Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-42-11-300-025 Diffuser Case - Replace The Diffuser Sealing Sleeves, Repair-025 (VRS3279)

Effectivity

FIG/ITEM PART NO. | |

|---|---|

01-010 | 2A0051 |

01-010 | 2A2081-01 |

01-010 | 2A2581-01 |

01-010 | 2A2883-01 |

01-010 | 2A2885-01 |

01-010 | 2A2889-01 |

01-010 | 2A2891-01 |

01-010 | 2A2896-01 |

01-010 | 2A2897-01 |

General

Price and availability - refer to IAE

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the cleaning and inspection procedures are done before this repair. |

Support Equipment

NONEConsumables, Materials and Expendables

NONESpares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| SLEEVE | 0AM53 | 2A1014 | AR | |

| SLEEVE - SEALING, DIFFUSER | 0AM53 | 2A3118 | AR |

Safety Requirements

NONEProcedure

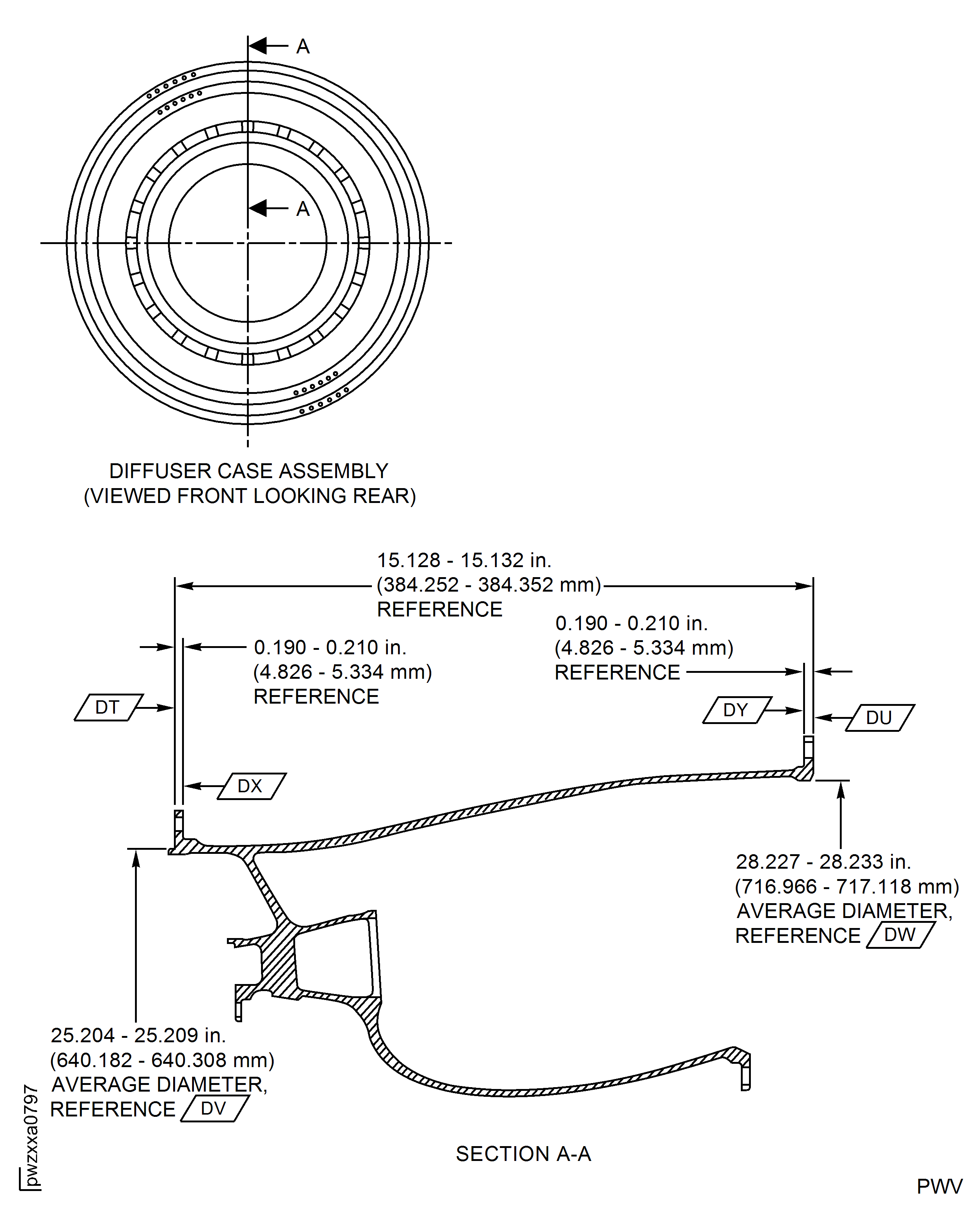

Refer to Figure.

