Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-32-300-020 HPC Stage 6 Variable Stator Vane - Repair A Worn Location Diameter, Repair-020 (VRS6615)

Effectivity

FIG/ITEM | PART NO. | |

|---|---|---|

05-500 | 6A3699 | Assembly A |

05-500 | 6A3763 | Assembly B |

05-600 | 6A3752 | Assembly C |

05-600 | 6A3764 | Assembly D |

Eqipment and Material

Standard equipment

Chemical cleaning equipment

Penetrant crack test equipment

Lathe

Dial test indicator

Abrasive blast equipment

Metal spray equipment

External grinding equipment

Vibro-engraving equipment

Consumable materials

Heat resistant paper masking tape | |

Metal spray wire | |

Metal spray powder | |

Plasma spray powder | |

Metal spray powder | |

Abrasive medium | |

Fluorescent penetrant | |

Special tools - none

Expendable parts - none

Repair parts - none

General

This TASK must only be done when the instuction to do so is given in TASK 72-41-32-200-000 (INSPECTION/CHECK-000)

This repair lets you repair a worn or damaged location diameter on the HP Compressor Variable Stator Vane, Stage 6.

The practices and processes referred to in procedure by the TASK/SUBTASK number are given in the SPM.

Material of componant

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

HP Compressor stage 6 variable stator vane Assembly A and Asessmbly C | EAX | Creep resisting - Ferritic steel - Vacuum melted |

or | ||

Assembly B and Assembly D | QMP | 52 percent Nickel |

19 percent Chromium | ||

18 percent Iron and | ||

5 percent Niobium |

Price and availability

Refer to International Areo Engines

NOTE

Equivalent materials or equipment can be used.

More equivalent and materials necessary to do this Repair are in the TASK given below:

TASK 70-09-00-400-501

TASK 70-11-01-300-503

TASK 70-11-39-300-503

TASK 70-12-02-120-501

TASK 70-23-04-230-501

TASK 70-34-01-340-501

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 | ||

| CoMat 02-019 TAPE, ADHESIVE PAPER HEAT RESISTING MASKING | 94960 | CoMat 02-019 | ||

| CoMat 05-002 ABRASIVE MEDIUM, ALUMINUM OXIDE | LOCAL | CoMat 05-002 | ||

| CoMat 03-036 METAL SPRAYING WIRE, Ni,Al | LOCAL | CoMat 03-036 | ||

| CoMat 03-308 METAL SPRAYING POWDER,Co BASE ALLOY | LOCAL | CoMat 03-308 | ||

| CoMat 03-096 PLASMA SPRAY POWDER | LOCAL | CoMat 03-096 | ||

| CoMat 03-320 METAL SPRAYING POWDER,WC/Co | LOCAL | CoMat 03-320 | ||

| CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) | IE200 | CoMat 03-038 |

Spares

NONESafety Requirements

NONEProcedure

Refer to TASK 72-41-32-200-000 (INSPECTION/CHECK-000).

use penetrant crack test equipment.

Cracks are not permitted.

Do a penetrant crack test.

SUBTASK 72-41-32-230-070 Do a Crack Test

Refer to Figure.

