Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-31-300-010 HPC Stage 6 Rotor Path Segment - Replace The Lining, Repair-010 (VRS6245)

General

This repair must only be done when the instruction to do so is given in 72-41-31 Inspection-XXX.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

After this repair the rotor path will be completed during assembly.

Price and availability

Refer to International Aero Engines.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Abrasive blast equipment | LOCAL | Abrasive blast equipment | ||

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Hardness tester | LOCAL | Hardness tester | ||

| Metal spray equipment | LOCAL | Metal spray equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Bottle | LOCAL | Bottle | Polythene | |

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-025 NITRIC ACID HNO3, TECHNICAL GRADE | LOCAL | CoMat 01-025 | ||

| CoMat 01-041 ALKALINE RUST REMOVER | LOCAL | CoMat 01-041 | ||

| CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY) | LOCAL | CoMat 02-198 | ||

| CoMat 03-036 METAL SPRAYING WIRE, Ni,Al | LOCAL | CoMat 03-036 | ||

| CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) | IE200 | CoMat 03-038 | ||

| CoMat 03-057 ALUMINIUM ALLOY/POLYESTERCOMPOSITE | LOCAL | CoMat 03-057 | ||

| CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5) | 00741 | CoMat 03-089 | ||

| CoMat 03-090 METAL SPRAYING POWDER Ni/Al (95/5) | 0AM53 | CoMat 03-090 | ||

| CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE | LOCAL | CoMat 05-001 | ||

| CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) | LOCAL | CoMat 06-063 |

Spares

NONESafety Requirements

NONEProcedure

Refer to the SPM TASK 70-33-59-300-503, SUBTASK 70-33-59-300-003.

Use CoMat 01-041 ALKALINE RUST REMOVER alkali rust remover.

Use chemical cleaning equipment.

Chemically remove the abradable lining.

SUBTASK 72-41-31-330-053 Chemically Remove the Abradable Lining

Refer to the SPM TASK 70-33-59-300-503, SUBTASK 70-33-59-300-002.

Use chemical cleaning equipment.

Put the assembly into the nitric acid and keep below the surface.

Stripping is complete when gassing stops.

Remove assembly from the acid immediately after gassing stops.

Chemically remove the bond coat.

SUBTASK 72-41-31-330-054 Chemically Remove the Bond Coat

Use CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY) or locally made fixture.

Seal the areas not to be sprayed.

SUBTASK 72-41-31-350-061 Seal the Areas not to be Sprayed

Abrasive blast.

SUBTASK 72-41-31-120-054 Abrasive Blast the Areas to be Sprayed

CAUTION

TO PREVENT CONTAMINATION, DO NOT TOUCH THE SURFACE WHICH IS CLEANED FOR REPAIR.

CAUTION

DO NOT DWELL IN ONE AREA, USE CONTINUOUS MOTION. EXTENDED DURATION OF ABRASIVE BLASTING CAN CAUSE DETERIORATION OF THE PREPARED SURFACE CONDITION AND MUST BE PREVENTED.Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-025 or SUBTASK 70-34-01-340-010.

For powder feed plasma spray gun, use CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5), CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5) or CoMat 03-090 METAL SPRAYING POWDER Ni/Al (95/5).

Alternatively for the wire feed combustion spraying, use CoMat 03-036 METAL SPRAYING WIRE, Ni,Al.

Pre heat the seal ring to 221 deg F to 257 deg F (105 deg C to 125 deg C).

Apply to a thickness of 0.0030 to 0.0050in. (0.076 to 0.127 mm).

Use metal spray equipment.

Apply bond coat to a test piece.

Apply the bond coat.

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-304-020.

Use metal spray equipment.

Apply a sufficient thickness to allow for machining.

Apply abradable lining to a test piece to check the spray hardness.

Recommended Guideline Spraying Data (METCO 7M and METCO 9M Systems)

Spray distance

150 mm

Voltage

75 v

Current

500 A

Power

37.5 Kw

Power feed rate

52.5 g/min

Argon pressure

100 psi

Argon flow

190

Hydrogen pressure

50 psi

Hydrogen flow

6

Apply the abradable lining.

