Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-33-300-004 HPC Stage 5 Variable Stator Vane Shroud - Replace The Lining, Repair-004 (VRS6040)

Material of component

PART IDENT | MATERIAL |

|---|---|

HP compressor stage 5 half shroud assembly | Corrosion resistant steel |

General

This repair must only be done when the instruction to do so is given in 72-41-33 Inspection/Check.

This repair has been issued for the HP compressor stage 5 half shroud assembly lining.

The practices and processes referred to in the procedure by the TASK/SUBTASK number are in the SPM.

Price and Availability.

Refer to International Aero Engines.

Related Repairs.

None.

NOTE

More equipment and materials necessary to do this repair are in the SPM TASKS given below.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Air grinder | LOCAL | |||

| Chemical strip equipment | LOCAL | |||

| Hardness Tester | LOCAL | |||

| Lathe | LOCAL | |||

| Metal spray equipment | LOCAL | |||

| Penetrant Crack Test Equipment | LOCAL | |||

| Rotary burr | LOCAL | |||

| Vibrating Marking Pencil | LOCAL | |||

| Workshop inspection equipment | LOCAL |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL | 76381 | CoMat 02-006 | ||

| CoMat 03-036 METAL SPRAYING WIRE, Ni,Al | LOCAL | CoMat 03-036 | ||

| CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) | 00BB6 | CoMat 03-038 | ||

| CoMat 03-057 ALUMINIUM ALLOY/POLYESTERCOMPOSITE | LOCAL | CoMat 03-057 | ||

| CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5) | 33870 | CoMat 03-089 | ||

| CoMat 03-090 METAL SPRAYING POWDER Ni/Al (95/5) | 0AM53 | CoMat 03-090 | ||

| CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE | LOCAL | CoMat 05-001 | ||

| CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE | LOCAL | CoMat 05-003 | ||

| CoMat 06-018 FLUORESCENT PENETRANT (POST-EMULSIFIED HIGH SENSITIVITY) | X222X | CoMat 06-018 |

Spares

NONESafety Requirements

NONEProcedure

Refer to SPM TASK 70-33-59-300-503, SUBTASK 70-33-59-300-003 and SUBTASK 70-33-59-300-002.

Refer to SPM TASK 70-33-59-300-503, SUBTASK 70-33-59-300-008.

SUBTASK 72-41-33-330-051 Remove the Remaining Bond Coat

Make sure that the lining and bond coat has been completely removed.

Make sure there is no damage to the parent material.

Make sure all the dimensions are in the limits shown.

Refer to SPM TASK 70-34-01-340-501.

Visually/dimensionally examine the stage 5 half shroud assembly.

SUBTASK 72-41-33-220-116 Examine the Stage 5 Half Shroud Assembly

Use CoMat 06-018 FLUORESCENT PENETRANT (POST-EMULSIFIED HIGH SENSITIVITY) fluorescent penetrant with the penetrant crack test equipment.

Cracks are not permitted.

Refer to SPM TASK 70-23-03-230-501.

Do the penetrant crack test.

SUBTASK 72-41-33-230-066 Examine the Stage 5 Half Shroud Assembly for Cracks

Refer to SPM TASK 70-11-01-300-503.

Remove the grease.

SUBTASK 72-41-33-110-056 Remove the Grease

Use CoMat 02-001 ADHESIVE TAPE (MASKING) or a locally manufactured mask.

Mask the areas not to be sprayed.

SUBTASK 72-41-33-350-061 Apply Adhesive Tape to the Areas not to be Sprayed

Remove the adhesive tape or masks when the component has been cleaned.

Do not touch the areas which have been cleaned.

Refer to SPM TASK 70-12-02-120-501.

Abrasive blast the areas to be sprayed.

SUBTASK 72-41-33-120-051 Clean the Areas to be Sprayed

Use CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL or a locally manufactured fixture.

Mask the areas not to be sprayed.

SUBTASK 72-41-33-350-062 Apply Adhesive Tape to the Areas not to be Sprayed

For powder feed plasma spray use CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) or CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5) or CoMat 03-090 METAL SPRAYING POWDER Ni/Al (95/5).

For the wire feed combustion spray use CoMat 03-036 METAL SPRAYING WIRE, Ni,Al.

