBE 72-0416: Remove the stage 5 stator vane outer bushes.

NOTE

The long bosses are at positions 1, 32, 33 and 64.Install IAE 1R18290 Removal extractor 1 off in to one of the inner bushes to be removed.

Remove the 64 stage 5 stator vane inner bushes.

SUBTASK 72-41-30-040-060 Remove the Stage 5 Actuating Ring and the Stage 5 Stator Vanes (Pre SBE 72-0410, SBE 72-0410, Pre SBE 72-0385, SBE 72-0416 and SBE 72-0385, SBE 72-0416)

SBE 72-0410: HP compressor variable inner shrouds - Introduction of revised one piece bushes

SBE 72-0385, SBE 72-0416: Introduction of revised actuating rings with increased dowel locations.

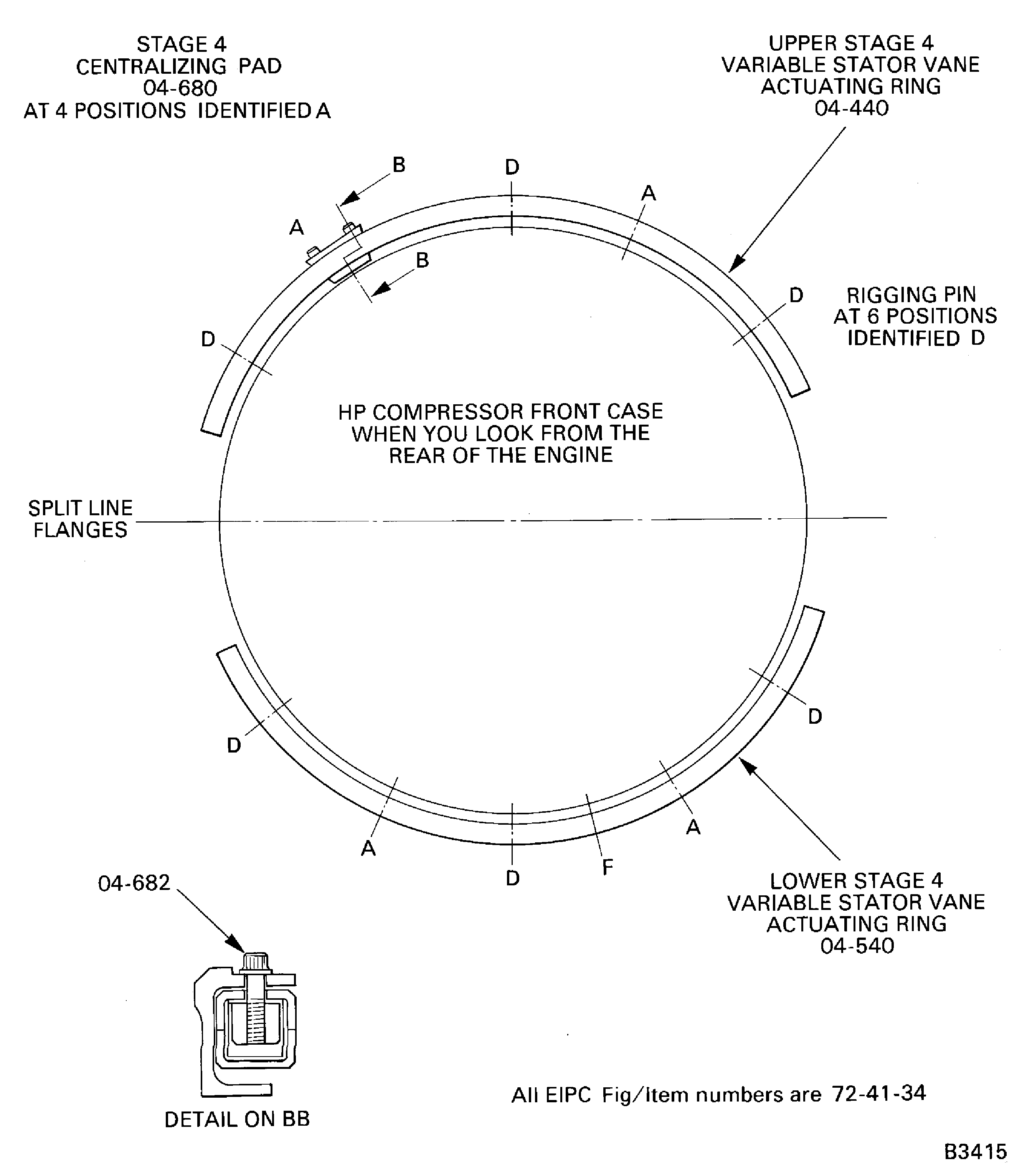

Pre SBE 72-0385, SBE 72-0416: Remove the stage 4 upper actuating ring and the actuating levers.

SBE 72-0385, SBE 72-0416: Remove the stage 4 upper actuating ring and the actuating levers.

Remove the stage 4 upper actuating ring from the upper half HP compressor front case.

Pre SBE 72-0385, SBE 72-0416: Remove the stage 4 lower actuating ring and the actuating levers.

SBE 72-0385, SBE 72-0416: Remove the stage 4 lower actuating ring and the actuating levers.

Remove the stage 4 lower actuating ring from the lower half HP compressor front case.