SUBTASK 72-42-11-350-079 Remove the Diffuser Sealing Sleeve

Refer to Figure.

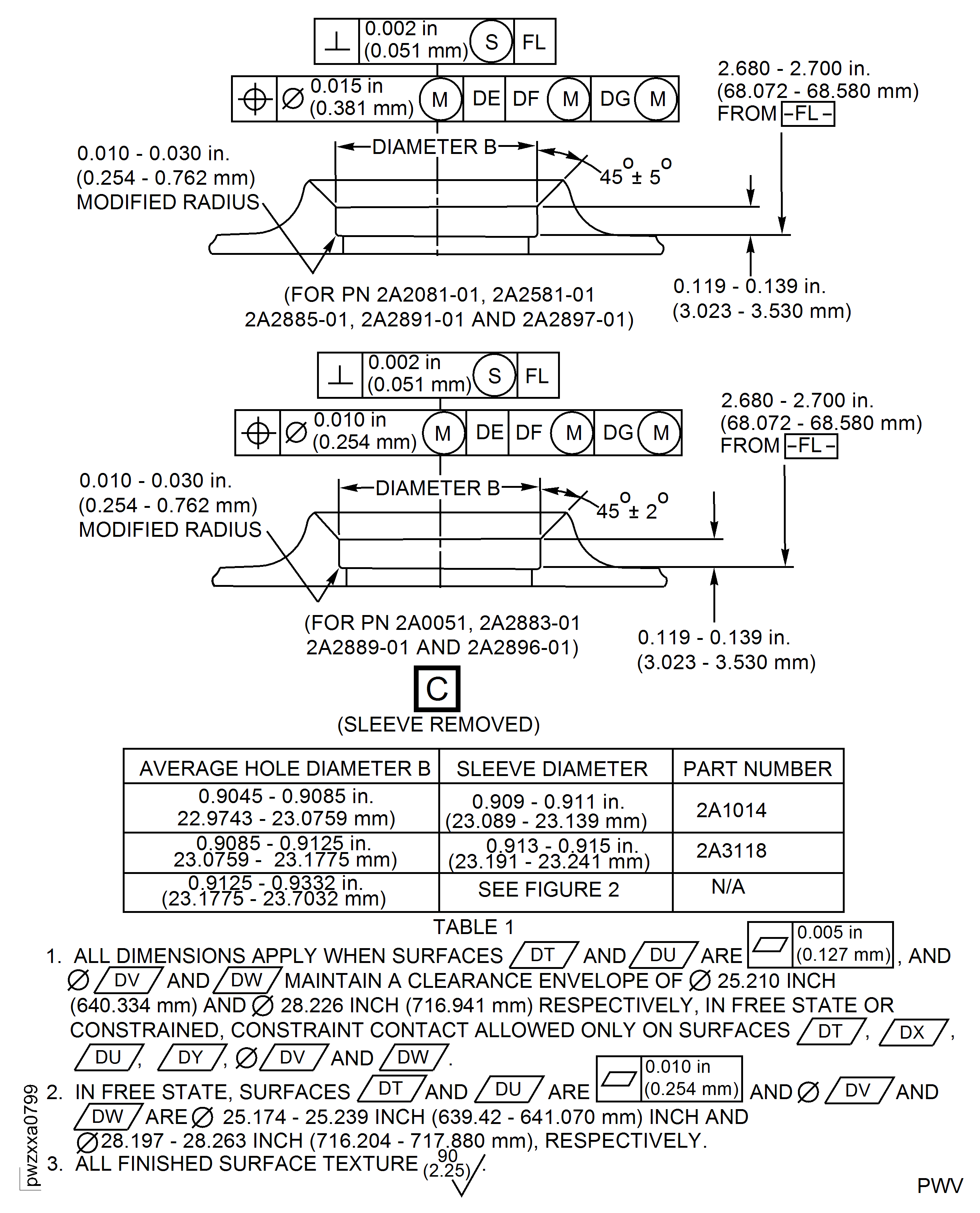

Machine to repair roundness by Table 1 in Figure.

Clean repair area by SPM TASK 70-11-26-300-503.

Do a fluorescent penetrant inspection on the Diameter B by SPM TASK 70-23-05-230-501. Use high sensitivity penetrant. No cracks are permitted.