Heat the shroud assembly to a temperature of 221 deg F to 257 deg F (105 deg C to 125 deg C).

Use the spray gun with the powder feed off. Apply a thickness of 0.0030 in. to 0.0050 in. (0.076 mm to 0.127 mm).

Refer to SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-025 and SUBTASK 70-34-01-340-010.

Apply the bond coat.

Apply sufficient thickness to allow for machining.

Also spray a test piece to examine for hardness.

Remove the adhesive tape when the lining has been applied.

Refer to SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-020.

Apply the lining to the stage 5 half shroud assembly.

SUBTASK 72-41-33-340-052 Apply the Lining to the Stage 5 Half Shroud Assembly

Refer to SPM TASK 70-34-01-340-501.

Visually examine the lining on the stage 5 half shroud assembly.

The average hardness must be 55 R15Y to 85 R15Y with the outer limits of 50 minimum and 90 maximum.

Refer to SPM TASK 70-34-01-340-501.

Do a hardness test on the test spray sample.

SUBTASK 72-41-33-220-117 Examine the Stage 5 Half Shroud Assembly Lining

Use vibro-engraving equipment.

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Vibro-engrave VRS6040 adjacent to the part number on the stage 5 half shroud assembly.

SUBTASK 72-41-33-350-065 Identify the Repair on the Stage 5 Half Shroud Assembly

