Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-34-300-029 HPC Stage 6 Unison Ring Connector Bridges - Replace The Surface Protection, Repair-029 (VRS6329)

Material of component

RR | ||

|---|---|---|

DESCRIPTION | SYMBOL | MATERIAL |

Bridge Piece | EAK | Jethete |

Bush | VEB | Graphite filled polymide |

resin |

General

This Repair must only be done when the instruction to do so is given in 72-41-34 Inspection.

This Repair has been issued for the HP compressor stage 6 actuating ring connector assembly surface damage.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

The surface protection will normally only be replaced if the bushes need to be removed if worn or damaged. Otherwise a local touch-up will be used if the surface is damaged.

The new bushes will be fitted after the surface protection has been completed.

Any surface protection damaged during the replacement of the bushes will be touched-up locally.

Price and availability

Refer to IAE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Paint stripping equipment | LOCAL | Paint stripping equipment | ||

| Degreasing equipment | LOCAL | Degreasing equipment | ||

| Dry abrasive blast equipment | LOCAL | Dry abrasive blast equipment | ||

| Spraying equipment | LOCAL | Spraying equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 06-073 INK, METAL MARKING | 88303 | CoMat 06-073 | ||

| CoMat 07-024 AEROLAC METAL PROTECTIVE VARNISH, CLEAR | LOCAL | CoMat 07-024 | ||

| CoMat 07-036 ALUMINIUM HIGH HEAT RESISTANT PAINT | 0AM53 | CoMat 07-036 | ||

| CoMat 07-038 AIR DRYING ENAMEL | K3504 | CoMat 07-038 | ||

| CoMat 07-075 HIGH-HEAT RESISTING STOVING ENAMEL | k3504 | CoMat 07-075 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Repair VRS6207 TASK 72-41-34-300-028.

Remove the bushes.

SUBTASK 72-41-34-350-062 Remove the Bushes

Refer to: Figure

SUBTASK 72-41-34-350-063 Prepare the Part to Apply the Surface Protection Coating

Refer to: Figure

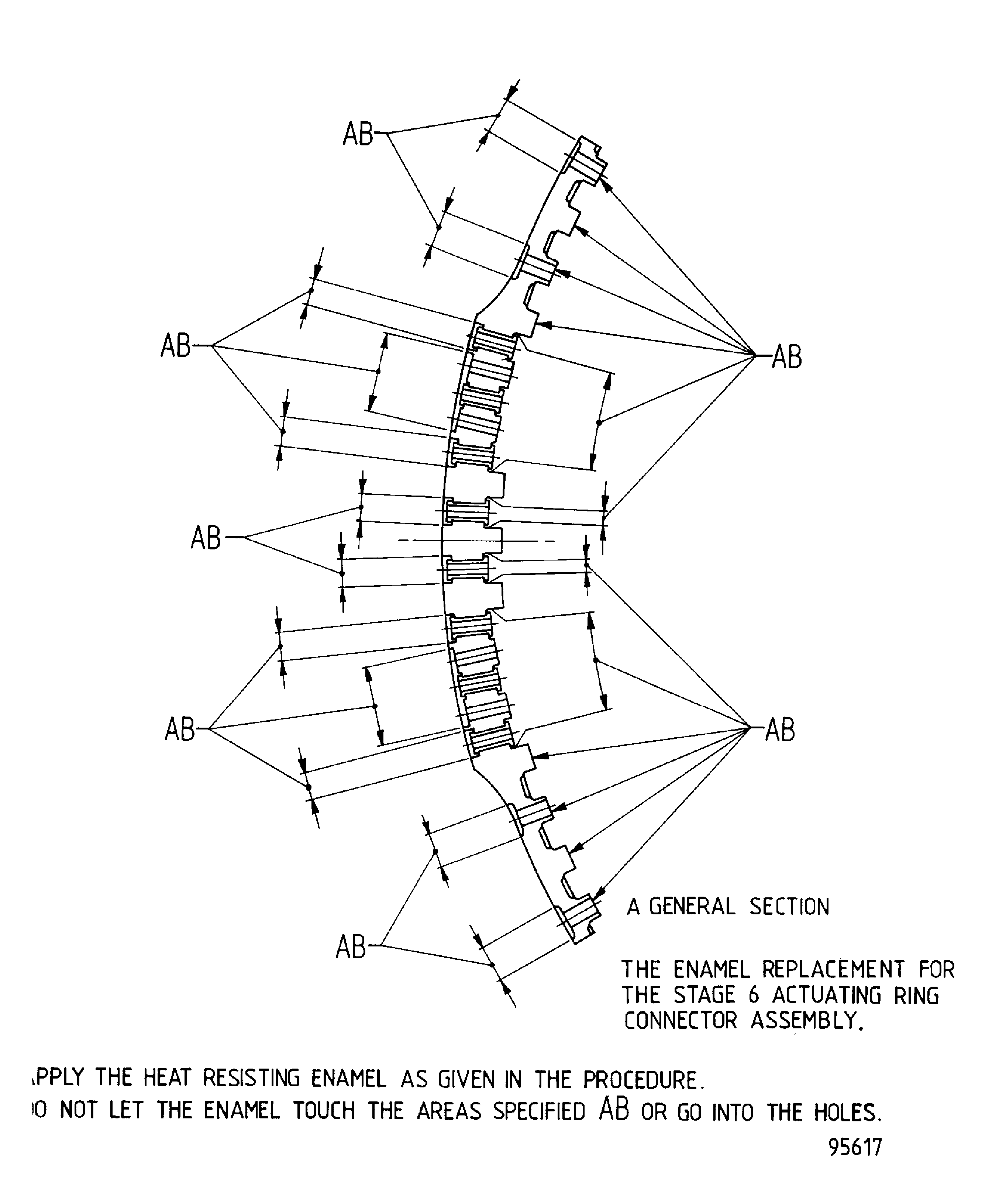

Use CoMat 07-075 HIGH-HEAT RESISTING STOVING ENAMEL, type C coating with a coating thickness of 0.0015in. (0.04 mm).

Apply the high heat resistant coating.

SUBTASK 72-41-34-380-051 Apply the High Heat Resistant Coating

Refer to: Figure

SUBTASK 72-41-34-220-190 Examine the Surface Coating

Refer to: Figure

SUBTASK 72-41-34-380-053 Touch-Up the Damaged Coating

SPM TASK 70-09-00-400-501 SUBTASK 70-09-00-400-002.

Use CoMat 06-073 INK, METAL MARKING followed by CoMat 07-024 AEROLAC METAL PROTECTIVE VARNISH, CLEAR.

Mark on the part number adjacent to the existing markings which are under the surface protection.

Re-identify the part.

SUBTASK 72-41-34-350-064 Identify the Part

Refer to Repair VRS6207 TASK 72-41-34-300-028.

Fit the bushes.

SUBTASK 72-41-34-350-065 Fit the Bushes

Figure: The stage 6 actuating ring connector assembly

The stage 6 actuating ring connector assembly