Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-32-300-009 HPC Stage 6 Variable Stator Vane - Blend Repair, Repair-009 (VRS6037)

Material of component

RR | ||

|---|---|---|

DESCRIPTION SYMBOL MATERIAL | ||

HP compressor stage 6 | EAX | Creep resisting - ferritic steel |

variable vane | - vacuum melted | |

HP compressor stage 6 | QMP | 52 percent nickel |

variable vane | 19 percent chromium | |

18 percent iron | ||

5 percent niobium | ||

General

This repair must only be done when the instruction to do so is given in TASK 72-41-32Inspection/Check.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

This Repair gives the instruction to remove damage on the HP compressor variable stator vane, stage 6, by material removal.

Not more than 10 percent of variable stator vanes that are dressed to the maximum limit of this Repair should be included in any one stator stage.

Variable stator vanes must be repaired as soon as damage or wear is monitored, to get back HP compressor efficiency and extend the variable stator vane life.

Material removal from the HP compressor variable stator vane airfoil fillet radius is not permitted.

Price and availability - refer to IAE

Related repairs

HP compressor stage 6 variable stator vanes - restore airfoil surface finish, refer to Repair VRS6044, TASK 72-41-32-300-018 (REPAIR-018).

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Portablegrinding equipment | LOCAL | Portable grinding equipment | ||

| Dimensional inspection equipment | LOCAL | Dimensional inspection equipment | ||

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-075 WATERPROOF SILICON CARBIDE | IE241 | CoMat 05-075 | ||