SUBTASK 72-41-31-340-052 Apply the Abradable Lining to the Repaired Part and Test Piece

Refer to the SPM TASK 70-34-01-340-501.

Visually examine the sprayed coating on the ring.

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-004.

Use hardness testing equipment.

Average hardness must be 55 to 85 R15Y, outer limits 50 min, 90 max.

If the hardness value is outside the limits, reject the assembly and do the repair again.

Do a hardness test on the sprayed coating on the test piece.

SUBTASK 72-41-31-220-133 Examine the Stage 6 Rotor Path Lining

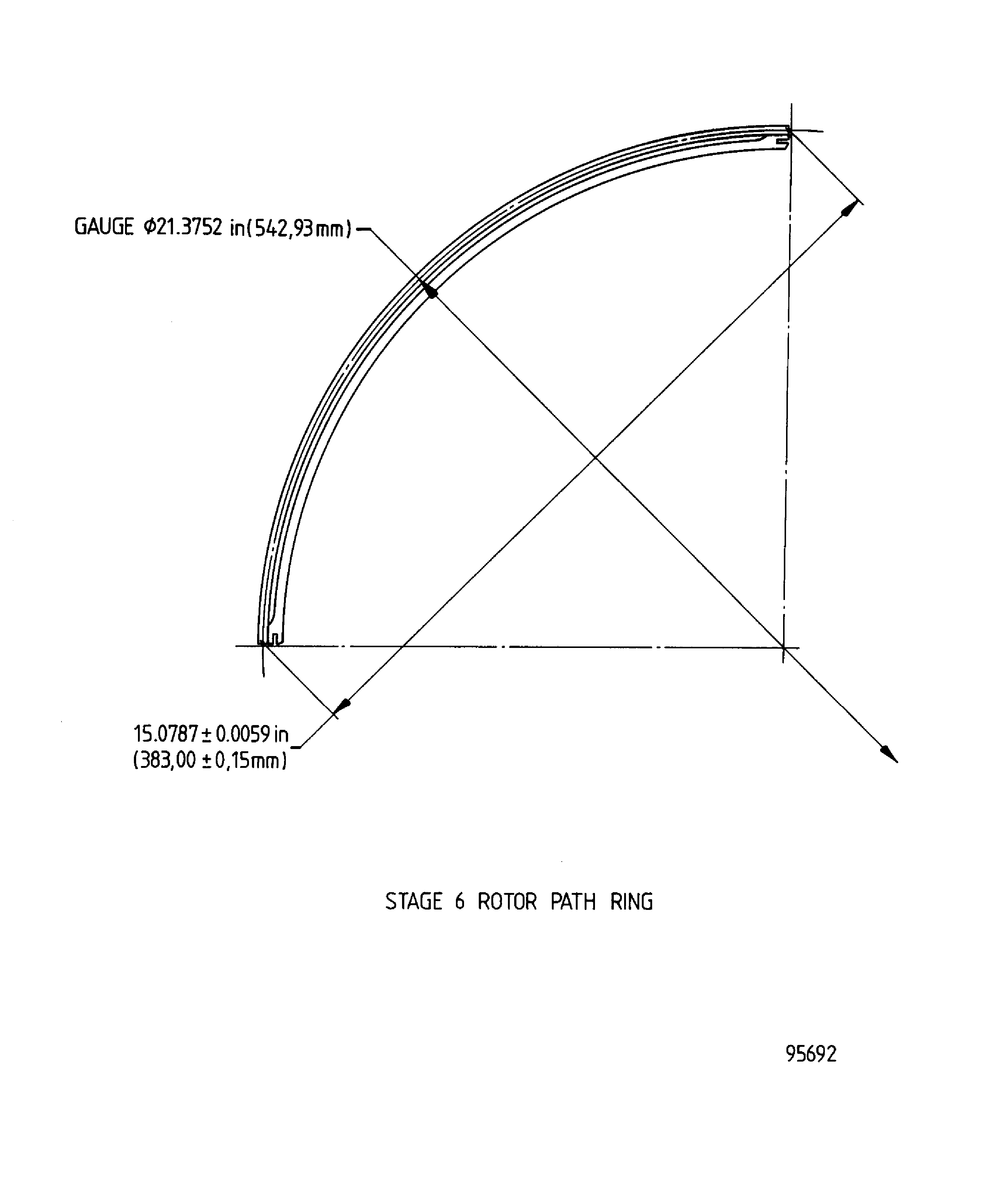

Refer to Figure.