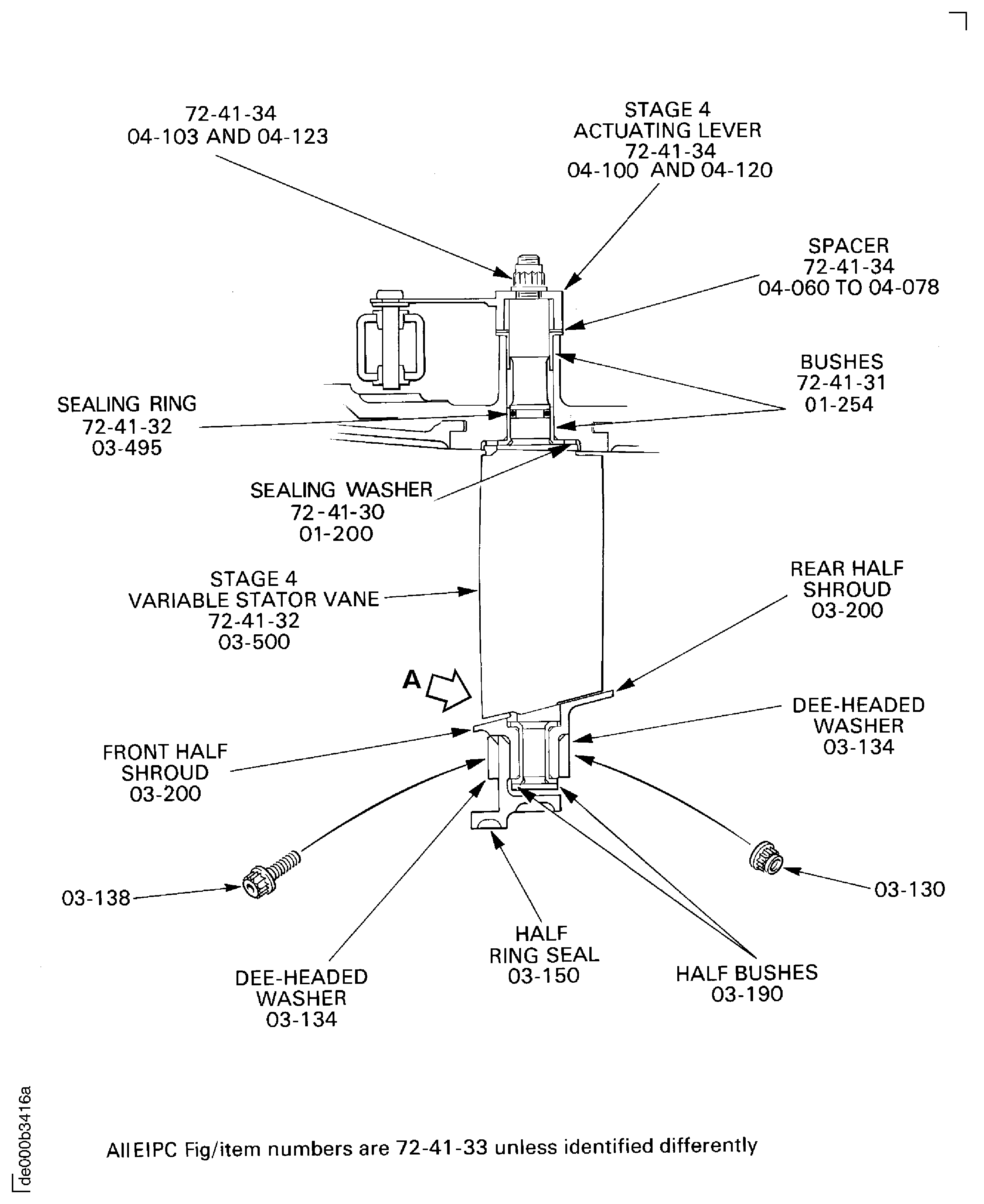

Pre SBE 72-410: Remove the 12 bolts, 24 washers and the 12 nuts which attach the stage 4 half shroud, the half bushes and the stage 4 half seal ring to the stage 4 stator vanes at the inner pivot point.

SBE 72-0410: Remove the front half shroud with the integral seal and rear half shroud and the one piece bushes.

Remove the stage 4 stator vanes from the lower half HP compressor front case.

Install the IAE 1R19559 Extractor inner clamp 1 off on the body. Tighten the clamp.

Install the IAE 1R18266 Impact extractor 1 off on the pin.

Tighten the adjuster A to attach the IAE 1R18266 Impact extractor to the pin.

Use the IAE 1R18266 Impact extractor to remove the bush.

Use IAE 1R19560 Impact extractor adapter 1 off to remove the 50 stage 4 stator vane outer bushes.

Pre SBE 72-0385, SBE 72-0416: Remove the 50 stage 4 stator vane outer bushes.

Install IAE 1R18266 Impact extractor 1 off on the pin.

Use IAE 1R18823 Bushing extractor 1 off to remove the 50 stage 4 stator vane outer bushes.

SBE 72-0385, SBE 72-0416: Remove the 50 stage 4 stator vane outer bushes.

Install IAE 1R18290 Removal extractor 1 off in to one of the inner bushes to be removed.

Remove the 50 stage 4 stator vane inner bushes.

SUBTASK 72-41-30-040-061 Remove the Stage 4 Actuating Ring and the Stage 4 Stator Vanes (Pre SBE 72-0410, SBE 72-0410, Pre SBE 72-0385, SBE 72-0416 and SBE 72-0385, SBE 72-0416)

