Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-32-300-004 HPC Stage 3 Variable Stator Vane - Vibro Polish To Restore The Surface Finish, Repair-004 (VRS6076)

Effectivity

FIG/ITEM | PART NO. | ASSEMBLY |

|---|---|---|

02-500 | 6A3813 | A |

02-500 | 6A3883 | A |

02-500 | 6A4401 | C |

02-500 | 6A5677 | C |

02-500 | 6A7729 | C |

02-500 | 6A8720 | E |

02-500 | 6B1271 | E |

02-550 | 6B1273 | G |

02-600 | 6A3815 | B |

02-600 | 6A3884 | B |

02-600 | 6A4402 | D |

02-600 | 6A5678 | D |

02-600 | 6A7730 | D |

02-600 | 6A8721 | F |

02-600 | 6B1272 | F |

Material of component

PART IDENT | MATERIAL | |

|---|---|---|

HP Compressor - Stage 3 VSV | Corrosion resistant steel or Nickel chromium alloy |

General

This repair must only be done when the instruction to do so is given in 72-41-32 Inspection/Check.

This repair gives the procedure to vibro-polish the HP compressor stage 3 variable stator vanes (VSV).

The stage 3 VSV must have been repaired, where necessary and inspected before vibro-polishing.

The stage 3 VSV can only have this repair completed on it three times.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and Availability

Refer to International Aero Engines

Related Repairs - None

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Degreasing Equipment | LOCAL | Degreasing Equipment | ||

| Surface Finish Measuring Equipment | LOCAL | Surface Finish Measuring Equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| Vibro-polishing equipment | LOCAL | Vibro-polishing equipment | ||

| IAE 3R18587 Mask | 0AM53 | IAE 3R18587 | 1 | |

| IAE 3R18588 Mask | 0AM53 | IAE 3R18588 | 1 | |

| IAE 3R18589 Mask | 0AM53 | IAE 3R18589 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-003 ADHESIVE TAPE BLACK WATERPROOF | LOCAL | CoMat 02-003 | ||

| CoMat 05-093 SUPERFINISHING MEDIA, CERAMIC, ANGLE CUT TRIANGLE | IAE56 | CoMat 05-093 | ||

| CoMat 05-093A SUPERFINISHING MEDIA, CERAMIC TRISTAR | IAE56 | CoMat 05-093A | ||

| CoMat 05-093B SUPERFINISHING MEDIA, CERAMIC, ANGLE CUT TRIANGLE | IE429 | CoMat 05-093B | ||

| CoMat 05-093C SUPERFINISHING MEDIA, CERAMIC ANGLE CUT TRISTAR | IE429 | CoMat 05-093C | ||

| CoMat 05-093D SUPERFINISHING MEDIA, CERAMIC TRIANGLE | U2008 | CoMat 05-093D | ||

| CoMat 05-095 LIQUID COMPOUND (VIBROPOLISHING FINISHING FLUID) | IE230 | CoMat 05-095 | ||

| CoMat 05-095A LIQUID COMPOUND (VIBROPOLISHING FINISHING FLUID) | IE429 | CoMat 05-095A | ||

| CoMat 05-181 VIBRO POLISHING MEDIA, CERAMIC PIN | LOCAL | CoMat 05-181 | ||

| CoMat 05-182 VIBRO POLISHING COMPOUND, LIQUID | IAE56 | CoMat 05-182 | ||

| CoMat 05-183 VIBRO POLISHING PASTE | IAE56 | CoMat 05-183 |

Spares

NONESafety Requirements

NONEProcedure

Use IAE 3R18588 Mask 1 off and IAE 3R18589 Mask 1 off and/or CoMat 02-003 ADHESIVE TAPE BLACK WATERPROOF.

Apply the mask to the minimum area of the VSV air washed surface.

Apply mask to the Stage 3 VSV spindles.

SUBTASK 72-41-32-350-058-A00 Apply the Mask to the stage 3 VSV, Assembly A, Assembly C, Assembly E and Assembly G

Use IAE 3R18587 Mask 1 off and IAE 3R18588 Mask 1 off and/or CoMat 02-003 ADHESIVE TAPE BLACK WATERPROOF.

