Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-31-300-027 HPC Front Cases - Weld Repair The Stage 6 VSV Gas Washed Surface And Stage 6 VSV Counterbore Recesses, Repair-027 (VRS6629)

General

This repair must only be done when the instruction to do so is given in 72-41-31 Inspection.

This repair gives the instruction to repair damage to the HP Compressor Front Case Assembly Stage 6 VSV Gas Washed Surface and Stage 6 VSV Counterbore Recesses by Welding.

This is a source demonstrated repair which can only be done by approved vendors.

Repair Facilities

The Source Demonstration requirements of this repair means that any facility not authorized to accomplish this repair either, utilize the Authorized Repair Vendors listed below or contact the IAE Repair Services Group to determine if a qualification program can be initiated at their facility.

IAE - INTERNATIONAL AERO ENGINES AG

ROLLS-ROYCE PLC

P.O. BOX 31

DERBY DE24 8BJ

ENGLAND

ATTN: Manager Technical Services

Authorized Repair Vendors for repair VRS6629 are listed below:

ROLLS-ROYCE PLC

AERO REPAIR AND OVERHAUL

MAVOR AVENUE

NERSTON

EAST KILBRIDE

GLASGOW G74 4PY

SCOTLAND

PRATT AND WHITNEY PSD INC

275 E. ROBINSON

SPRINGDALE

ARKANSAS 72764

U.S.A.

The designation by IAE of an Authorized Repair Vendor indicates that the Repair Vendor has demonstrated the necessary capability to enable it to carry out the listed repair work. However, IAE makes no warranties or representations concerning the qualifications or quality standards of the Repair Vendors to carry out the repair work and accepts no responsibility whatsoever for any work that may be carried out by a Repair Vendor other than when IAE is listed as the Repair Vendor. Authorized Repair Vendors do not act as agents or representatives of IAE.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| IAE 3R19420 Retaining Ring | 0AM53 | IAE 3R19420 | 1 | |

| IAE 3R19421 Location Pin | 0AM53 | IAE 3R19421 | 10 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 | ||

| CoMat 05-075 WATERPROOF SILICON CARBIDE | IE241 | CoMat 05-075 | ||

| CoMat 05-106 ABRASIVE STONE | K6835 | CoMat 05-106 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 |

Spares

NONESafety Requirements

NONEProcedure

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - DO NOT USE FORCE WITH MECHANICAL CUTTERS OR THE MATERIAL WILL BECOME TOO HOT.

CAUTION

TITANIUM COMPONENT - MAXIMUM SPEED FOR MECHANICAL TOOLS MUST NOT EXCEED 1000 REVOLUTIONS PER MINUTE.

CAUTION

TITANIUM COMPONENT - YOU MUST MAKE SURE THAT DURING DRESSING, BLENDING AND POLISHING NO SPARKS ARE PRODUCED. MASK ADJACENT AREAS OF THE COMPONENT.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.Refer to the SPM TASK 70-35-03-300-501.

Remove highspots and damage to depth.

Remove no more material than is necessary.

Use standard workshop equipment.

Remove the area(s) of damage as necessary.

SUBTASK 72-41-31-350-100 Remove the Damage

Use IAE 3R19420 Retaining Ring, 1 off and IAE 3R19421 Location Pin, 10 off.

Install the retaining ring on to the HPC Front Case Assembly rear flange, (Datum C).

SUBTASK 72-41-31-350-101 Assemble the Front Case Half Cases

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - DO NOT USE FORCE WITH MECHANICAL CUTTERS OR THE MATERIAL WILL BECOME TOO HOT.

CAUTION

TITANIUM COMPONENT - MAXIMUM SPEED FOR MECHANICAL TOOLS MUST NOT EXCEED 1000 REVOLUTIONS PER MINUTE.

CAUTION

TITANIUM COMPONENT - YOU MUST MAKE SURE THAT DURING DRESSING, BLENDING AND POLISHING NO SPARKS ARE PRODUCED.MASK ADJACENT AREAS OF THE COMPONENT.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.