| CoMat 05-076 WATERPROOF SILICON CARBIDE | K3895 | CoMat 05-076 | ||

| CoMat 05-077 WATERPROOF SILICON CARBIDE | K6835 | CoMat 05-077 | ||

| CoMat 05-079 WATERPROOF SILICON CARBIDE | K3895 | CoMat 05-079 | ||

| CoMat 05-082 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-082 |

Spares

NONESafety Requirements

NONEProcedure

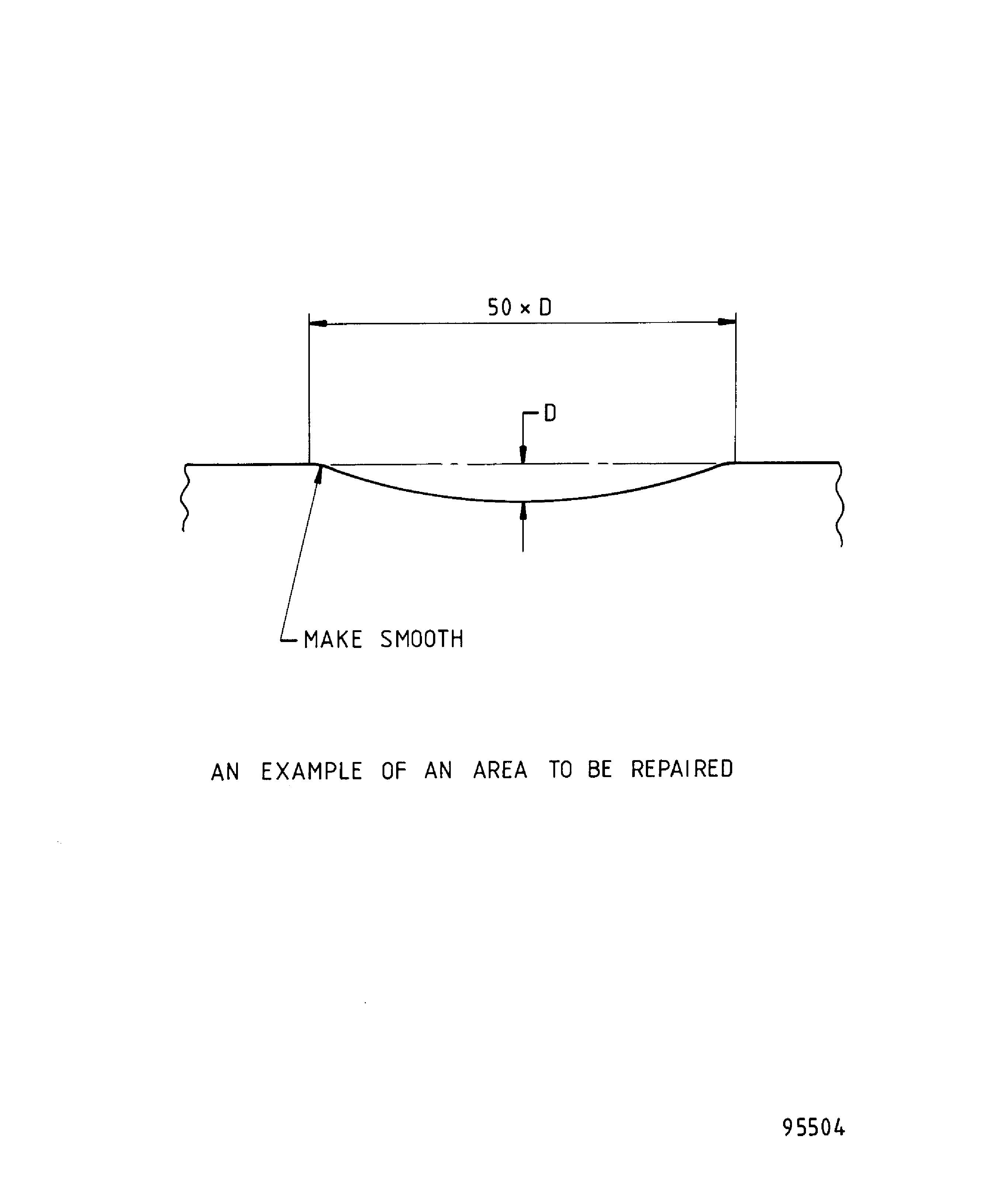

Refer to Figure.

Use portable grinding equipment.

Continue to remove material until all the damage is removed.

The maximum depth to remove the damage must not be more than 0.005in. (0.13 mm).

The diameter of the repaired area is to be 50 times the depth.

Remove the damage on the airfoil surfaces by material removal.

Use CoMat 05-077 WATERPROOF SILICON CARBIDE or CoMat 05-076 WATERPROOF SILICON CARBIDE and/or CoMat 05-075 WATERPROOF SILICON CARBIDE.

Polish the repaired area to remove scratches and to give a surface finish the same as the adjacent material.

NOTE

The last polish is to be in a radial direction.

Polish the repaired area.

SUBTASK 72-41-32-350-055 Remove the Damage from the HP Compressor Stage 6 Variable Stator Vane

Refer to: Figure

SUBTASK 72-41-32-350-073 Identify the Repair

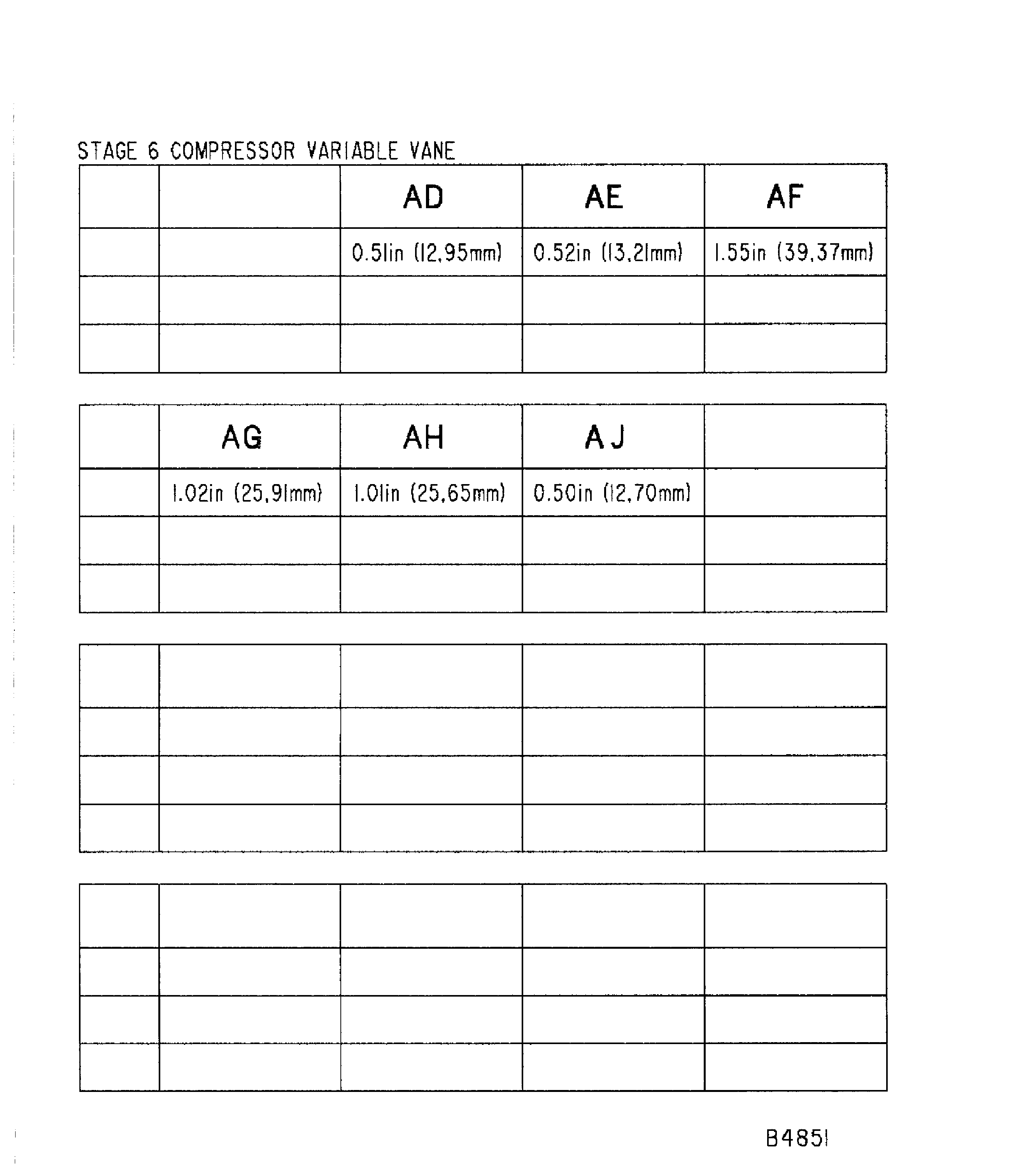

Figure: Repair details and dimensions

Repair details and dimensions