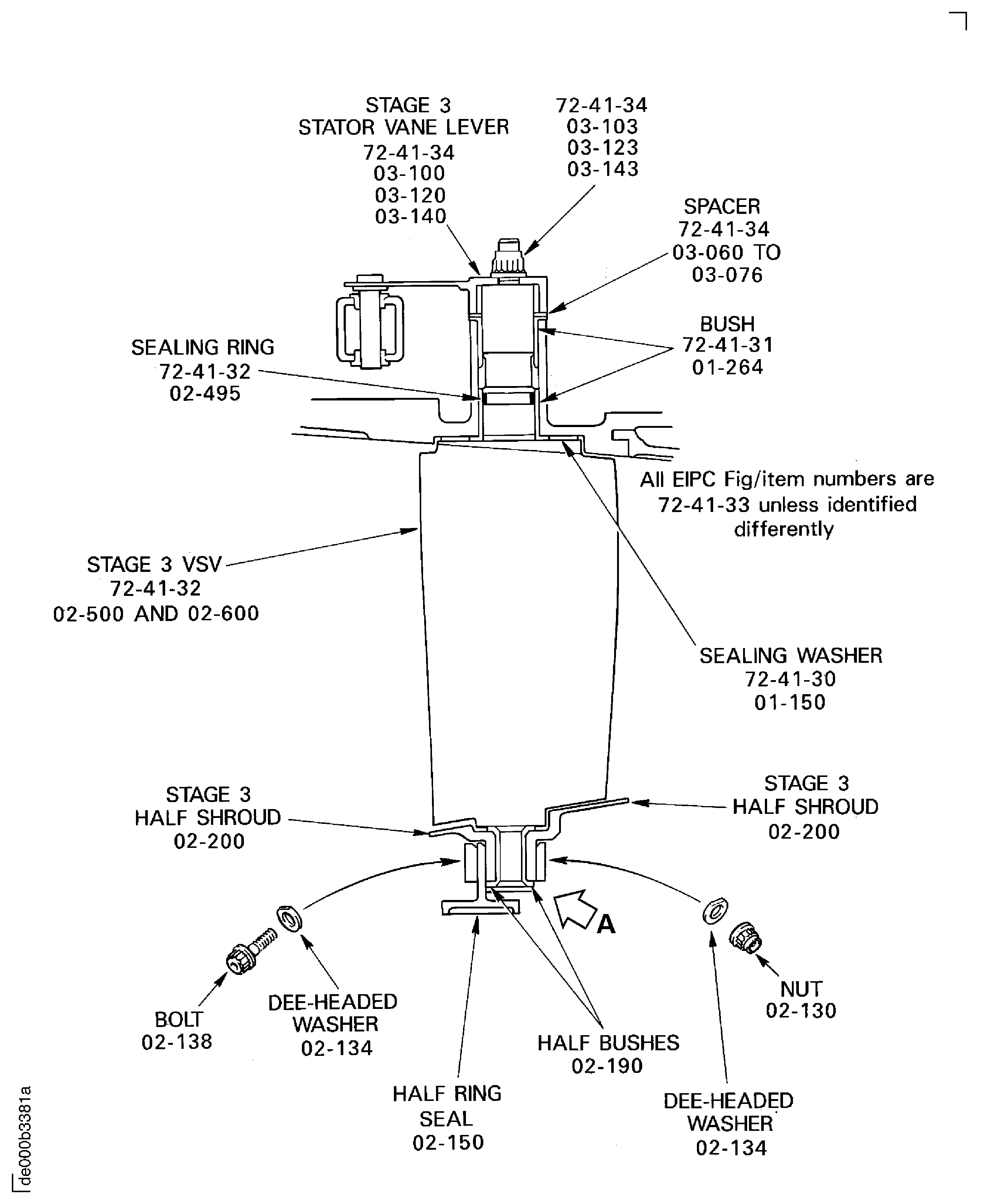

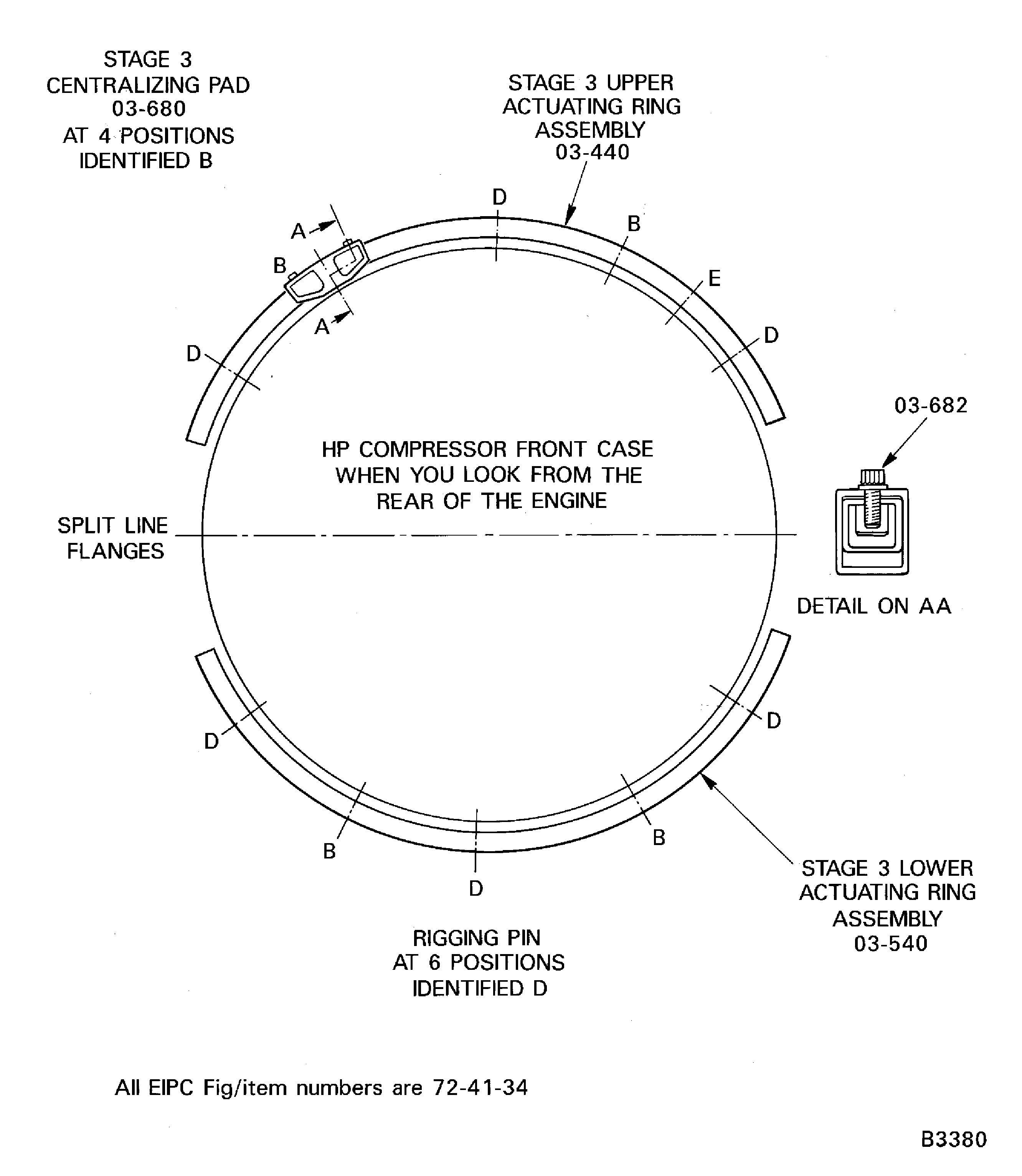

Refer to Figure.

SBE 72-0410: HP compressor variable inner shrouds - Introduction of revised one piece bushes

SBE 72-0385or SBE 72-0416: Introduction of revised actuating rings with increased dowel locations.

Pre SBE 72-0385 or SBE 72-0416:Remove the stage 3 upper actuating ring and actuating levers.

SBE 72-0385 or SBE 72-0416:Remove the stage 3 upper actuating ring and actuating levers.

Remove the stage 3 upper actuating ring from the upper half HP compressor front case.

Pre SBE 72-0385 or SBE 72-0416: Remove the stage 3 lower actuating ring and the actuating levers.

SBE 72-0385 or SBE 72-0416: Remove the stage 3 lower actuating ring and the actuating levers.

Remove the stage 3 lower actuating ring from the lower half HP compressor front case.

Pre SBE 72-0410: Remove the eight bolts, the 16 washers and the eight nuts which attach the stage 3 front and rear half shroud, the half bushes and the stage 3 front half seal ring to the stage 3 stator vanes at the inner pivot points.

SBE 72-0410: Remove the front half shroud with the integral seal and rear half shroud and the one piece bushes.

Remove the stage 3 stator vanes from the upper half HP compressor front case.

Install IAE 1R18266 Impact extractor 1 off on the screw.

Use IAE 1R18270 Removal adapter 1 off to remove the two outer bushes at the two short bosses. Refer to Figure.

Install IAE 1R18266 Impact extractor 1 off on the pin.

Use IAE 1R18822 Bushing extractor 1 off to remove the remaining 30 outer bushes. Refer to Figure.

Remove the stage 3 stator vane outer bushes.