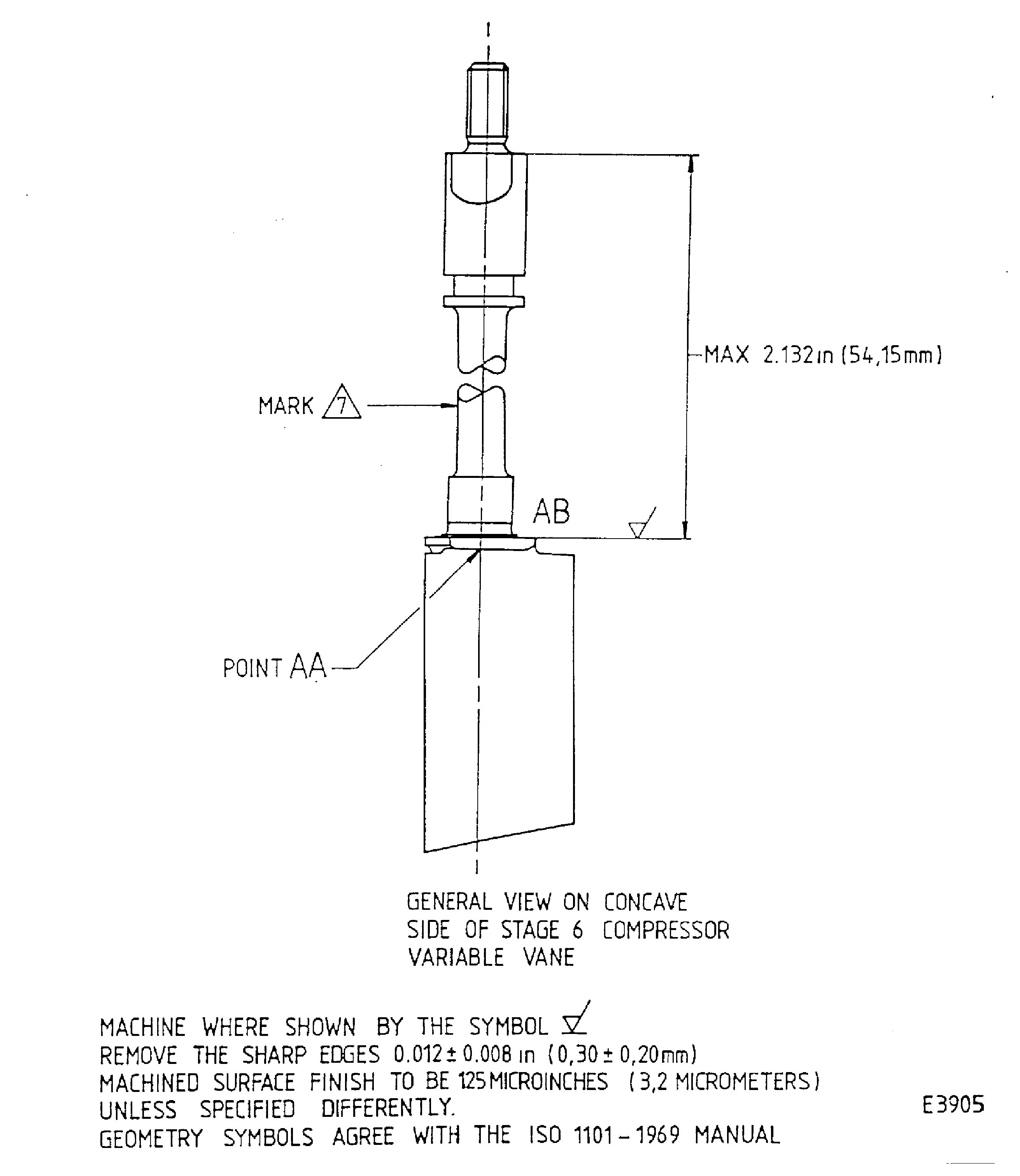

SUBTASK 72-41-32-220-126 Examine the HP Compressor Variable Stator Vane, Stage 5, Assembly A and Assembly C

Refer to Figure.