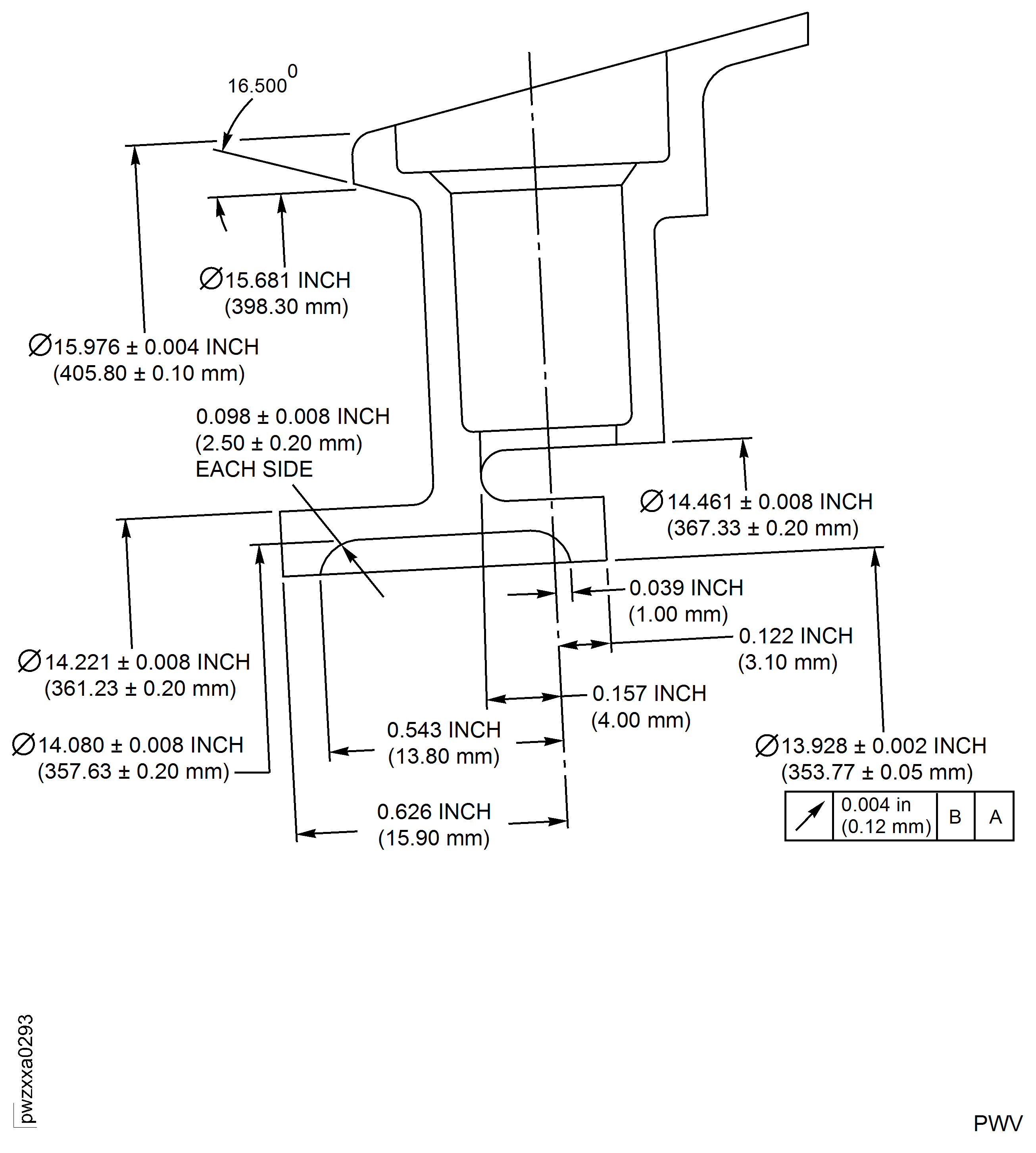

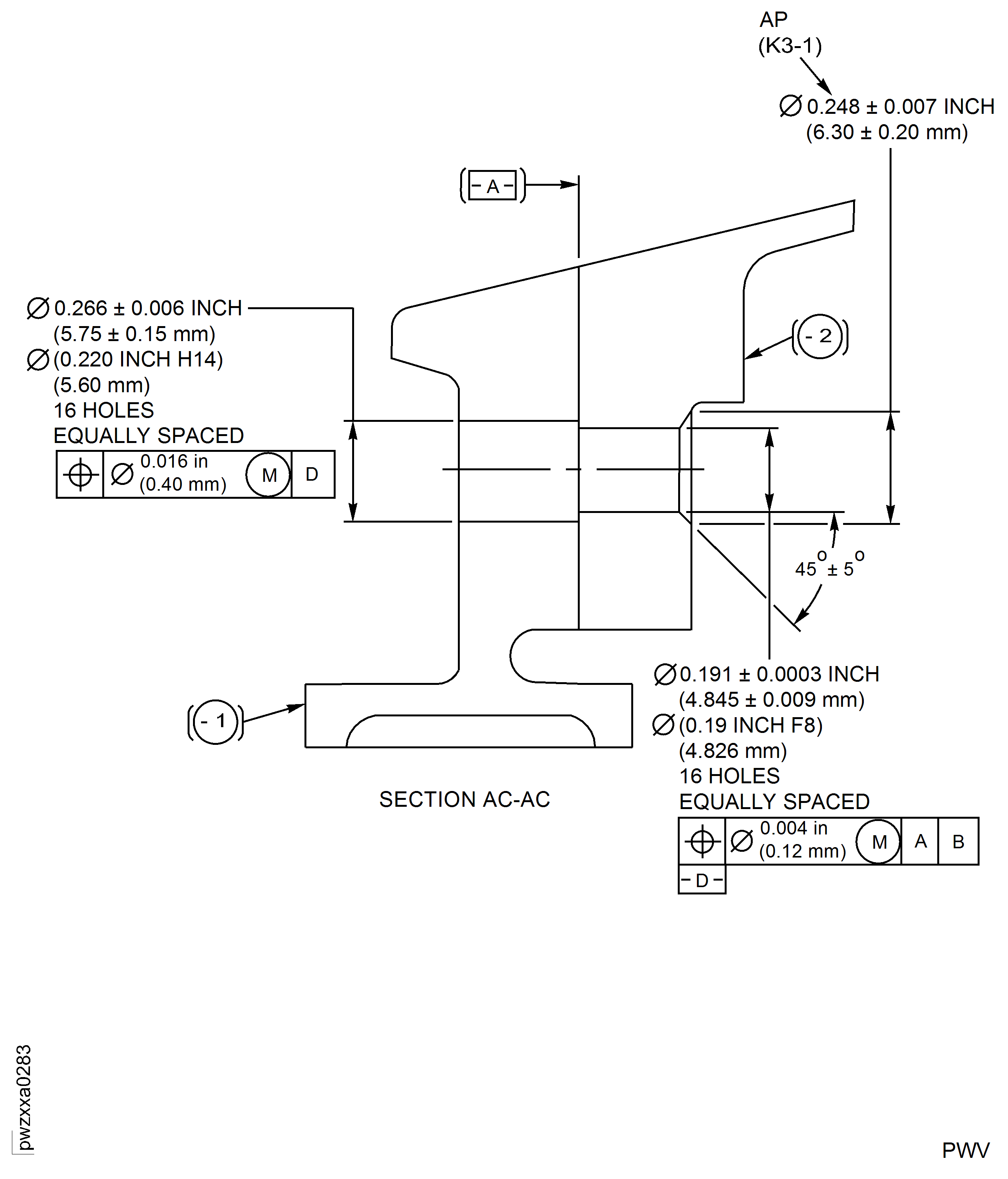

Figure: Details to Machine the Stage 5 Half Shroud Assembly - Assembly A

Details to Machine the Stage 5 Half Shroud Assembly - Assembly A

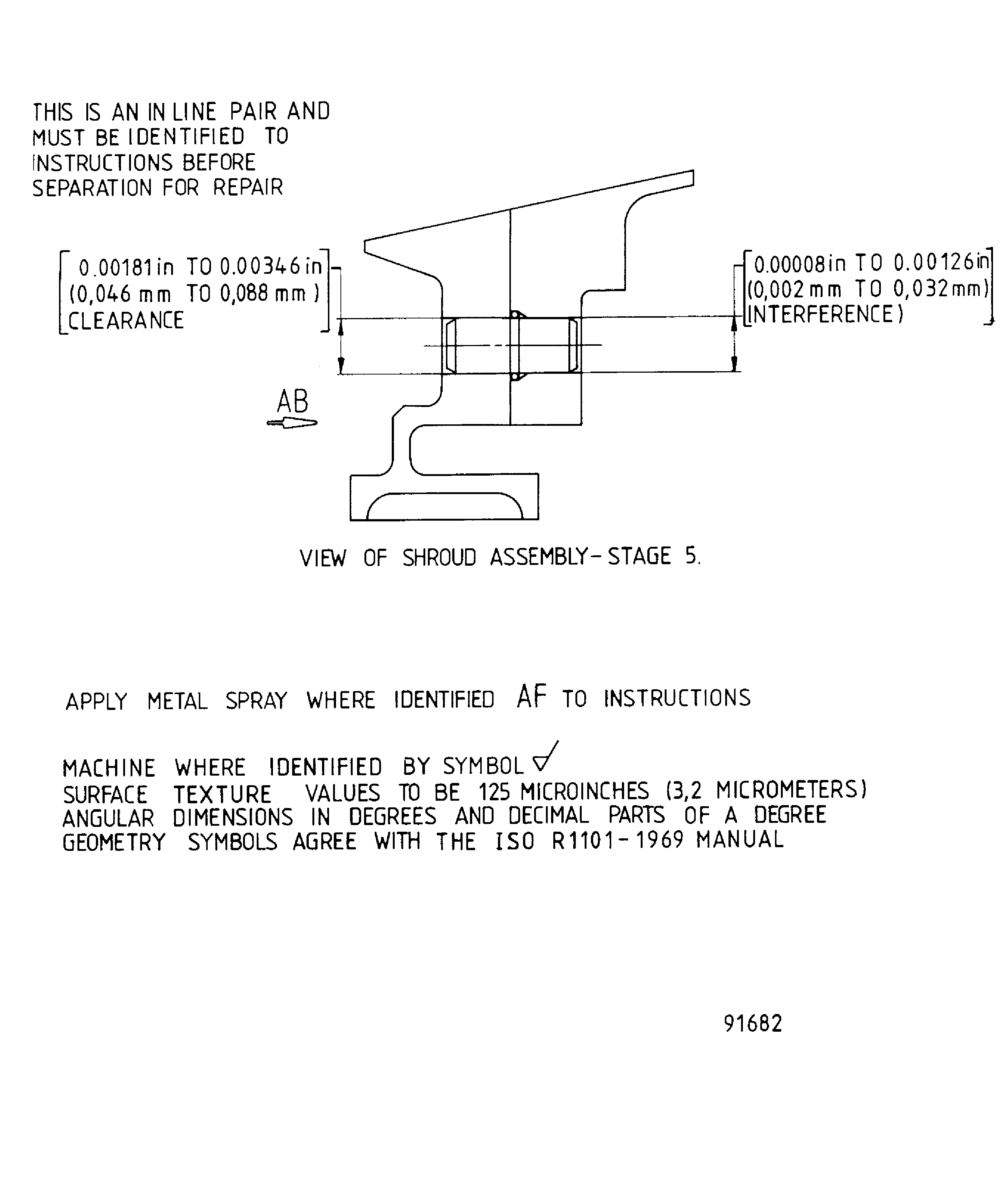

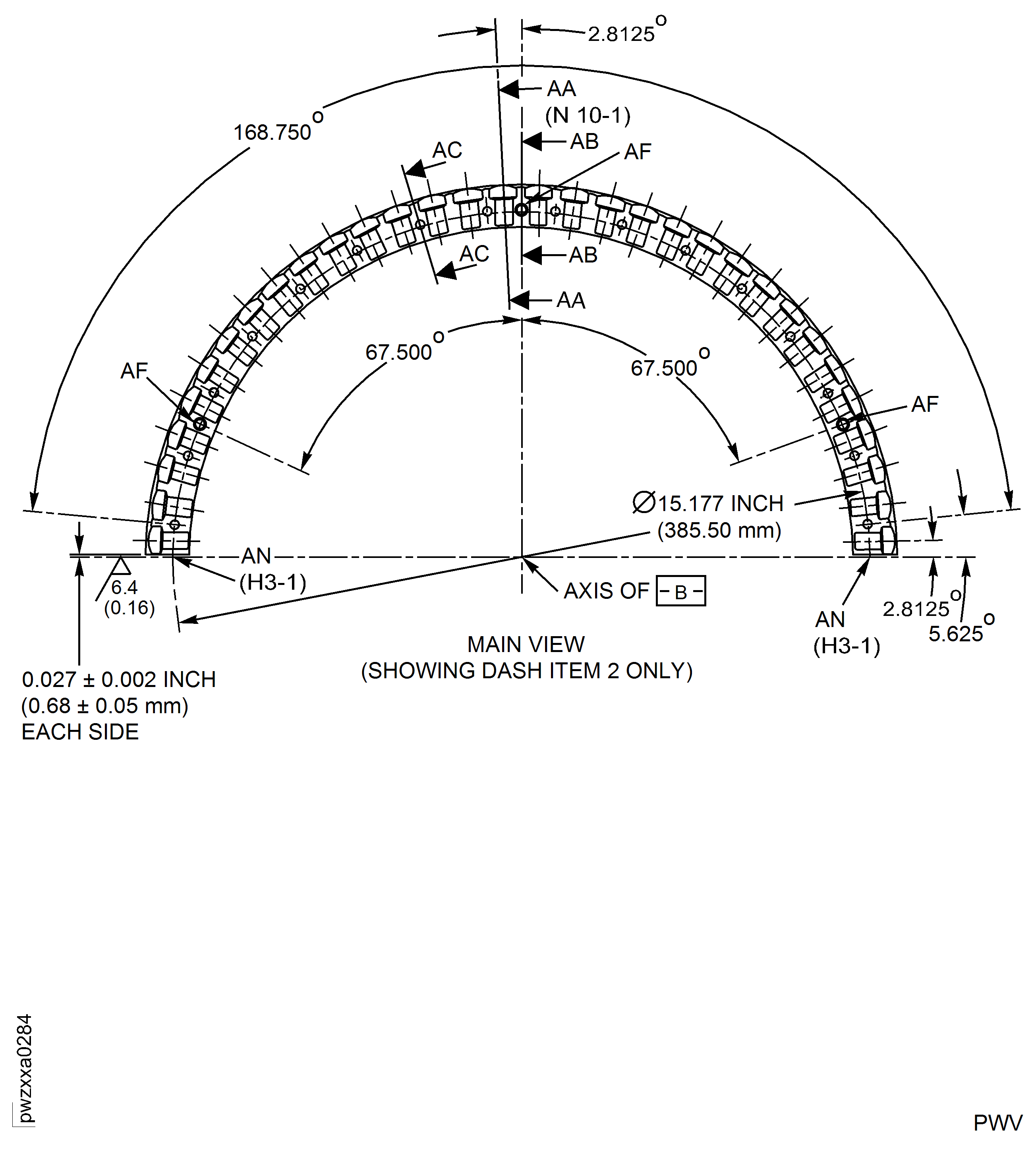

Figure: Details to Apply the Lining to the Stage 5 half Shroud Assembly - Assembly A

Sheet 1

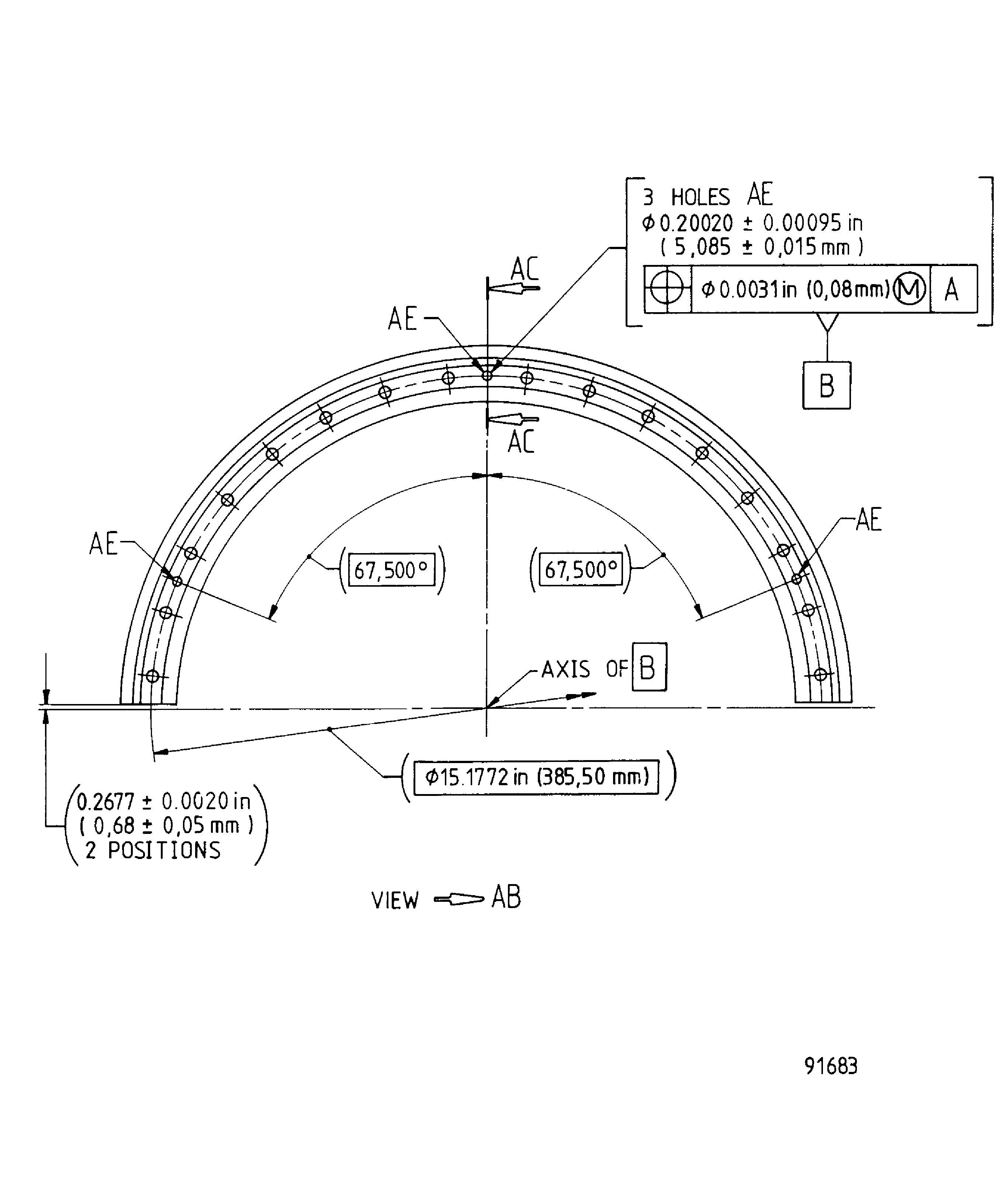

Figure: Details to Apply the Lining to the Stage 5 Half Shroud Assembly - Assembly A

