Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-34-300-064 HPC Inlet Variable Stator Vane Unison Rings - Repair of Crack in rivet weld by Welding, Repair-064 (VRS6544)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

02-440 | 6A7580 |

02-440 | 6A7849 |

02-440 | 6A7899 |

02-440 | 6A8075 |

02-540 | 6A7584 |

02-540 | 6A7851 |

02-540 | 6A7901 |

02-540 | 6A8077 |

03-440 | 6A7588 |

03-440 | 6A7861 |

03-440 | 6A7863 |

03-440 | 6A7903 |

03-440 | 6A8115 |

03-540 | 6A7590 |

03-540 | 6A7865 |

03-540 | 6A7906 |

03-540 | 6A8119 |

04-440 | 6A7596 |

04-440 | 6A7868 |

04-440 | 6A7888 |

04-440 | 6A8117 |

04-440 | 6A8121 |

04-540 | 6A7599 |

04-540 | 6A7890 |

05-440 | 6A7605 |

05-440 | 6A7894 |

05-440 | 6A8086 |

05-440 | 6A8088 |

05-540 | 6A7607 |

05-540 | 6A7896 |

General

This repair must only be done when the instruction to do so is given in the inspection procedures (identified by the applicable part number) located in section 72-41-34.

This TASK gives the procedure to repair the cracks in the rivet welds on the HPC Inlet Variable Stator Vane Unison Rings by welding.

TASKS identified by SPM TASK are in the Standard Practices and Processes Manual (SPM).

Price and availability.

Refer to International Aero Engine.

NOTE

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Welding equipment | LOCAL | Welding equipment | ||

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Standard workshop tools | LOCAL | Standard workshop tools | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON | IE304 | CoMat 02-121 | ||

| CoMat 03-366 WELDING FILLER WIRE | LOCAL | CoMat 03-366 | ||

| CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) | LOCAL | CoMat 06-063 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 | ||

| CoMat 05-106 ABRASIVE STONE | K6835 | CoMat 05-106 | ||

| CoMat 05-111 EMERY POLISHING PAPER | 06565 | CoMat 05-111 |

Spares

NONESafety Requirements

NONEProcedure

Refer to SPM TASK 70-35-03-300-501.

Dress to remove cracking. Remove burrs and sharp edges from weld only.

Removal of parent material on the HPC Inlet Variable Stator Vane Unison Rings is not permitted.

Removal of parent material on the rivet is not permitted; if the rivet is damaged refer to VRS6265.

Prepare the repair area for welding.

SUBTASK 72-41-34-110-147 Prepare the Repair Area for Welding

Refer to SPM TASK 70-23-05-230-501.

Cracks are not permitted.

Do a local penetrant crack test on the repair area of dressing.

SUBTASK 72-41-34-230-198 Do a Crack Test

Refer to TASK 72-41-34-100-000.

Chemically clean the HPC Inlet Variable Stator Vane Unison Rings.