NOTE

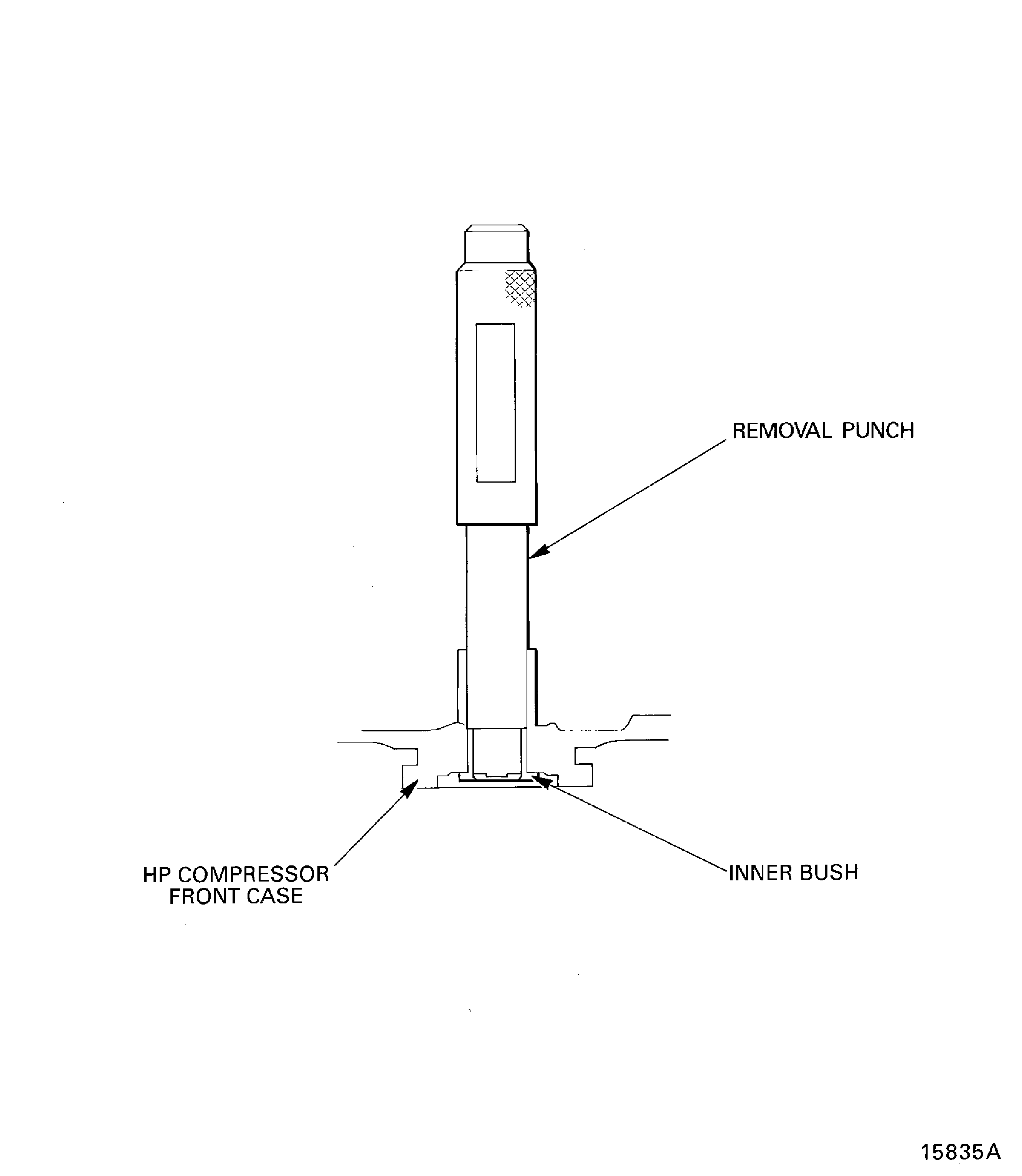

The short bosses are at positions 8 and 9.Install IAE 1R18265 Removal punch 1 off in to one of the inner bushes to be removed.

Remove the 32 stage 3 stator vane inner bushes. Refer to Figure.

SUBTASK 72-41-30-040-062 Remove the Stage 3 Actuating Ring and the Stage 3 Stator Vanes,and 72-41-30-990-202-002 (Pre SBE 72-0410, SBE 72-0410, Pre SBE 72-0385or SBE 72-0416 and SBE 72-0385or SBE 72-0416)