CAUTION

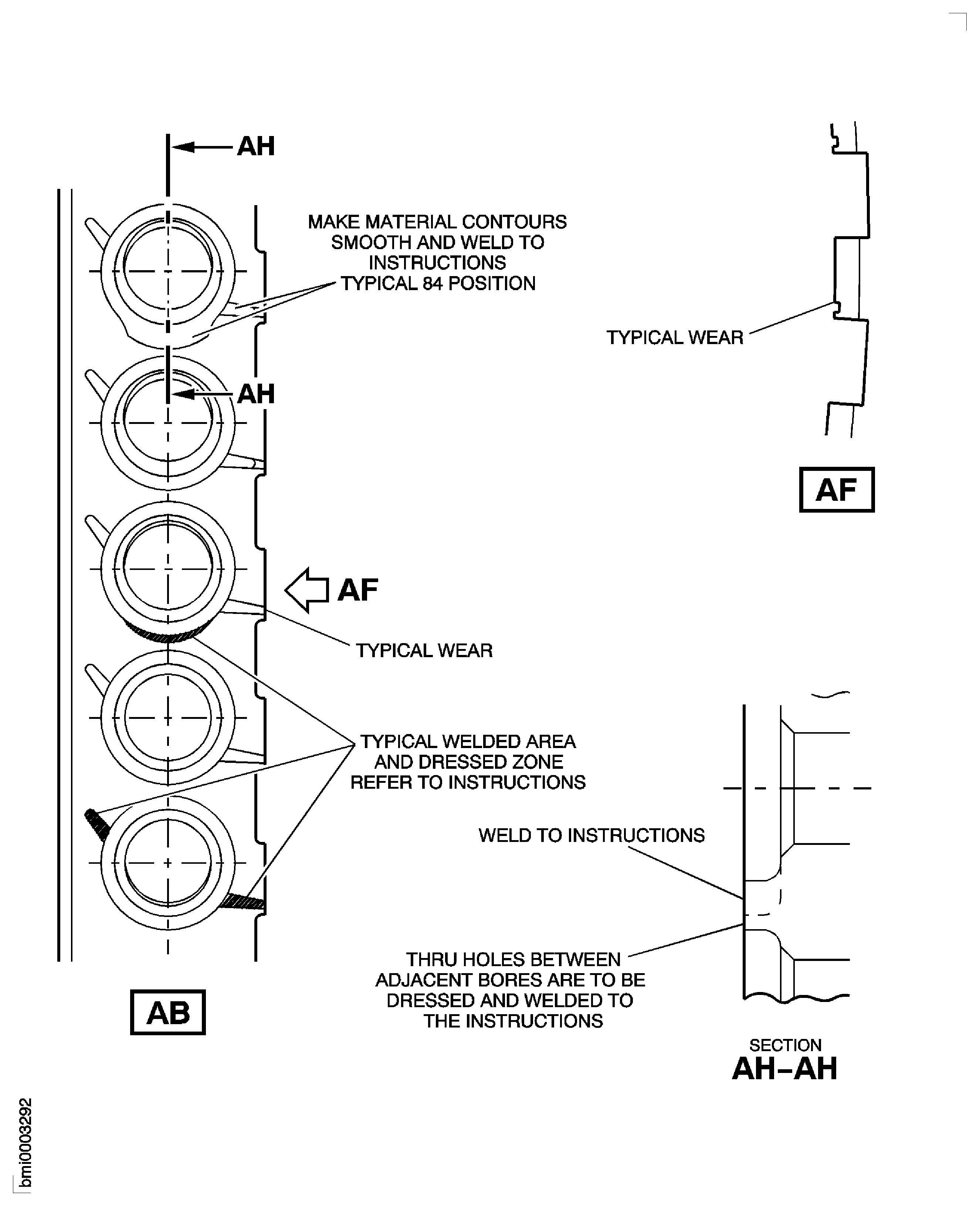

YOU MUST ENSURE THAT DURING THE DRESSING OPERATION THE MINIMUM AMOUNT OF PARENT MATERIAL IS REMOVED FROM SURFACE AH.

CAUTION

YOU MUST ONLY REMOVE MATERIAL FROM AREA(S) THAT HAVE BEEN WELDED ON SURFACE AH.Refer to the SPM TASK 70-35-03-300-501.

