Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-42-11-300-036 Diffuser Case - Repair The Thread Of The Igniter Boss, Repair-036 (VRS3819)

FIG/ITEM | PART NO. |

|---|---|

01-010 | 2A0051 |

01-010 | 2A2081-01 |

01-010 | 2A2581-01 |

01-010 | 2A2883-01 |

01-010 | 2A2885-01 |

01-010 | 2A2889-01 |

01-010 | 2A2891-01 |

01-010 | 2A2896-01 |

01-010 | 2A2897-01 |

01-010 | 2A3132 |

General

Price and availability - refer to IAE

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Tap 1.0625-16UNJ-3B | LOCAL | Tap 1.0625-16UNJ-3B |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-284 WELDING FILLER WIRE, NiBASE | LOCAL | CoMat 03-284 | ||

| CoMat 03-209 WELDING FILLER WIRE, NiBASE 5% Cr | LOCAL | CoMat 03-209 | ||

| Sleeve | LOCAL | Locally fabricated | AMS 5663 | |

| Pin | LOCAL | SAE AS9389-80 | AMS 5735 |

Spares

NONESafety Requirements

NONEProcedure

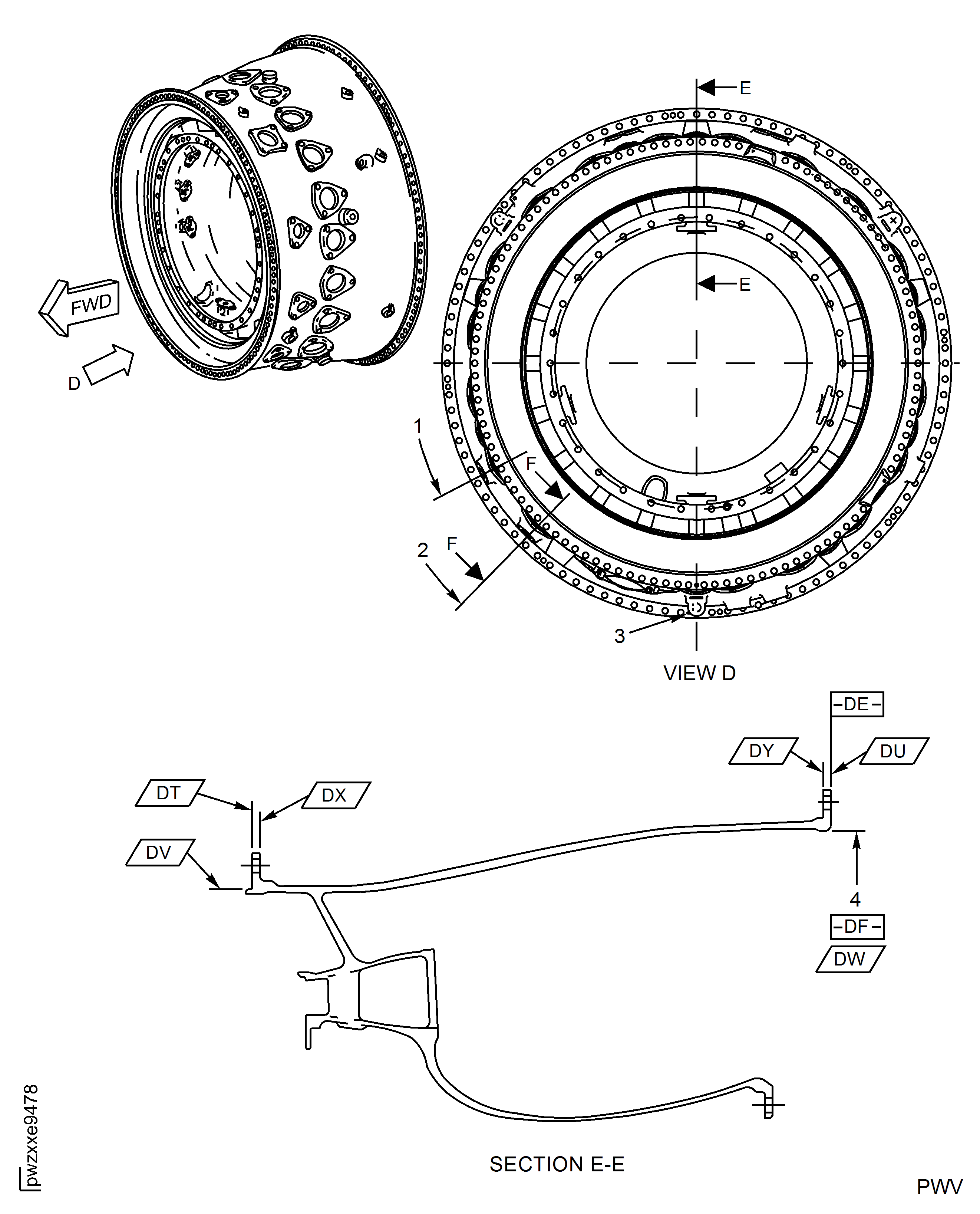

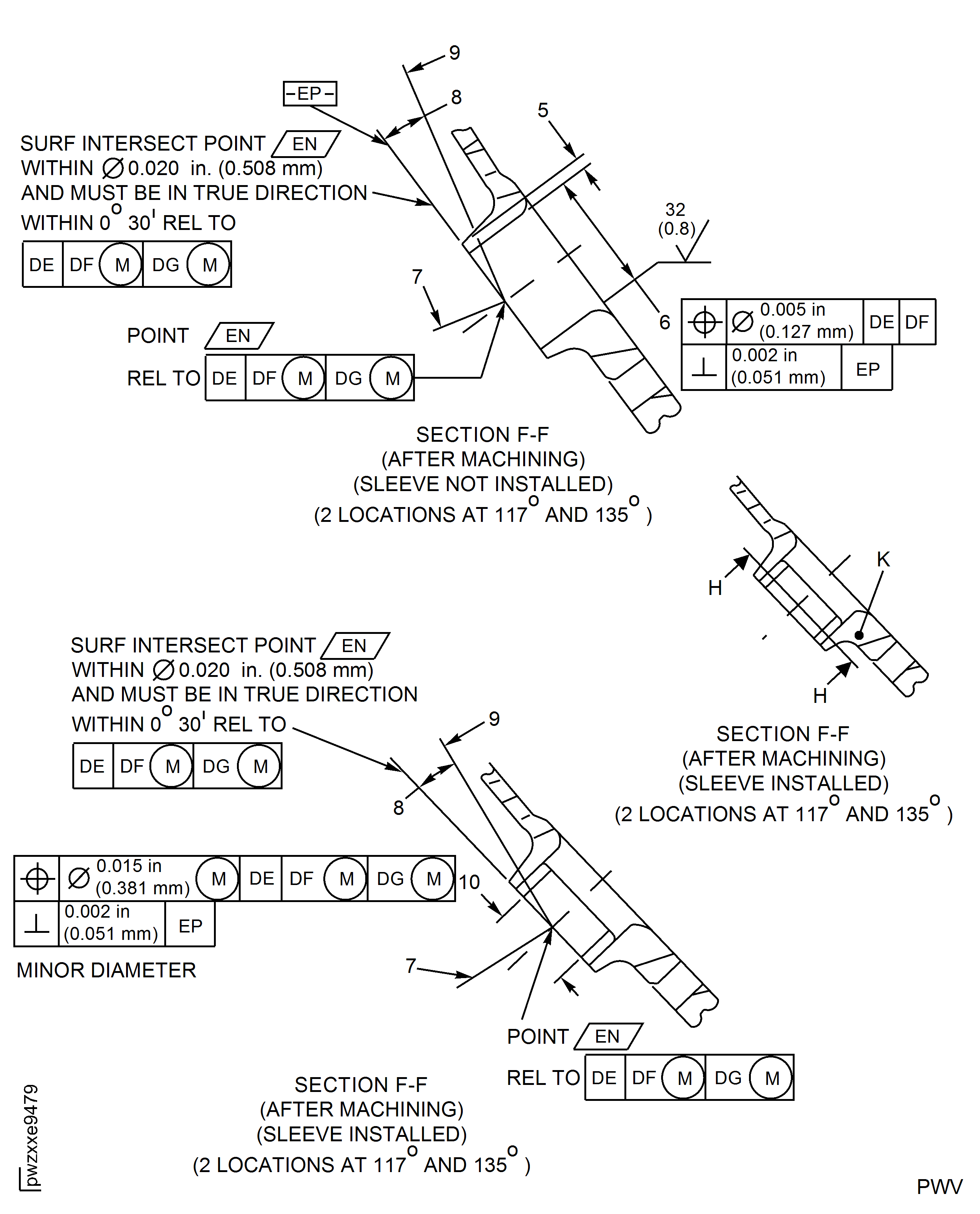

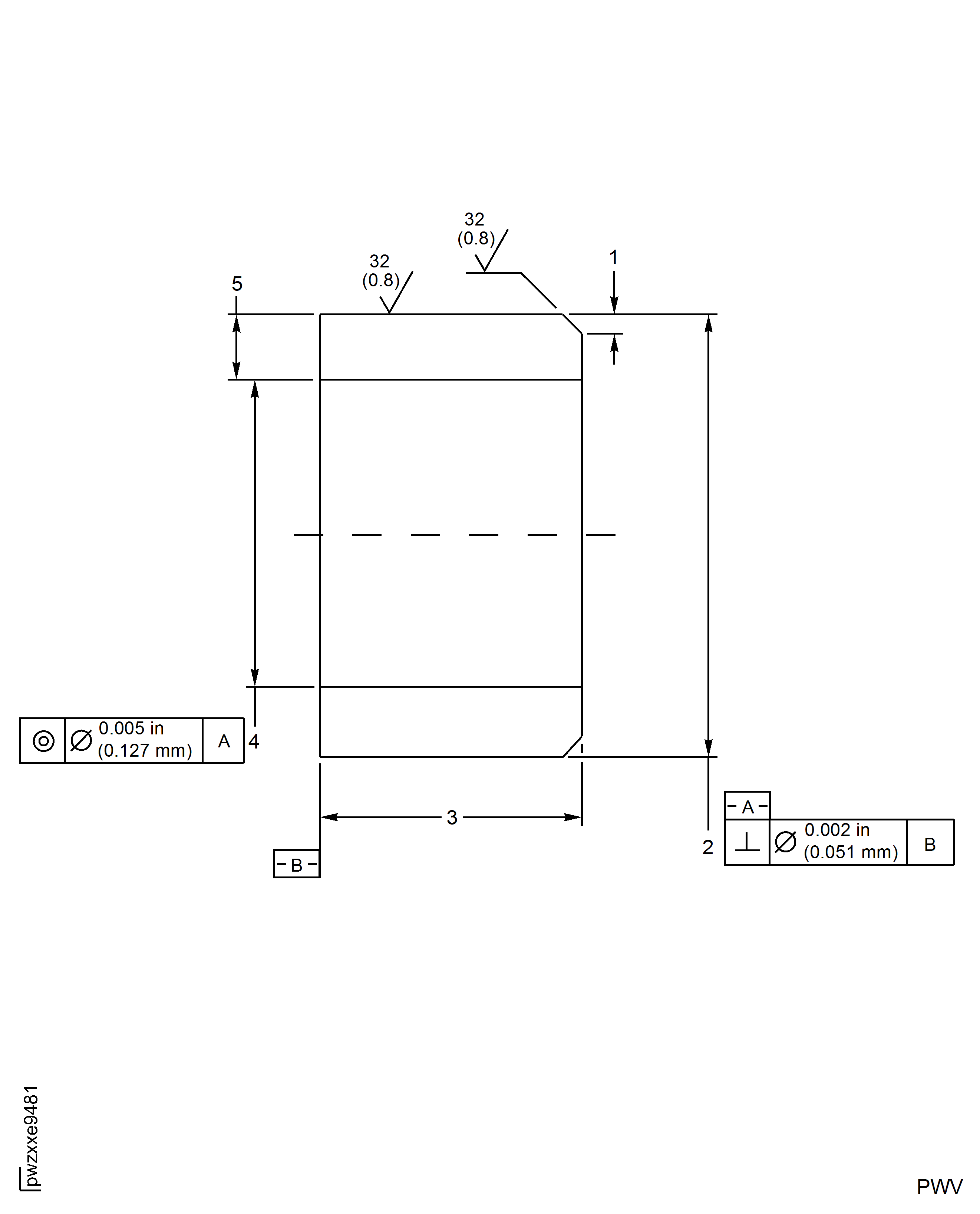

Machine bosses to the dimensions shown in Figure.

Clean the diffuser case. Refer to SPM TASK 70-11-03-300-503.

Do a fluorescent penetrant inspection of machined bosses by TASK 70-23-05-230-501.

Clean the sleeve. Refer to SPM TASK 70-11-03-300-503.

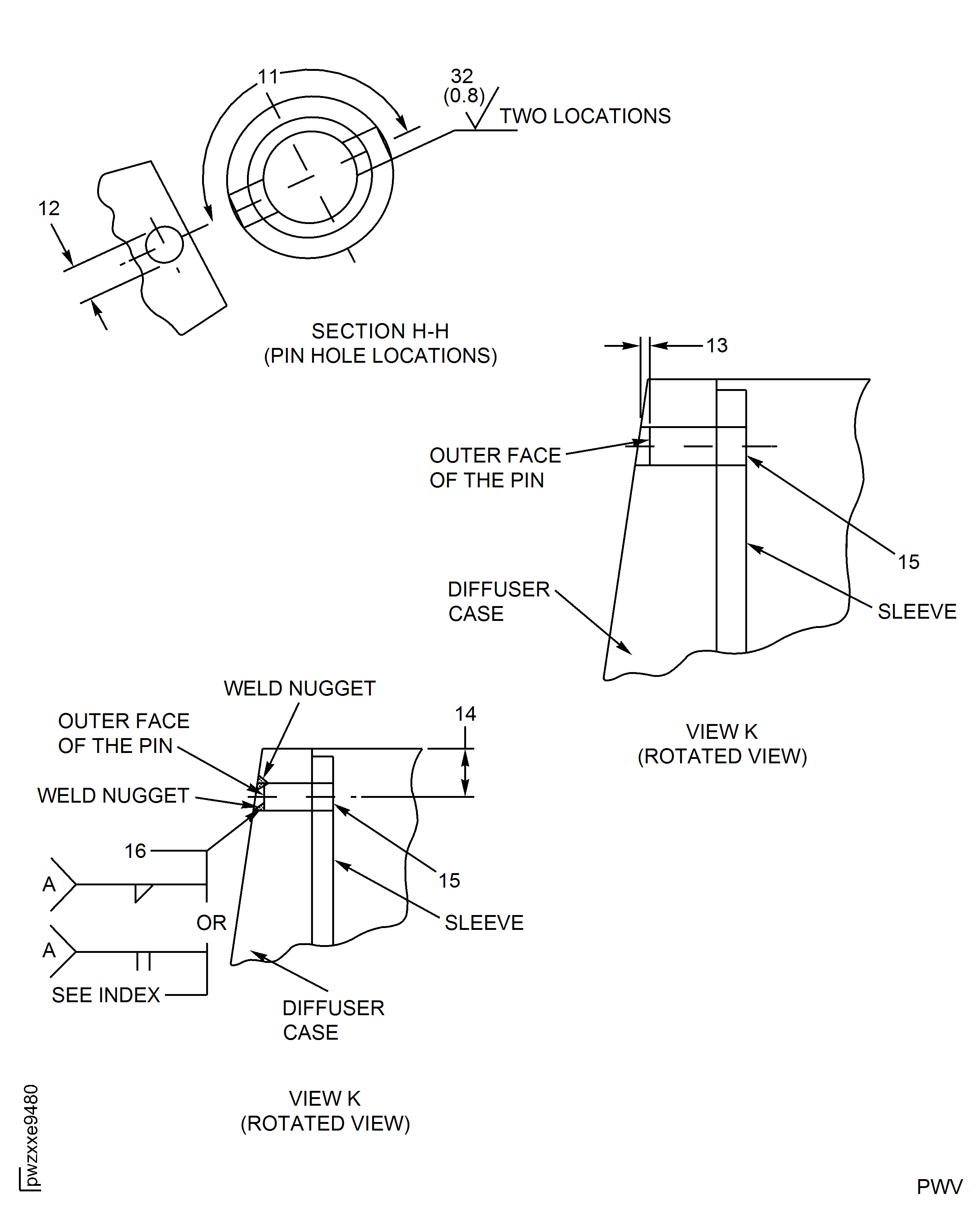

Locally make a sleeve to the dimensions shown in Figure. Use AMS 5663 material.

Do a fluorescent penetrant inspection of sleeve by TASK 70-23-05-230-501.

Heat the boss and chill the sleeve. Refer to SPM TASK 70-46-04-400-501.

NOTE

The next step must be done immediately after you remove the sleeve from its cooling medium and the igniter boss from its heating medium because both the sleeve and the case will normalize quickly.Install the sleeve into the machined boss, lead-in chamfer first, until outer sleeve face is flush to 0.002 in. (0.051 mm) below outer boss face.

Drill and ream two holes through boss and sleeve. Refer to Figure.

Clean the drilled and reamed holes. Refer to SPM TASK 70-11-03-300-503.

Clean the areas to be tack-welded as shown in Figure. Refer to SPM TASK 70-11-26-300-503.

Tack-weld each pin at two locations per IAE 16-3322 as shown in Figure. Refer to SPM TASK 70-31-13-310-501. Use the Manual Gas Tungsten Arc Weld (GTAW-MA) method and CoMat 03-284 WELDING FILLER WIRE, NiBASE or CoMat 03-209 WELDING FILLER WIRE, NiBASE 5% Cr.

Do a fluorescent penetrant inspection of tack weld areas by TASK 70-23-05-230-501.

Install the sleeve in the part.

Trim each installed pin flush with the inside diameter of the sleeve before finish machining the threads.

Machine the threads in the installed sleeve to the limits shown in Figure.

Clean the diffuser case. Refer to SPM TASK 70-11-03-300-503.

Repair thread damage by the procedure that follows:

NOTE

This repair is for cases that have not undergone this repair before.

Subtask 72-42-11-320-099 Method A

Machine sleeve to a thin wall condition.

Push pins out using a drift. Remove and discard.

Collapse sleeve, remove and discard.

Machine the bosses to remove any damage, to the dimensions shown in Figure.

For pin holes that you will not use again, any damage must be removed by machining the hole to maximum diameter of 0.207 in. (5.258 mm)

Visually inspect the repair area. No damage permitted:

Clean the diffuser case. Refer to SPM TASK 70-11-03-300-503.

Do a fluorescent penetrant inspection of machined bosses by TASK 70-23-05-230-501.

Locally make a sleeve to the dimensions shown in Figure. Use AMS 5663 material.

Clean the sleeve. Refer to SPM TASK 70-11-03-300-503.

Do a fluorescent penetrant inspection of sleeve by TASK 70-23-05-230-501.

Heat the boss and chill the sleeve. Refer to SPM TASK 70-46-04-400-501.

NOTE

The next step must be done immediately after you remove the sleeve from its cooling medium and the igniter boss from its heating medium because both the sleeve and the case will normalize quickly.Install the sleeve into the machined boss, lead-in chamfer first, until outer sleeve face is flush to 0.002 in. (0.051 mm) below outer boss face.

If necessary, drill and ream two new holes through boss and sleeve. See Figure. If any existing hole(s) on the boss are used, transfer drill onto the new sleeve.

Clean the drilled and reamed holes (both new and existing). Refer to SPM TASK 70-11-03-300-503.

Clean the areas to be tack-welded as shown in Figure. Refer to SPM TASK 70-11-26-300-503.

Tack-weld each pin at two locations per IAE 16-3322 as shown in Figure. Refer to SPM TASK 70-31-13-310-501. Use the Manual Gas Tungsten Arc Weld (GTAW-MA) method and CoMat 03-284 WELDING FILLER WIRE, NiBASE or CoMat 03-209 WELDING FILLER WIRE, NiBASE 5% Cr.

Do a fluorescent penetrant inspection of tack weld areas by TASK 70-23-05-230-501.

Install the sleeve in the part.

Trim each installed pin, flush with the inside diameter of the sleeve before finish machining the threads.

Machine the threads in the installed sleeve to the limits shown in Figure.

Clean the diffuser case. Refer to SPM TASK 70-11-03-300-503.

Do an inspection of the repaired area to the limits given in Figure.

Repair thread damage or sleeves that are loose, missing or damaged by the procedure that follows:

NOTE

This repair is for cases that have undergone this repair before.

SUBTASK 72-42-11-320-100 Method B

Figure: Diffuser Case Assembly, Igniter Boss Thread - Sleeve Repair

Diffuser Case Assembly, Igniter Boss Thread - Sleeve Repair

Diffuser Case Assembly, Igniter Boss Thread - Sleeve Repair

Diffuser Case Assembly, Igniter Boss Thread - Sleeve Repair

Diffuser Case Assembly, Igniter Boss Thread - Sleeve Repair

Figure: Diffuser Case Assembly, Igniter Boss Thread - Sleeve Repair

Diffuser Case Assembly, Igniter Boss Thread - Sleeve Repair

Diffuser Case Assembly, Igniter Boss Thread - Sleeve Repair