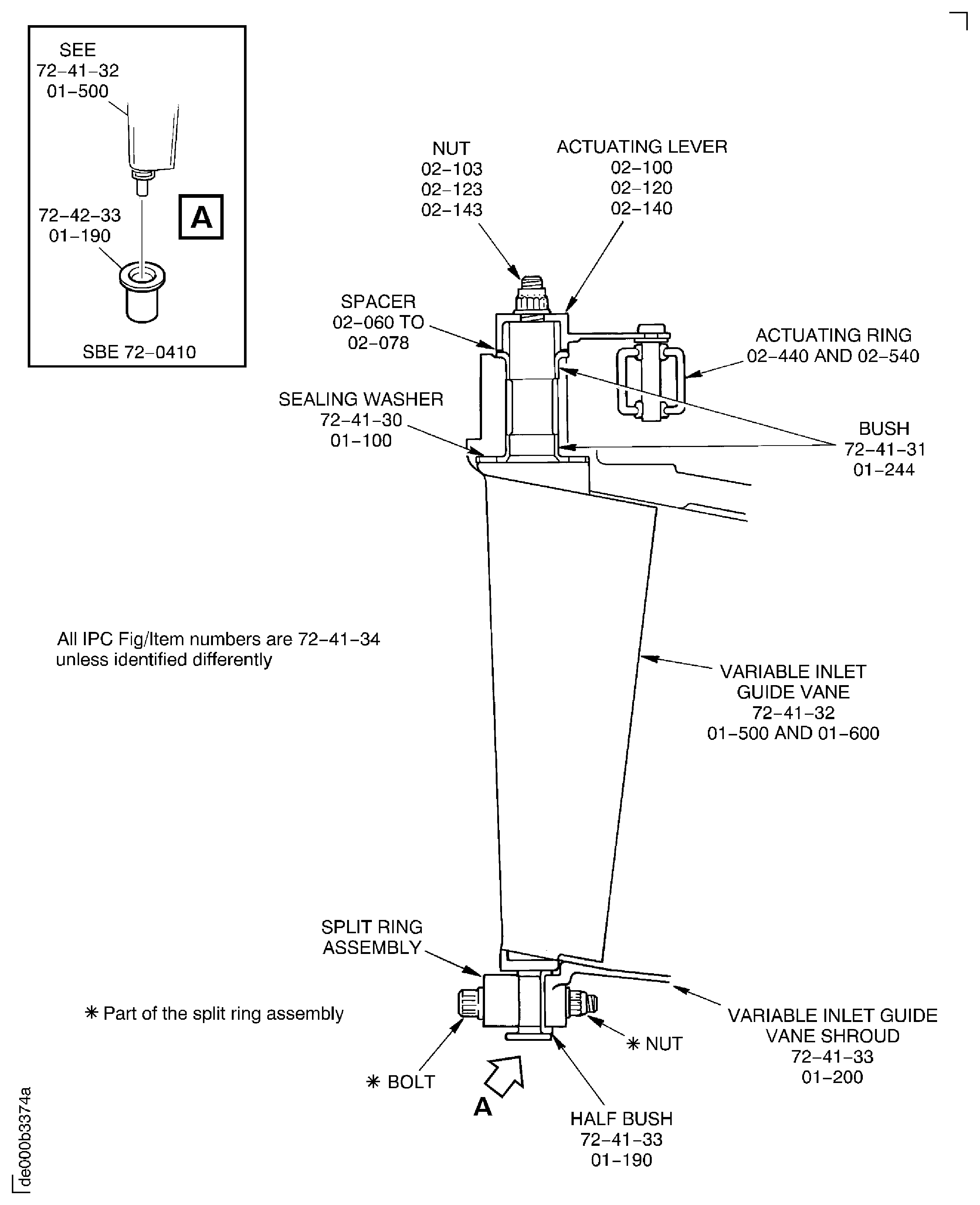

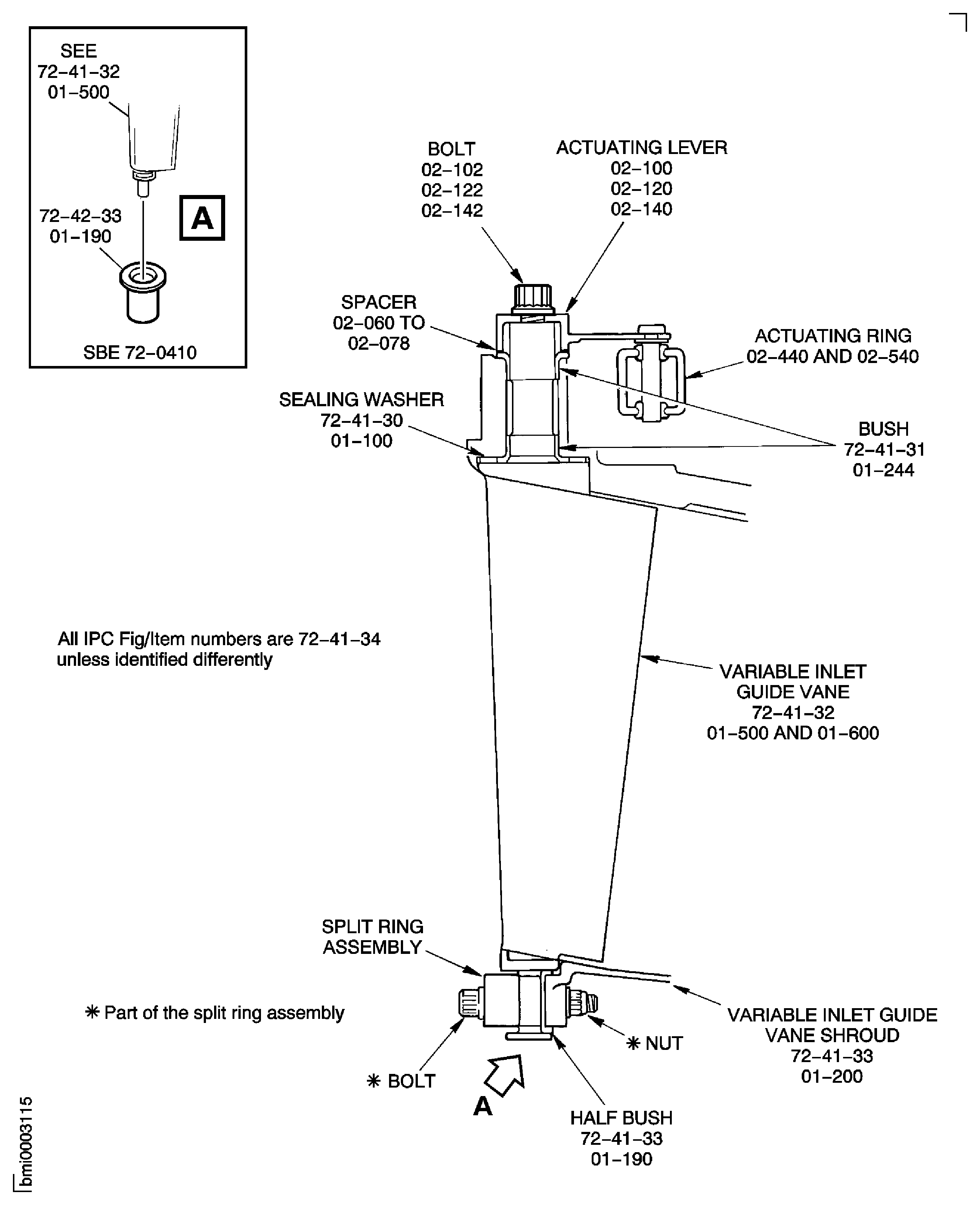

SBE 72-0486: HP compressor variable vanes - Introduction of a revised VIGV with an optimised spindle.

SBE 72-0410: HP compressor variable inner shrouds - Introduction of revised one piece bushes.

SBE 72-0385or SBE 72-0416: Introduction of revised actuating rings with increased dowel locations.

Pre SBE 72-0486:

Remove the 16 nuts which attach the inlet guide vane actuating levers to the inlet guide vanes at the positions 3 to 18.

Pre SBE 72-0486:

Remove the four nuts, the actuating levers and the eight spacers from the spindles of the inlet guide vanes at the positions 1, 2, 19 and 20.

Remove the inlet guide vane actuating ring from the upper half HP compressor front case.

Pre SBE 72-0486:

Remove the 16 nuts which attach the inlet guide vane actuating levers to the inlet guide vanes at the positions 23 to 38.

Pre SBE 72-0486:

Remove the four nuts, the actuating levers and the eight spacers from the spindles of the inlet guide vanes at the positions 21, 22, 39 and 40.

Remove the inlet guide vane actuating ring from the lower half HP compressor front case.

Pre SBE 72-0410:

Remove the inlet guide vane half shroud with the 20 half bushes and the split ring assembly.

Remove the inlet guide vanes from the upper half HP compressor front case.

Install IAE 1R18266 Impact extractor 1 off on the screw.

Use IAE 1R18819 Bushing extractor 1 off to remove the two short spindle bushes. These are at the positions 10 and 11 on the upper half HP compressor front case.

Install IAE 1R18266 Impact extractor 1 off on the pin.

Use IAE 1R18289 Bushing extractor 1 off to remove the remaining 38 spindle bushes.

Remove the inlet guide vane spindle outer bushes.

Install IAE 1R18264 Removal punch 1 off in to one of the spindle bushes to be removed.

Remove the 40 inlet guide vane spindle inner bushes.

SUBTASK 72-41-30-040-063 Remove the Inlet Guide Vane Actuating Ring and the Inlet Guide Vanes (Pre SBE 72-0486, SBE 72-0486, Pre SBE 72-0410, SBE 72-0410, Pre SBE 72-0385or SBE 72-0416 and SBE 72-0385or SBE 72-0416)

