Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-33-300-009 HPC Stage 3 Variable Stator Vane Shroud - Replace The Dowel Pins, Repair-009 (VRS6085)

Material of component

PART IDENT | MATERIAL |

HP compressor stage 3 inner shroud | Aluminium alloy |

Dowel pin | Nimonic 80A |

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

This repair must only be done when the instruction to do so is given in TASK 72-41-33Inspection/Check.

This Repair has been issued to replace worn/damaged dowel pins in the HP compressor stage 3 inner shroud.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and Availability

Refer to International Aero Engines

Related Repairs - None

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 03-026 LIQUID NITROGEN | LOCAL | CoMat 03-026 | ||

| CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) | LOCAL | CoMat 06-063 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| PART IDENT | PART NO. | |||

| Retaining ring | AS20762 | |||

| Retaining ring | AS20763 | |||

| Grooved headless pin | AS20745 | (dowel pin) | ||

| Locating pin | LK41751 | (dowel pin) |

Safety Requirements

NONEProcedure

Refer to the SPM TASK 70-11-26-300-503.

Use CoMat 02-099 LINT-FREE CLOTH and blast with clean dry compressed air.

Clean the holes.

SUBTASK 72-41-33-070-001 Remove the Dowel Pins, Assembly A and Assembly B

WARNING

BE CAREFUL WHEN YOU USE COMPRESSED AIR. PUT ON PROTECTIVE CLOTHING AND GOGGLES. MAKE SURE THAT ALL PERSONS ARE AT A SAFE DISTANCE.Examine the holes for scores.

Reject the part if damage is found.

Make sure the fits and clearances for the pins are satisfactory.

Examine the rear shroud interference fit dowel hole for wear.

If the diameter of the hole is between 0.1963 to 0.1970 in. (4.987 to 5.005 mm), continue with the repair.

If the diameter is more than 0.1970 in. (5.005 mm), reject the part.

Examine the front shroud clearance fit dowel hole for wear.

If the diameter of the hole is between 0.200 to 0.201 in. (5.07 to 5.10 mm), continue with the repair.

If the diameter is more than 0.201 in. (5.10 mm), reject the part.

Do a visual and dimensional inspection.

SUBTASK 72-41-33-220-124-A00 Examine the Holes, Assembly A

Examine the holes for scores.

If damage is found, reject the part.

Make sure the fits and clearances for the pins are satisfactory.

Examine the rear shroud interference fit dowel hole for wear.

If the diameter of the hole is between 0.2357 to 0.2364 in. (5.987 to 6.005 mm), continue with the repair.

If the diameter is more than 0.2364 in. (6.005 mm), reject the part.

Examine the front shroud clearance fit dowel hole for wear.

If the diameter of the hole is between 0.239 to 0.240 in. (6.07 to 6.10 mm), continue with the repair.

If the diameter is more than 0.240 in. (6.10 mm), reject the part.

Do a visual and dimensional inspection.

SUBTASK 72-41-33-220-124-B00 Examine the Holes, Assembly B

Refer to the SPM TASK 70-23-05-230-501.

Use CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) or CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) with penetrant crack test equipment.

No cracks are permitted.

Do a penetrant crack test.

SUBTASK 72-41-33-230-083 Do a crack Test

Freeze the pins with CoMat 03-026 LIQUID NITROGEN.

Use an applicable installation tool to install the pins in position.

Use heat-protecting gloves.

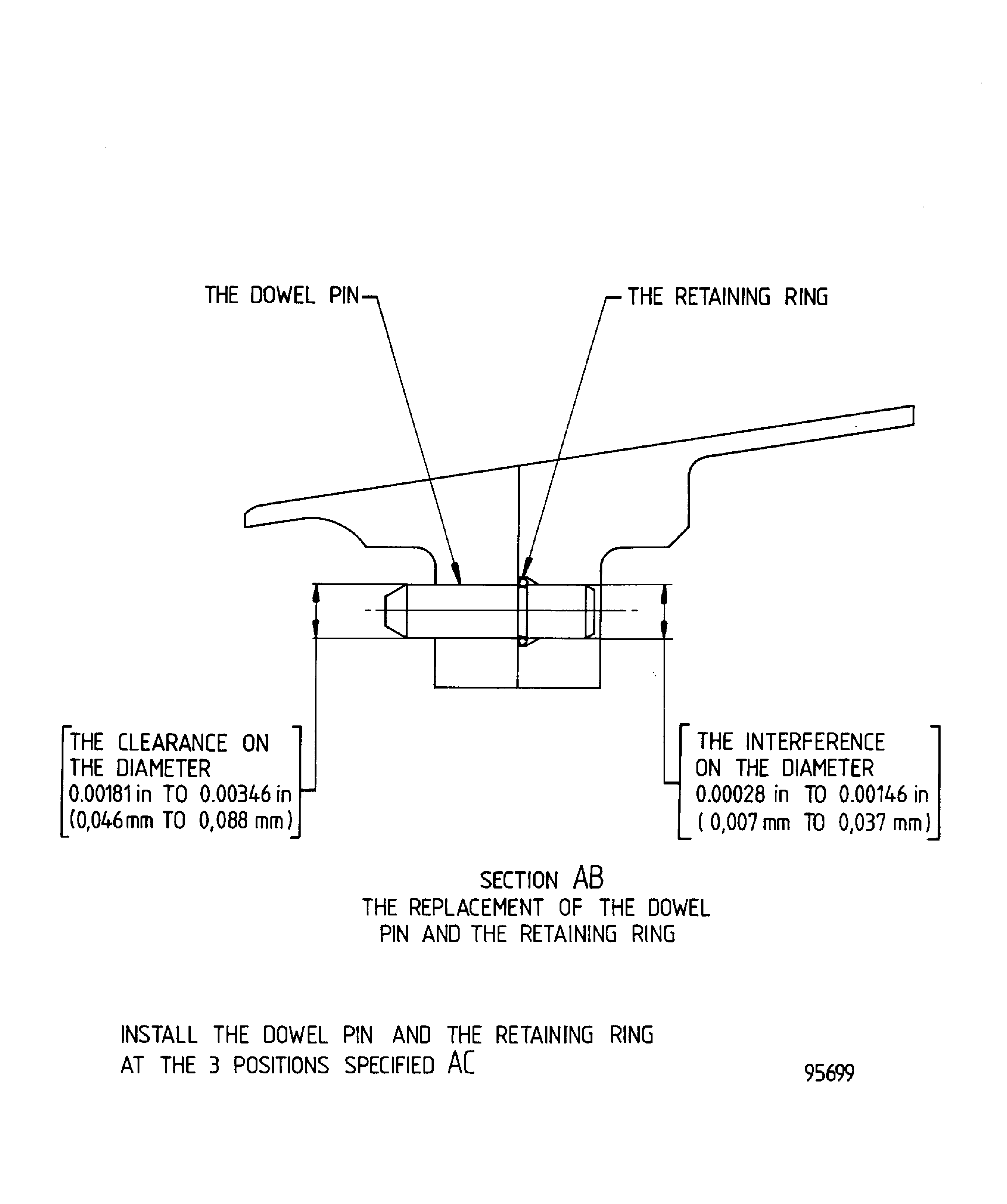

Install the dowel pins into the half shrouds.

SUBTASK 72-41-33-350-071-A00 Replace the Dowel Pins, Assembly A

WARNING

DO NOT GET LIQUID NITROGEN ON YOUR SKIN OR IN YOUR EYES. PUT ON PROTECTIVE CLOTHING, GLOVES, GOGGLES AND A MASK. LIQUID NITROGEN IS AN ASPHYXIATOR. USE THE LIQUID IN A WELL VENTILATED AREA. IF YOU GET THE LIQUID ON YOUR SKIN OR IN YOUR EYES, FLUSH IT AWAY WITH WATER. GET MEDICAL HELP IF YOUR SKIN OR EYES BECOME IRRITATED.Freeze the pins with CoMat 03-026 LIQUID NITROGEN.

Use an applicable installation tool to install the pins in position.

Use heat-protecting gloves.

Install the dowel pins into the half shrouds.

SUBTASK 72-41-33-350-071-B00 Replace the Dowel Pins, Assembly B

WARNING

DO NOT GET LIQUID NITROGEN ON YOUR SKIN OR IN YOUR EYES. PUT ON PROTECTIVE CLOTHING, GLOVES, GOGGLES AND A MASK. LIQUID NITROGEN IS AN ASPHYXIATOR. USE THE LIQUID IN A WELL VENTILATED AREA. IF YOU GET THE LIQUID ON YOUR SKIN OR IN YOUR EYES, FLUSH IT AWAY WITH WATER. GET MEDICAL HELP IF YOUR SKIN OR EYES BECOME IRRITATED.Refer to the SPM TASK 70-38-02-300-503.

Locally touch up the repaired area(s).

SUBTASK 72-41-33-380-061 Apply the Surface Protection

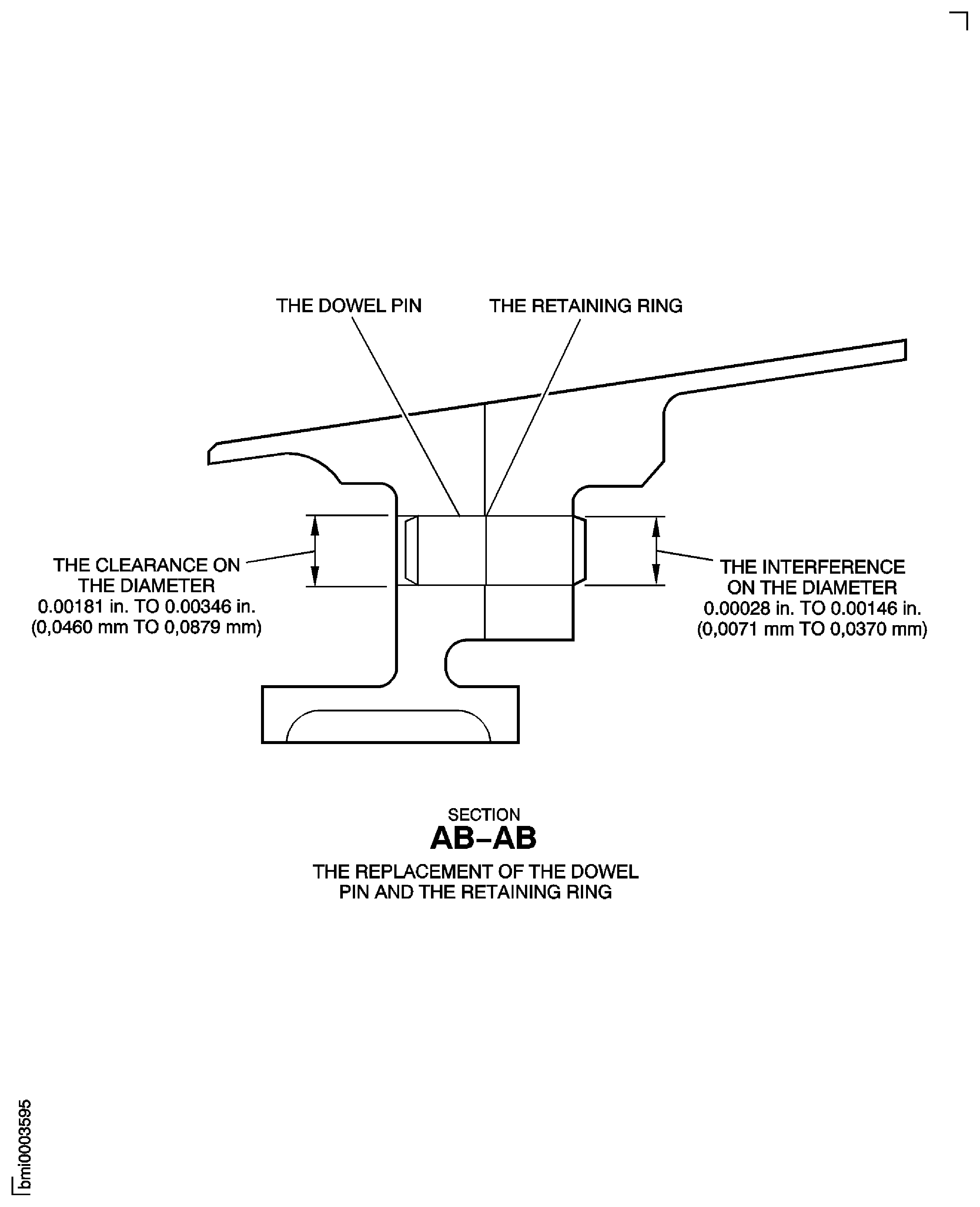

Figure: Repair Details and Dimensions - Assembly A and Assembly B

Sheet 1

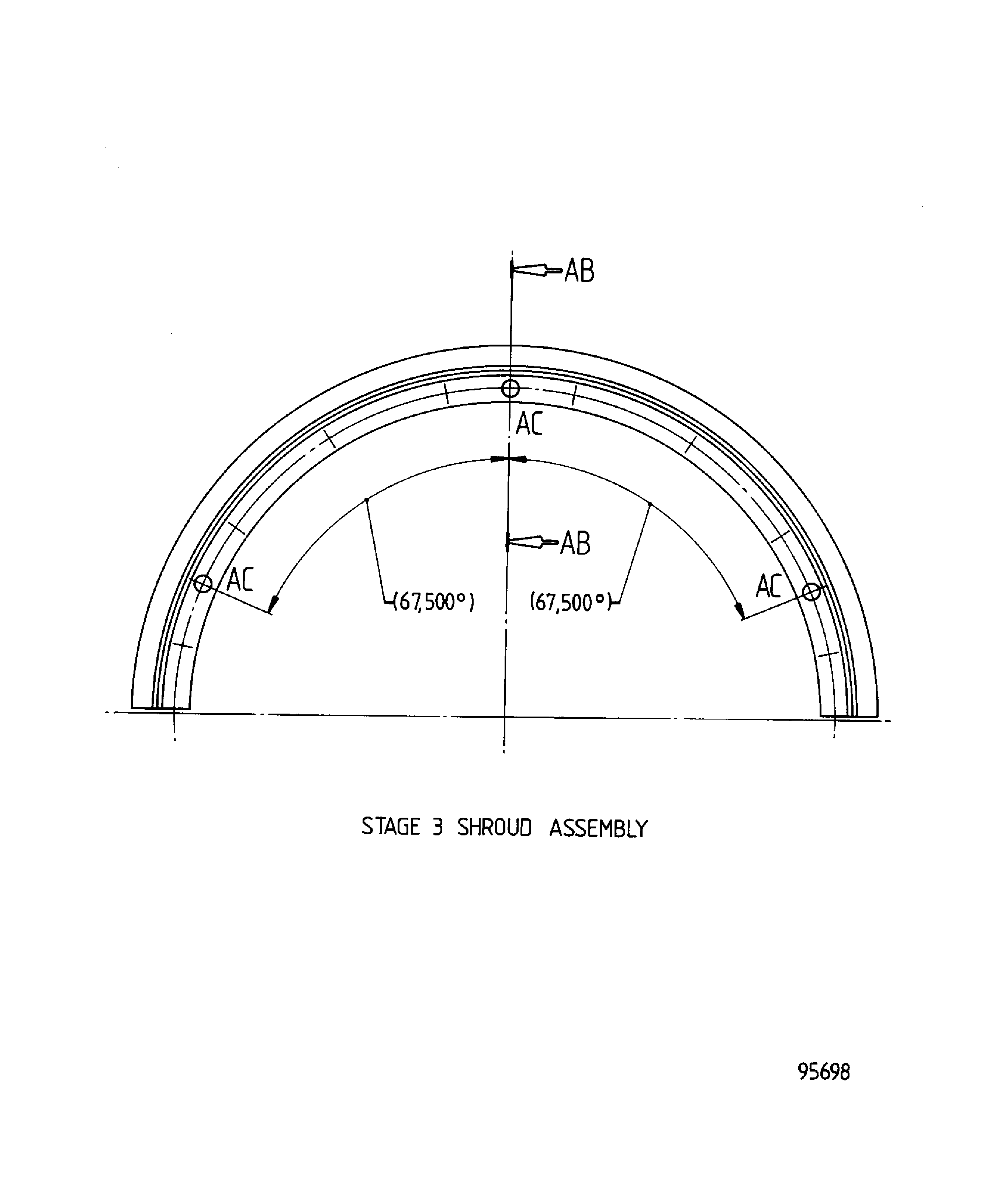

Figure: Repair Details and Dimensions - Assembly A

Sheet 2

Figure: Repair Details and Dimensions - Assembly B

Sheet 3