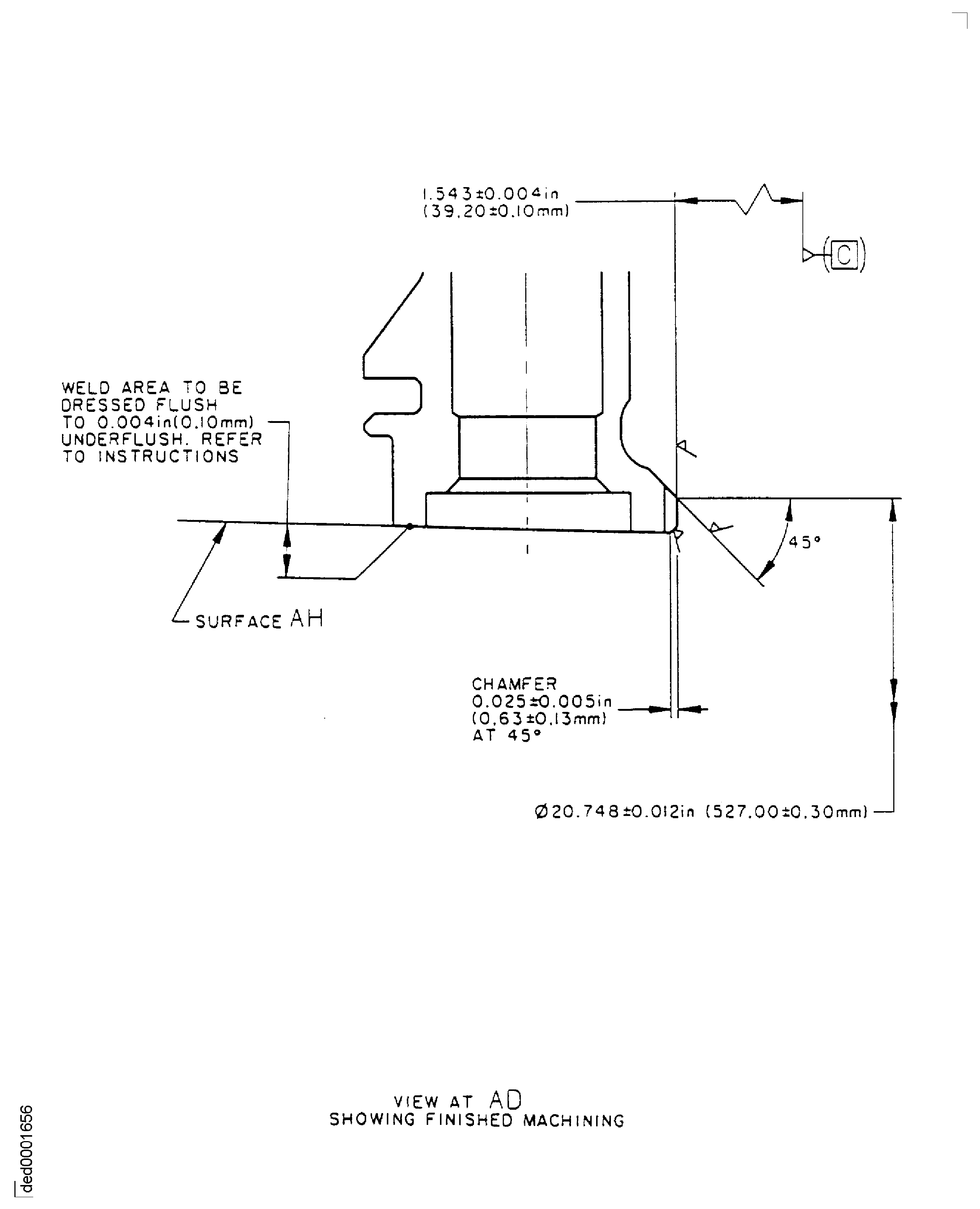

Dress the area(s) of weld on surface AH only.

NOTE

The dressing of the weld bead must be flush to underflush, refer to the limits given in Figure.

It is mandatory that during operation 13 the retaining fixture and location pins remain installed.

SUBTASK 72-41-31-230-113 Dress Surface AH of the HP Compressor Front Case Assembly

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - DO NOT USE FORCE WITH MECHANICAL CUTTERS OR THE MATERIAL WILL BECOME TOO HOT.

CAUTION

TITANIUM COMPONENT - MAXIMUM SPEED FOR MECHANICAL TOOLS MUST NOT EXCEED 1000 REVOLUTIONS PER MINUTE.