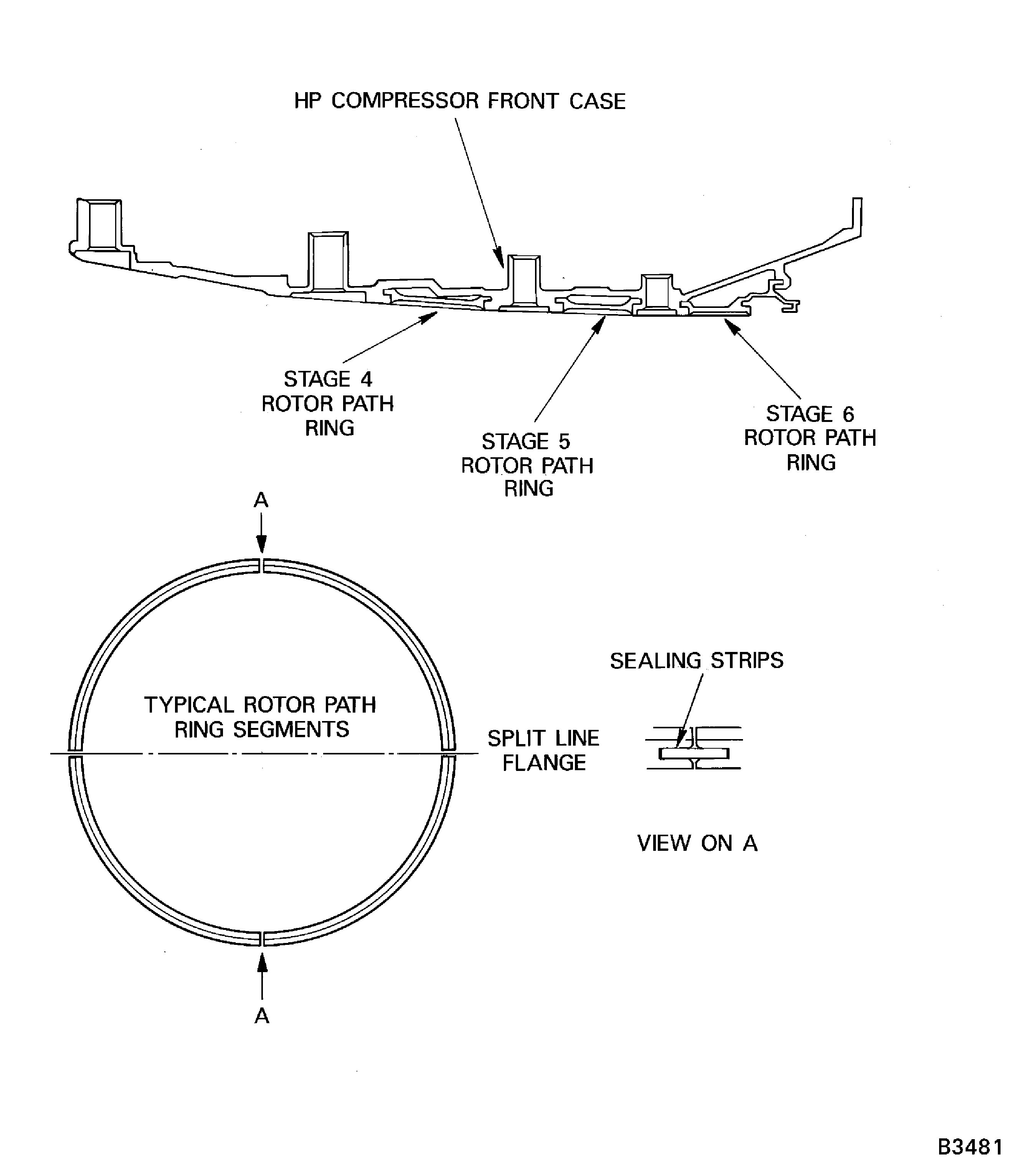

Refer to Figure.

SBE 72-0345: Introduction of revised stage 4 and 5 rotor path seal ring segments.

Remove the stage 6 stop vane installed at the center position. Use vibration peening equipment to identify the stop vane with its position number. Refer to Figure.

Remove the stage 6 rotor path ring with liners from the upper half HP compressor front case.

Pre and Post SBE 72-0345: Remove the segment of the stage 5 rotor path ring at the opposite flange to the anti-rotation pin.

Remove the stage 5 rotor path ring from the upper half HP compressor front case.

Pre and Post SBE 72-0345: Remove the stage 4 rotor path ring from the upper half HP compressor front case.

SUBTASK 72-41-30-040-064 Remove the Stages 4 to 6 Rotor Path Rings (Pre SBE 72-0345 and SBE 72-0345)

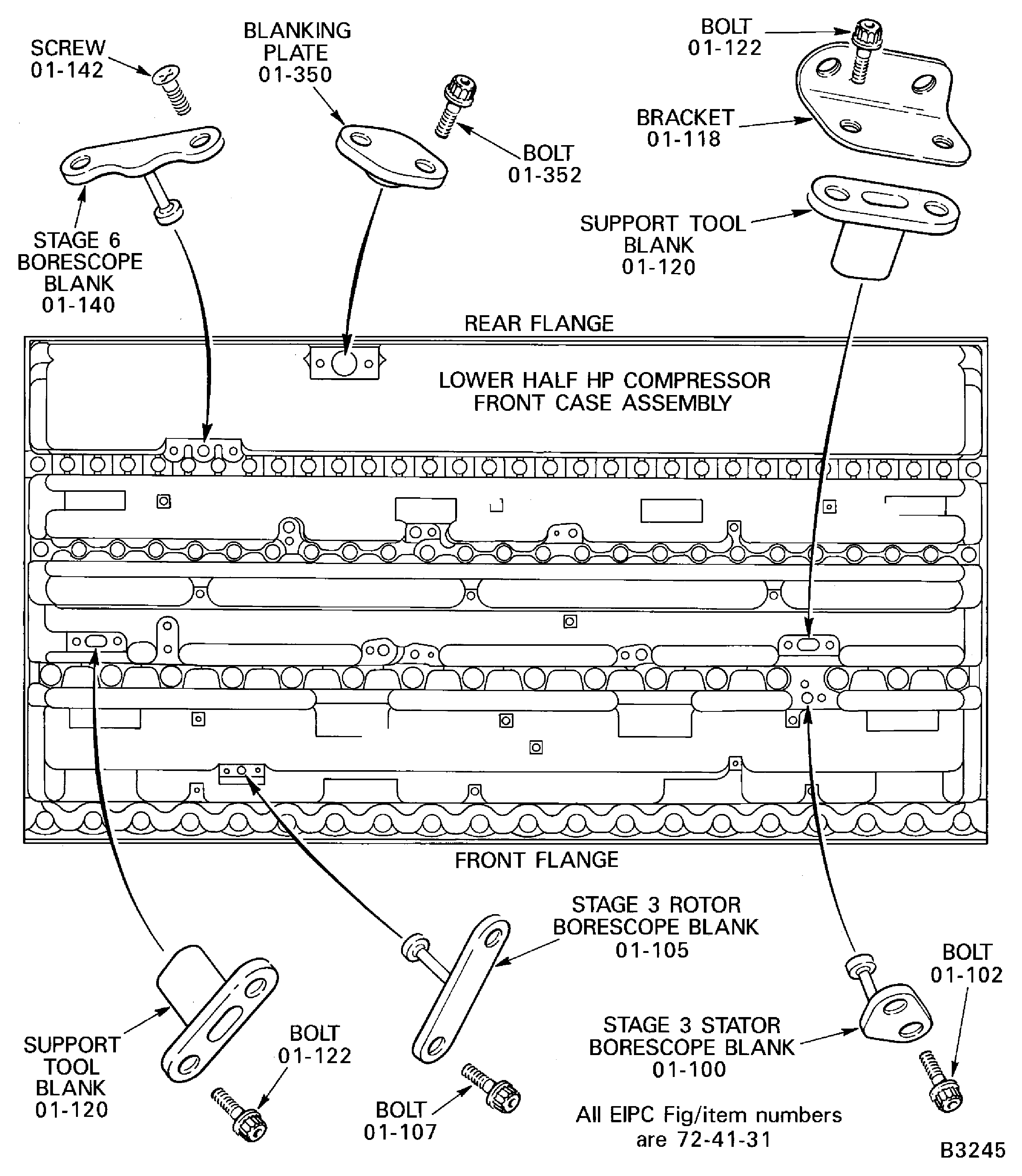

SBE 72-0265: Introduction of revised stage 5 and 6 borescope blanking plug with single bolt.

SBE 72-0317: Introduction of revised stage 5 and 6 borescope blanking plug with additional bolt.

SBE 72-0337: Introduction of revised stage 5 and 6 borescope blanking plug with increased stem diameter.

Use IAE 1R18648 Puller extractor 1 off to remove the stage 3 stator borescope blank.

Use IAE 1R18648 Puller extractor 1 off to remove the stage 3 rotor borescope blank.

Pre SBE 72-0265: Remove the two bolts which attach the stage 6 stator borescope blank to the lower half HP compressor front case.

SBE 72-0265: Remove the bolt which attaches the stage 6 stator borescope blank to the lower half HP compressor front case.

SBE 72-0317 and 72-0337: Remove the two bolts which attach the stage 6 stator borescope blank to the lower half HP compressor front case.