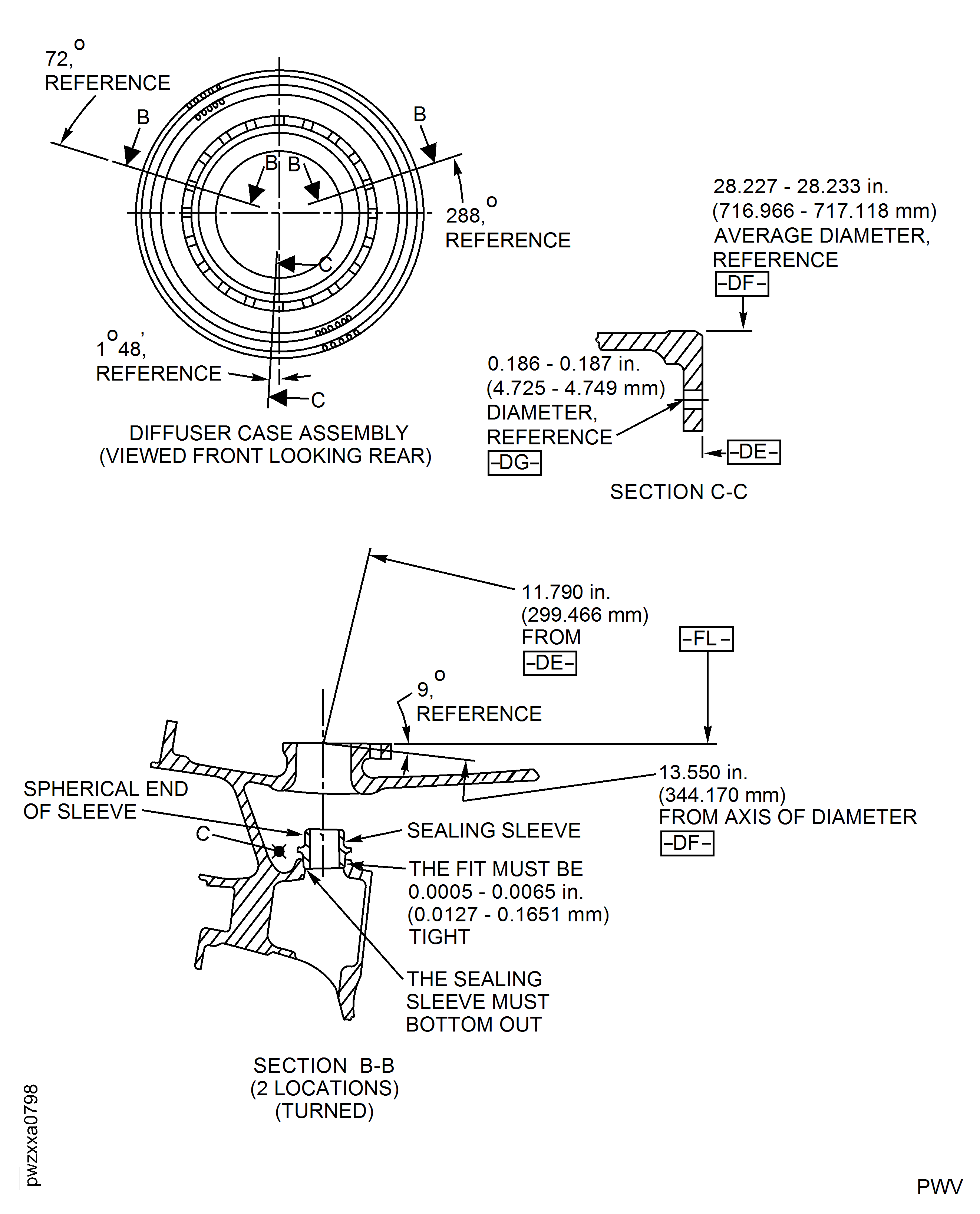

Examine the dimension of Diameter B by Figure.

Examine the dimension of Diameter B at one or two locations for roundness. If Diameter B is out of round, do the following procedures, if not, continue to Step.

For Diameter B that measure 0.9045 in. to 0.9125 in. (22.9743 mm to 23.1775 mm), choose a procurable sleeve, continue to Step.

For Diameter B that measure 0.9125 in. to 0.9332 in. (23.1775 mm to 23.7032 mm), locally make sleeve(s) by Step.

Interference fit must be 0.0005T in. - 0.0065T in. (0.0127T mm - 0.1651T mm).

Choose the applicable repair procedure at one or two locations.

SUBTASK 72-42-11-220-108 Examine the Diffuser Sealing Sleeve Bore Inner Diameter

Refer to Figure.

Refer to the SPM TASK 70-11-26-300-503.

Clean the locally made sleeve(s).

Refer to the SPM TASK 70-23-01-230-501 or SPM TASK 70-23-02-230-501. No cracks are permitted.

Do a fluorescent penetrant inspection of the locally made sleeve(s).