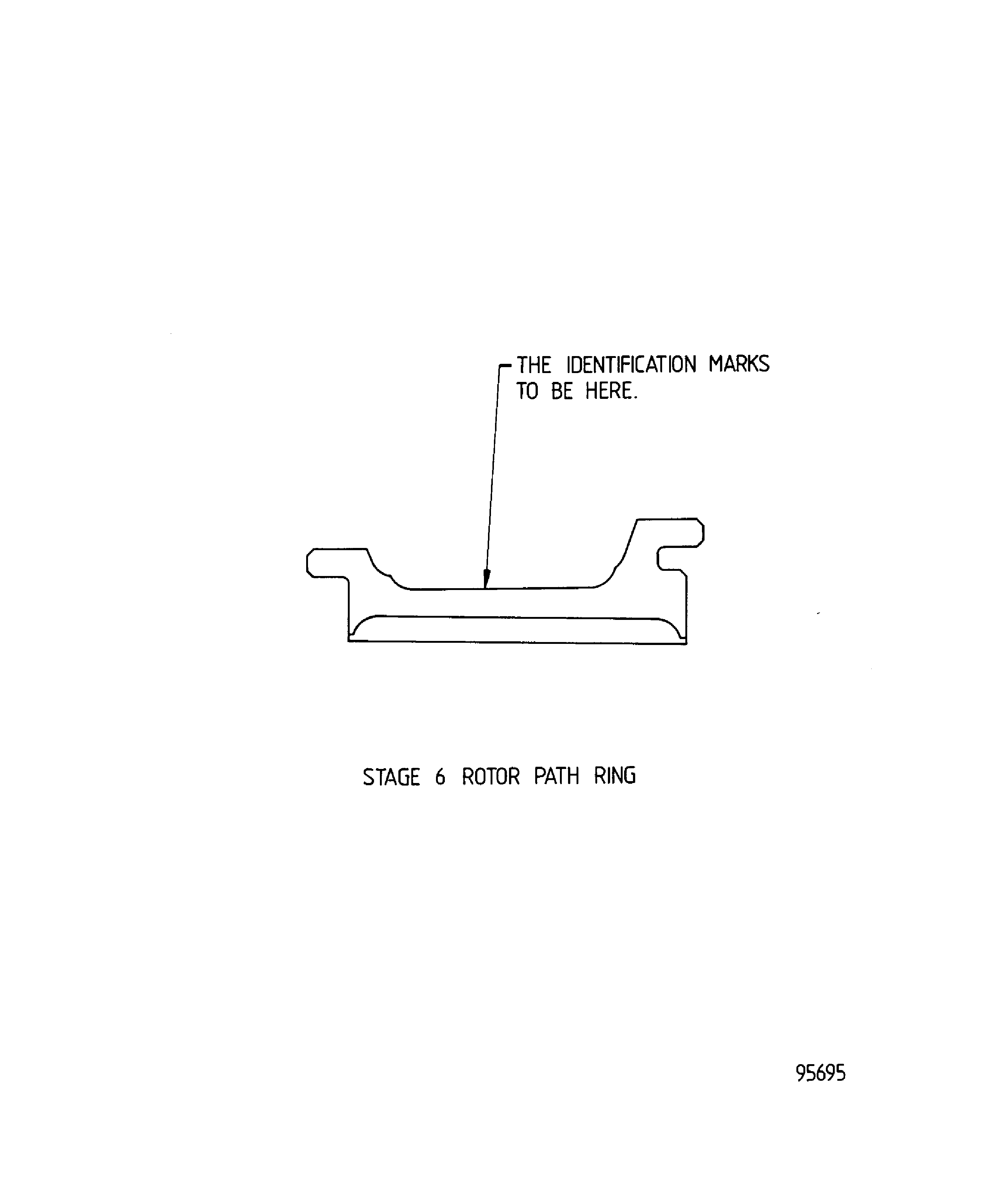

SUBTASK 72-41-31-350-064 Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions

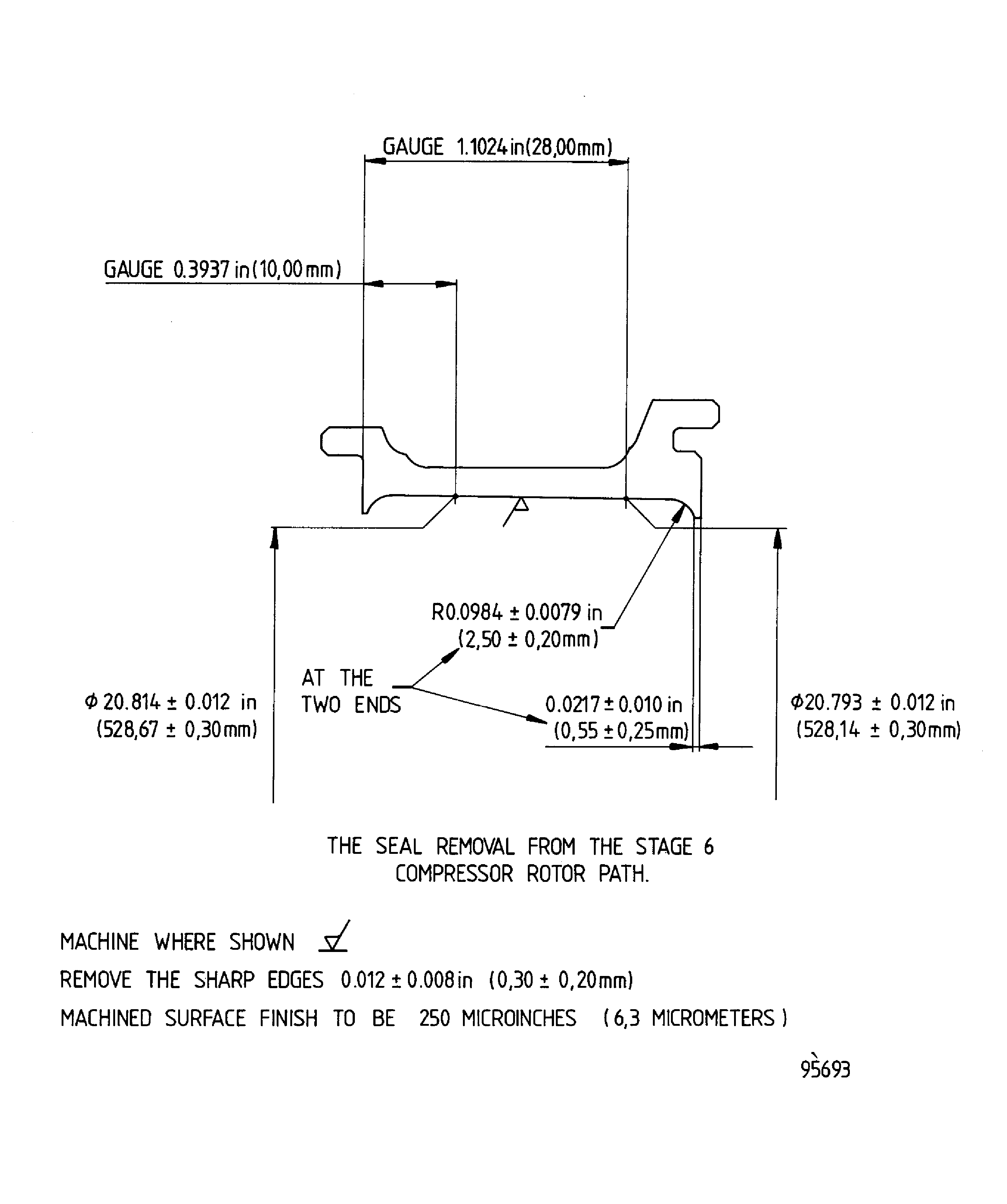

Figure: Repair Details and Dimensions

Repair Details and Dimensions

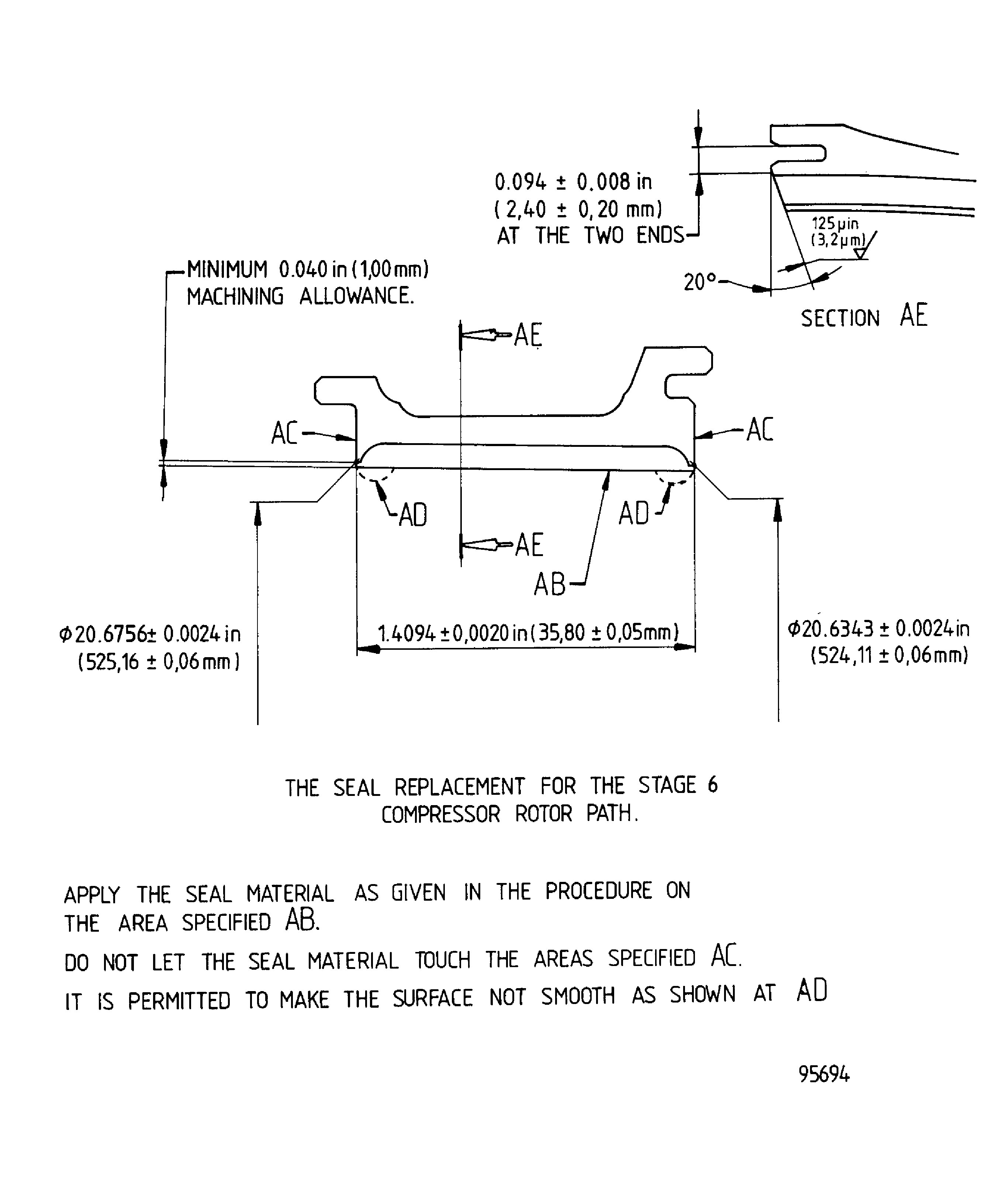

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions (Assembly B)

Repair Details and Dimensions (Assembly B)

Figure: Repair Details and Dimensions (Assembly B)

Repair Details and Dimensions (Assembly B)

Figure: Repair Details and Dimensions (Assembly B)

Repair Details and Dimensions (Assembly B)

Figure: Repair Details and Dimensions (Assembly B)

Repair Details and Dimensions (Assembly B)