SUBTASK 72-41-30-040-065 Remove the Stage 3 and 6 Borescope Blanks (Pre SBE 72-0265, SBE 72-0265, Pre SBE 72-0317and Pre SBE 72-0337 and SBE 72-0317and SBE 72-0337)

Figure: View through the HP compressor front case

View through the HP compressor front case

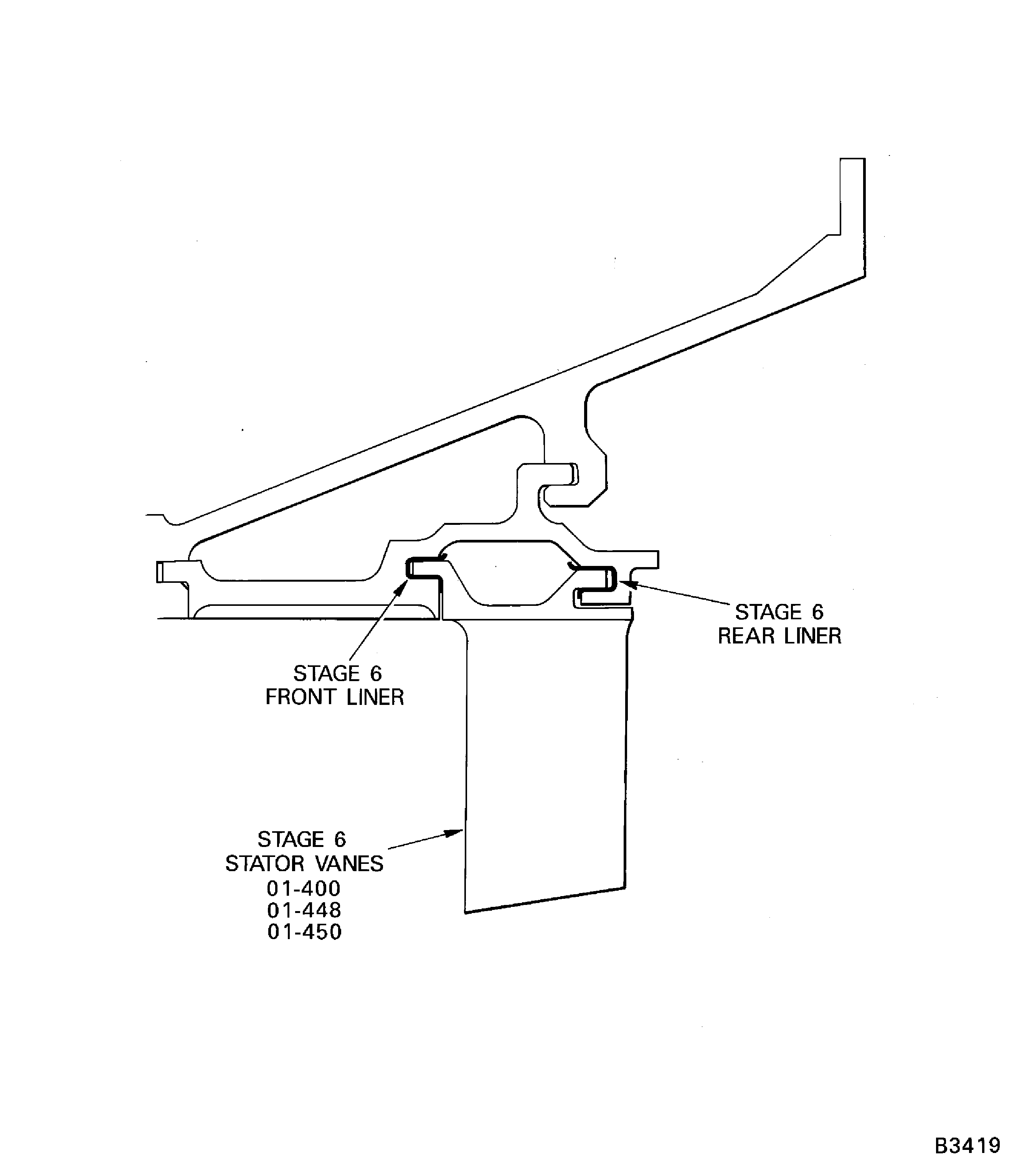

Figure: Remove the stage 6 stator vanes and the stage 6 front and rear liners

Remove the stage 6 stator vanes and the stage 6 front and rear liners

Figure: Remove the Stage 6 Stator Vanes and the Stage 6 Front and Rear Liners

Sheet 2

Figure: Remove the stage 6 stator vanes and the stage 6 front and rear liners

Remove the stage 6 stator vanes and the stage 6 front and rear liners

Figure: Remove the control rod connector brackets

Remove the control rod connector brackets

Figure: SB 72-0385 and SB 72-0416: Tools to Remove the Stator Vane Spindle Outer Bushes

Sheet 1

Figure: SB 72-0385 and SB 72-0416: Tools to Remove the Stator Vane Spindle Outer Bushes

Sheet 2

Figure: Pre SB 72-0385 and SB 72-0416: Tools to Remove the Stator Vane Spindle Outer Bushes