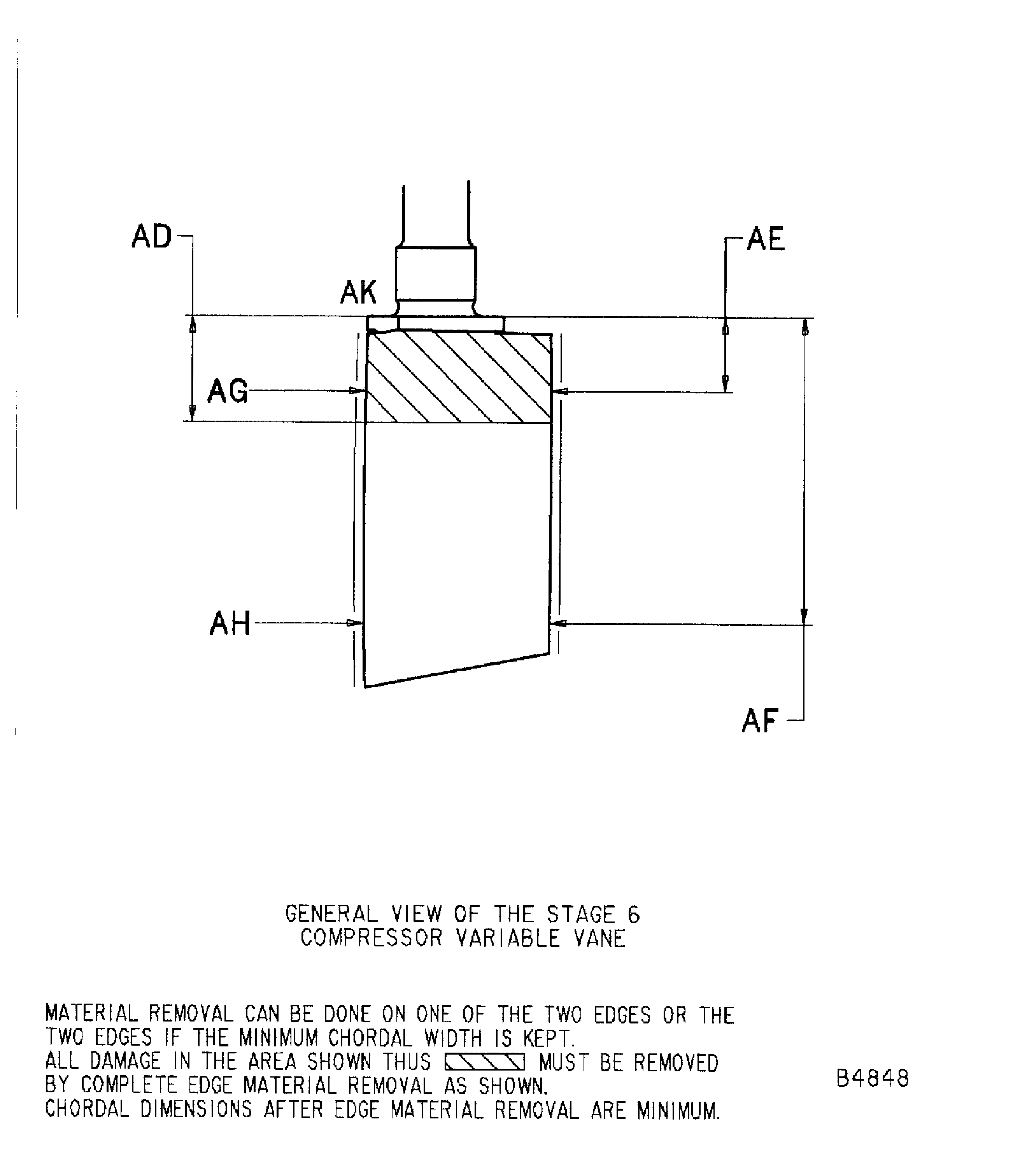

Figure: Repair details and dimensions

Repair details and dimensions

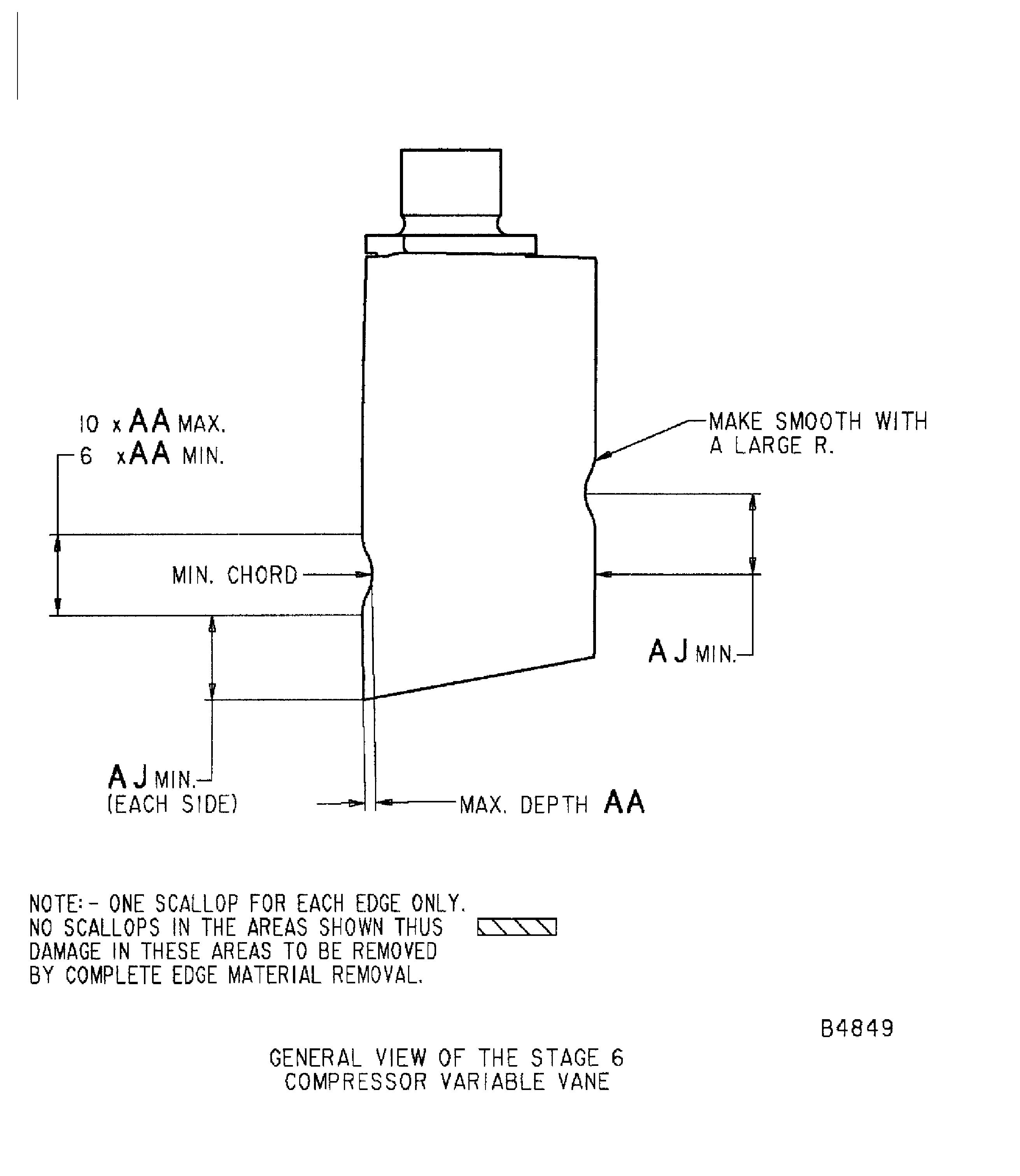

Figure: Repair detials and dimensions