Sheet 2

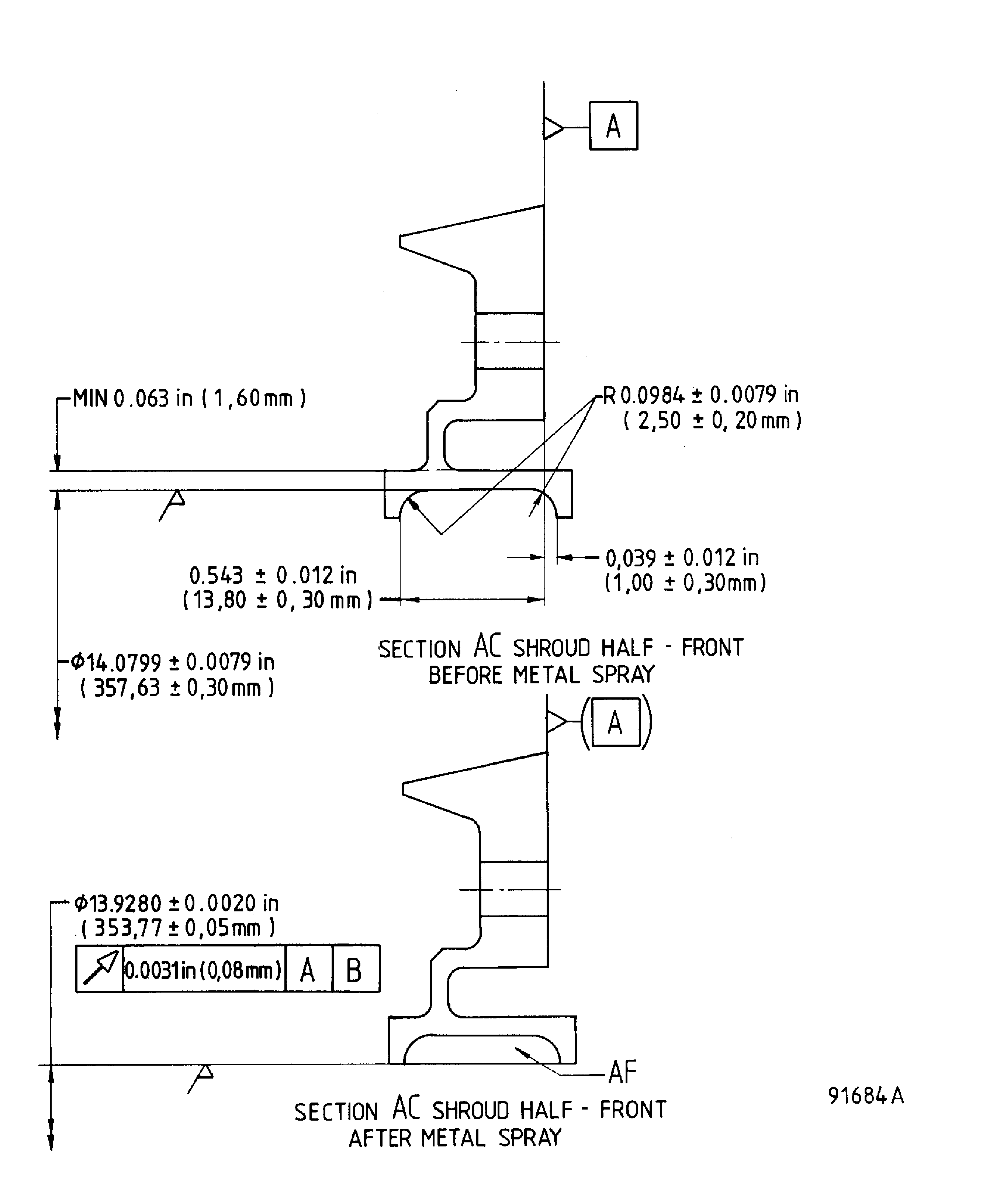

Figure: Details to Machine the Stage 5 Half Shroud Assembly - Assembly B

Details to Machine the Stage 5 Half Shroud Assembly - Assembly B

Figure: Details to Apply the Lining to the Stage 5 Half Shroud Assembly - Assembly B

Details to Apply the Lining to the Stage 5 Half Shroud Assembly - Assembly B

Figure: Details to Apply the Lining to the Stage 5 Half Shroud Assembly - Assembly B

Details to Apply the Lining to the Stage 5 Half Shroud Assembly - Assembly B