Sheet 3

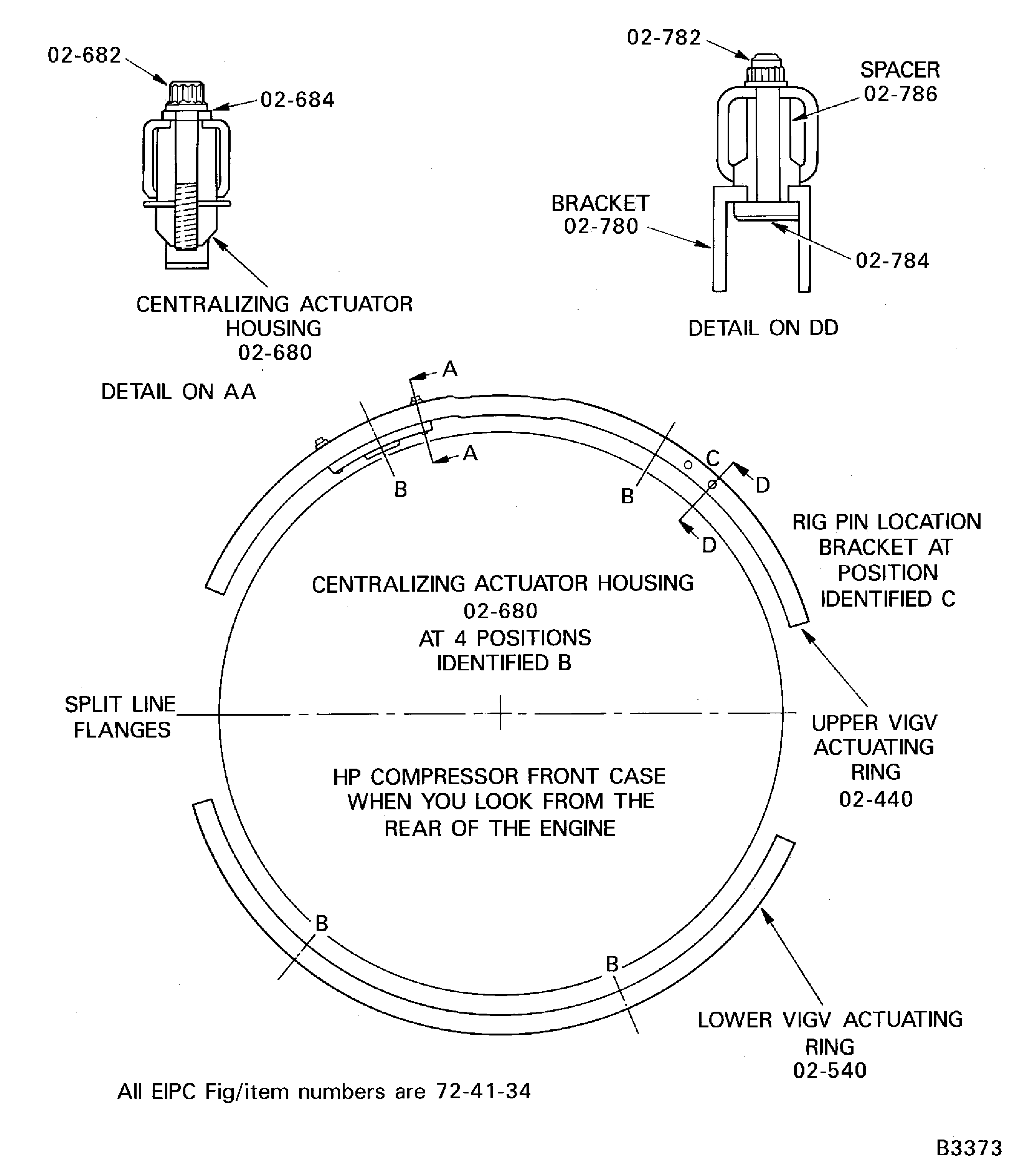

Figure: Remove the stage 5 stator vanes, the actuating ring and the centralizing pads

Sheet 1

Figure: Remove the Stage 5 Stator Vanes, the Actuating Ring and the Centralizing Pads

Sheet 2

Figure: Remove the stage 5 stator vanes, the actuating ring and the centralizing pads

Remove the stage 5 stator vanes, the actuating ring and the centralizing pads

Figure: Remove the inner bushes

Remove the inner bushes

Figure: Remove the stage 4 stator vanes, the actuating ring and the centralizing pads

Sheet 1

Figure: Remove the stage 4 stator vanes, the actuating ring and the centralizing pads

Sheet 2

Figure: Remove the Stage 4 Stator Vanes, the Actuating Ring and the Centralizing Pads

Sheet 3

Figure: Remove the stage 4 stator vanes, the actuating ring and the centralizing pads

Sheet 4

Figure: Remove the stage 3 stator vanes, the actuating ring and the centralizing pads

Sheet 1

Figure: Remove the stage 3 stator vanes, the actuating ring and the centralizing pads

Sheet 2

Figure: Remove the Stage 3 Stator Vanes, the Actuating Ring and the Centralizing Pads

Sheet 3

Figure: Remove the stage 3 stator vanes, the actuating ring and the centralizing pads

Sheet 4

Figure: Pre SBE 72-0486: Remove the Variable Inlet Guide Vanes, the Actuating Ring and the Centralizing Pads

Sheet 1

Figure: SBE 72-0486: Remove the Variable Inlet Guide Vanes, the Actuating Ring and the Centralizing Pads

Sheet 2

Figure: Remove the Variable Inlet Guide Vanes, the Actuating Ring and the Centralizing Pads

Sheet 3

Figure: Remove the Variable Inlet Guide Vanes, the Actuating Ring and the Centralizing Pads

Sheet 4

Figure: Remove the stage 4 to 6 rotor path rings

Remove the stage 4 to 6 rotor path rings

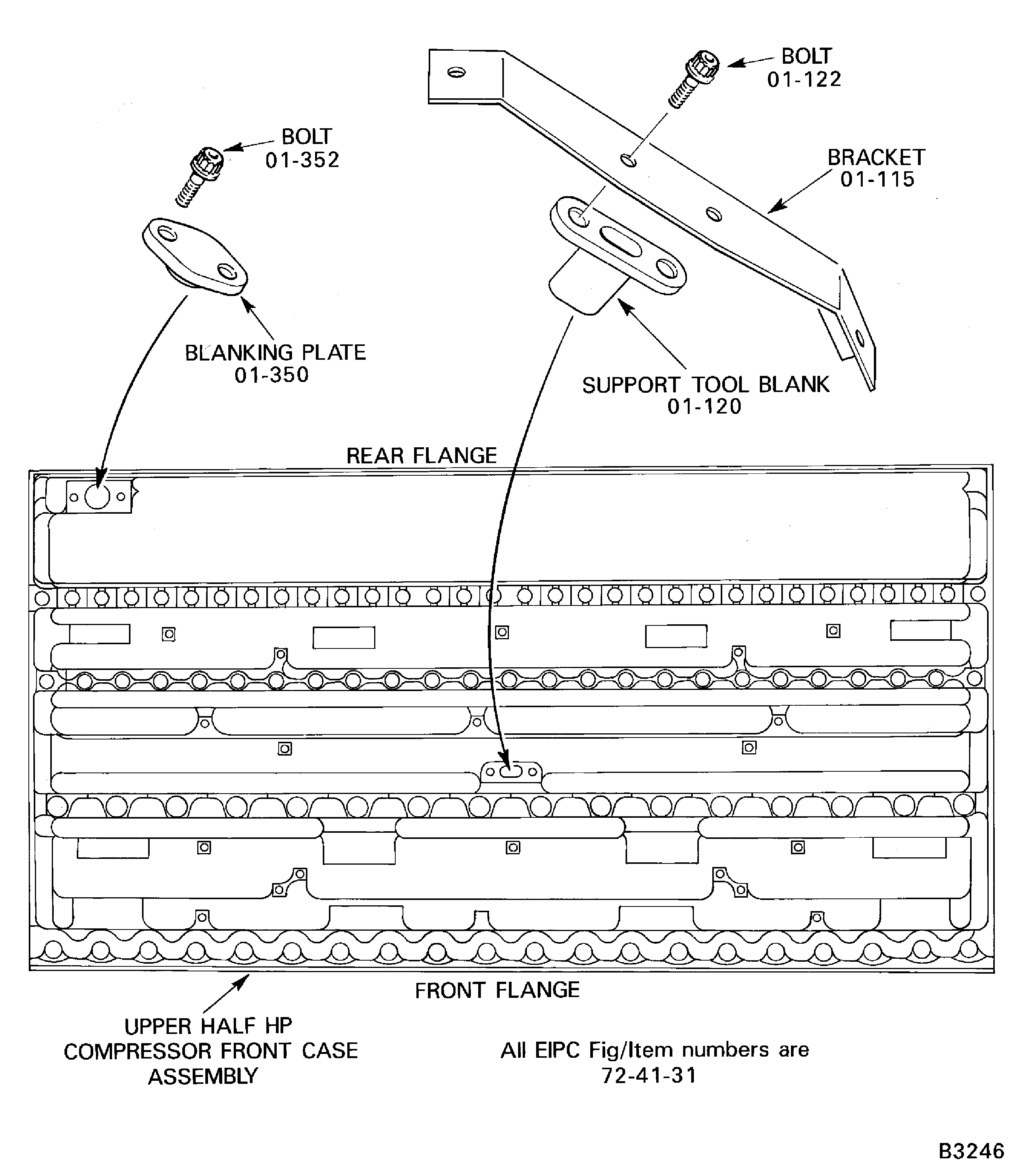

Figure: Remove the stage 3 and 6 borescope blanks and the support tool blanks

Remove the stage 3 and 6 borescope blanks and the support tool blanks

Figure: Remove the stage 3 and 6 borescope blanks and the support tool blanks

Remove the stage 3 and 6 borescope blanks and the support tool blanks