Apply the mask to the minimum area of the VSV air washed surface.

Apply mask to the stage 3 VSV spindles.

SUBTASK 72-41-32-350-058-B00 Apply the Mask to the Stage 3 VSV, Assembly B, Assembly D and Assembly F

Refer to Figure.

Refer to the SPM TASK 70-38-25-380-501.

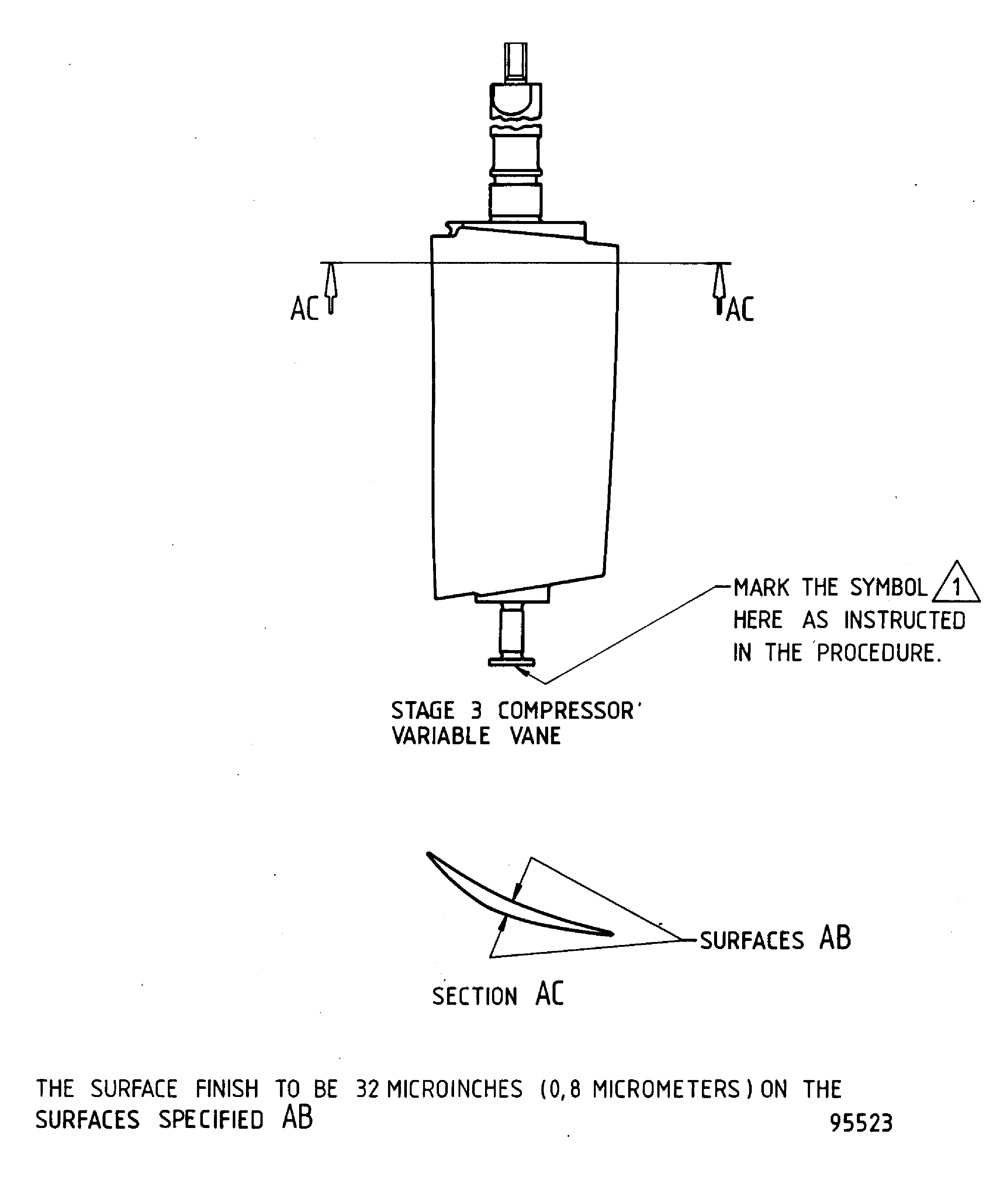

Polish the surfaces in the area specified AB as given in the procedure.

The surface finish is to be 32 microinches (0.80 micrometers).

Do not have more than five VSV for one cubic foot of the superpolishing media.

Use vibro-polish facility.

Use one of the superpolishing media and one of the liquid compounds given below:

Vibro-polish the VSV airfoil and the adjacent annulus surfaces. Prepare the component for inspection.

SUBTASK 72-41-32-380-052-A00 Vibro-Polish the Stage 3 VSV Airfoil, Assembly A and Assembly B

CAUTION

THIS VSV IS A GLASS BEAD PEENED COMPONENT. DO NOT ABRASIVE BLAST THE VSV.Refer to Figure.

Refer to the SPM TASK 70-38-25-380-501.

The surface finish is to be 16 microinches (0.40 micrometers) on a minimum of 70 percent of the surface area.

On the remainder of the VSV the surface finish is to be between 16 microinches (0.40 micrometers) and 32 microinches (0.80 micrometers).

Do not have more than five VSV for one cubic foot of the superpolishing media.

Use vibro-polish facility.

Use one of the superpolishing media and one of the liquid compounds given below:

Vibro-polish the VSV airfoil and adjacent annulus surfaces. Prepare the component for inspection.

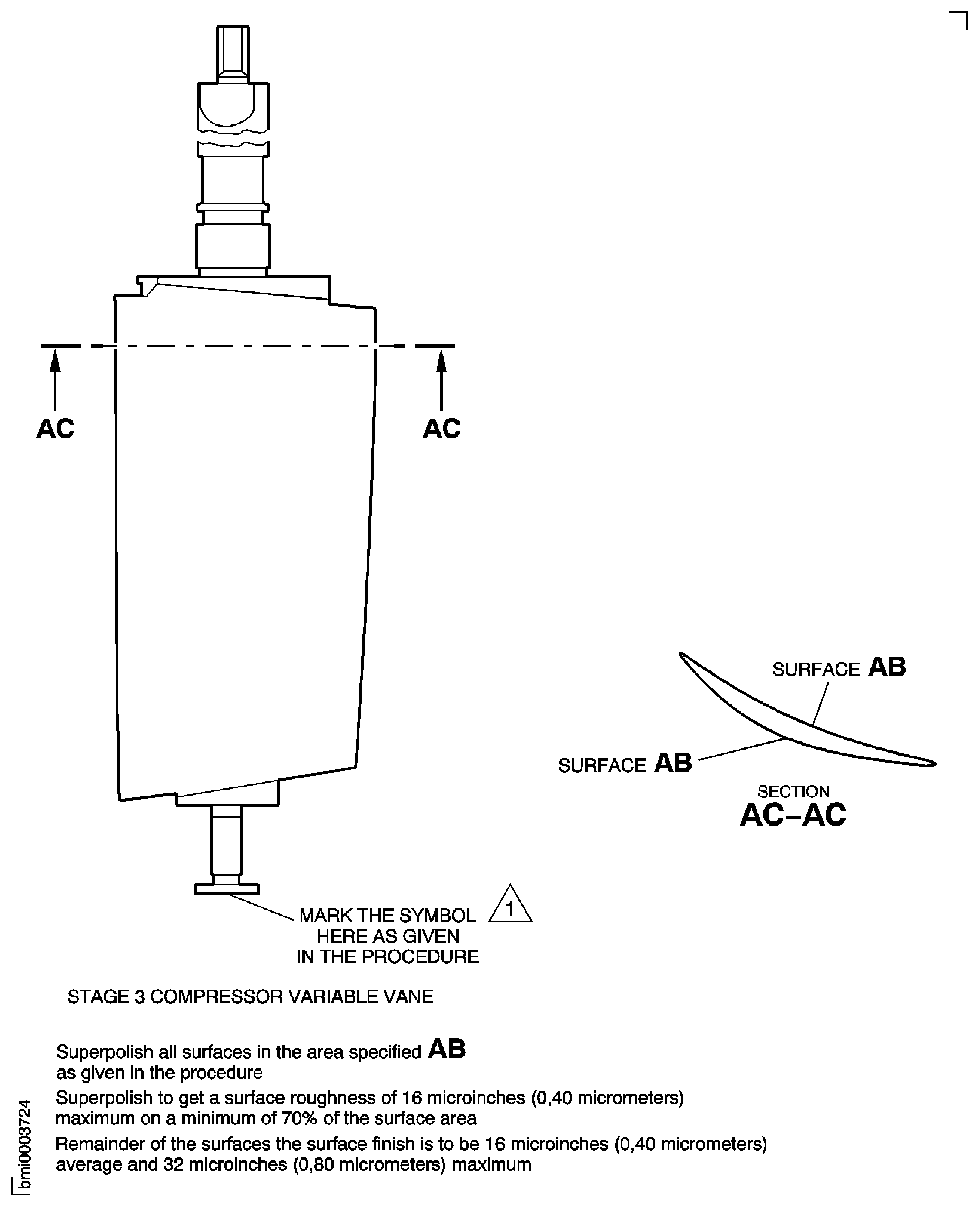

SUBTASK 72-41-32-380-052-B00 Vibro-Polish the Stage 3 VSV Airfoil, Assembly C and Assembly D

CAUTION

THIS VSV IS A GLASS BEAD PEENED COMPONENT. DO NOT ABRASIVE BLAST THE VSV.Refer to Figure.

Refer to the SPM TASK 70-38-25-380-501.

Polish the surfaces in the area specified AB as given in the procedure.

The VSV airfoil and fillet surfaces are to have a surface finish of 10 microinches (0.25 micrometers).

On the remainder of the VSV the surface finish is to be 16 microinches (0.40 micrometers) maximum.

Do not have more than five VSV for one cubic foot of the superpolishing media.

Use vibro-polish facility.

Use one of the superpolishing media and one of the liquid compounds given below:

Vibro-polish the VSV airfoil and adjacent annulus surfaces. Prepare the component for inspection.

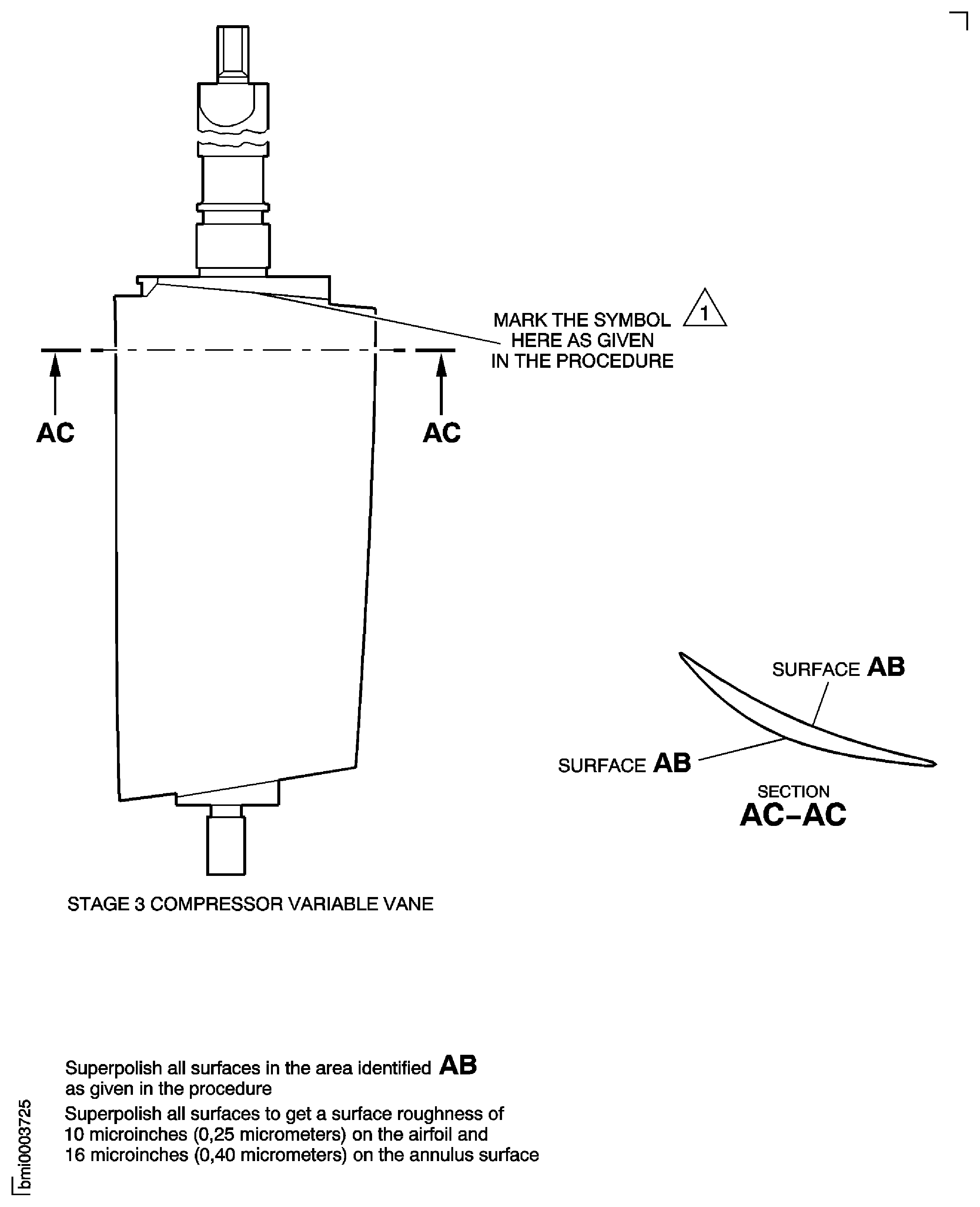

SUBTASK 72-41-32-380-052-C00 Vibro-Polish the Stage 3 VSV Airfoil, Assembly E, Assembly F and Assembly G

Refer to Figure.

SUBTASK 72-41-32-220-105-A00 Examine the Stage 3 VSV Surface Finish, Assembly A and Assembly B

Refer to Figure.

NOTE

Check the surface finish on the two sides of the airfoil and the adjacent surfaces in the area specified AB. The surface finish is to be 16 microinches (0.40 micrometers) on minimum of 70 percent of the surface area. On the remainder of the VSV the surface finish is to be between 16 microinches (0.40 micrometers) and 32 microinches (0.80 micrometers).

SUBTASK 72-41-32-220-105-B00 Examine the Stage 3 VSV Surface Finish, Assembly C and Assembly D

Refer to Figure.

SUBTASK 72-41-32-220-105-C00 Examine the Stage 3 VSV Surface Finish, Assembly E, Assembly F and Assembly G

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

If this is the first time this repair has been completed on the VSV, vibro engrave a 1 in a triangle adjacent to the part number.

If this is the second time this repair has been completed on the VSV, vibro engrave /1 adjacent to the triangle.

If this is the third time this repair has been completed on the VSV, vibro engrave /2 adjacent to the triangle.

Use vibro-engraving equipment.

Identify the repair.

SUBTASK 72-41-32-350-059 Identify the Repair

Figure: Repair Details and Dimensions - Assembly A and Assembly B

Repair Details and Dimensions - Assembly A and Assembly B

Figure: Repair Details and Dimensions - Assembly C and Assembly D

Repair Details and Dimensions - Assembly C and Assembly D

Figure: Repair Details and Dimensions - Assembly E, Assembly F and Assembly G

Repair Details and Dimensions - Assembly E, Assembly F and Assembly G