Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-43-30-300-007 No. 4 Bearing Heatshield - Weld Repair Cracks And Patch Repair, Repair-007 (VRS3123)

General

Price and availability - refer to IAE

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Silicon carbide wheel | LOCAL | Silicon carbide wheel | ||

| Stress-relief equipment | LOCAL | Stress-relief equipment | ||

| Welding equipment | LOCAL | Welding equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-284 WELDING FILLER WIRE, NiBASE | LOCAL | CoMat 03-284 | ||

| CoMat 03-335 HASTELLOY X SHEET STOCK | LOCAL | CoMat 03-335 |

Spares

NONESafety Requirements

NONEProcedure

Refer to TASK 72-43-30-100-000 (CLEANING-000).

Clean the heat shield.

SUBTASK 72-43-30-110-059 Clean the No. 4 Bearing Heat Shield

Refer to Figure. Manual gas tungsten arc weld the heat shield. Use CoMat 03-284 WELDING FILLER WIRE, NiBASE. Refer to the SPM TASK 70-31-13-310-501.

Weld the cracks in the heat shield.

SUBTASK 72-43-30-310-052 Weld the No. 4 Bearing Heat Shield

Refer to the SPM TASK 70-37-01-370-501.

Stress-relieve the heat shield.

SUBTASK 72-43-30-370-052 Stress-Relieve the No. 4 Bearing Heat Shield

Refer to SPM TASK 70-35-21-350-501.

Blend the weld repaired areas to the contour of the adjacent areas.

SUBTASK 72-43-30-350-054 Blend the No. 4 Bearing Heat Shield after Weld Repair

Refer to the SPM TASK 70-23-01-230-501. No cracks are permitted.

Fluorescent penetrant inspect the heat shield.

SUBTASK 72-43-30-230-056 Examine the No. 4 Bearing Heat Shield

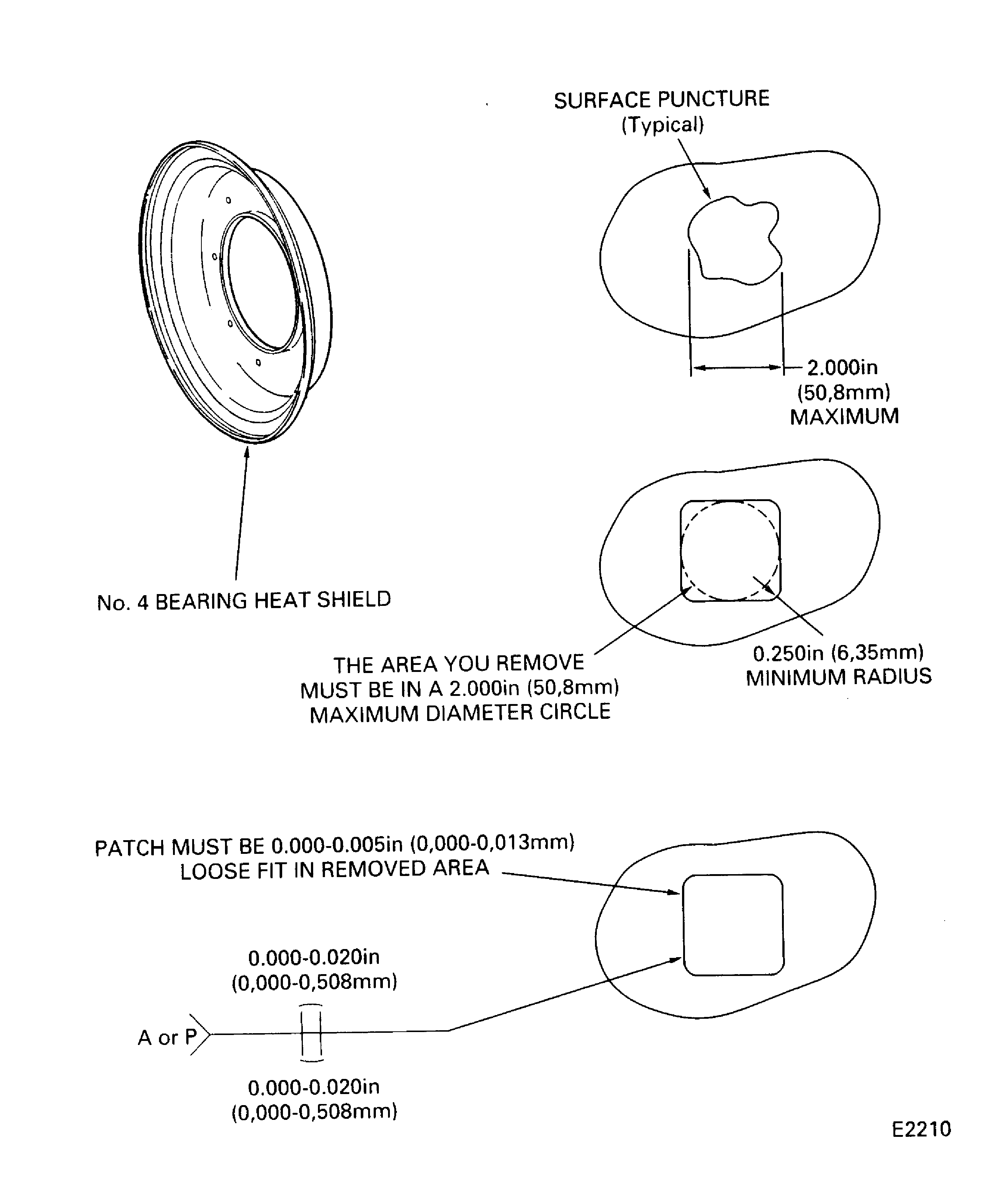

Refer to Figure. The area you machine can be any shape. The area must be in a 2.000in. (50.8 mm) diameter circle. The inside and outside corner radii must be a minimum of 0.250in. (6.35 mm).

Machine to remove damage in the heat shield.

SUBTASK 72-43-30-350-055 Remove Rough Edges or Distorted Areas Around Holes in the No. 4 Bearing Heat Shield

Refer to Figure. Use can cut patches from discarded heat shields with the same part number, or you can use CoMat 03-335 HASTELLOY X SHEET STOCK.

NOTE

Patches made from CoMat 03-335 HASTELLOY X SHEET STOCK must be heat treated to HRC 36 minimum or equivalent before you weld them.

Make a patch so the fit in the hole you machined will be 0.000 to 0.005in. (0.000 to 0.013 mm) loose.

Refer to Figure and the SPM TASK 70-31-13-310-501.

Weld the patch.

SUBTASK 72-43-30-310-053 Weld Patches on Holes in the No. 4 Bearing Heat Shield

Refer to SPM TASK 70-35-21-350-501.

Blend the repaired area.

SUBTASK 72-43-30-350-056 Blend the No. 4 Bearing Heat Shield after Weld Repair

Refer to the SPM TASK 70-37-01-370-501.

Stress-relieve the heat shield.

SUBTASK 72-43-30-370-053 Stress-Relieve the No. 4 Bearing Heat Shield

Refer to the SPM TASK 70-23-01-230-501. No cracks are permitted.

Fluorescent penetrant inspect the heat shield.

SUBTASK 72-43-30-230-057 Examine the No. 4 Bearing Heat Shield

Refer to TASK 72-43-30-200-000 (INSPECTION-000).

Examine the heat shield after repair.

SUBTASK 72-43-30-220-061 Examine the Repair

Figure: No. 4 bearing heat shield crack and patch weld repair

No. 4 bearing heat shield crack and patch weld repair