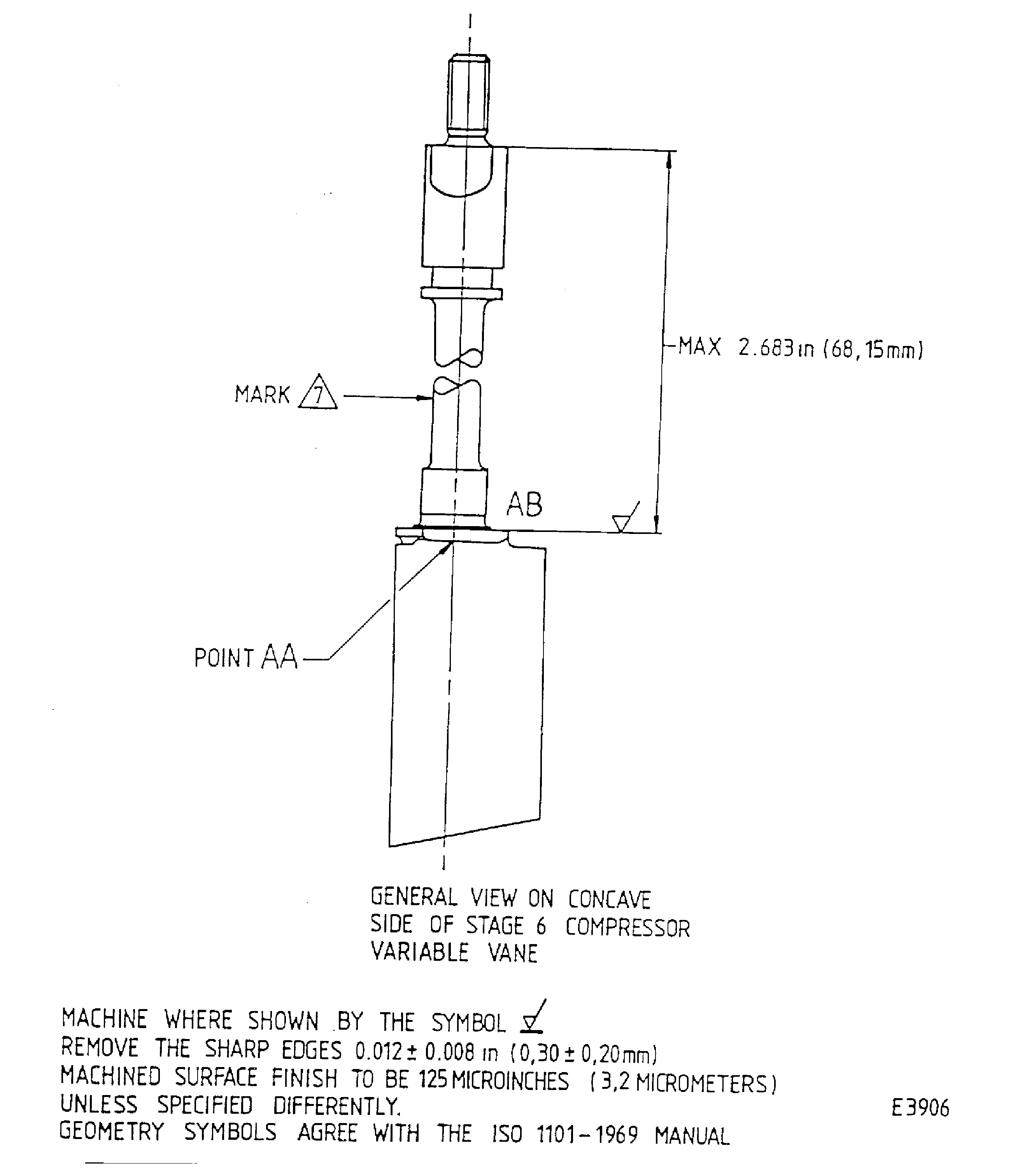

SUBTASK 72-41-32-220-127 Examine the HP Compressor Variable Stator Vane, Stage 6, Assembly B and Assembly D

Refer to Figure.

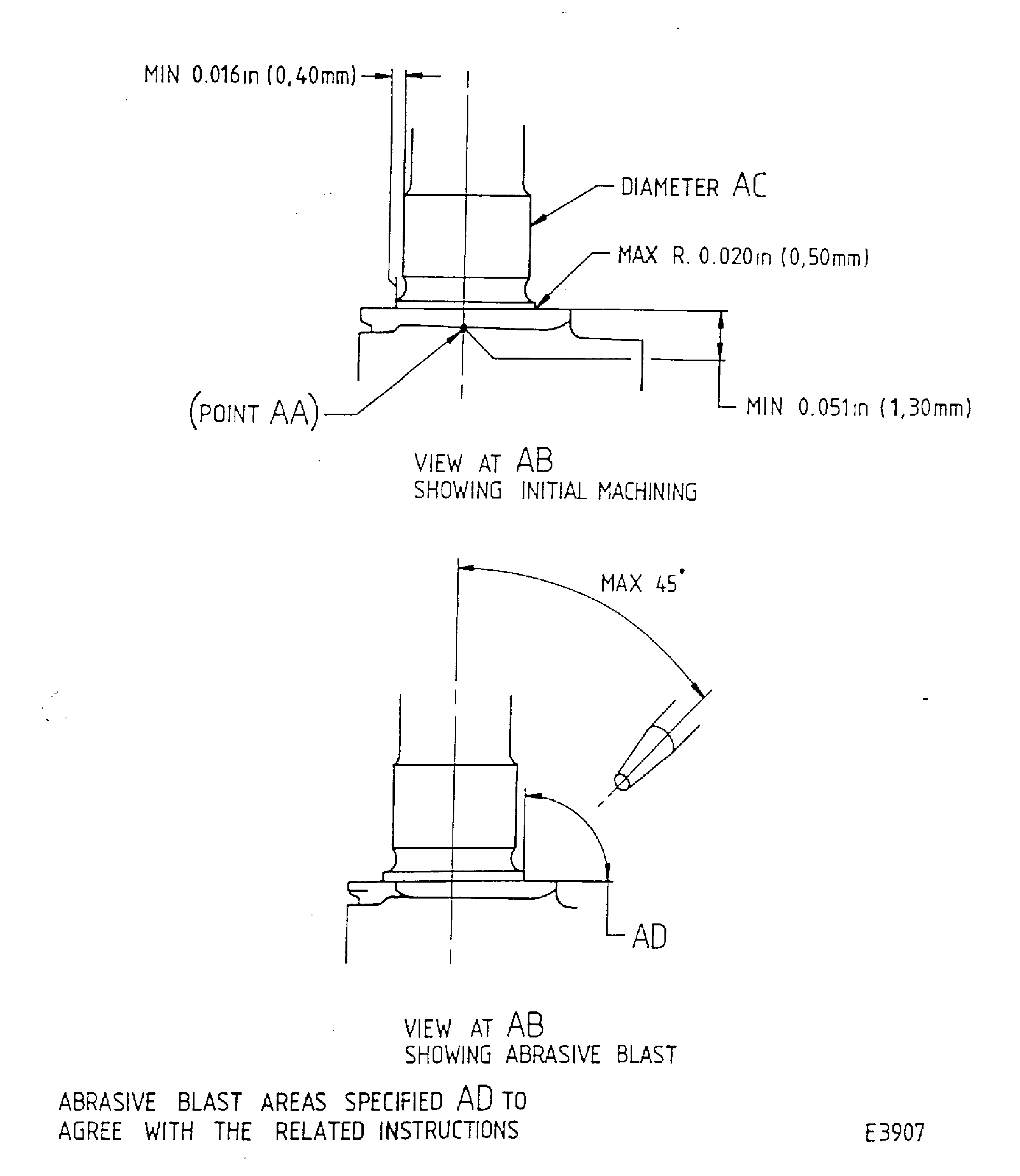

SUBTASK 72-41-32-325-051 Remove Damage from the HP Compressor Variable Stator Vane, Stage 6

CAUTION

DO NOT REMOVE MATERIAL FROM THE HP COMPRESSOR VARIABLE STATOR VANE, STAGE 6 SPINDLE, DIAMETER AC.Refer to the SPM TASK 70-23-04-230-501.

Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY), with penetrant crack test equipment.

Cracks are not permitted.

Do a penetrant crack test on the repair.

SUBTASK 72-41-32-230-071 Do a Crack Test

Refer to Figure.

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-002.

Use CoMat 05-002 ABRASIVE MEDIUM, ALUMINUM OXIDE , with abrasive blast equipment.

Abrasive blast the surfaces to be repaired.

SUBTASK 72-41-32-120-053 Prepare the Surfaces for Repair

CAUTION

DO NOT TOUCH SURFACES TO BE REPAIRED AFTER THEY HAVE BEEN CLEANED.

CAUTION

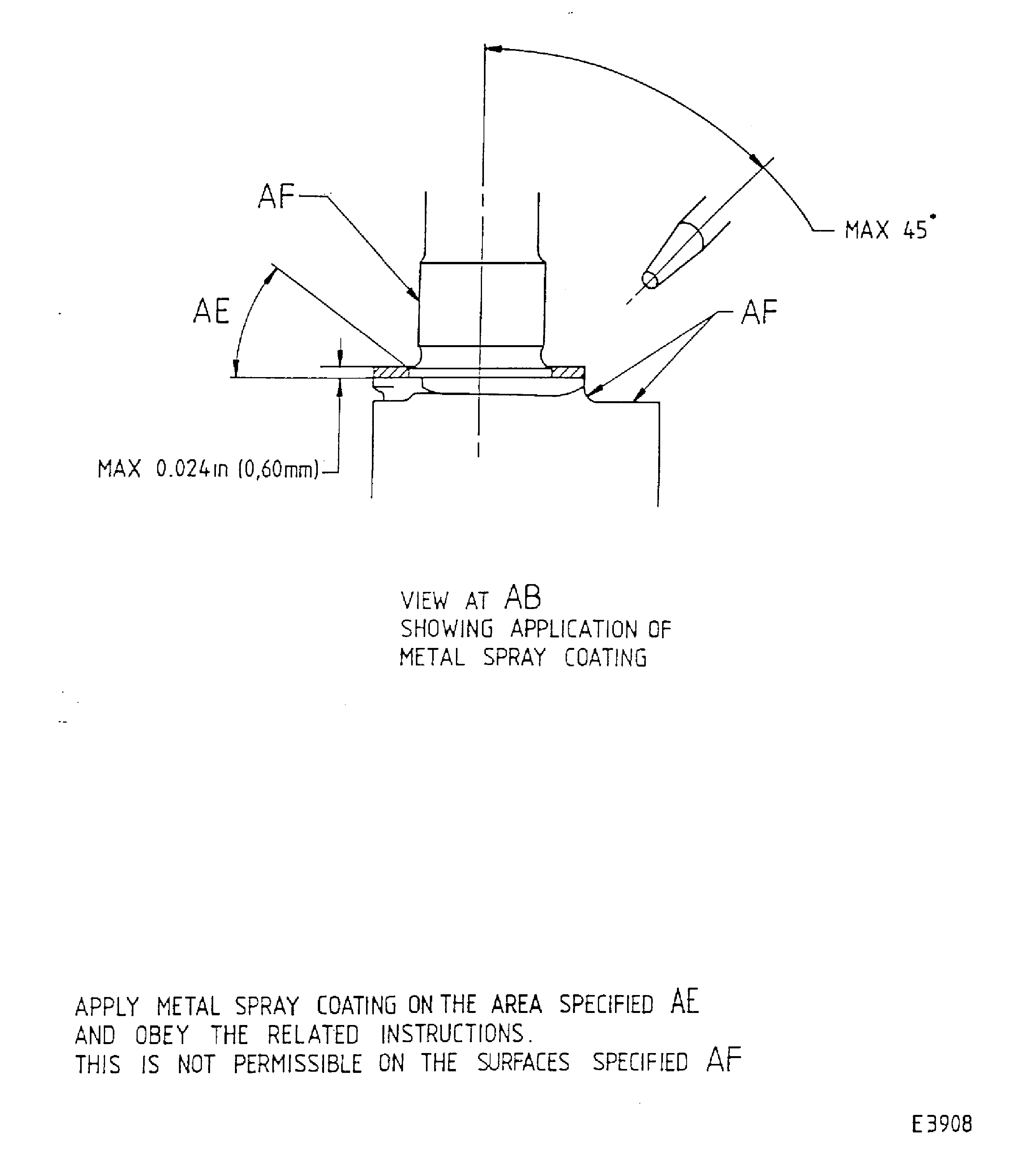

TOO MUCH ABRASIVE BLAST CAN CAUSE DETERIORATION OF THE PREPARED SURFACE CONDITION AND MUST BE PREVENTED.Refer to Figure.

Refer to the SPM TASK 70-34-01-340-501 , SUBTASK 70-34-01-340-002.

Use CoMat 03-036 METAL SPRAYING WIRE, Ni,Al , CoMat 03-308 METAL SPRAYING POWDER,Co BASE ALLOY or CoMat 03-096 PLASMA SPRAY POWDER, with metal spray equipment.

Apply a thickness of 0.003 to 0.005 in. (0.07 to 0.13 mm).

Apply the bond coat to the HP Compresor Variable Stator Vane, Stage 6, location diameter.

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-340-014 OR SUBTASK 70-34-01-340-026.

Use CoMat 03-320 METAL SPRAYING POWDER,WC/Co, with metal spray equipment.

Apply a layer of sufficient thickness, to get correct diamensions after the component is machined.

NOTE

The maximum permitted thickness of coat allowed after spraying is 0.024 in. (0.060 mm).

Apply the top coat to the HP Compressor Variable Stator Vane, Stage 6, location diameter.

SUBTASK 72-41-32-340-051 Apply the Metal Spray Coat

Refer to Figure.

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-002.

Make sure the maximum thickness of metal sprayed coat is no more than o.024 in.(0.060 mm).

Visually examine and measure the diamensions of the sprayed coating.

SUBTASK 72-41-32-220-130 Examine the Metal Spray Coat

Refer to Figure.