CAUTION

TITANIUM COMPONENT - YOU MUST MAKE SURE THAT DURING DRESSING, BLENDING AND POLISHING NO SPARKS ARE PRODUCED.MASK ADJACENT AREAS OF THE COMPONENT.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.

SUBTASK 72-41-31-230-115 Machine the HP Compressor Front Case Stage 6 VSV Counterbore Recesses

Refer to the SPM TASK 70-23-05-230-501.

Use CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) with penetrant crack test equipment.

Cracks are not permitted.

Do a local penetrant crack test on the repaired area(s).

SUBTASK 72-41-31-230-116 Do a Crack Test

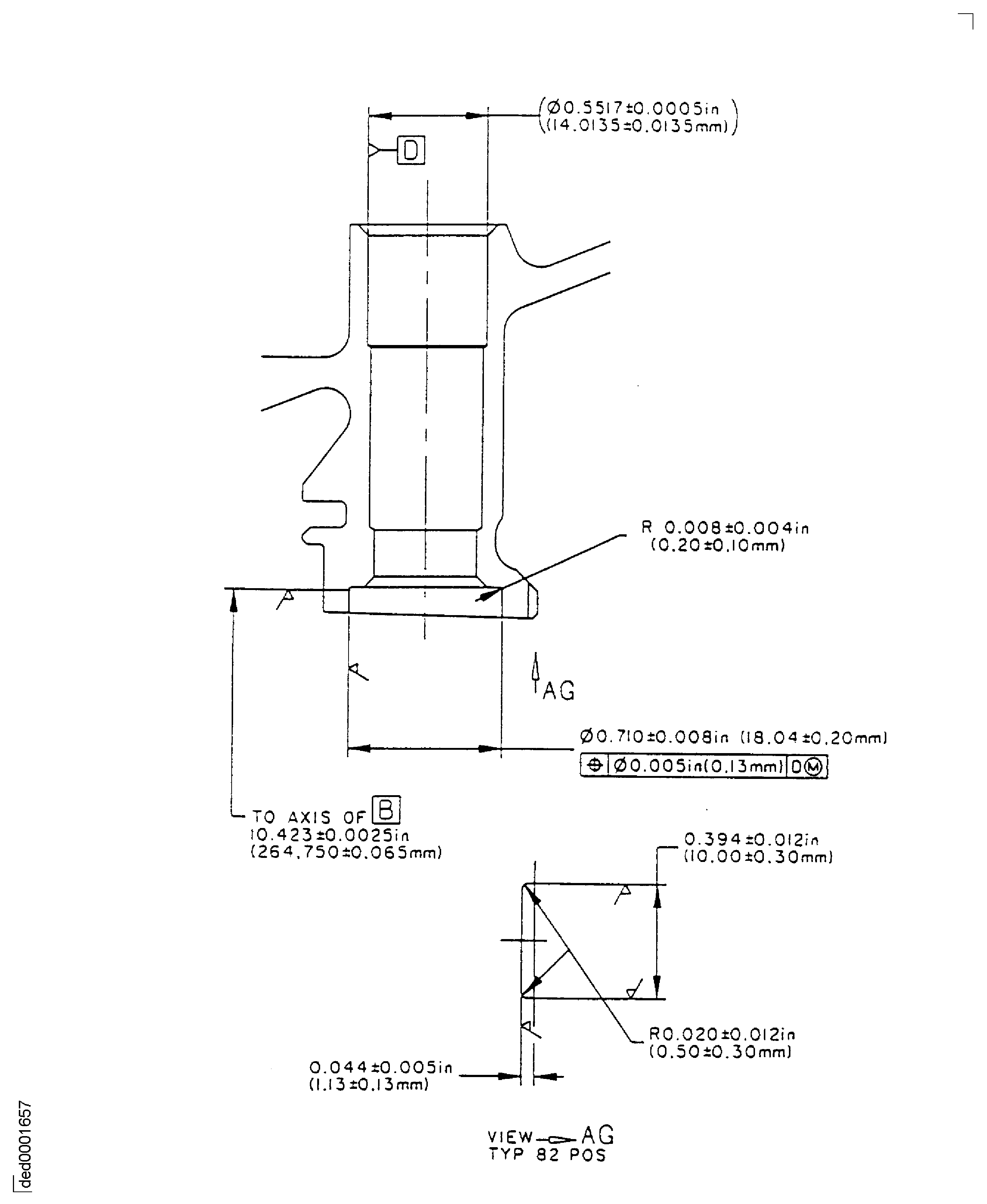

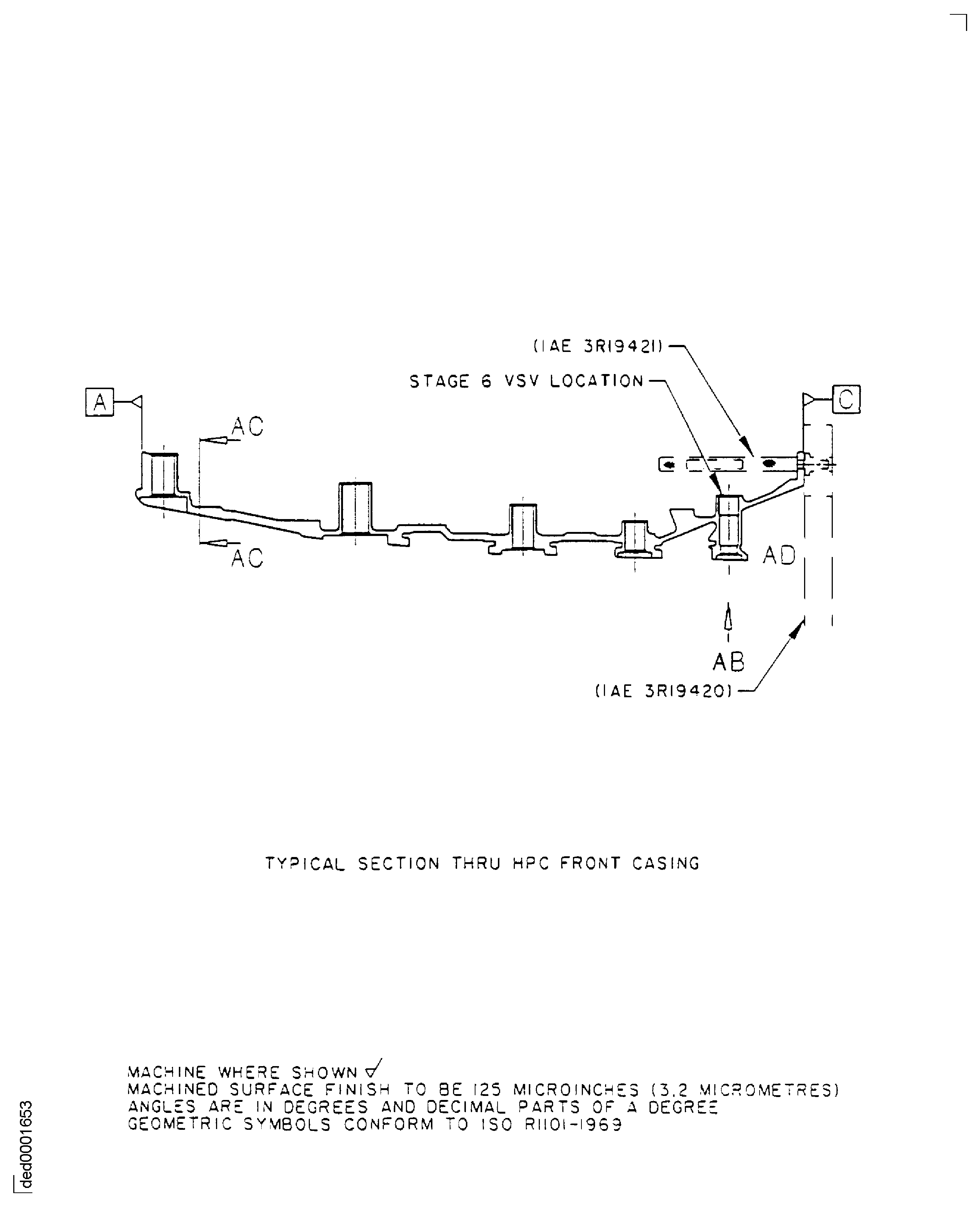

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions