Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-38-25-380-501 Superfinishing

Table of Contents

Introduction | ||

Equipment and Materials | ||

Makeup and Control of the Superfinishing Media | ||

Control of the Superfinish Achieved | ||

Set-up of the Surface Measuring Machine | ||

Measure the Surface Finish of the Parts Media | ||

Superfinishing Procedure Method One | ||

Superfinishing Procedure Method Two | ||

Inspection Procedures | ||

Suggested Starting Conditions for Superfinishing | ||

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-002 ADHESIVE TAPE GENERALPURPOSE PAPER | LOCAL | CoMat 02-002 | Use for Method 1 Only | |

| CoMat 02-003 ADHESIVE TAPE BLACK WATERPROOF | LOCAL | CoMat 02-003 | Use for Method 1 Only | |

| CoMat 02-181 MODELLING CLAY | LOCAL | CoMat 02-181 | ||

| CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE | X222X | CoMat 05-003 | Use for Method 1 Only | |

| CoMat 05-004 ABRASIVE MEDIUM, ALUMINUM OXIDE, 140/400 GRADE | X222X | CoMat 05-004 | ||

| CoMat 05-093 SUPERFINISHING MEDIA, CERAMIC, ANGLE CUT TRIANGLE | CK340 | CoMat 05-093 | ||

| CoMat 05-094 SUPERFINISHING MEDIA, CERAMIC TRIANGLE | CK340 | CoMat 05-094 | ||

| CoMat 05-095 LIQUID COMPOUND (VIBROPOLISHING FINISHING FLUID) | DL610 | CoMat 05-095 | ||

| CoMat 05-097 SUPERFINISHING MEDIA, CERAMIC | U2008 | CoMat 05-097 | ||

| CoMat 05-098 SUPERFINISHING MEDIA, CERAMIC, ANGLE CUT TRIANGLE | DL610 | CoMat 05-098 | ||

| CoMat 05-100 SUPERFINISHING MEDIA, CERAMIC, TRIANGLE | K6835 | CoMat 05-100 | ||

| CoMat 05-101 VIBRO POLISHING MEDIUM, CERAMIC | K6835 | CoMat 05-101 | ||

| CoMat 05-102 VIBRO POLISHING MEDIUM, CERAMIC | K6835 | CoMat 05-102 | ||

| CoMat 05-103 VIBRO POLISHING MEDIUM, CERAMIC | K6835 | CoMat 05-103 | ||

| CoMat 05-181 VIBRO POLISHING MEDIA, CERAMIC PIN | LOCAL | CoMat 05-181 | ||

| CoMat 05-182 VIBRO POLISHING COMPOUND, LIQUID | IAE56 | CoMat 05-182 | ||

| CoMat 05-183 VIBRO POLISHING PASTE | IAE56 | CoMat 05-183 | ||

| CoMat 05-198 ALUMINUM OXIDE, 320-GRIT | 1280N | CoMat 05-198 | Use for Method 1 Only | |

| CoMat 05-199 ALUMINUM OXIDE, F500 GRIT | 1280N | CoMat 05-199 | Use for Method 1 Only | |

| CoMat 05-230 ABRASIVE MEDIUM ALUMINUM OXIDE, 280/500 GRADE | C5214 | CoMat 05-230 | Use for Method 1 Only | |

| CoMat 05-200 POLISHING COMPOUND (FOR HAND POLISHING) | IE441 | CoMat 05-200 | ||

| CoMat 05-201 POLISHING COMPOUND (FOR HAND POLISHING) | IE441 | CoMat 05-201 | ||

| CoMat 05-202 POLISHING COMPOUND (CHEMICAL) | LOCAL | CoMat 05-202 | ||

| CoMat 05-203 POLISHING COMPOUND (CHEMICAL) | LOCAL | CoMat 05-203 | ||

| CoMat 05-204 POLISHING COMPOUND | LOCAL | CoMat 05-204 | ||

| CoMat 05-205 POLISHING COMPOUND (CHEMICAL) | LOCAL | CoMat 05-205 | ||

| CoMat 05-206 POLISHING COMPOUND | LOCAL | CoMat 05-206 | ||

| CoMat 05-207 VIBRO POLISHING MEDIA | LOCAL | CoMat 05-207 | ||

| CoMat 05-208 VIBRO POLISHING PASTE | LOCAL | CoMat 05-208 | ||

| CoMat 05-209 VIBRO POLISHING FINISHING FLUID | LOCAL | CoMat 05-209 | ||

| CoMat 05-210 SUPERFINISHING MEDIA, CERAMIC | LOCAL | CoMat 05-210 | ||

| CoMat 05-214 LIQUID POLISHING SOAP | LOCAL | CoMat 05-214 | ||

| CoMat 05-215 VIBRO POLISHING MEDIA, CERAMIC | LOCAL | CoMat 05-215 | ||

| CoMat 05-216 VIBRO POLISHING MEDIA, CERAMIC | LOCAL | CoMat 05-216 | ||

| CoMat 05-217 VIBRO POLISHING MEDIA, PLASTIC | LOCAL | CoMat 05-217 | ||

| CoMat 05-218 POLISHING MEDIA, CERAMIC BARRELING CHIP | LOCAL | CoMat 05-218 | ||

| CoMat 05-219 POLISHING MEDIA, CERAMIC BARRELING CHIP | LOCAL | CoMat 05-219 | ||

| CoMat 05-220 POLISHING POWDER COMPOUND (FOR STAINLESS STEEL AND PRECIOUS METALS) | LOCAL | CoMat 05-220 | ||

| CoMat 05-221 POLISHING POWDER COMPOUND MEDIUM GRADE | LOCAL | CoMat 05-221 | ||

| CoMat 05-222 GRINDING POWDER (FOR HARDENED STEEL) | LOCAL | CoMat 05-222 | ||

| CoMat 05-223 POLISHING POWDER COMPOUND FINE GRADE | LOCAL | CoMat 05-223 | ||

| CoMat 05-224 VIBRO POLISHING MEDIA, CERAMIC | LOCAL | CoMat 05-224 | ||

| CoMat 05-225 VIBRO POLISHING MEDIA, CERAMIC | LOCAL | CoMat 05-225 | ||

| CoMat 05-226 VIBRO POLISHING MEDIA, CERAMIC | LOCAL | CoMat 05-226 | ||

| CoMat 05-227 LIQUID ACIDIC BURNISHING COMPOUND | LOCAL | CoMat 05-227 | ||

| CoMat 05-228 VIBRO POLISHING MEDIA, CERAMIC | LOCAL | CoMat 05-228 | ||

| CoMat 05-229 VIBRO POLISHING MEDIA, PLASTIC | LOCAL | CoMat 05-229 | ||

| CoMat 05-254 Media - Quartz-abrasive, Barrel-finishing, Triangular-shaped | X222X | CoMat 05-254 | ||

| CoMat 05-255 Media - Ceramic, Cone-shaped, Lightweight | IE550 | CoMat 05-255 | Use for Method 2 Only | |

| CoMat 05-256 Media - Aluminum Oxide Barrel Finishing | X222X | CoMat 05-256 | ||

| CoMat 05-257 Polishing Compound (for Refinement step) | 0P6N9 | CoMat 05-257 | Use for Method 2 Only | |

| CoMat 05-258 Burnishing Compound (for Final Polish step) | 0P6N9 | CoMat 05-258 | Use for Method 2 Only | |

| CoMat 05-259 Liquid Detergent for Barrel Finishing | X222X | CoMat 05-259 | ||

| CoMat 05-262 SUPERFINISHING MEDIA, CERAMIC, TRIANGLE | DL610 | CoMat 05-262 | ||

| CoMat 05-263 SUPERFINISHING MEDIA, CERAMIC, TRIANGLE | K6835 | CoMat 05-263 | ||

| CoMat 05-264 SUPERFINISHING MEDIA, CERAMIC, TRIANGLE | K6835 | CoMat 05-264 | ||

| DELETED | LOCAL | DELETED | Deleted CoMats - 05-211, 05-212, 05-213, 05-231, 05-232, 05-254A, 05-256A, 05-259A |

Spares

NONESafety Requirements

WARNING

WARNING

Procedure

This process gives the method One or Two for the Superfinishing (also known as Vibropolishing or Vibrobarrelling) of blade and vane airfoils. The process uses non-metallic media to produce a fine surface finish. Superfinishing must only be used where specified in the applicable Engine Manual or Repair Scheme, or damage to the parts may result. The superfinishing of coated components usually specifies special precautions to prevent damage. For example, certain coating systems (for example, Silicon-modified Aluminides) must not be superfinished after coating.

If the applicable Engine Manual or Repair Scheme work instructions do not specify the applicable polishing media, it is the responsibility of the operator to select the applicable polishing media. Trials are necessary to identify the optimum media and process time. You can improve the effect of the process by the addition of chemical polishing solutions.

Superfinishing media usually consists of aluminum oxide bonded in a ceramic, porcelain, or plastic and is available in many types of shapes and sizes. The choice of media is controlled by the material to be finished and the component geometry. The finish produced by superfinishing is directly related to the old surface condition of the component but is affected by the media composition and geometry.

SUBTASK 70-38-25-860-001 Introduction

NOTE

Keep the machine drain open to prevent unwanted material building up in the equipment.If no instructions to prepare/condition the new media are given, then prepare the media for a minimum of 3 hours at 80 percent to 100 percent machine running speed. The actual time required will be dependent on the amount of media to be prepared. As you prepare the media, it is necessary to add a liquid compound compatible with the superfinishing media to the media. This may be a one-off addition of compound and water in the case of a small barrel, or a continuous flow, at the specified proportions, of compound and water, while the machine is ON. Add the quantity of the liquid compound as specified by the compound manufacturer.

It is necessary to prepare (also known as conditioning) new media before the superfinishing of engine parts to remove sharp edges from the media. Prepare (condition) the media as specified by the media manufacturer.

NOTE

Keep the machine drain open to prevent unwanted material building up in the equipment.If no instructions are given, prepare the media for a minimum of 3 hours at 80 percent to 100 percent machine running speed. The actual time necessary is applicable to the amount of media to be prepared. As you prepare the media, it is necessary to add a liquid compound compatible with the superfinishing media must be added to the media. This may be a one-off addition of compound and water in the case of a small barrel, or a continuous flow, at the specified proportions, of compound and water, while the machine is ON. Add the quantity of the liquid compound as specified by the compound manufacturer.

Prepare the media as specified by the media manufacturer.

For additions of media of more than 20 percent by weight, preparation of the media is necessary and must be carried out as follows:

Add media, as necessary, to one of the procedures that follows:

For machines which do not flow the water/compound mixture continually to drain, it is necessary to drain the liquid after each batch of parts and to wash the media with water before you start superfinishing. For continuous flow machines, keep the drain open. Permit the excess solution to flow to the drain through via a settlement tank to catch solid material.

Removal of unwanted material from the working chamber.

SUBTASK 70-38-25-380-001 Makeup and Control of the Superfinishing Media

NOTE

Due to the variability of types of machine and media used, it is not possible to define exactly the necessary parameters. For guidance on typical parameters, see Step for guidance.For each type of part (for example, H.P.3 stators, or H.P.5 compressor blades), a test batch of parts must be done to assess the effectiveness of the parameters.

SUBTASK 70-38-25-380-002 Control of the Superfinish Produced

Be sure that the measuring probe is horizontal relative to the test piece, and that the stylus touches the surface; use a piece of CoMat 02-181 MODELLING CLAY, for example, to make sure the test piece is horizontal.

For additions of media of more than 20 percent by weight, preparation of the media is necessary and must be carried out as follows.

Assemble the surface finish measuring machine to the manufacturer's instructions. Then do as follows:

SUBTASK 70-38-25-380-003 Set-up of the Surface Measuring Machine

Set-up and test the surface finish checking machine. Refer to Step.

SUBTASK 70-38-25-380-004 Measure the Surface Finish of the Parts

CAUTION

EFFECTIVE MASKING FOR CHEMICAL SUPER POLISHING IS DIFFICULT. STAGNANT CHEMICALS UNDER THE MASKING MUST CAUSE NO DAMAGE TO THE PART.

CAUTION

MEDIA USED TO PROCESS TITANIUM, ALUMINUM, OR ALUMINUM COATED COMPONENTS MUST NOT BE USED TO PROCESS NICKEL OR COBALT BASE COMPONENTS.

CAUTION

BLOCKAGE AND THEREFORE BUILD UP OF CHEMICALS IN A MACHINE CAN CAUSE UNACCEPTABLE LEVELS OF HYDROGEN IN TITANIUM ALLOYS.

CAUTION

YOU MUST NOT ABRASIVE BLAST OIL SYSTEMS OR PARTS THAT HAVE A COMPLEX SHAPE IN WHICH THE MEDIA CAN GET CAUGHT AND REMOVAL IS NOT POSSIBLE. ALSO IT MUST BE POSSIBLE TO EXAMINE THE PARTS FULLY TO MAKE SURE ALL OF THE MEDIA HAS BEEN REMOVED. IF YOU DO NOT OBEY THIS INSTRUCTION, YOU CAN CAUSE DAMAGE TO THE PART(S).Initially clean the parts by the procedures in the SPM TASK 70-11-03-300-503, if necessary, to remove grease, oil, and dirt.

Initial cleaning.

Mask off areas for which abrasive blasting is not necessary. Whenever possible, use superfinishing masks specially made for the parts. If the masks are not available use CoMat 02-002 ADHESIVE TAPE GENERALPURPOSE PAPER or CoMat 02-003 ADHESIVE TAPE BLACK WATERPROOF, as applicable.

Mask before abrasive blasting.

Wet abrasive blast by one of the methods in the SPM TASK 70-12-01-120-501, or SPM TASK 70-12-06-120-501; use the media in CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE, or CoMat 05-004 ABRASIVE MEDIUM, ALUMINUM OXIDE, 140/400 GRADE, or CoMat 05-198 ALUMINUM OXIDE, 320-GRIT, or CoMat 05-199 ALUMINUM OXIDE, F500 GRIT, or CoMat 05-230 ABRASIVE MEDIUM ALUMINUM OXIDE, 280/500 GRADE.

All parts except aluminized turbine blades and aluminized nozzle guide vanes. For the abrasive blasting of Aluminized Turbine Blades and Aluminized Nozzle Guide Vanes refer to paragraph 2(c).

Dry abrasive blast by one of the methods in the SPM TASK 70-12-01-120-501, or SPM TASK 70-12-02-120-501, or SPM TASK 70-12-09-120-501; use CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE, or CoMat 05-004 ABRASIVE MEDIUM, ALUMINUM OXIDE, 140/400 GRADE, or CoMat 05-198 ALUMINUM OXIDE, 320-GRIT, or CoMat 05-199 ALUMINUM OXIDE, F500 GRIT, or CoMat 05-230 ABRASIVE MEDIUM ALUMINUM OXIDE, 280/500 GRADE.

All parts except titanium, aluminized turbine blades and aluminized nozzle guide vanes. For the abrasive blasting of Aluminized Turbine Blades and Aluminized Nozzle Guide Vanes refer to paragraph 2(c).

Glass bead or ceramic bead peen aluminized turbine blades and aluminized nozzle guide vanes by the method in the SPM TASK 70-12-03-120-501, or SPM TASK 70-12-12-300-503; refer to the Repair Scheme or Engine Manual for required bead size.

Aluminized Turbine Blades and Aluminized Nozzle Guide Vanes.

Abrasive blast the parts, by one of the methods that follow:

CAUTION

DO NOT ABRASIVE BLAST THE AIRFOIL SURFACES OF PARTS WHICH HAVE ALREADY BEEN PEENED.NOTE

An abrasive blast is optional. It is only necessary when the surface finish is unsatisfactory for immediate superfinishing. An unsatisfactory surface finish for immediate superfinishing can be the result of:Local blending or dressing operations.Components that have been chemically etched for inspection purposes.Minor pitting or damage of the airfoil.Abrasive blast.

Mask off areas for which superfinishing is not necessary; use superfinishing masks specially made for the part. If these are not available, use CoMat 02-003 ADHESIVE TAPE BLACK WATERPROOF.

Mask prior to superfinishing.

NOTE

It is necessary for some parts to have a mask for abrasive blasting but not during superfinishing. Specific masking instructions will be given in the Engine Manual.Set the required parameters and start the superfinishing machine; refer to Step.

CAUTION

DO NOT DROP THE PARTS ONTO THE MEDIA TO PREVENT DAMAGE MAY BE CAUSED TO THE PARTS.

CAUTION

DO NOT PUT TOO MANY PARTS IN THE SUPERFINISHING MACHINE.Superfinish cycle.

Examine the parts by the procedure in Step (Inspection Procedures).

Inspection.

SUBTASK 70-38-25-380-005 - 001 Superfinishing Procedure Method One

METHOD 2A is a cut-down process.

METHOD 2B is a refinement polishing process.

This procedure gives two vibratory finishing process methods for surface finish improvement.

Method selection is determined by the average surface roughness (Ra) condition of the blade or variable vane airfoil at the start of the process. Refer to Ra qualification limits in Procedure METHODS 2A and 2B, that follow.

Consumable materials, media and cleaning or burnishing compounds are identified separately for each method.

CAUTION

DO NOT DO THIS VIBRATORY FINISHING PROCESS BEFORE FLUORESCENT PENETRANT INSPECTION.NOTE

To provide a smooth surface finish for all model engines front and rear compressor blade and variable vane airfoils (excluding Fan Blades).NOTE

This airfoil refurbishment process increases performance of front and rear compressor blade and variable vane airfoils because it gives a better surface finish. This operation is not for the repair of leading edge erosion.Introduction.

Remove antigallant and clean airfoil. Refer to Engine Manual cleaning requirements.

Do fluorescent penetrant inspection. Refer to Engine Manual requirements.

Peen airfoil, if specified by the Engine Manual.

Do an airfoil surface roughness inspection to determine the Average Roughness (Ra) surface condition for the quantity of parts before the vibratory finishing process. This determines whether to use METHOD 2A or 2B.

Mask the variable vane trunnion before vibratory finishing the airfoils.

Prerequisites.

ROUGHNESS WIDTH: The distance parallel to the nominal surface between the successive peaks or ridges which constitute the predominant pattern of the roughness.

ROUGHNESS WIDTH CUTOFF (INSTRUMENT CUT-OFF): The greatest spacing of repetitive surface irregularities to be included in the measurement of average roughness height. Roughness width cutoff corresponds to the low frequency cutoff of the instrument and is specified in inches.

Definitions.

Vibratory finishing machine, bowl-type, 10 cu.ft (0.28 cu.m.) capacity recommended Surface roughness instrument

Equipment:

Consumable Materials

For METHOD 2A:

Table 2. Plastic, Quartz-abrasive, Barrel-finishing, Triangular-shaped (alternate to CoMat 05-255)

Media - Ceramic, Lightweight, Cone-shaped (alternate to CoMat 05-254)

Liquid Detergent for Barrel Finishing

For METHOD 2B:

Table 3. Aluminum Oxide Barrel Finishing Media

Polishing Compound (for Refinement step)

Burnishing Compound (for Final Polish step)

Fill the vibratory finishing machine, to 3.0 in. (76.2 mm) from the top of the outside rim of the machine or by the manufacturer's instructions, with CoMat 05-254 Media - Quartz-abrasive, Barrel-finishing, Triangular-shaped or CoMat 05-255 Media - Ceramic, Cone-shaped, Lightweight.

Set up the vibratory finishing machine. Refer to the manufacturer's instructions.

Adjust the water flow rate to 20 gallons/hour (75.7 liters/hour).

Add CoMat 05-259 Liquid Detergent for Barrel Finishing at a rate of 1 - 1.5 fluid ounces of detergent/gallon of water/hour (7.7 ml - 11.55 ml of detergent/liter of water/hour) for a 10 cu.ft (0.28 cu.m.) machine. Adjust proportionately for other size machines.

Open the drain valve, as necessary.

Start the vibratory finishing machine.

Makeup and control media as follows:

In lots of up to two complete blade sets for each cycle of any one stage or

In lots with mixed blades of other stages that are the equivalent of up to two blade sets.

CAUTION

IF NEW MEDIA IS IN THE MACHINE, IT MUST FIRST HAVE ITS SHARP/ROUGH EDGES REMOVED. OPERATE THE MACHINE FOR A MINIMUM OF TWO HOURS WITH A WATER FLOW OF 20 GALLONS/HOUR (75.7 LITERS/HOUR) BEFORE YOU START TO BURNISH.

CAUTION

IF NEW MEDIA IS ADDED TO KEEP UP THE OPERATIONAL VOLUME OF THE MACHINE, A BREAK-IN CYCLE TO REMOVE SHARP/ROUGH EDGES IS RECOMMENDED WHEN THE ADDED MEDIA IS GREATER THAN 10 PERCENT BY WEIGHT OF OPERATIONAL VOLUME. NO BREAK-IN IS NECESSARY WHEN NEW MEDIA WEIGHT IS LESS THAN 10 PERCENT OF THE OPERATIONAL VOLUME.

CAUTION

IF THE MACHINE DOES NOT FLOW THE WATER MIXTURE CONTINUOUSLY TO DRAIN, THE WATER MIXTURE MUST BE DRAINED AFTER EACH QUANTITY OF PARTS AND THE MEDIA FLUSHED WITH WATER BEFORE THE NEXT QUANTITY OF PARTS IS PROCESSED.

CAUTION

MAKE SURE THAT BLADES HAVE EQUAL DISTANCES BETWEEN THEM IN THE MEDIA AND THAT THE MACHINE IS NOT TOO FULL. THIS IS TO PREVENT DAMAGE TO THE BLADES AND VARIABLE VANES.Put the blades, one at a time (with airfoil first), into the media in the vibratory finishing machine as follows to prevent part damage:

Operate the vibratory finishing machine up to three hours.

Flush in cold water and air-dry with filtered shop air.

Put in hot water, 150 deg F - 200 deg F (66 deg C - 93 deg C) to flash dry.

Clean by TASK 70-11-03-300-503.

Remove the blades and/or variable vanes and do one of the steps that follow:

Do the airfoil roughness inspection per Step.

A scheduled screening procedure is recommended to remove media which has been worn to 3/8 in. (9.128 mm) or less in size.

NOTE

Be sure to calibrate the surface roughness gage against a Standard before use.

Procedure METHOD 2A: Repair Blade Or Variable Vane Airfoil (With Surface Finish Roughness More Than 30Ra)

Fill the vibratory finishing machine, to 3.0 in. (76.2 mm) from the top of the outside rim of the machine or by the manufacturer's instructions, with CoMat 05-256 Media - Aluminum Oxide Barrel Finishing.

Set up the vibratory finishing machine. Refer to the manufacturer's instructions.

Close the drain valve, as necessary.

Add 3 gallons (11.355 liters) of water for every 10 cu.ft (0.28 cu.m.) of machine capacity (medium water level).

To the water added above, add 8 oz.wt./gallon (60 grams/liter) of CoMat 05-257 Polishing Compound (for Refinement step).

Start the vibratory finishing machine.

Makeup and control media as follows:

In lots of up to two complete blade sets for each cycle of any one stage or

In lots with mixed blades of other stages that are the equivalent of up to two blade sets.

Put the blades, one at a time (with airfoil first), into the media in the vibratory finishing machine as follows to prevent part damage:

Operate the vibratory finishing machine up to two hours.

Open the drain valve and remove the water.

Adjust the water flow to 10 gallons/hour (37.85 liters/hour).

Add CoMat 05-258 Burnishing Compound (for Final Polish step) at a rate of 1 - 1.5 fluid ounces/gallon of water/hour (7.7 - 11.55 ml/liter of water/hour) for a 10 cu.ft (0.28 cu.m.) machine. Adjust proportionately for other size machines.

Start the vibratory finishing machine.

Adjust the makeup and control the media as follows:

Operate the vibratory finishing machine up to one hour.

NOTE

For vibratory finishing machines that have more than a 10 cu.ft (0.28 cu.mm) capacity, a minimum flow of 1 gallon/hour/ cubic foot (3.785 liters/hour/0.03 cubic meter) of machine capacity is necessary.Flush fully in cold water and air-dry with filtered shop air.

Put fully in hot water at 150 deg F- 200 deg F (66 deg C - 93 deg C) to flash dry.

Clean by TASK 70-11-03-300-503.

Remove the blades and/or variable vanes and do one of the steps that follow:

Do the airfoil roughness inspection per Step.

NOTE

If the surface finish is not smooth enough, the METHOD 2B vibratory finishing process can be done again one more time. (Refer to Definitions).

Procedure Method 2B: Repair Blade Or Variable Vane Airfoil (With Surface Finish Roughness Of 30Ra Or Less)

SUBTASK 70-38-25-380-005-002 Superfinishing Procedure Method Two option for HPC Airfoils

Accept/Reject Criteria.

Accept superficial scuffing or surface marking that cannot be felt with a non-metallic scriber or finger nail drawn across the scuffing or marking.

Reject any scuffing or marking that can be felt with a non-metallic scriber or finger nail drawn across the scuffing or marking.

NOTE

If the parts are not immediately necessary for further operations, apply an approved preservative, refer to the engine manual. For short-term protection, refer to the SPM TASK 70-62-00-620-501 and SPM TASK 70-38-37-300-503.