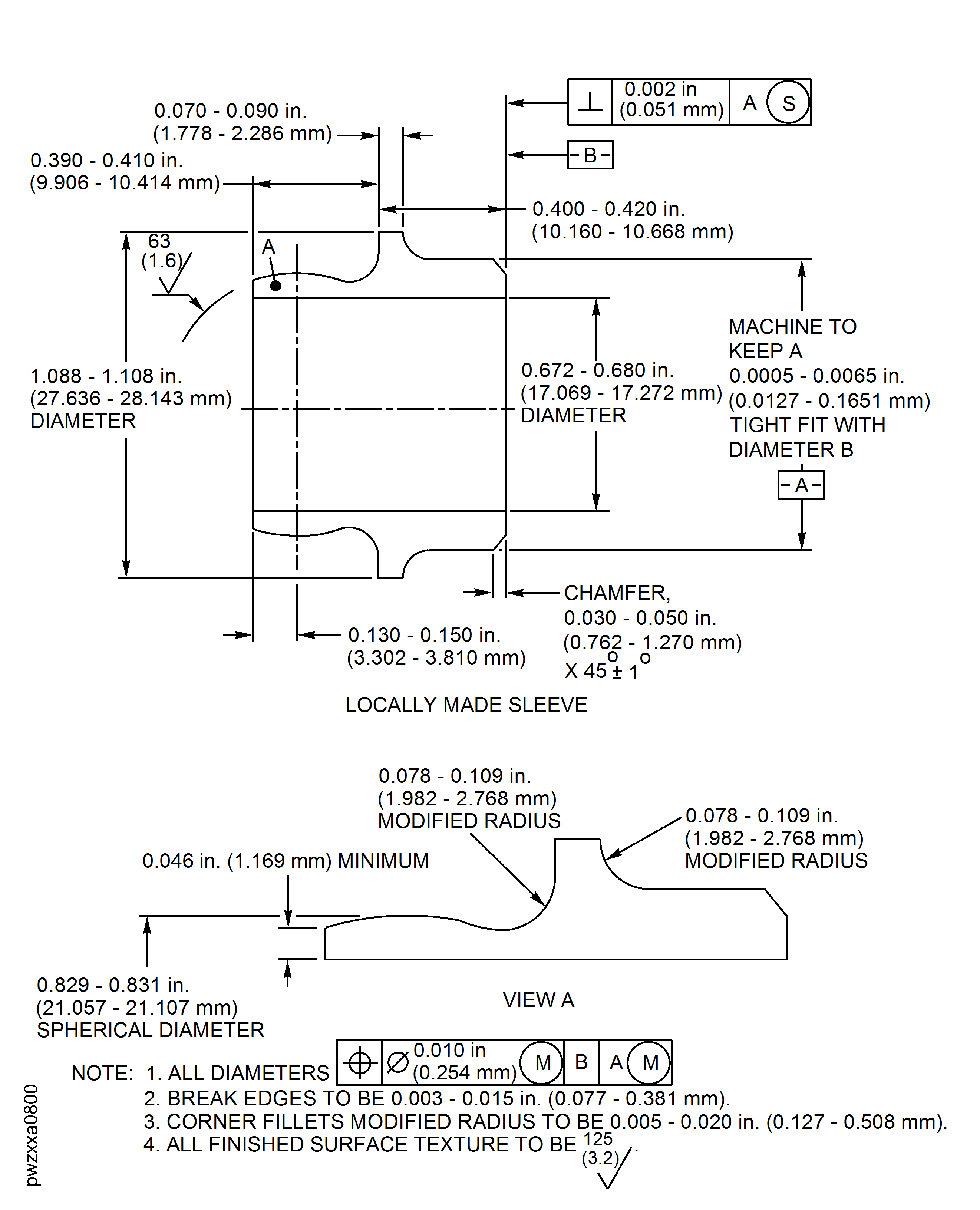

SUBTASK 72-42-11-350-119 Make the Sleeve(s) Locally For Diameter B

Refer to Figure.

Chill the procured or locally made sleeve(s). Refer to the SPM TASK 70-46-04-400-501.

SUBTASK 72-42-11-350-120 Install the Sleeve(s) in to Diameter B

Refer to Figure.

Examine the new sleeve(s). Refer to TASK 72-42-11-200-000 (INSPECTION-000).

SUBTASK 72-42-11-220-079 Examine the Repair

Refer to SPM TASK 70-09-00-400-501. Remove raised metal caused by marking.

Vibration peen VRS3279 adjacent to the part number.

SUBTASK 72-42-11-350-080 Identify the Repair

Figure: Repair Details And Dimensions

Repair Details And Dimensions

Repair Details And Dimensions

Repair Details And Dimensions

Figure: Locally Made Sleeve Requirements

Locally Made Sleeve Requirements