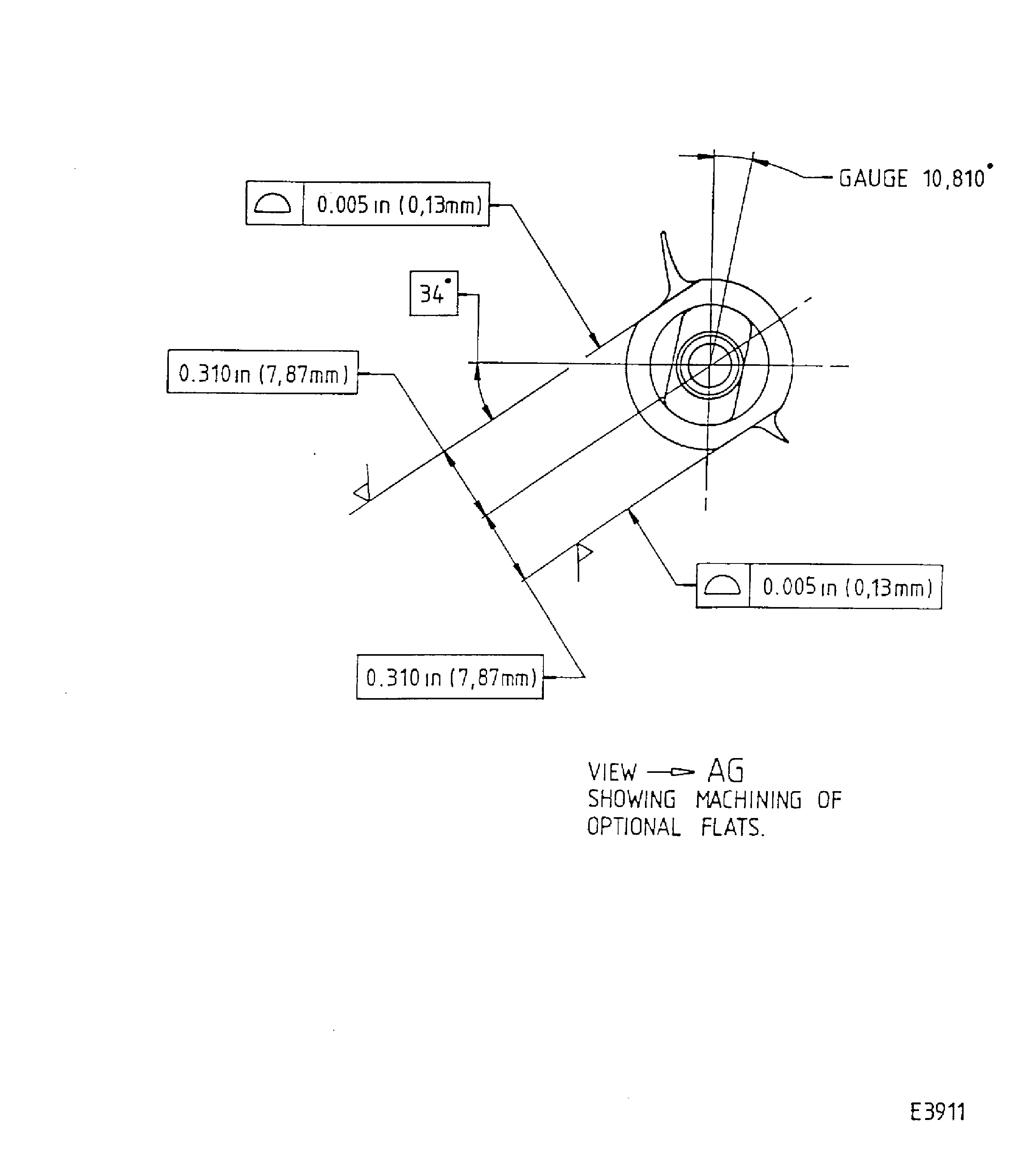

Put back the optional flats, as necessary.

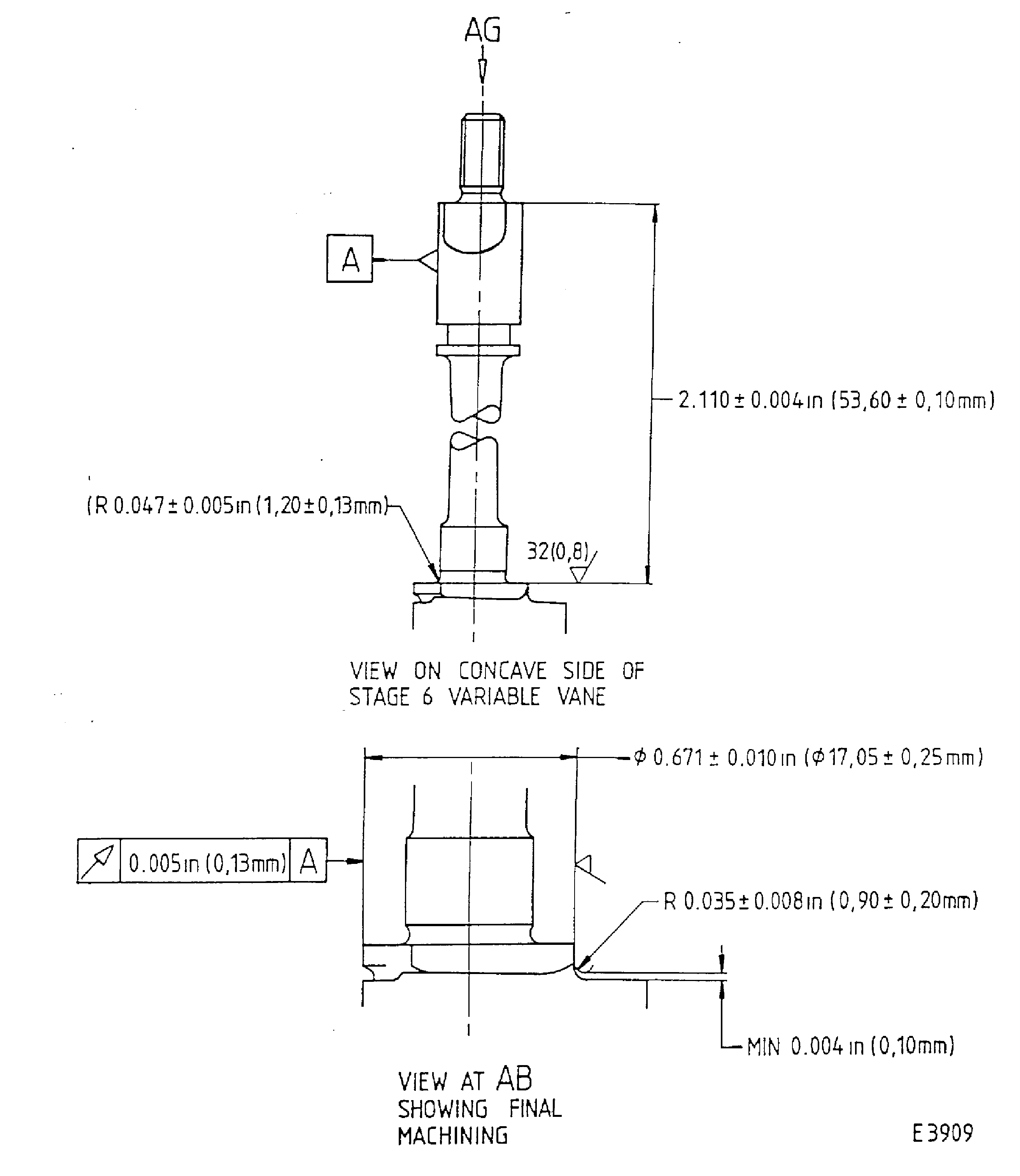

SUBTASK 72-41-32-324-051 Grind the HP Compressor Variable Staor Vane, Stage 6 Location Diameter, Assembly A and Assembly C

Refer to Figure.

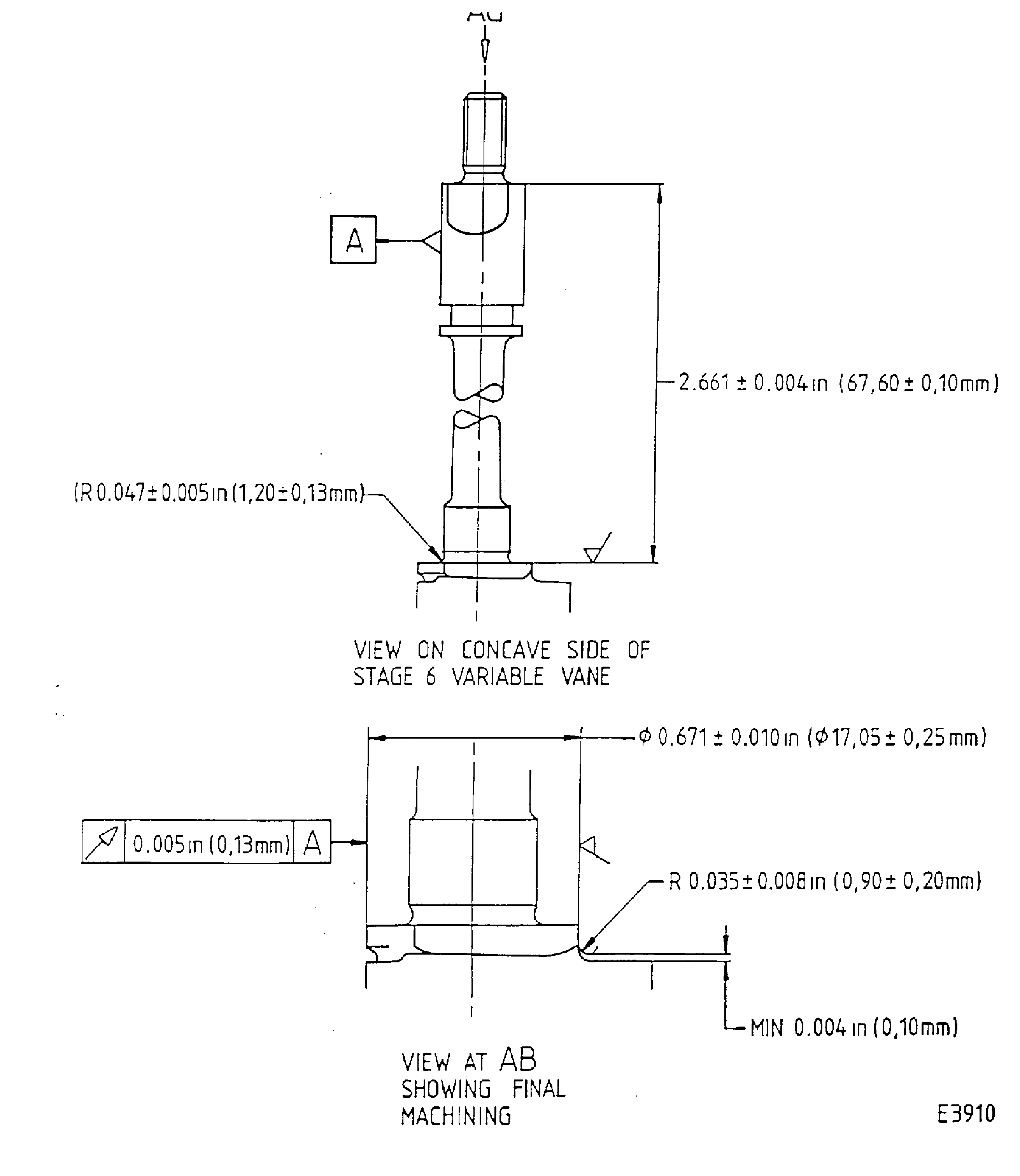

Put back the optional flats as necessary.

SUBTASK 72-41-32-324-052 Grind the HP Compressor Variable Stator Vane, Stage 6 Location Diameter, Assembly B and Assembly D

CAUTION

DO NOT REMOVE MATERIAL FROM THE HP COMPRESSOR VARIABLE STATOR VANE, STAGE 6 SPINDLE, DIAMETER AC.Refer to the SPM TASK 70-23-04-230-501.

Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) with penetrant crack test equipment.

Cracks are not permitted.

Do a penetrant crack test on the repair area.

SUBTASK 72-41-32-230-072 Do a Crack Teat

Refer to Figure and Fig. 72-41-32-990-058.

SUBTASK 72-41-32-220-131 Examine the HP Compressor Variable Stator Vane, Stage 6, Assembly A and Assembly C

Refer to Figure.

SUBTASK 72-41-32-350-082 Identify the Repiar, Assembly A and Assembly C

Refer to Figure.

SUBTASK 72-41-32-350-083 Identify the Repair, Assembly B and Assembly D

Figure: Repair details and dimensions - Assy A and Assy C

Repair details and dimensions - Assy A and Assy C

Figure: Repair details and dimensions - Assy B and Assy D

Repair details and dimensions - Assy B and Assy D

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and diamensions - Assy A and Assy C

Repair details and diamensions - Assy A and Assy C

Figure: Repair details and diamensions - Assy B and Assy D

Repair details and diamensions - Assy B and Assy D

Figure: Repair details and diamensions

Repair details and diamensions