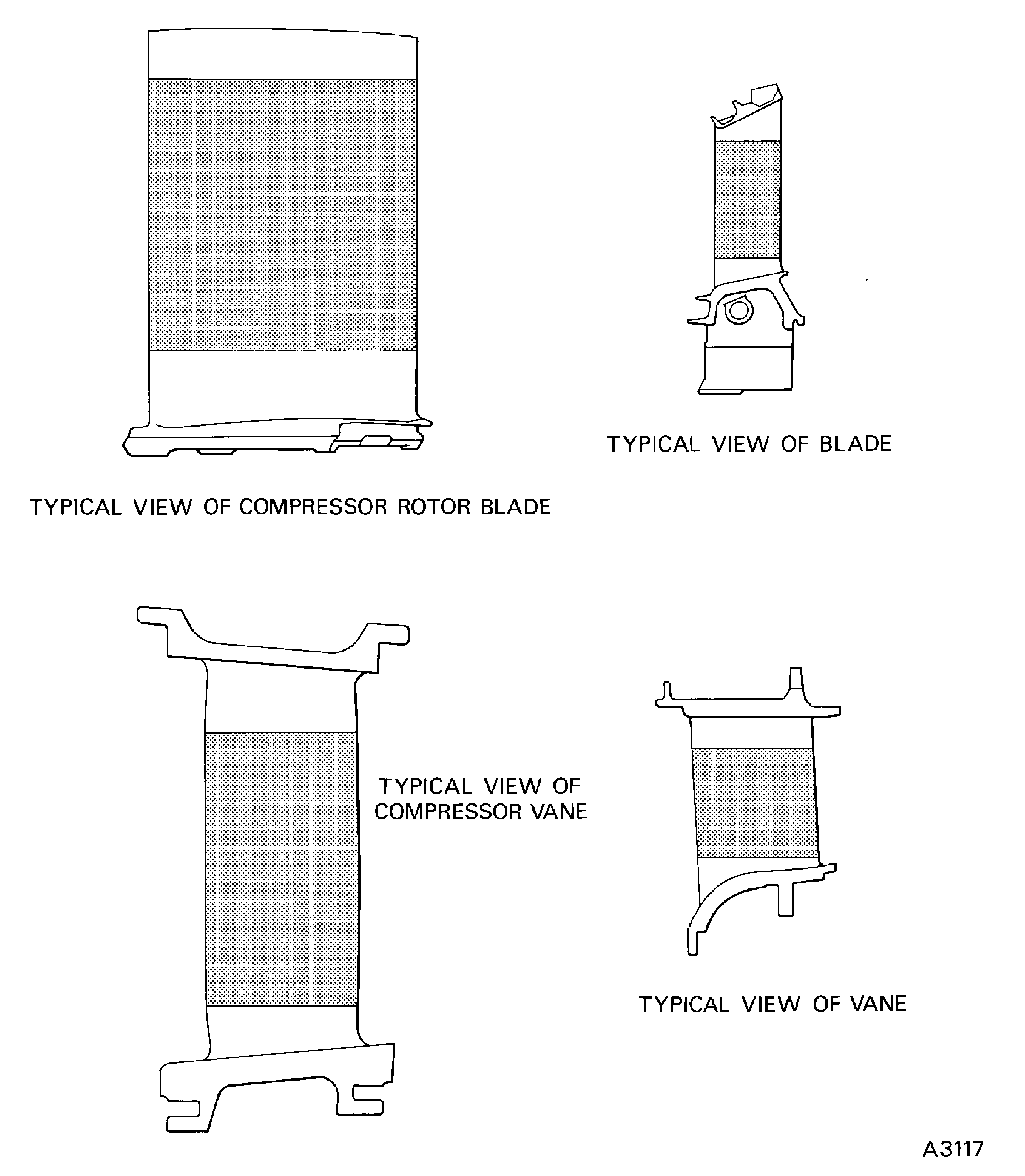

Examine 5 percent minimum of the airfoils for the surface finish produced, refer to Step and Step. Measure within the areas given in Figure. The surface finish requirement will be given in the Engine Manual or Repair Scheme.

SUBTASK 70-38-25-380-006 Inspection Procedures

For suggested start parameters to produce a 0.5 micrometer (20 micro inch) finish for steel or nickel base alloys or aluminized nickel base alloys and titanium, refer to the tables as follows.

Table 4. Table 1: Machine Volume is 3 cu.ft (0.085 cu.m.) Media size

Material to Superfinish

Polish Time at 25 Hz

up to 10 mm

Steel

4 hours

Nickel base alloys

4 hours

Aluminized nickel base alloys

6 hours

Titanium

3 hours

Table 5. Table 2: Machine Volume is 9 cu ft or 18 cu ft (0.25 cu m or 0.5 cu m) Media size

Material to Superfinish

Polish Time at 25 Hz

up to 10 mm

Steel

4 hours

Nickel base alloys

4 hours

Aluminized nickel base alloys

6 hours

Titanium

3 hours

Table 6. Table 3: Machine Volume is 9 cu ft or 18 cu ft (0.25 cu m or 0.5 cu m) Media size

Material to Superfinish

Polish Time at 25 Hz

10 mm to 15 mm

Steel

2 hours 30 minutes

Nickel base alloys

2 hours 30 minutes

Aluminized nickel base alloys

3 hours 30 minutes

Titanium

2 hours

Table 7. Table 4: 9 cu ft or 18 cu ft (0.25 cu m or 0.5 cu m) Media size

Material to Superfinish

Polish Time at 25 Hz

15 mm to 25 mm

Steel

2 hours

Nickel base alloys

2 hours

Aluminized nickel base alloys

3 hours

Titanium

1 hour 30 minutes

The start parameters that follow are included for guidance and do not constitute actual conditions for production purposes.

SUBTASK 70-38-25-380-007 Suggested Start Conditions for Superfinishing

Figure: Areas in which Superfinishing must be measured, on convex side of Airfoil Fig 70-38-25-990-002

Areas in which Superfinishing must be measured, on convex side of Airfoil Fig 70-38-25-990-002