Repair detials and dimensions

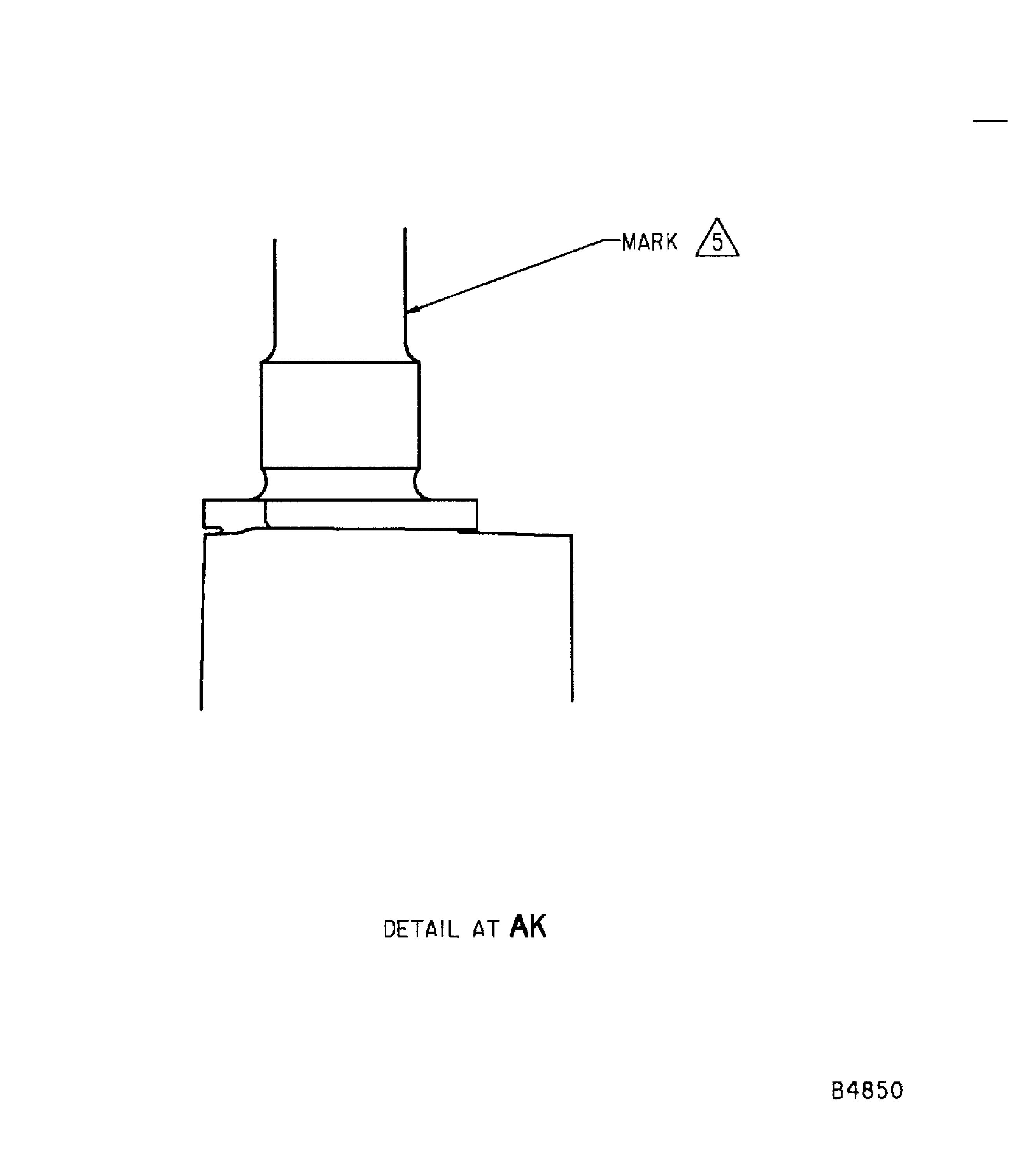

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and diemensions

Repair details and diemensions