SUBTASK 72-41-34-110-148 Chemically Clean

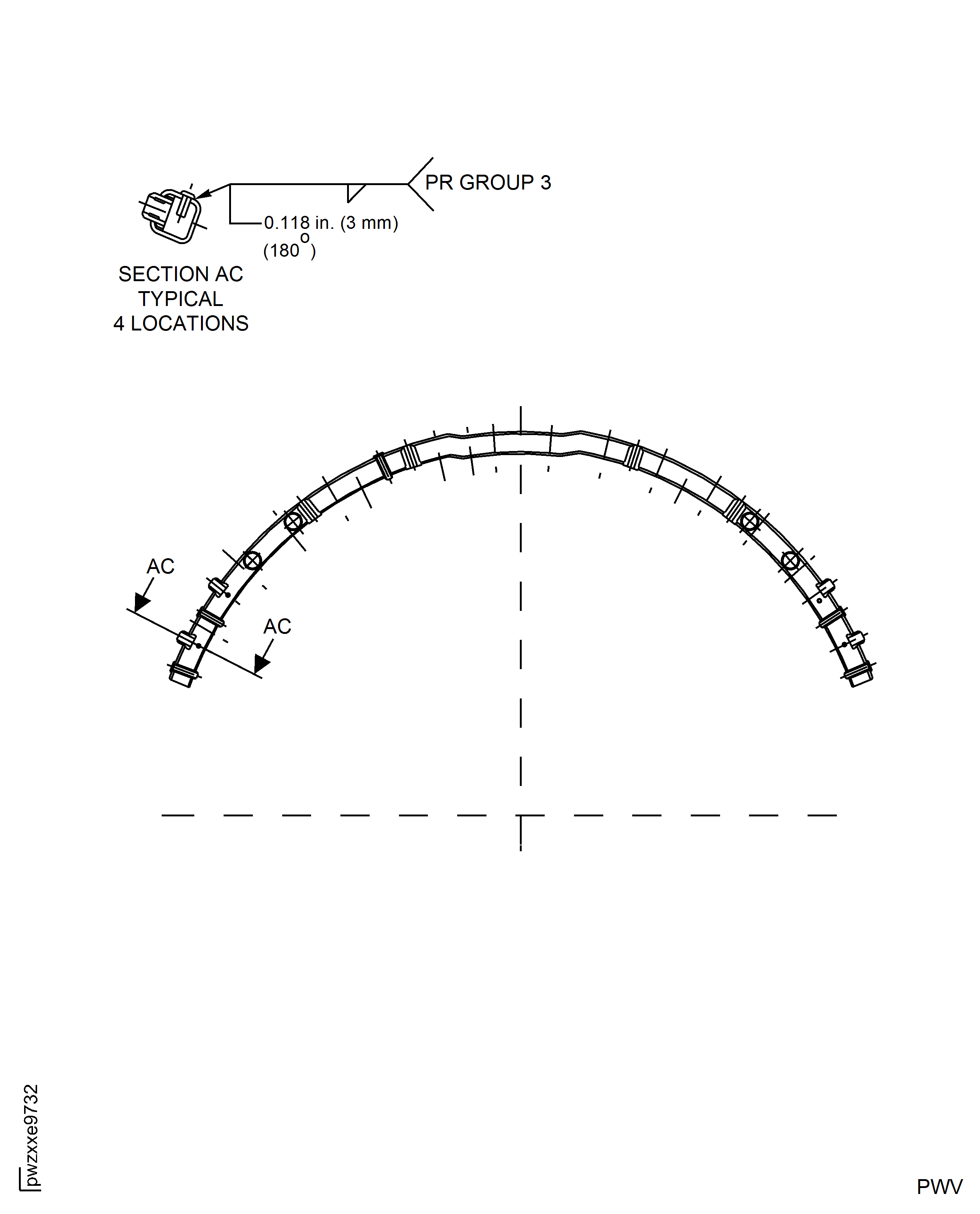

Refer to Figure.

Refer to SPM TASK 70-31-02-310-501-001.

Tack weld location pin (UP11019) repair areas, to capture respective dowel assemblies in actuating ring.

Weld build up dressed area.

SUBTASK 72-41-34-350-201 Weld Build up the damaged Area

Refer to TASK 72-41-34-100-000.

Chemically clean the HPC Inlet Variable Stator Vane Unison Rings.

SUBTASK 72-41-34-110-149 Chemically Clean

Refer to Figure.

Refer to SPM TASK 70-31-02-310-501-001, SUBTASK 70-31-02-220-002.

Visually and dimensionally inspect the repaired area.

SUBTASK 72-41-34-220-675 Examine the HPC Inlet Variable Stator Vane Unison Rings

Refer to SPM TASK 70-23-05-230-501.

Cracks are not permitted.

Do a local penetrant crack test on the repaired area.

SUBTASK 72-41-34-230-199 Do a Crack Test

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Mark VRS6544/ and the number of repairs adjacent to the part number.

SUBTASK 72-41-34-350-202 Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions